Three-phase catalytic oxidization wastewater treatment method and reactor

A sewage treatment method and technology of the treatment method, which are applied in the directions of oxidized water/sewage treatment, water/sewage treatment, illumination water/sewage treatment, etc., can solve the problem of increasing the cost of the treatment process, the inability to generate three phases simultaneously, and the expensive cost of the catalytic unit. and other problems, to achieve the effect of improving the oxidation reaction efficiency, fully utilizing the oxidant, and prolonging the hydraulic retention time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

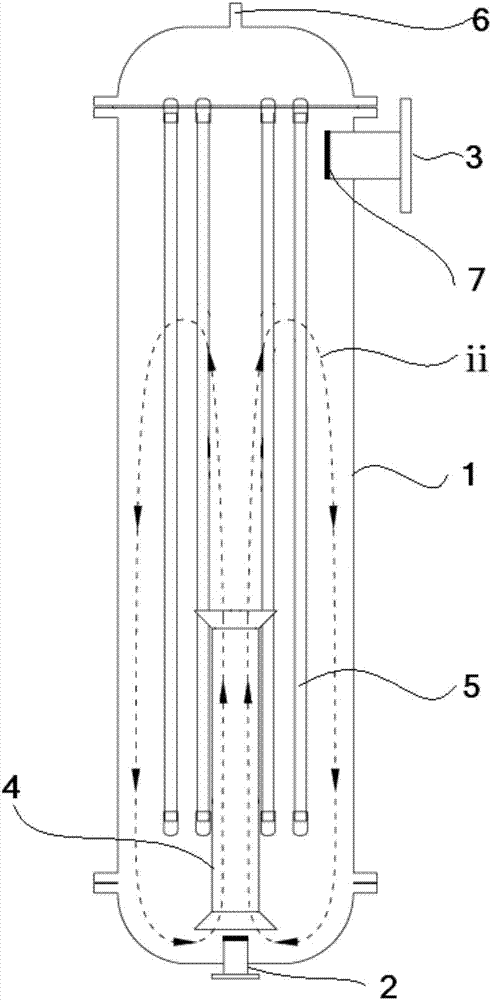

[0036] Comply with the above technical solutions, such as figure 1 As shown, this embodiment provides a three-phase catalytic oxidation sewage treatment method: first add ozone microbubbles to the sewage to be treated, and then use an air-dissolving device to dissolve ozone in the sewage to be treated, and release it in the reaction vessel For micro-bubbles, the air-holding equipment can be dissolved air pump, pressure dissolved air tank, etc., not limited to the above dissolved air methods;

[0037] While irradiating the solid catalyst with ultraviolet light, the sewage to be treated contacts the solid catalyst, and drives the solid catalyst to move upward in a fluidized state to react, the solid catalyst settles, and the ozone microbubbles are either consumed, broken, or attached to the catalytic particles On, or released, after the sewage to be treated is reacted, the refractory organic matter is effectively removed. After testing, using this method, the COD removal rate c...

Embodiment 2

[0039] This embodiment provides a reactor, which includes a columnar housing 1, the lower part of the housing 1 is provided with a water inlet 2, the upper part of the housing 1 is provided with a water outlet 3, and the central axis of the inner cavity of the housing 1 is provided with a columnar The diversion reaction cylinder 4, the diversion reaction cylinder 4 is not completely in contact with the bottom of the housing 1 and the height of the diversion reaction cylinder 4 is lower than the height of the housing 1, and the inner cavity of the housing 1 is provided with A plurality of ultraviolet generators 5 use ultraviolet photocatalytic oxidants to promote advanced oxidation reactions. In consideration of safety, a pressure relief hole 6 is processed on the top of the casing 1 .

[0040]The ultraviolet generator 5 includes an ultraviolet lamp tube or an industrial ultraviolet tube. The luminous wavelength of the ultraviolet generator 5 includes 254nm or 365nm, especially...

Embodiment 3

[0051] This example differs from Comparative Example 1 in that: the gas production rate of the ozone generator is 10g / h, the effective ozone volume is 945, and the sewage to be treated enters the reactor at a linear velocity of 1.5m / h and a water inlet pressure of 30kPa.

[0052] The sewage stays in the whole reaction process for 20 minutes and then enters the product water tank. The COD of the product water is 73.12, and the COD removal rate is 66.47%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com