Apparatus for treating discharge gas and system for treating discharge gas

A waste gas treatment device and waste gas technology, applied in gas treatment, combustion product treatment, chemical/physical processes, etc., can solve the problems of inapplicable large-capacity waste gas treatment, etc., and achieve the effect of increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

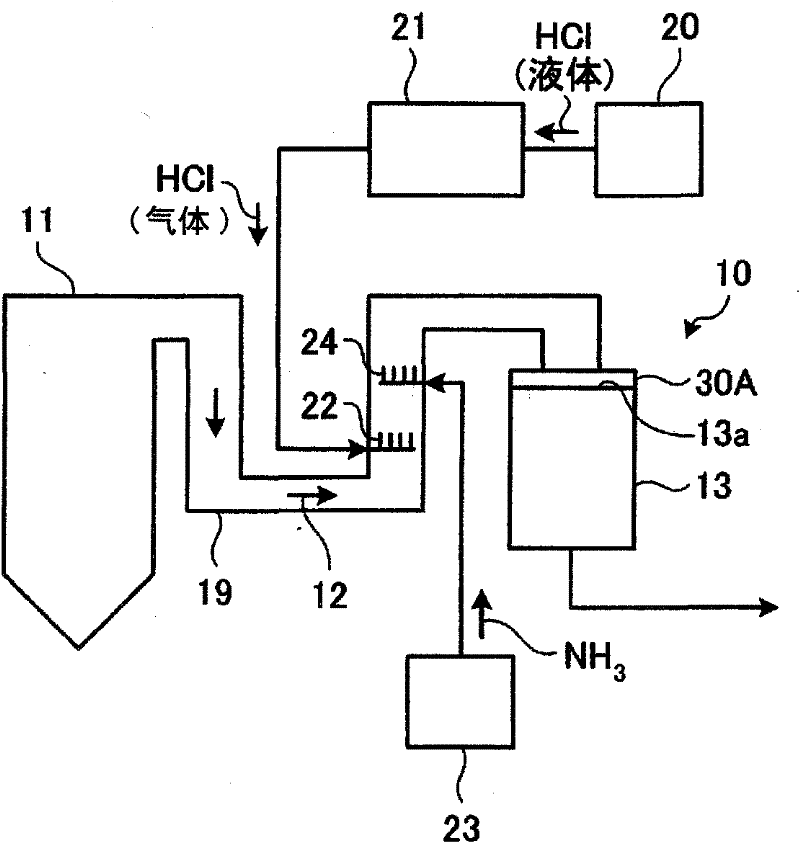

[0049] An exhaust gas treatment system to which an exhaust gas treatment device according to an embodiment of the present invention is applied will be described with reference to the drawings.

[0050] In addition, because the configuration and Figure 8 The shown exhaust gas treatment system has the same configuration, so in this embodiment, the configuration of the exhaust gas treatment device will be described.

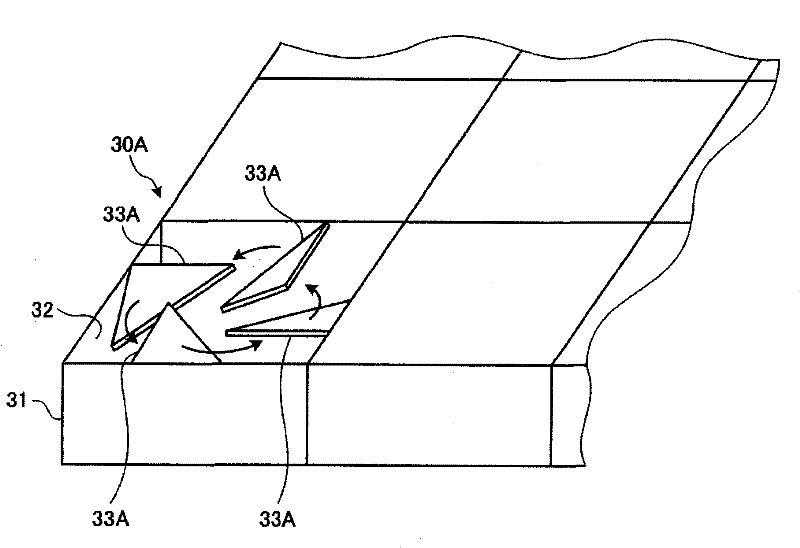

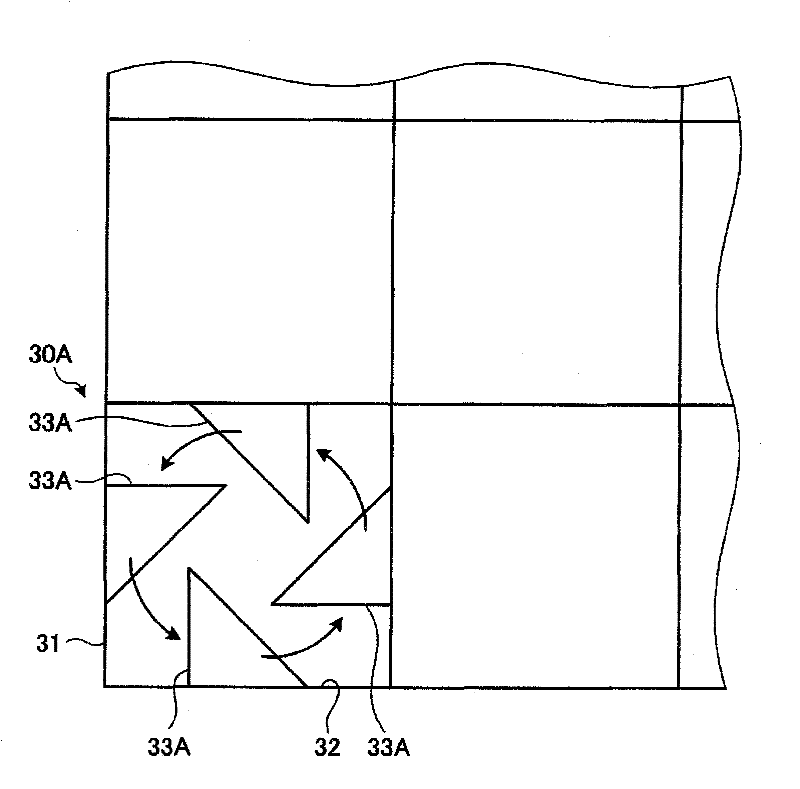

[0051] figure 1 It is a schematic diagram showing the exhaust gas treatment device of the embodiment, figure 2 is a perspective view of the vortex generating part, image 3 This is a view of the swirl flow generating member viewed from the axial direction.

[0052] in addition, figure 1 is composed of Figure 8 Since it is a part of the exhaust gas treatment system shown, the same symbols will be added to the same components as those of the existing ones, and repeated descriptions will be omitted.

[0053] Such as figure 1 As shown, the exhaust gas treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com