Oxide semiconductor manufacturing method

A technology of oxide semiconductors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems such as uncontrollable or adjustment, and affect the manufacturing quality of thin-film transistors, and achieve the effect of improving manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

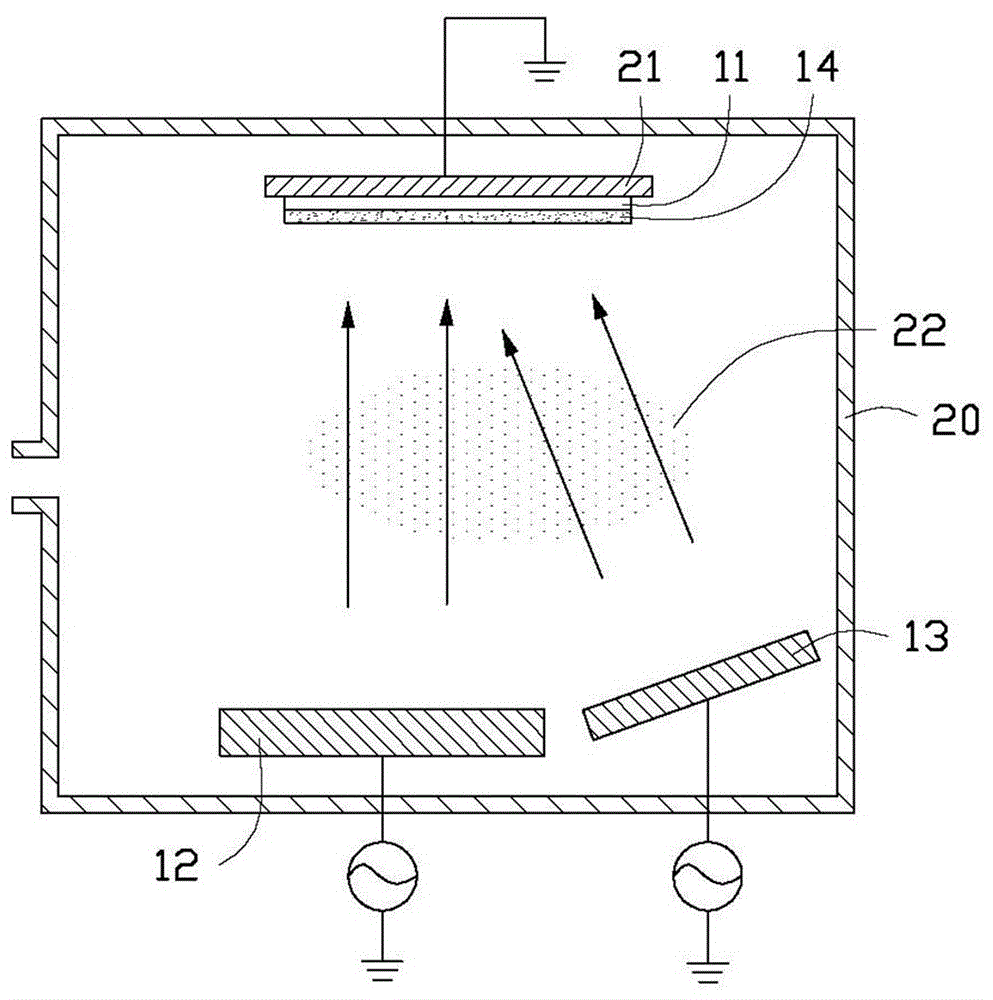

[0027] see figure 1 , the first embodiment of the present invention provides a method for manufacturing an oxide semiconductor, the steps of which are specifically described as follows.

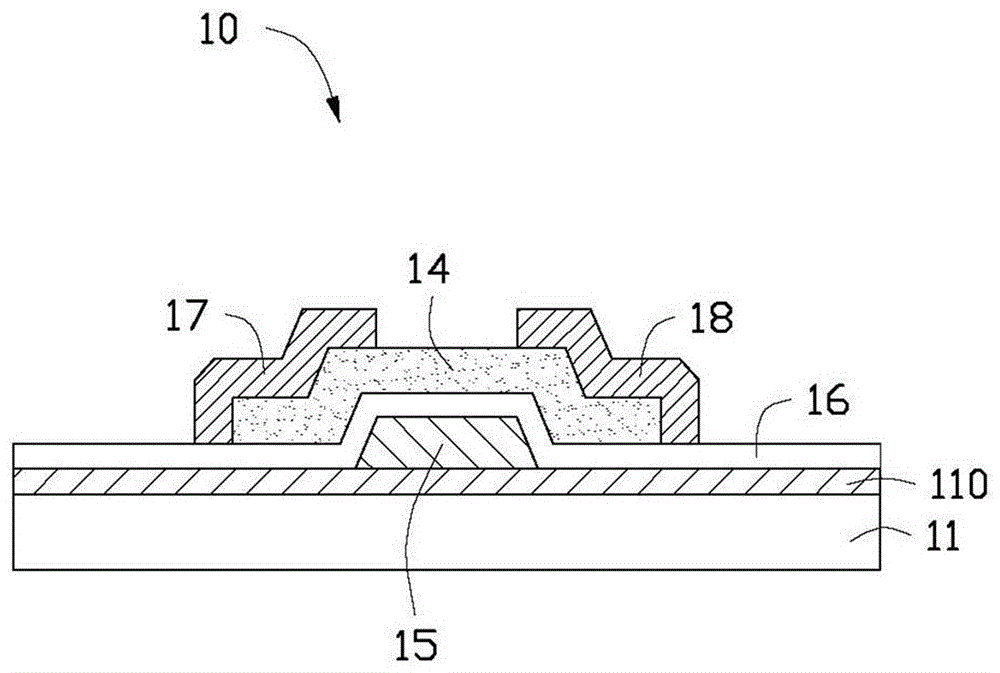

[0028] First, a substrate 11 is provided. The substrate 11 is used to carry the subsequently formed oxide semiconductor thin film. The substrate 11 can be glass, quartz, silicon wafer, plastic and so on.

[0029] Secondly, metal ions from the first metal oxide target 12 are sputtered on the substrate 11, and at least two metal ions from the second metal oxide target 13 are sputtered on the substrate 11 to deposit and form oxides Semiconductor film 14. The at least two metal ions on the second metal oxide target are different from the metal ions on the first metal oxide target. When depositing metal ions, the composition ratio of the oxide semiconductor film 14 can be adjusted by controlling the deposition rate of the oxide semiconductor film 14 and the service period of the baffle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com