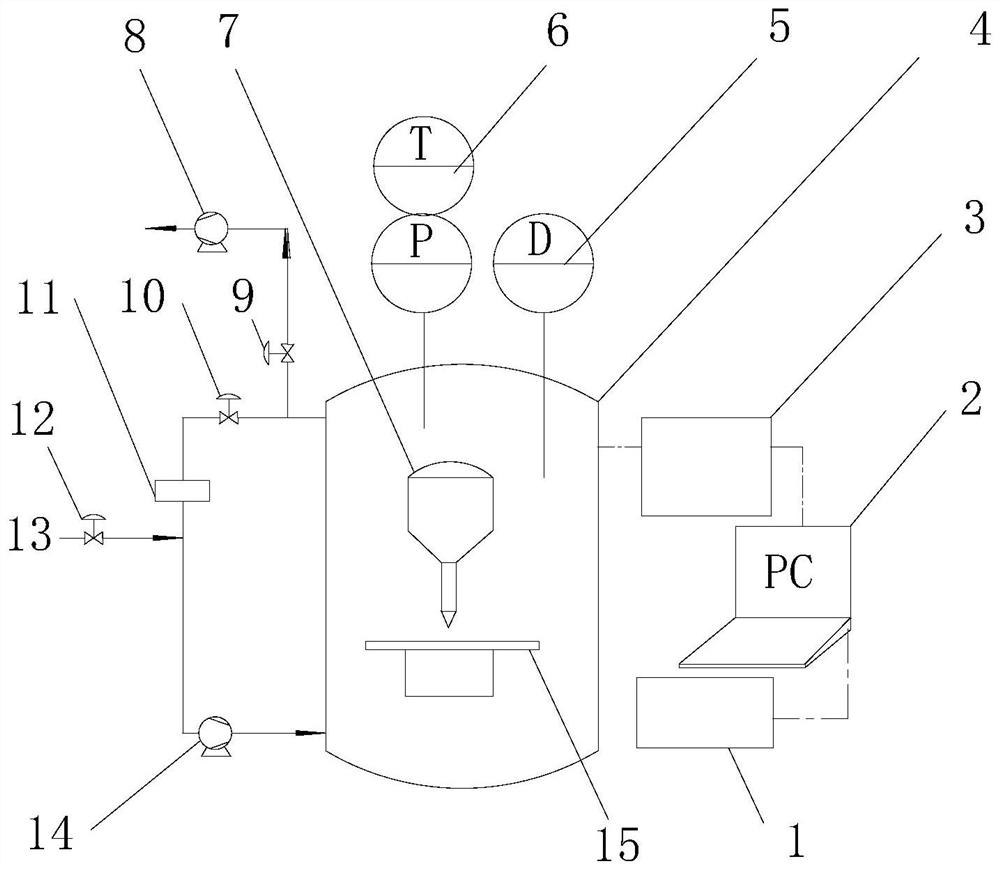

A multi-silo, pressure-adjustable 3D printing system and method

A 3D printing, multi-silo technology, applied in the field of 3D printing manufacturing, can solve the problems of single product component material, unable to meet the diversity of internal microstructure of components, single microstructure, etc., to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

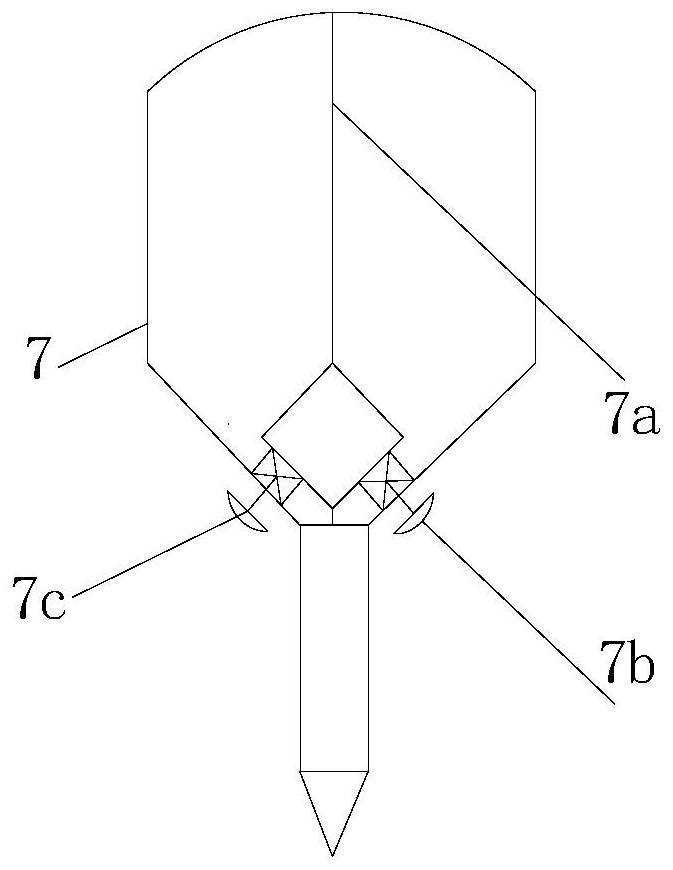

Method used

Image

Examples

Embodiment example 1

[0044] Implementation case 1, the system of the present invention processes "vehicle-mounted high-pressure hydrogen storage cylinders with aluminum inner tubes".

[0045] Since iron and steel materials will melt into trace amounts of hydrogen during the smelting process, if used improperly, hydrogen embrittlement will easily occur and fracture will occur. Therefore, high-pressure hydrogen storage equipment generally cannot use steel materials, and steel materials exposed to high-pressure hydrogen will accelerate the occurrence of hydrogen embrittlement. Usually high-pressure hydrogen storage tanks are made of aluminum alloy, but the strength of aluminum alloy is much lower than that of steel. With the promotion of hydrogen energy vehicles, it has always been the dream of hydrogen production enterprises to manufacture high-quality, low-cost hydrogen storage equipment with aluminum inner tubes and steel sheaths. It would be a good choice to make "vehicle-mounted high-pressure h...

Embodiment example 2

[0054] Example 2, the system of the present invention processes "SiC carrier of hydrogen production catalyst by hydrolysis of sodium borohydride".

[0055] The "SiC carrier of sodium borohydride hydrolysis hydrogen production catalyst" prepared by the known technology is usually granular. Since the internal microstructure of the SiC carrier is required to be loose, permeable, and the specific surface area is large enough, the manufacturing process of the known technology is complicated. Acid corrosion is required, and polluted waste is discharged. However, the system of the present invention can use argon gas whose working gas pressure is lower than 1 standard atmospheric pressure, and 3D print out "SiC carrier of hydrogen production catalyst by hydrolysis of sodium borohydride".

[0056] This case is matched with a cylindrical hydrolysis hydrogen production reaction vessel, and the "catalyst SiC carrier" is designed as a cylinder with a certain appropriate wall thickness. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com