Enhanced anti-oxidation conductive additive, lead-acid battery positive electrode paste and preparation method

A technology of lead-acid battery and positive electrode paste, which is applied in the direction of lead-acid battery, battery electrode, electrode manufacturing, etc. It can solve the problems of short service life, sliming and falling off, and achieve not easy sliming and falling off, increased conductivity, and stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of enhanced antioxidant conductive agent, comprising the following process:

[0038]Add 10-20 parts by mass of graphite powder to 70-80 parts by mass of ethanol solution, then add 1-2 parts by mass of metal conductive ceramic MAX powder, and ball mill for 3-5 hours at a speed of 800-1000r / min in a high-energy ball mill , and the obtained mixture is dried at 80° C. to 110° C., that is, an enhanced anti-oxidation conductive agent is obtained.

[0039] The existing conductive agent is a carbon-containing conductive agent, such as graphite, which is the most commonly used, but due to the high voltage of the positive electrode, the graphite will be oxidized soon during the use of the battery. The present invention adopts metal conductive ceramic MAX powder material After coating, it can prevent the oxidation of graphite.

[0040] In the high-energy ball mill of the present invention, ball mill at a speed of 800-1000r / ...

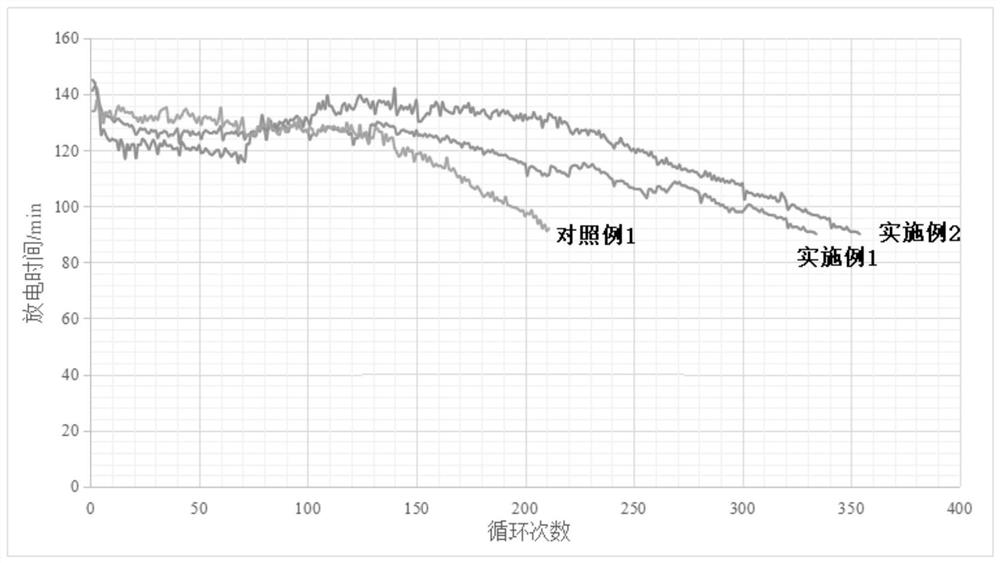

Embodiment 1

[0065] This embodiment provides a positive lead paste for lead-acid batteries, which can be used for deep cycle power, comprising the following steps:

[0066] Step 1, preparing enhanced antioxidant conductive agent;

[0067] Specifically, the preparation method of the enhanced anti-oxidation conductive agent is as follows: add 10 parts of flake graphite by mass to 73 parts of ethanol solution, then add 2 parts of metal conductive ceramic MAX powder, and grind it in a high-energy ball mill at 800 / min The speed of ball milling was 5 hours, and the obtained mixture was dried at 100° C. for 1.5 hours to obtain an enhanced antioxidant conductive agent.

[0068] In step 1, metal conductive ceramic MAX powder is Ti 3 AlC 2 .

[0069] Step 2, dry mixing the components of the positive lead paste;

[0070] Specifically, 75 parts of lead powder calculated by mass ratio, 10 parts of deionized water, 5 parts of red lead, 6 parts of dilute sulfuric acid, 1 part of stannous sulfate, 1 p...

Embodiment 2

[0076] This embodiment provides a lead-acid battery positive electrode paste, which is mainly used for deep cycle power, including the following steps:

[0077] Step 1, preparing enhanced antioxidant conductive agent;

[0078] Specifically, the preparation method of the enhanced anti-oxidation conductive agent is as follows: add 15 parts of graphite flakes by mass to 80 parts of ethanol solution, then add 1 part of metal conductive ceramic MAX powder, and grind in a high-energy ball mill at 100 / min The speed of ball milling was 4h, and the obtained mixture was dried at 100°C to obtain an enhanced anti-oxidation conductive agent.

[0079] In the above step 1, the metal conductive ceramic MAX powder is Ti 2 AlC.

[0080] Step 2, dry mixing the components of the positive lead paste;

[0081] Specifically, 80 parts of lead powder, 8 parts of deionized water, 5 parts of red lead, 6 parts of dilute sulfuric acid, 0.5 parts of stannous sulfate, 1 part of antimony trioxide, enhance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com