Melting process for positive electrode lead belt of lead-acid storage battery

A lead-acid battery, spraying technology, applied in metal material coating process, electrode carrier/collector, fusion spraying, etc., can solve the problem of affecting the deep cycle life of the battery and the closer combination of the positive grid and the positive lead paste , positive grid refractory oxidation reaction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

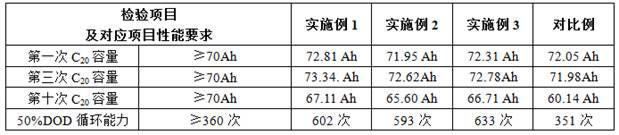

Examples

Embodiment 1

[0018] Use the positive electrode grid alloy of the conventional start-up lead-acid battery, and adopt the method of continuous casting and rolling lead strip to produce the positive electrode grid alloy billet, and the thickness H1 of the positive electrode grid alloy billet is 8.0mm;

[0019] The configured Pb (99.86 parts)-Sn (0.1 parts)-Bi (0.03 parts)-Sb (0.01 parts) alloy is attached to the positive electrode grid alloy blank by spraying, and the thickness of the sprayed alloy film layer is controlled at 150um-180um;

[0020] The lead billet attached to the sprayed alloy film layer is prepared into a positive electrode lead strip with a thickness H of 1.0mm through 5 rollings;

[0021] The positive electrode lead strip is punched to make a positive electrode grid, which is prepared into a 70Ah AGM start-stop battery through a conventional production process.

Embodiment 2

[0023] Use the positive electrode grid alloy of the conventional start-up lead-acid battery, and adopt the method of continuous casting and rolling lead strip to produce the positive electrode grid alloy billet, and the thickness H1 of the positive electrode grid alloy billet is 8.0mm;

[0024] The positive electrode grid alloy billet is prepared into a 3.1mm pre-rolled positive electrode grid alloy strip through two rolling passes;

[0025] The pre-rolled positive electrode grid alloy strip is cleaned by spraying pure water on-line, and dried by hot air through an air duct with a temperature of 100°C-130°C;

[0026] The configured Pb (97.95 parts)-Sn (0.5 parts)-Bi (1.5 parts)-Sb (0.05 parts) alloy is attached to the dry and clean surface of the pre-rolled positive grid alloy strip by spraying On the surface, the thickness of the sprayed alloy film is controlled at 20um-30um;

[0027] The pre-rolled positive electrode grid alloy strip with the sprayed alloy film layer is pre...

Embodiment 3

[0030] Use the positive electrode grid alloy of the conventional start-up lead-acid battery, and adopt the method of continuous casting and rolling lead strip to produce the positive electrode grid alloy billet, and the thickness H1 of the positive electrode grid alloy billet is 8.0mm;

[0031] The positive electrode grid alloy billet is prepared into a 3.1mm pre-rolled positive electrode grid alloy strip through two rolling passes;

[0032] The pre-rolled positive electrode grid alloy strip is cleaned by spraying pure water on-line, and dried by hot air through an air duct with a temperature of 100°C-130°C;

[0033] The configured Pb (98.92 parts)-Sn (0.3 parts)-Bi (0.75 parts)-Sb (0.03 parts) alloy is attached to the dry and clean surface of the pre-rolled positive grid alloy strip by spraying On the surface, the thickness of the sprayed alloy film is controlled at 20um-30um;

[0034] The pre-rolled positive electrode grid alloy strip with the sprayed alloy film layer is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com