Method for preparing cyclohexanol and cyclohexanone based on multi-layer guide cylinder bubbling reactor

A technology of bubbling reactors and guide tubes, which is applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of hydroxyl compounds, etc., can solve the problems of increased material consumption and decreased selectivity of target products, and achieve improved efficiency and improved circulation The effect of increasing the rate and improving the mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

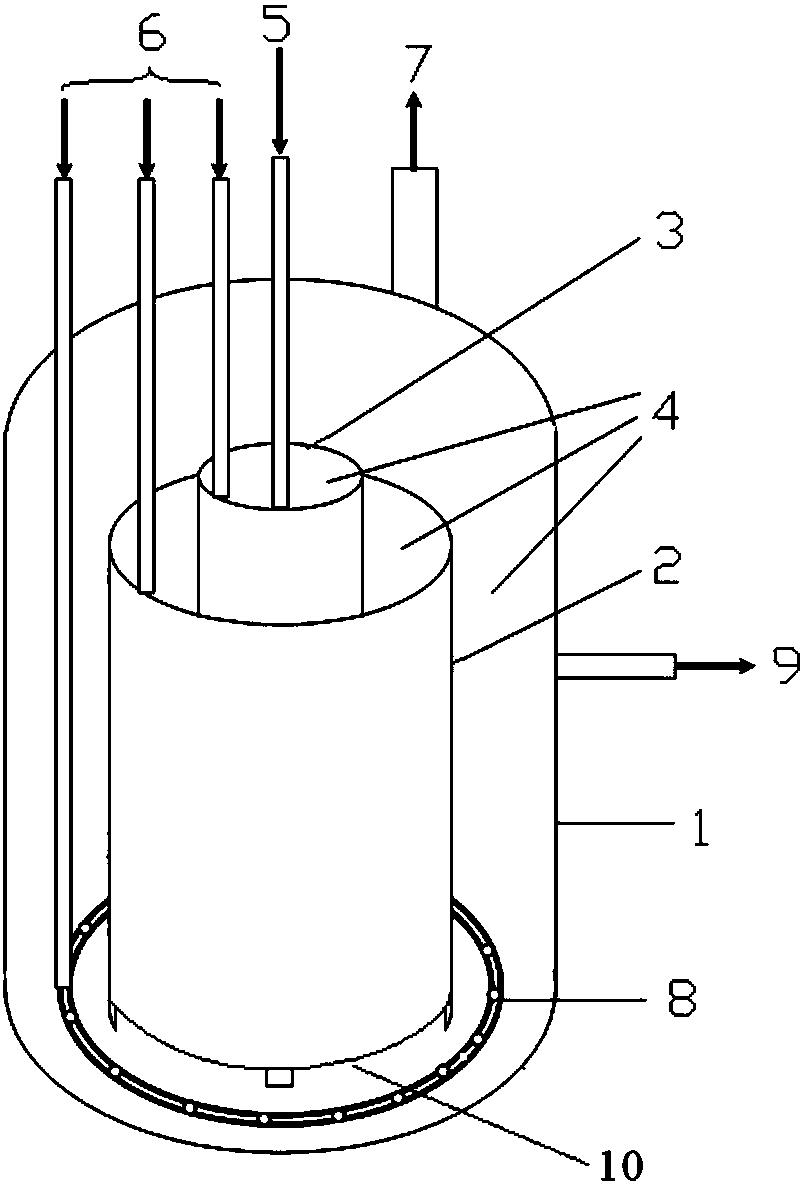

[0053] see figure 1 , the reactor housing 1 of the cyclohexane oxidation reactor is set with a multi-layer guide tube. The flow tube 2, the two-layer flow guide tube is coaxially arranged with the reactor shell 1, and has different diameters, which divides the reactor shell 1 into three-stage annular areas 4, and the height of the flow guide tube is along the 3 is lowered step by step toward the outer guide tube 2, and the bottoms of the inner guide tube 3 and the outer guide tube 2 are left with a water gap 10 at the bottom of the reactor shell 1, so that the three-stage annular area It can not only flow step by step through the water gap 10 between the guide tube and the bottom of the shell, but also overflow and connect step by step through the top. The inner guide tube 3 in the center is connected to the liquid inlet 5, and each stage is annular Area 3 and the inner layer guide tube 3 in the center are all connected to the air inlet 6, and the liquid inlet 5 and the air i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com