Composite catalyst of MoS2/defective MIL-100 (Fe) and preparation method and application thereof

A composite catalyst and defect-type technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve a wide range of pH applications, promote oxidation reaction efficiency, overcome traditional The effect of quality-limiting problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

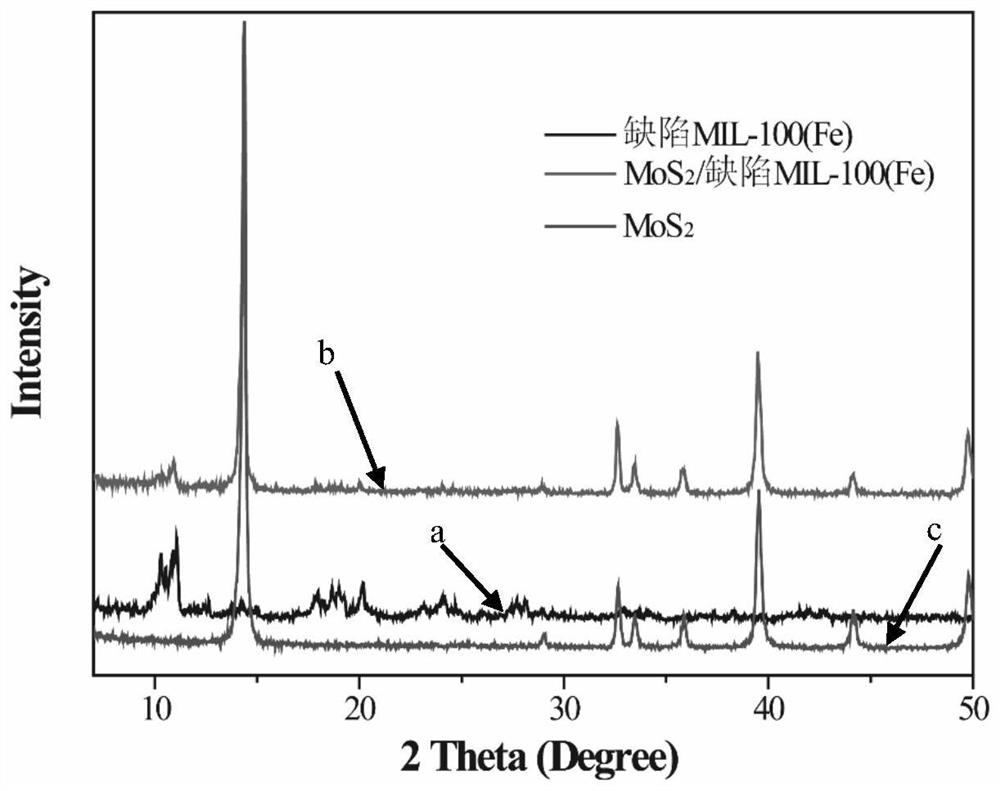

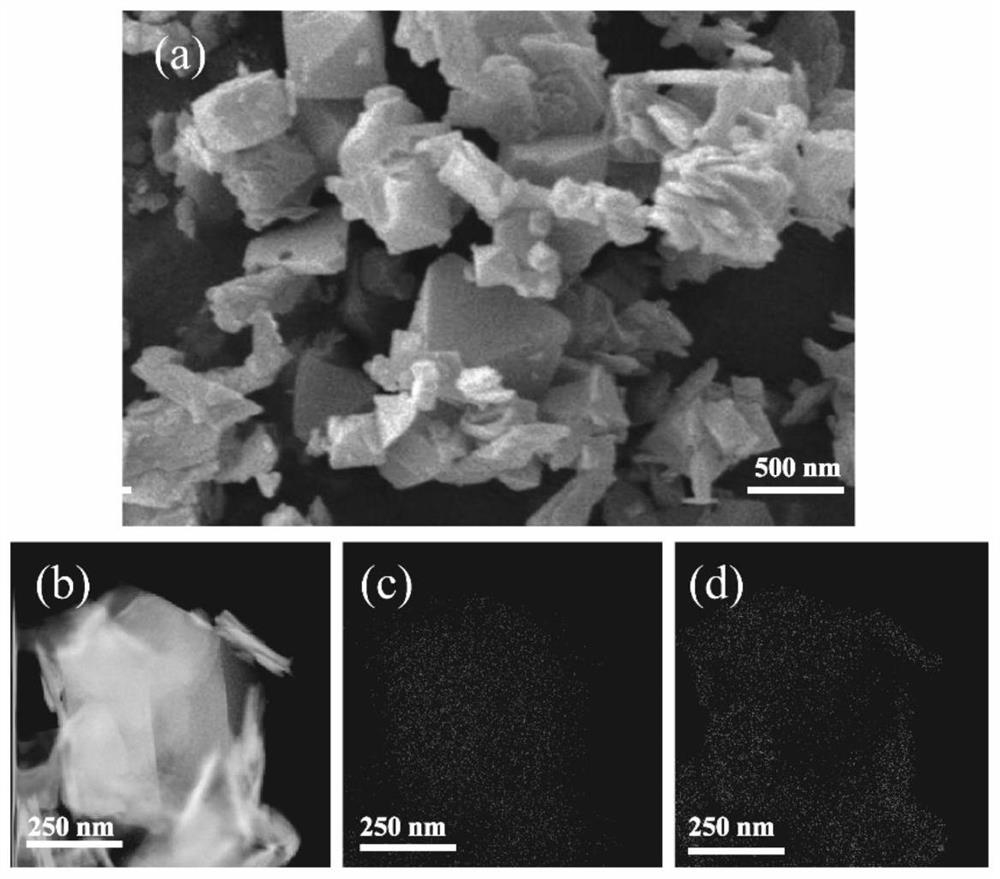

[0045] Embodiment 1: MoS of this embodiment 2 The preparation process of / defective MIL-100 (Fe) class Fenton composite catalyst comprises the following steps:

[0046] (1) Take MoS 2 The mass ratio of / MIL-100(Fe) is 0.2, and 0.128g MoS 2 Add it into 50mL of N,N-dimethylformamide, stir evenly, and then ultrasonicate for 5min to obtain MoS 2 the dispersion liquid;

[0047] (2) To the MoS obtained in step (1) 2 Add 0.27g FeCl to the dispersion 3 ·6H 2 O and 0.17g 1,4-H 2 BDC (terephthalic acid), then the mixed solution was ultrasonicated for 5 min, and then transferred to a dry polytetrafluoroethylene reactor.

[0048] (3) Gradually heat the polytetrafluoroethylene reactor in step (2) to 150° C. within 8 hours and keep it for 24 hours. After natural cooling, filter to obtain a precipitate.

[0049] (4) The precipitate obtained in step (3) is washed with deionized water and ethanol to remove residual unreacted reactants and colored impurities, and then dried in a vacuum o...

Embodiment 2

[0056] Embodiment 2: MoS of this embodiment 2 The preparation process of / defective MIL-100 (Fe) class Fenton composite catalyst comprises the following steps:

[0057] (1) Take MoS 2 The mass ratio of / MIL-100(Fe) is 0.6, and 0.384g MoS 2 Add it into 50mL of N,N-dimethylformamide, stir evenly, and then ultrasonicate for 8min to obtain MoS 2 the dispersion liquid;

