Oil-soluble self-vulcanizing molybdenum catalyst, and preparation method, use method and application of oil-soluble self-vulcanizing molybdenum catalyst

A molybdenum sulfide, oil-soluble technology, used in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. The dispersion process is complex and cannot be guaranteed to be converted into sulfided metals, etc., to achieve the effect of improving overall economic benefits, maintaining long-term operation, and not reducing catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

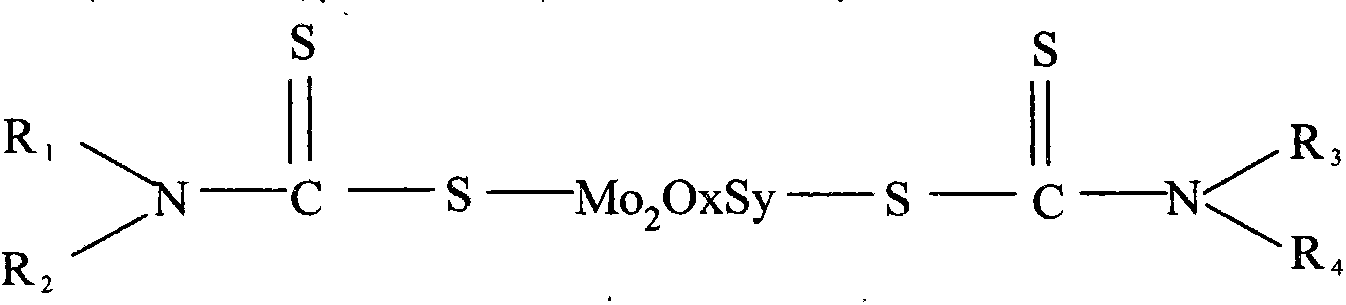

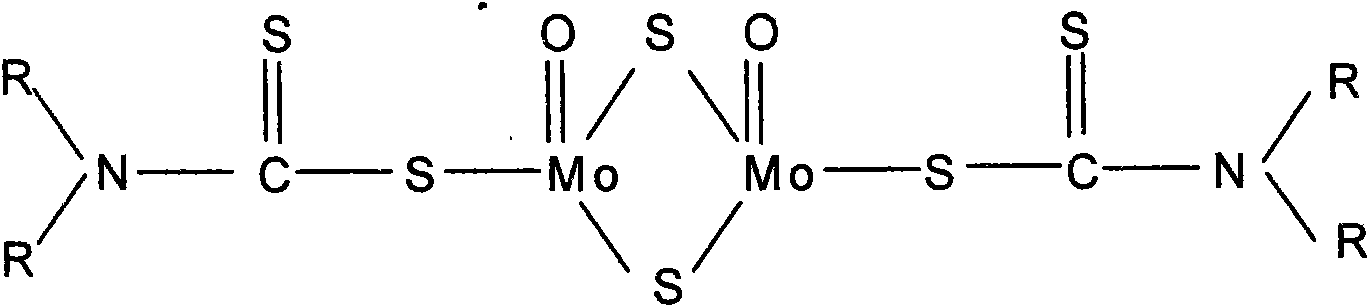

Method used

Image

Examples

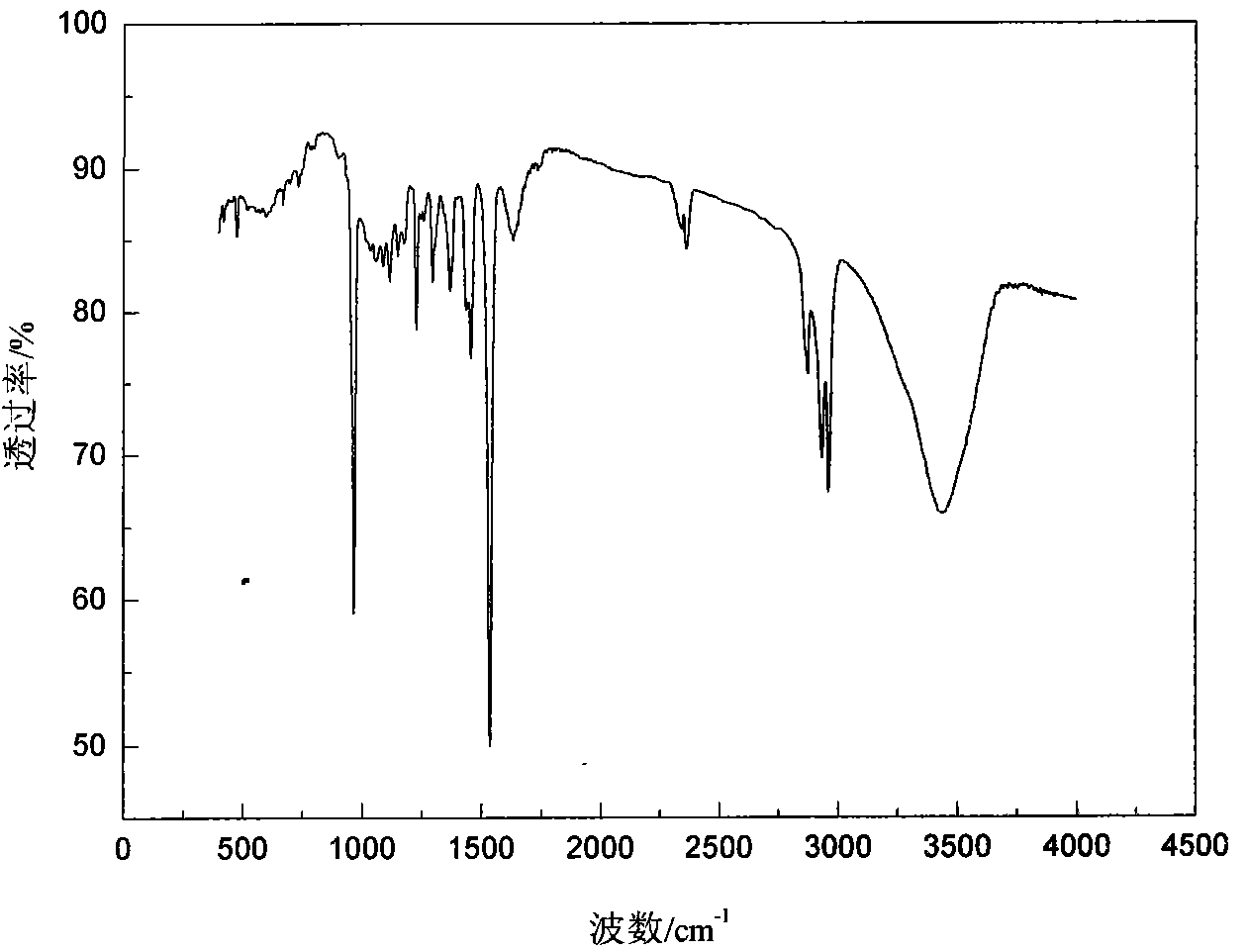

Embodiment 1

[0028] 0.05mol MoO under nitrogen protection 3 Add the powder to 100ml water, add 0.05mol 15% Na 2 S solution, then add 0.5mol toluene, acidify with 0.01mol35% sulfuric acid, cool to 25℃, react for 10min; then add 0.05mol di-n-butylamine and 0.05mol carbon disulfide at room temperature, stir for 30min, heat up to 85℃ After the reaction is completed for 4 hours, the product is cooled, filtered with suction, washed with methanol, and dried to obtain a yellow solid of oil-soluble molybdenum sulfide catalyst with a yield of 66%.

Embodiment 2

[0030] Under the protection of nitrogen, add 0.05mol NaMoO 4 ·2H 2 Add O powder to 100ml water, add 0.05mol 15% Na 2 S solution, then add 0.63mol methanol, acidify with 0.01mol35% sulfuric acid, cool to 15℃, react for 150min; then add 0.06mol di-n-butylamine and 0.06mol carbon disulfide at room temperature, stir for 30min, heat up to 90℃ After reacting for 3 hours, after the reaction, the product was cooled, filtered with suction, washed with methanol, and dried to obtain a yellow solid of oil-soluble molybdenum sulfide catalyst with a yield of 75%.

Embodiment 3

[0032] Under the protection of nitrogen, add 0.05mol MoO 3 Add the powder to 100ml water, add 0.05mol 15% Na 2 S solution, then add 0.7 mol methanol, acidify with 0.01 mol 35% sulfuric acid, cool to 10°C, and react for 60 minutes; then add 0.1 mol di-n-butylamine and 0.15 mol carbon disulfide at room temperature, stir for 30 minutes, heat up to 95°C After reacting for 5 hours, after the reaction, the product was cooled, filtered with suction, washed with methanol, and dried to obtain a yellow solid of oil-soluble molybdenum sulfide catalyst with a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com