Regeneration process of cobalt-removing resin

A process and resin technology, which is applied in the field of cobalt removal resin regeneration process, can solve the problems of increasing equipment investment cost, increasing the amount of medicament used, that is, operating cost, etc., and achieve the effect of saving investment and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

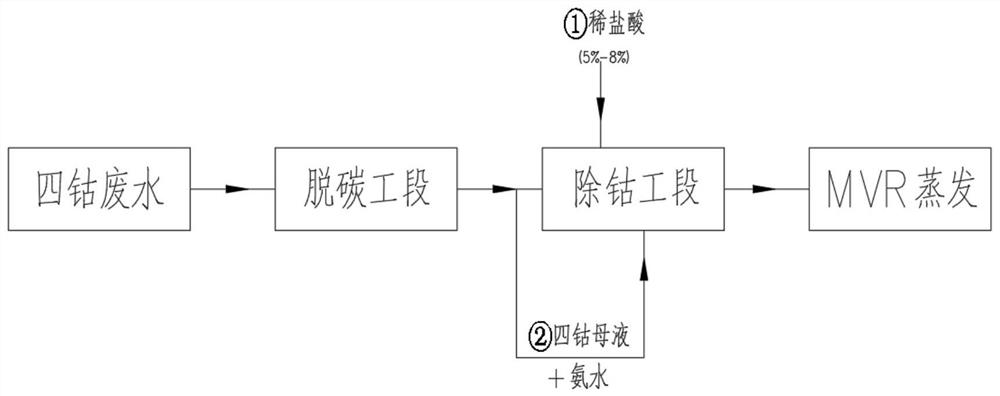

[0024] This embodiment provides a regeneration process for removing cobalt resin, and the process flow includes:

[0025] In order to avoid that the carbonate and bicarbonate contained in the tetracobalt wastewater have an impact on the operation of the cobalt removal resin and reduce the cobalt removal efficiency, the tetracobalt wastewater is first sent to the decarbonization system to remove the carbonate and bicarbonate contained therein to obtain Tetracobalt wastewater after decarbonization;

[0026] Hydrogen-type divalent chelation cobalt removal resin CH-90 is used to adsorb and remove cobalt from tetracobalt wastewater after decarburization (RH + +Co 2+ →RCo+H + , wherein, R represents the resin, the same below), after the adsorption is saturated, switch to the regeneration process, and the tetracobalt waste water that does not contain cobalt ions after the resin adsorption enters the subsequent evaporation process;

[0027] The regeneration process includes: adopti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com