Positive electrode lead paste for pregnant solution storage battery and preparation method thereof

A positive electrode paste and storage battery technology, which is applied in the direction of battery electrodes, lead-acid batteries, negative electrodes, etc., can solve the problems of not being able to meet the functional requirements of customers, and achieve the improvement of deep cycle life, excellent electrical conductivity and long life performance, and enhanced The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

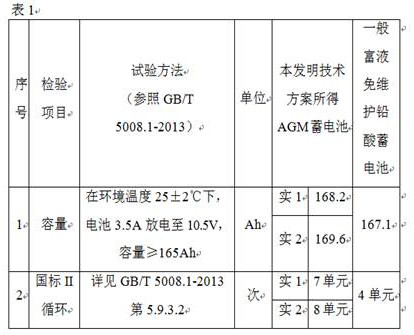

Examples

preparation example Construction

[0035] A kind of preparation method of positive electrode lead paste for liquid-rich accumulator of the present invention comprises the following steps:

[0036] 1) Add antimony trioxide, sodium perborate tetrahydrate, red lead, high-strength glass fiber and 4BS:

[0037] Weigh antimony trioxide, sodium perborate tetrahydrate, red lead, high-strength glass fiber and 4BS in proportion, add to the paste equipment, mix and stir evenly to obtain the additive mixture;

[0038] 2) Mix lead powder:

[0039] After the lead powder is mixed with the additive mixture in step 1), fully stir and mix. The mixing and stirring time is 2 to 4 minutes. After dry mixing, add an appropriate weight of pure water within 1 to 3 minutes, and fully stir and mix. The mixing and stirring time is 3 to 6 minutes lead powder mixture;

[0040] 3) Add acid:

[0041] Add sulfuric acid to the lead powder mixture obtained in step 2) in the form of a spray while stirring to obtain the acid mixture;

[0042] ...

Embodiment 1

[0046] A positive lead paste for liquid-rich batteries, comprising the following components in parts by weight: 700kg of lead powder, 0.6kg of antimony trioxide, 0.6kg of high-strength glass fiber, 6.5kg of 4BS, 90kg of red lead, and 0.25kg of sodium perborate tetrahydrate , sulfuric acid 60kg and pure water 89kg.

[0047] Among them, the size range of high-strength glass fiber is 2 ~ 4mm;

[0048] The density of sulfuric acid is 1.35 ~ 1.45g / cm 3, the iron content in sulfuric acid is not more than 1ppm;

[0049] The iron content in lead powder is not more than 10ppm;

[0050] The lead powder is lead powder containing PbO, and the content of PbO in the lead powder is 70wt%;

[0051] According to the proportioning of above-mentioned positive electrode lead paste, make following preparation:

[0052] 1) Add antimony trioxide, sodium perborate tetrahydrate, red lead, high-strength glass fiber and 4BS:

[0053] Weigh an appropriate weight of antimony trioxide, sodium perborat...

Embodiment 2

[0061] A positive lead paste for a liquid-rich storage battery, comprising the following components in parts by weight: 900 kg of lead powder, 0.9 kg of antimony trioxide, 0.8 kg of high-strength glass fiber, 8.6 kg of 4BS, 110 kg of red lead, and 0.4 kg of sodium perborate tetrahydrate , sulfuric acid 78kg and pure water 105kg.

[0062] Among them, the size range of high-strength glass fiber is 2 ~ 4mm;

[0063] The density of sulfuric acid is 1.35 ~ 1.45g / cm 3 , the iron content in sulfuric acid is not more than 1ppm;

[0064] The iron content in lead powder is not more than 10ppm;

[0065] The lead powder is lead powder containing PbO, and the content of PbO in the lead powder is 73wt%;

[0066] According to the proportioning of above-mentioned positive electrode lead paste, make following preparation:

[0067] 1) Add antimony trioxide, red lead, high-strength glass fiber and 4BS:

[0068] Weigh an appropriate weight of antimony trioxide, red lead, high-strength glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size range | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com