Precipitating-hydrothermal preparation with high visible light catalytic activity nano CdxZn1-xS photocatalyst

A cdxzn1-xs, photocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unstable photocatalyst performance, limited popularization and use, and difficult control of production process, etc. Achieve the effects of improving solar energy utilization efficiency, high visible light catalytic activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

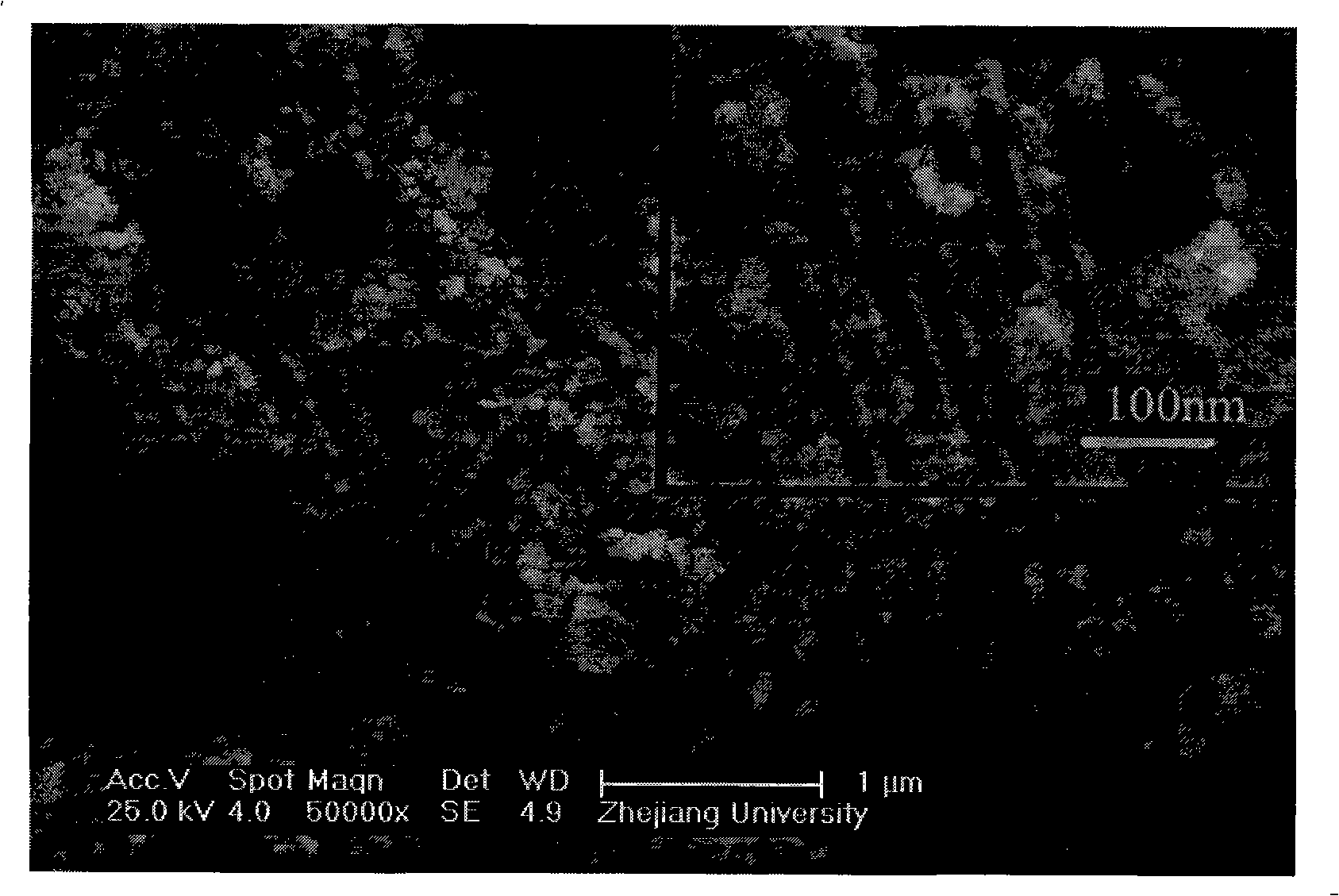

[0023] Gradually drop the mixed solution containing 0.0075mol cadmium nitrate and 0.0425mol zinc nitrate into the solution containing 0.06mol sodium sulfide, keep the total volume of the solution at about 80ml, the temperature of the mixed solution is 10°C, and after stirring for 1.5h, the nano Powder precursor precipitation;

[0024] Precipitate the above-mentioned nano-powder precursor into the reactor, heat it up to 180°C at a rate of 1°C / min for hydrothermal reaction, stop heating after 24 hours of reaction, take it out after the reactor is naturally cooled to room temperature, and use deionized water Washed with absolute ethanol for 3 times, put it into a vacuum oven and dried at 80°C, and obtained nano-Cd that formed a solid solution x Zn 1-x S photocatalyst.