[0058] (2) To the MoS obtained in step (1) 2 Add 0.27g FeCl to the dispersion 3 ·6H 2 O and 0.17g 1,4-H 2 BDC, then the mixed solution was ultrasonicated for 8 min, and then transferred to a dry polytetrafluoroethylene reactor.

[0059] (3) Gradually heat the polytetrafluoroethylene reactor in step (2) to 150° C. within 8 hours and keep it for 24 hours. After natural cooling, the precipitate was obtained by filtration.

[0060] (4) The precipitate obtained in step (3) was washed with deionized water and ethanol to remove residual unreacted reactants and colored impurities, and then dried in a vacuum oven at...

Embodiment 3

[0062] Embodiment 3: MoS of this embodiment 2 The preparation process of / defective MIL-100 (Fe) class Fenton composite catalyst comprises the following steps:

[0063] (1) Take MoS 2 The mass ratio of / MIL-100(Fe) is 0.8, and 0.512g MoS 2 Add it into 50mL of N,N-dimethylformamide, stir evenly, and then sonicate for 10min to obtain MoS 2 the dispersion liquid;

[0064] (2) To the MoS obtained in step (1) 2 Add 0.27g FeCl to the dispersion 3 ·6H 2 O and 0.167g 1,4-H 2 BDC, then the mixed solution was ultrasonicated for 10 min, and then transferred to a dry polytetrafluoroethylene reactor.

[0065] (3) Gradually heat the polytetrafluoroethylene reactor in step (2) to 150° C. within 8 hours and keep it for 24 hours. After natural cooling, filter to obtain a precipitate.

[0066] (4) The precipitate obtained in step (3) is washed with deionized water and ethanol to remove residual unreacted reactants and colored impurities, and then dried in a vacuum oven at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com