Long-term anti-yellowing polyester resin as well as preparation method and application thereof

A polyester resin, anti-yellowing technology, applied in polyester coatings, coatings, powder coatings, etc., can solve the problems of poor decorative protection effect, poor adhesion of substrates, complex preparation process, etc., and improve the efficiency of oxidation reaction. , broad application prospects, excellent anti-yellowing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

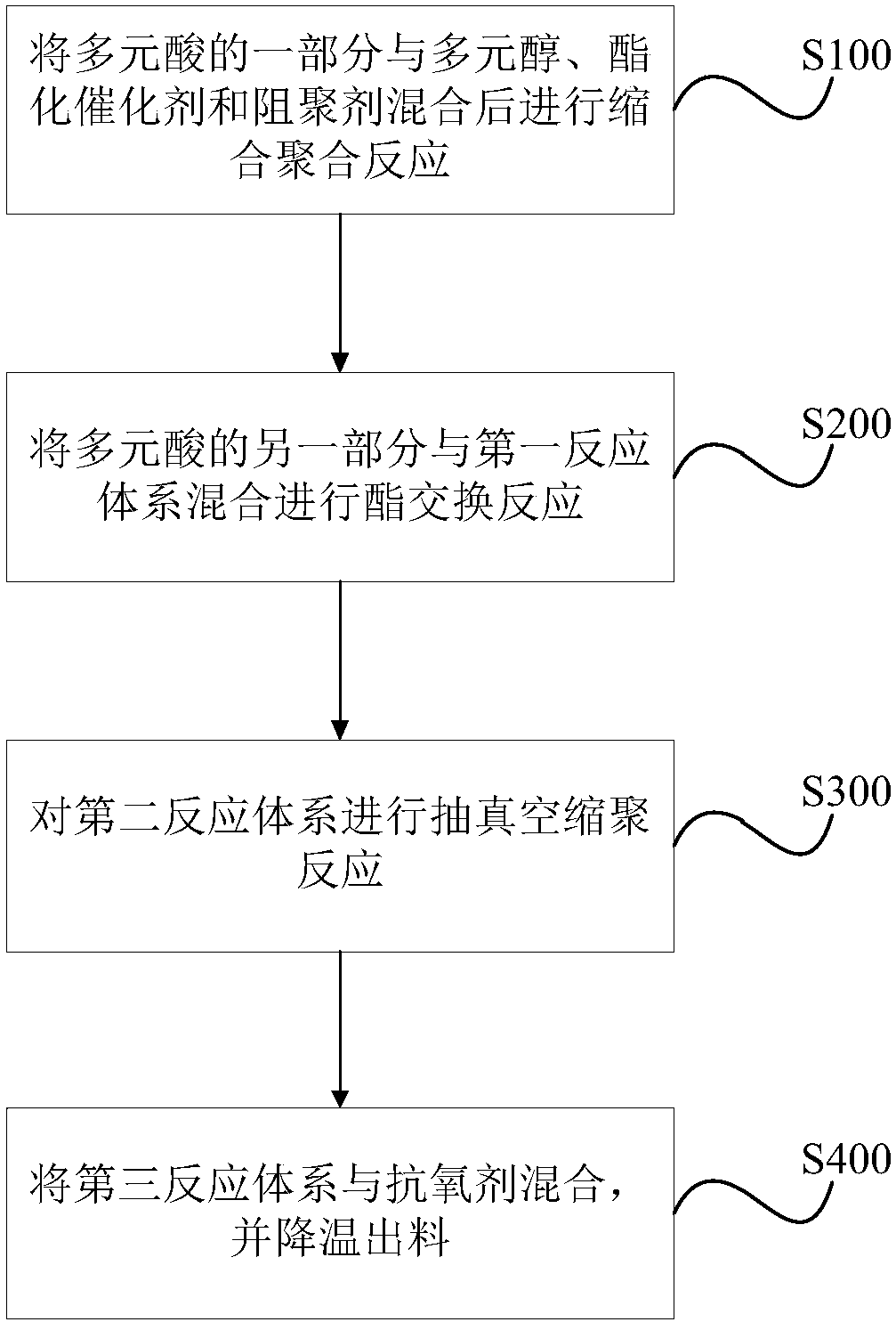

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-2

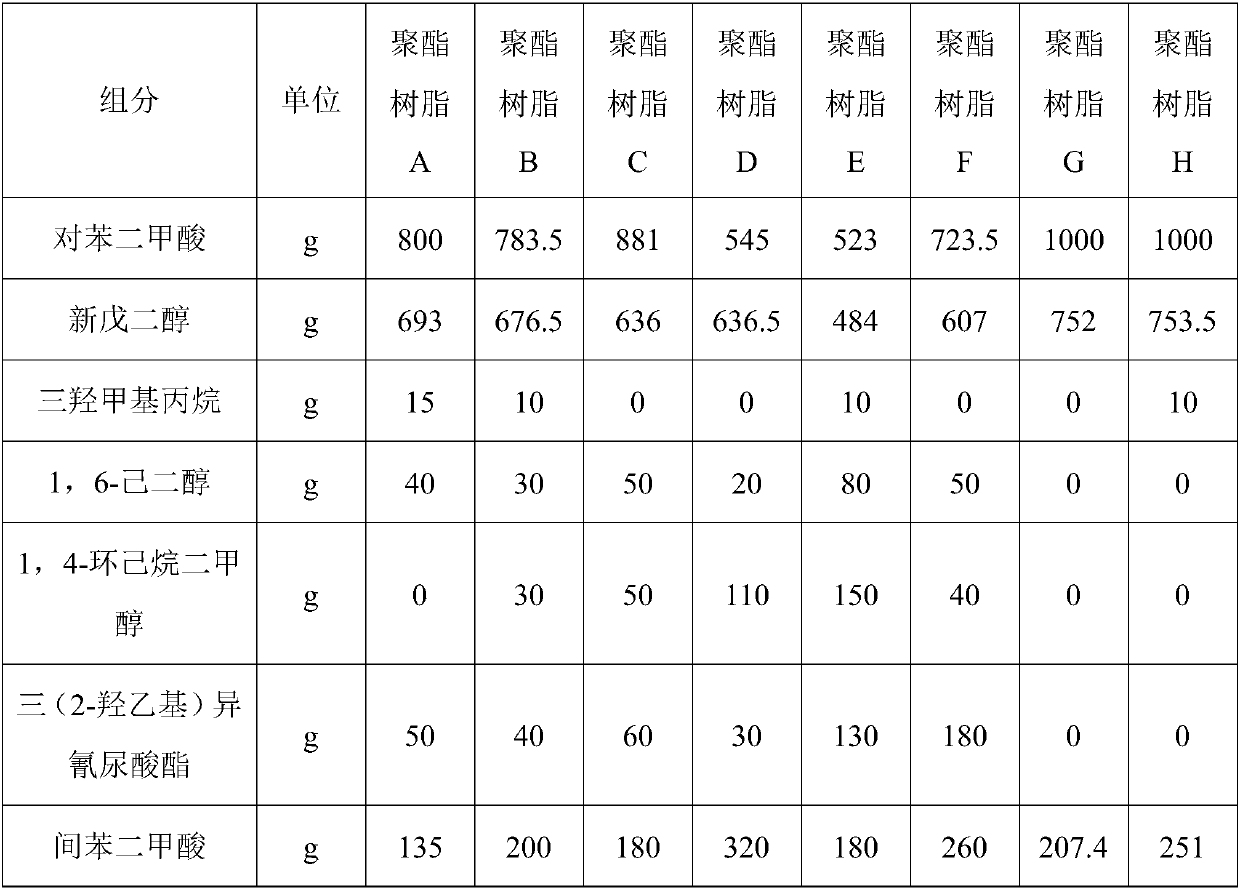

[0103] (1) Raw material

[0104] Neopentyl glycol was purchased from Korea LG Company.

[0105] 1,6-Hexanediol was purchased from BASF Corporation of the United States.

[0106] 1,4-Cyclohexanedimethanol was purchased from Eastman Company, USA.

[0107] Tris(2-hydroxyethyl)isocyanurate was purchased from Jinan Zi'an Chemical Co., Ltd.

[0108] Trimethylolpropane was purchased from Mitsubishi Chemical Corporation, Japan.

[0109] Terephthalic acid was purchased from Yangzi Petrochemical Co., Ltd.

[0110] Isophthalic acid and adipic acid were purchased from China National Petroleum Corporation.

[0111] 1,4-Cyclohexanedicarboxylic acid was purchased from Huainan Kedi Chemical Technology Co., Ltd.

[0112] Monobutyltin oxide, dibutyltin oxide, and monobutyldihydroxytin chloride were purchased from Nantong Advan Chemical Co., Ltd.

[0113] Triphenyl phosphite and tris(2,4-di-tert-butylphenyl) phosphite were purchased from Jiangsu Changhe Chemical New Material Co., Ltd.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com