Garbage fly ash recycling treatment process

A technology of waste fly ash and treatment process, applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. products, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

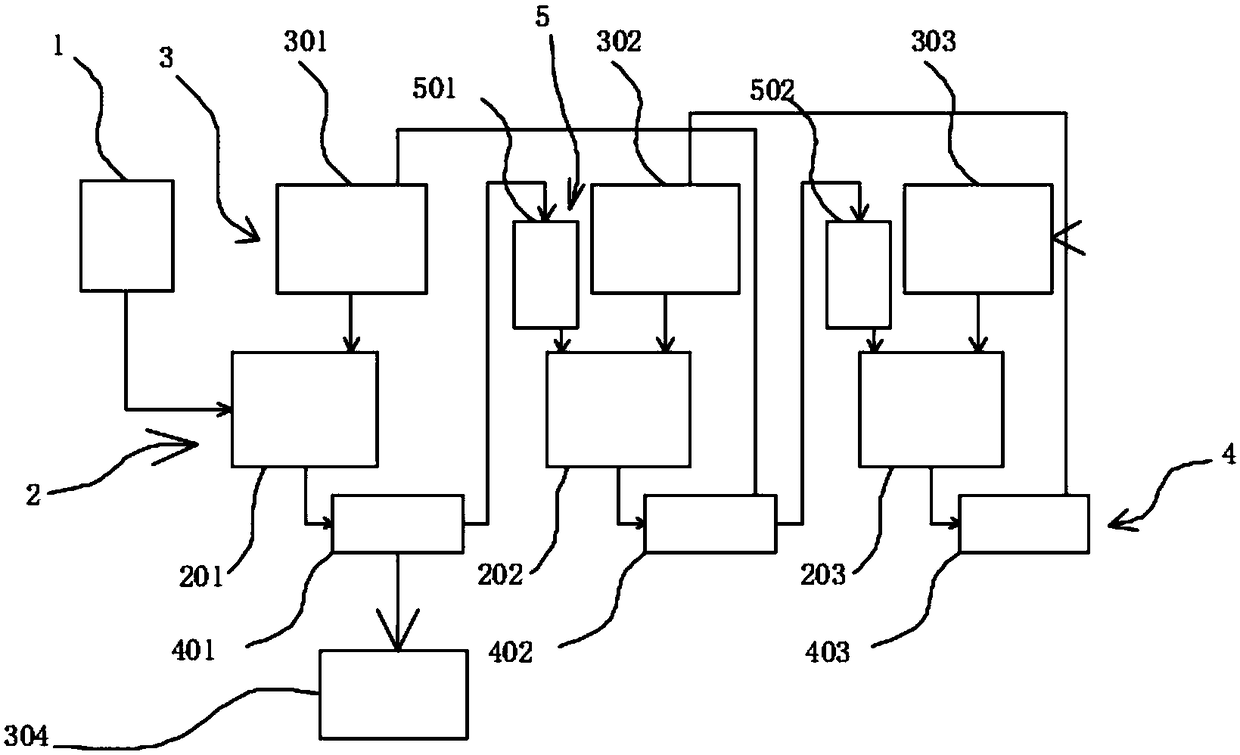

[0042] A waste fly ash resource utilization treatment process, the steps are as follows:

[0043] S1 water elution chlorine, the waste fly ash is removed chlorine element in the fly ash by the water elution chlorine process, and the water washing process obtains chlorine-containing washing wastewater; the water washing process is three-stage countercurrent washing; details are as follows:

[0044] The specific steps of the washing process are as follows:

