Blast furnace external molten iron pretreatment desiliconization agent, and preparation method and use method thereof

A technology of molten iron pretreatment and desiliconization agent, which is applied in the field of iron and steel metallurgy, can solve the problems of low desiliconization efficiency, serious temperature drop of molten iron, and long time consumption, and achieve good desiliconization effect, effective recycling, and stable temperature drop of molten iron obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

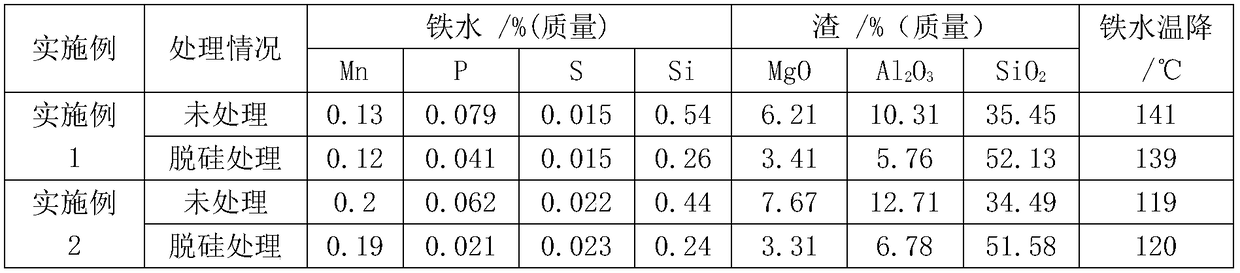

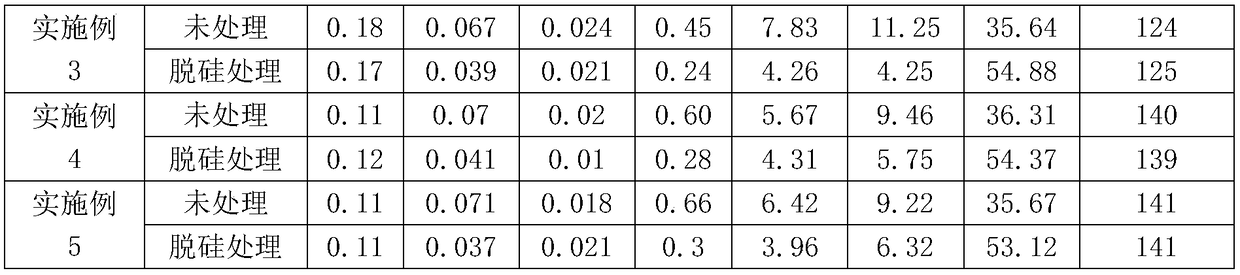

Examples

preparation example Construction

[0037] The method for preparing a desiliconizer for pretreatment of molten iron outside a blast furnace includes the following steps:

[0038] a) According to the formula of the inner layer of the mixture and the outer layer of the mixture separately, the required raw materials are crushed, rolled, and ground to make the proportion of the particle size less than 0.074mm reach more than 70%; then the raw materials of the inner layer of the mixture The raw materials of the outer layer and the outer layer of the mixture are separately put into the mixing equipment and mixed evenly, and the inner mixed powder and the outer mixed powder are dried separately for use;

[0039] b) The inner mixed powder is made into agglomerates of 5mm~30mm through pelletizing or pressing equipment;

[0040] c) The agglomerates prepared in step b and the outer layer mixed powder are made into 10mm-40mm composite agglomerates through pelletizing equipment, dried until the moisture content is less than 1%, and...

Embodiment 1

[0046] In this embodiment, when preparing the desiliconizer for pretreatment of molten iron outside the blast furnace, the ingredients are separately prepared according to the formula of the inner layer of the mixture and the outer layer of the mixture, and the required raw materials are crushed, rolled, and ground, so that the particle size is less than 0.074mm. The ratio reaches more than 70%; then put the raw materials of the inner layer of the mixture and the raw materials of the outer layer of the mixture into the mixing equipment and mix them evenly, and dry the prepared inner and outer mixed powders separately for use ; The inner layer mixed powder is made into agglomerates of 5mm~30mm through pelletizing or pressing equipment; the obtained agglomerates and the outer layer mixed powder are made into 10mm~40mm composite agglomerates through pelletizing equipment, and dried Until the moisture is less than 1%, set aside.

[0047] In this embodiment, the composition and mass p...

Embodiment 2

[0051] In this embodiment, when preparing the desiliconizer for pretreatment of molten iron outside the blast furnace, the ingredients are separately prepared according to the formula of the inner layer of the mixture and the outer layer of the mixture, and the required raw materials are crushed, rolled, and ground, so that the particle size is less than 0.074mm. The ratio reaches more than 70%; then put the raw materials of the inner layer of the mixture and the raw materials of the outer layer of the mixture into the mixing equipment and mix them evenly, and dry the prepared inner and outer mixed powders separately for use ; The inner layer mixed powder is made into agglomerates of 5mm~30mm through pelletizing or pressing equipment; the obtained agglomerates and the outer layer mixed powder are made into 10mm~40mm composite agglomerates through pelletizing equipment, and dried Until the moisture is less than 1%, set aside.

[0052] In this embodiment, the composition of the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com