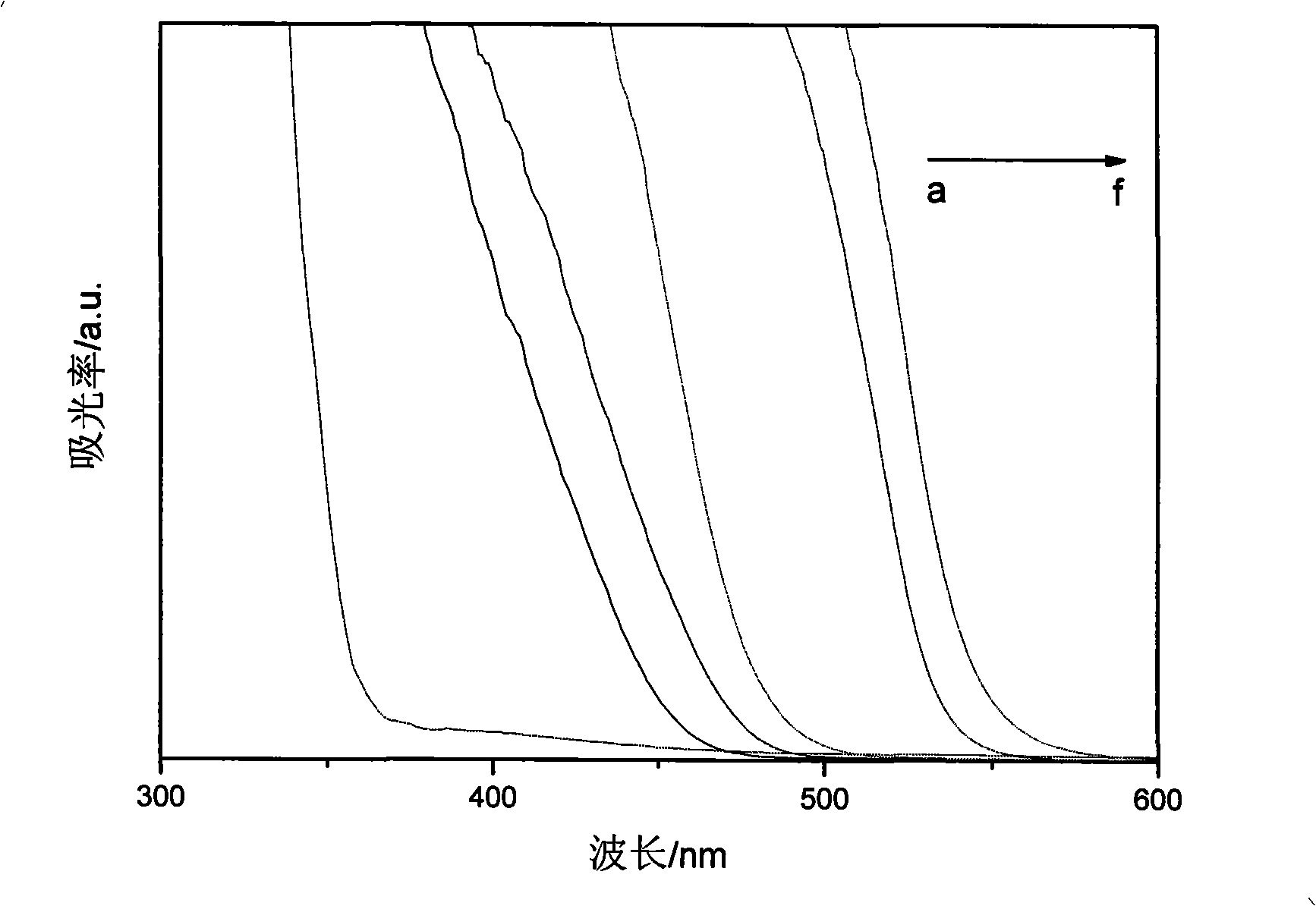

[0025] The nano-Cd x Zn 1-x S photocatalyst is composed of Cd 0.15 Zn 0.85 A solid solution of S. We set 10ml of 20mg / L methyl orange solution as the object of organic matter catalysis, took 20mg of the pow...

Embodiment 2

[0028] The mixed solution containing 0.005mol cadmium nitrate and 0.045mol zinc nitrate was gradually dropped into the solution containing 0.06mol sodium sulfide, so that the total volume of the solution was kept at about 80ml, the temperature of the mixed solution was 40°C, and after stirring for 2.5h, the nano Powder precursor precipitation;

[0029] Precipitate the above-mentioned nano-powder precursor into the reactor, heat it up to 200°C at a rate of 5°C / min for hydrothermal reaction, stop heating after 20 hours of reaction, take it out after the reactor is naturally cooled to room temperature, and use deionized water Washed with absolute ethanol for 3 times, put it into a vacuum oven and dried at 80°C, and obtained nano-Cd that formed a solid solution x Zn 1-x S photocatalyst. The photocatalytic performance was tested under the same experimental conditions as in Example 1.

[0030] Compared with P25 (Degussa), a photocatalytic effect similar to that of Example 1 was o...

Embodiment 3

[0032] Gradually drop the mixed solution containing 0.00625mol cadmium nitrate and 0.01875mol zinc nitrate into the solution containing 0.025mol sodium sulfide, keep the total volume of the solution at about 80ml, the temperature of the mixed solution is 15°C, and after stirring for 3 hours, nano powder is obtained body precursor precipitation;

[0033] Precipitate the above-mentioned nano-powder precursor into the reactor, heat it up to 240°C at a rate of 2°C / min for hydrothermal reaction, stop heating after 12 hours of reaction, take it out after the reactor is naturally cooled to room temperature, and use deionized water Washed with absolute ethanol for 3 times, put it into a vacuum drying oven and dried at 50 °C, and obtained nano-Cd that formed a solid solution x Zn 1-x S photocatalyst. The photocatalytic performance was tested under the same experimental conditions as in Example 1.

[0034] Compared with P25 (Degussa), a photocatalytic effect similar to that of Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com