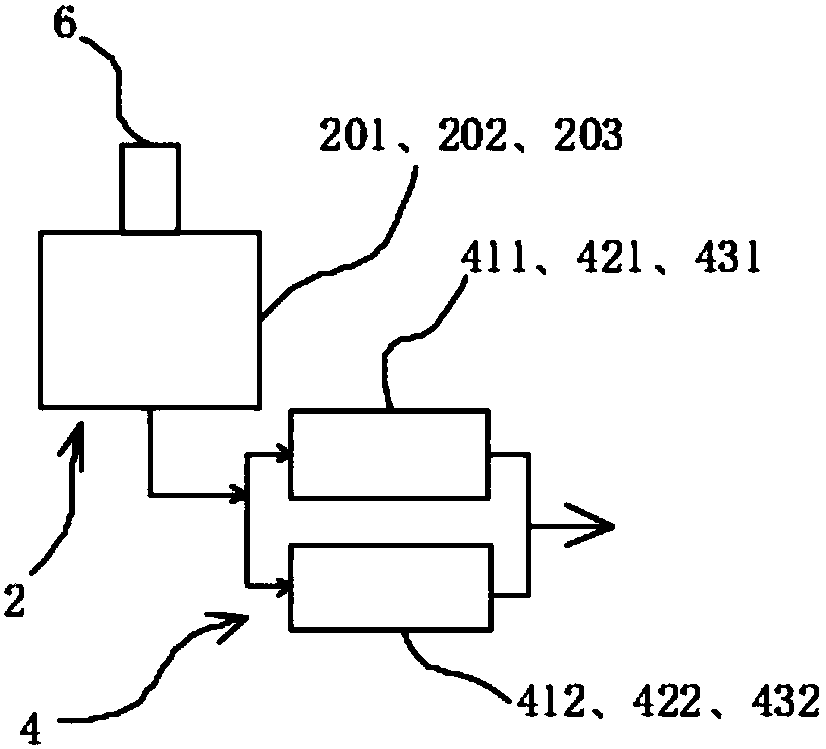

[0045] Step 1. The fly ash storage tank 1 transports the fly ash to the primary cleaning tank 201 and mixes it with the water in the first storage tank 301. The ratio of fly ash to water is 1:1; aerate and stir for 10 minutes, and then use the first stage The filter press 411 and / or the second stage filter press 412 perform press filtration, the filtrate enters the reaction storage tank 304, and the fly ash sludge enters the second sludge pulverizer 501; the ammonia absorption tower 6 uses water as an absorbent to absorb amm...

Embodiment 2

[0062] A waste fly ash resource utilization treatment process, the steps are as follows:

[0063] S1 water elution chlorine, the waste fly ash is removed chlorine element in the fly ash by the water elution chlorine process, and the water washing process obtains chlorine-containing washing wastewater; the water washing process is three-stage countercurrent washing; details are as follows:

[0064] The specific steps of the washing process are as follows:

[0065] Step 1. The fly ash storage tank 1 transports the fly ash to the primary cleaning tank 201, and mixes it with the water in the first storage tank 301. The ratio of fly ash to water is 1:2; aerate and stir for 20 minutes, and then use the first stage The filter press 411 and / or the second stage filter press 412 perform press filtration, the filtrate enters the reaction storage tank 304, and the fly ash sludge enters the second sludge pulverizer 501; the ammonia absorption tower 6 uses water as an absorbent to absorb am...

Embodiment 3

[0082] A waste fly ash resource utilization treatment process, the steps are as follows:

[0083] S1 water elution chlorine, the waste fly ash is removed chlorine element in the fly ash by the water elution chlorine process, and the water washing process obtains chlorine-containing washing wastewater; the water washing process is three-stage countercurrent washing; details are as follows:

[0084] The specific steps of the washing process are as follows:

[0085] Step 1. The fly ash storage tank 1 transports the fly ash to the primary cleaning tank 201 and mixes it with the water in the first storage tank 301. The ratio of fly ash to water is 1:1.5; aerate and stir for 30 minutes, and then use the first stage The filter press 411 and / or the second stage filter press 412 perform press filtration, the filtrate enters the reaction storage tank 304, and the fly ash sludge enters the second sludge pulverizer 501; the ammonia absorption tower 6 uses water as an absorbent to absorb a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com