Method for preparing iron oxide red by carrying out reducing roasting on high-sulfur gold concentrate and enhancing acid solution

A technology of gold concentrate and acid solution is applied in the field of preparing iron red from leaching solution obtained by strengthening acid dissolution with hydrochloric acid, and can solve the problems of waste of resources, less than 80%, and difficulty in improving gold leaching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

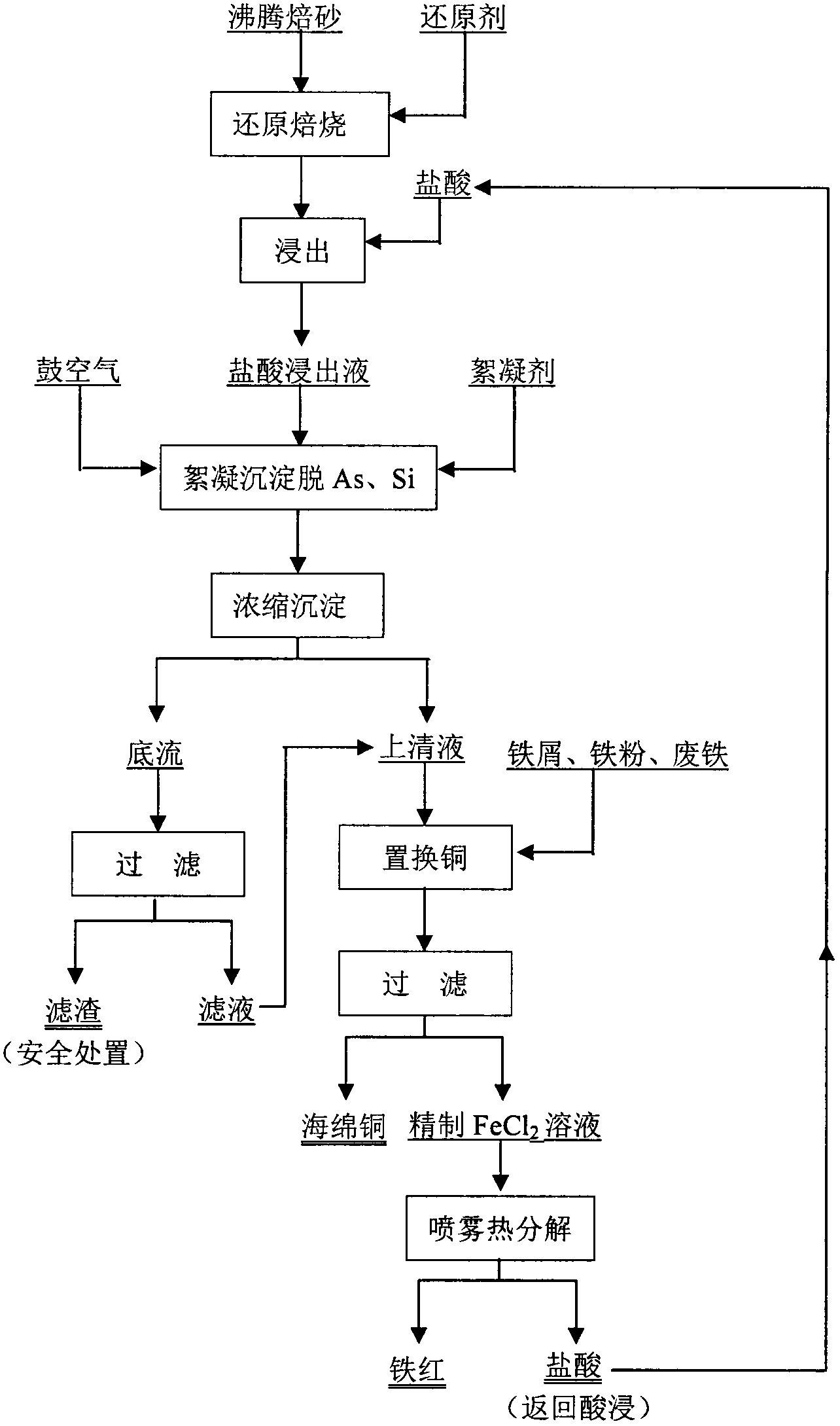

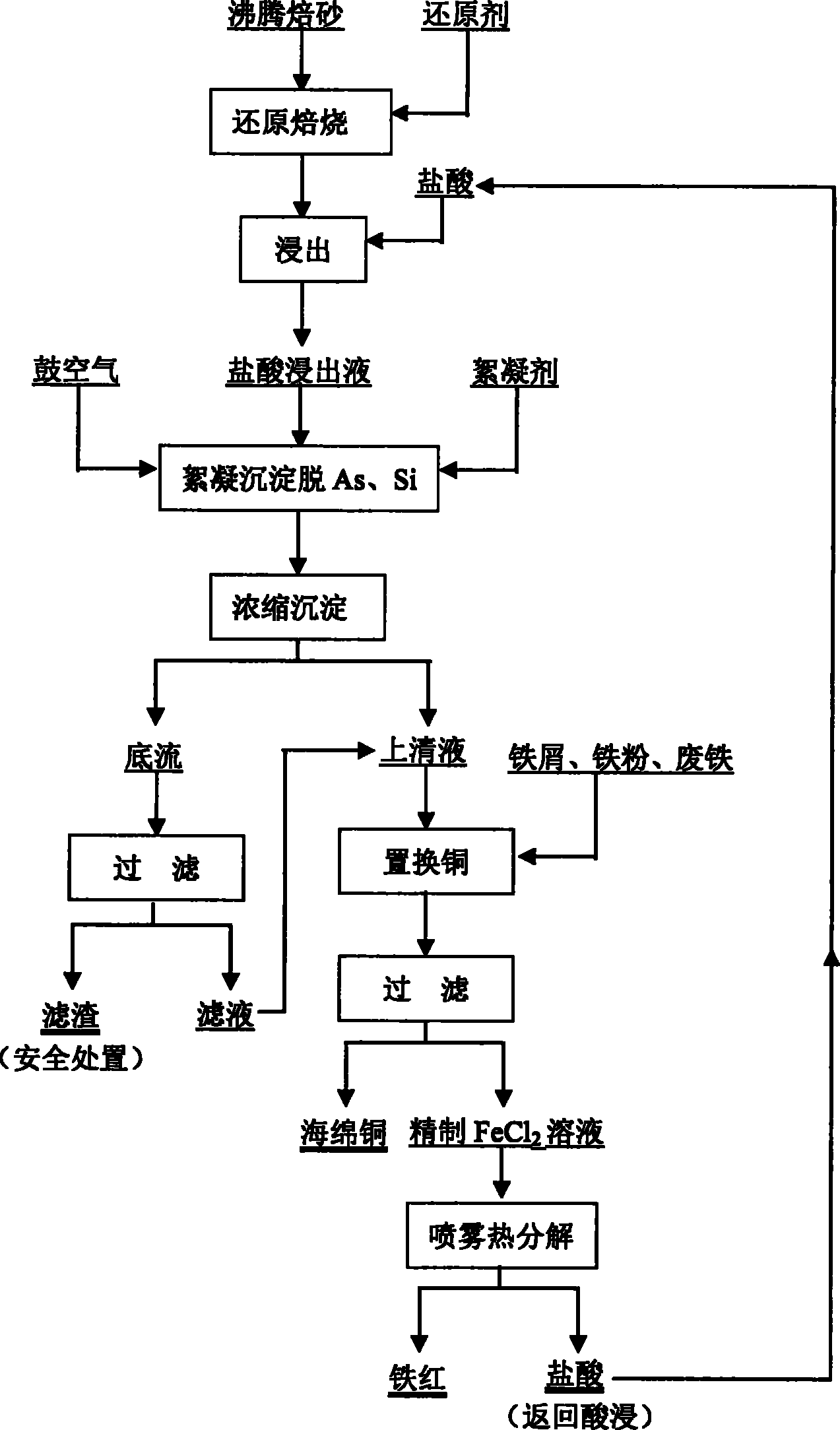

Image

Examples

Embodiment 1

[0043] A method for preparing iron red from high-sulfur gold concentrate calcine reduction roasting intensified acid solution includes the following steps:

[0044] First, the sulfur-containing gold concentrate calcine and the reducing agent are mixed and then placed in a reduction roaster for roasting; the reduced roasted calcine is acid-leached with hydrochloric acid; then the acid-leached reduced calcine is filtered, and after filtering Take 1m 3 The hydrochloric acid leachate contains Fe 110g / L, As 0.95g / L, Si 0.098g / L, and Cu1.8g / L. Adjust pH to 3.0 with ammonia water, add 1kg polyacrylamide, and blow Fe 2+ Oxidize until its concentration drops to 109g / L, coagulate for 35min, clarify and filter. Add 2kg of iron powder