Method of reducing amount of regenerated wastewater discharged from chelating resin tower

A technology for chelating resin towers and regenerated wastewater, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of regenerated wastewater discharge, reduce emissions, realize wastewater reuse, and reduce sewage treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

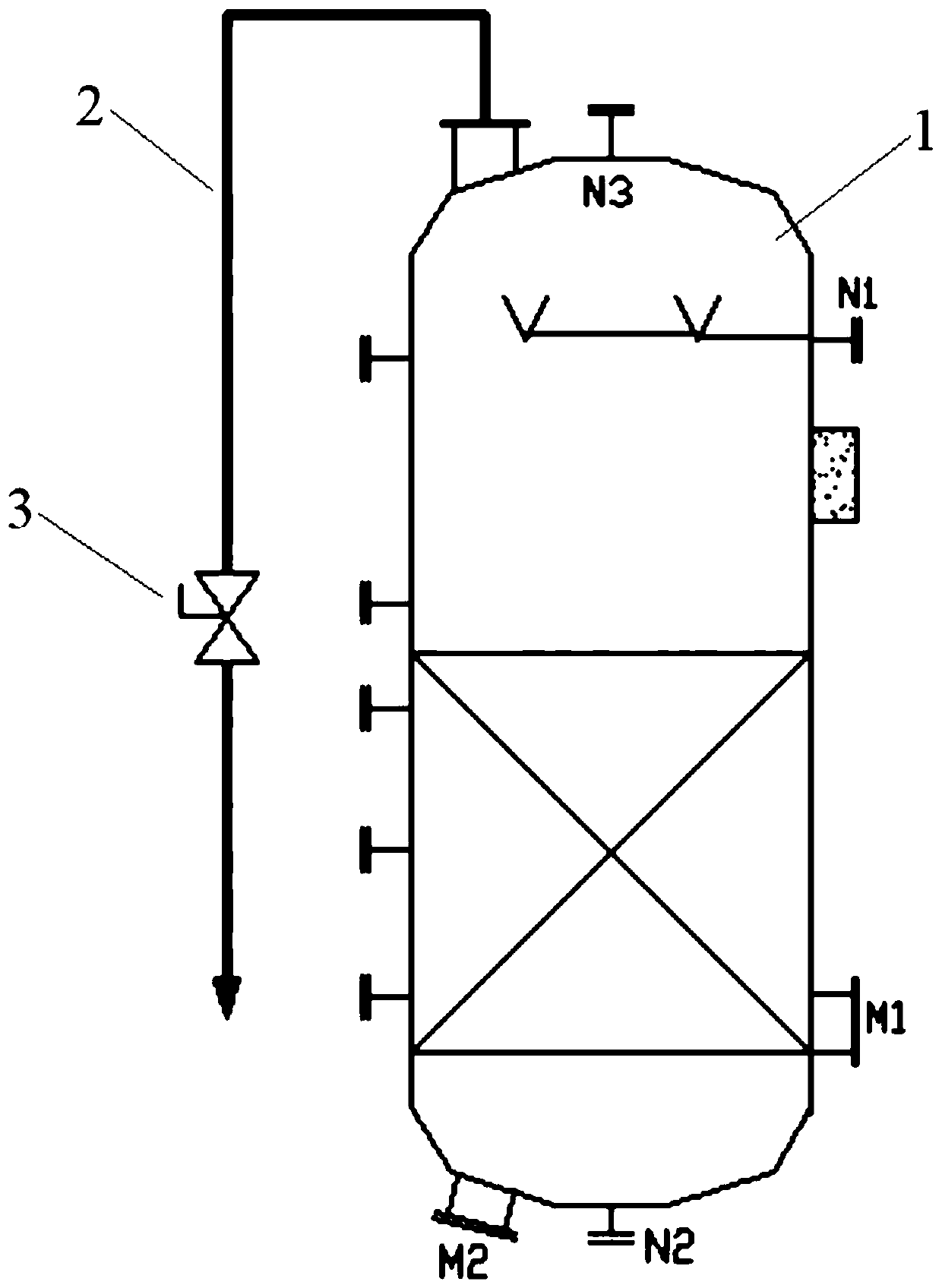

[0018] In this example, the method for reducing the discharge of regeneration wastewater from the chelating resin tower includes dividing the technological process of the regeneration of the chelating resin tower into the first water washing, backwashing, hydrochloric acid regeneration, the second water washing, NaOH regeneration, and the third Washing and brine replacement steps; according to the above steps, the regeneration wastewater of the chelating resin tower is divided into the first washing wastewater, backwash wastewater, hydrochloric acid regeneration wastewater, the second washing wastewater, NaOH regeneration wastewater, the third washing wastewater and brine Replacing waste water; reclaiming the waste water generated in each step separately, reclaiming the waste water that meets the standards as the primary refined brine in the chlor-alkali production process, and discharging the rest of the waste water that does not meet the standards for treatment, thereby reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com