to the supernatant to replace copper. Spray thermal decomposition at 700℃ to obtain iron red Fe 2 O 3 And hydrochloric acid. Iron red meets the first-class product requirements in GB / T 1863-2008, the hydrochloric acid regeneration rate is 99.5%, and the coppe...

Embodiment 2

[0046] A method for preparing iron red from high-sulfur gold concentrate calcine reduction roasting intensified acid solution includes the following steps:

[0047] First, the sulfur-containing gold concentrate calcine and the reducing agent are mixed and then placed in a reduction roaster for roasting; the reduced roasted calcine is acid-leached with hydrochloric acid; then the acid-leached reduced calcine is filtered, and after filtering Take 1m 3 The hydrochloric acid leaching solution contains Fe 132g / L, As 1.25g / L, Si 0.11g / L, and Cu3.3g / L. Adjust the pH to 3.0 with ammonia water, add 2.1kg polyacrylamide, and blow the Fe 2+ Oxidize until its concentration drops to 130g / L, coagulate for 60min, clarify and filter. Add 8.5kg iron powder to the supernatant to replace copper. Spray thermal decomposition at 950°C to obtain iron red and hydrochloric acid. Iron red meets the requirements of the first grade product in GB / T 1863-2008, the hydrochloric acid regeneration rate is 99.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com