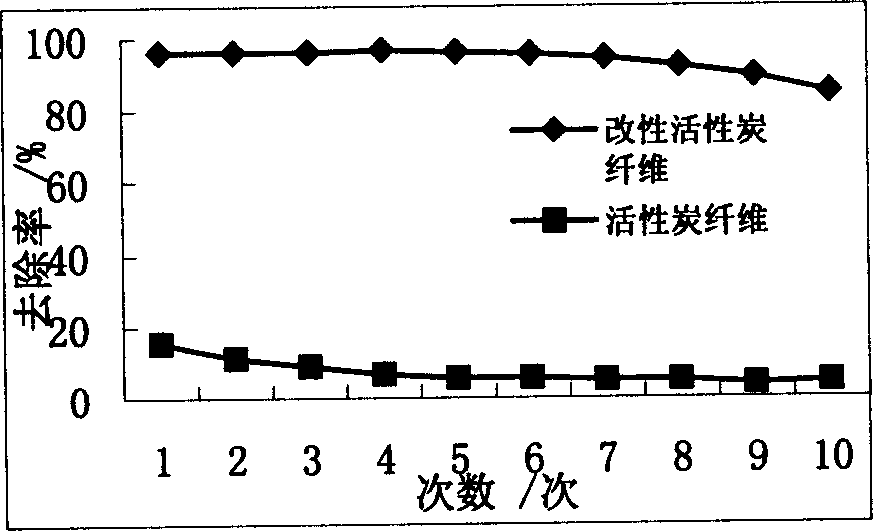

Process for preparing Fe-Sn modified active carbon fibre catalyst for microwave induced oxidation

A technology of activated carbon fibers and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low catalyst efficiency and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific embodiment one: this embodiment mode is realized in this way: a, activated carbon fiber is impregnated in containing Fe 2+ , Sn 2+ In the mixed solution, then add urea, in which activated carbon fiber, Fe 2+ , Sn 2+ The weight ratio with urea is 1: (0.5 ~ 2): (0.5 ~ 3): (5 ~ 10); b, the above mixture is placed at 50 ~ 90 ° C for 10 ~ 15h, and the precipitation attached to the surface of the activated carbon fiber is cleaned and then drying at 100-150°C to obtain a catalyst precursor; c. Calcining the catalyst precursor in a muffle furnace for 2.5-4.0 hours, wherein the calcination temperature is controlled at 250-400°C, and the heating rate is 3-6°C / min , and cooled to room temperature after calcination to obtain a modified activated carbon fiber catalyst.

specific Embodiment approach 2

[0006] Specific embodiment two: the difference between this embodiment and specific embodiment one is that activated carbon fiber, Fe 2+ , Sn 2+ The weight ratio with urea is 1: (0.6-1.2): (0.6-1.5): (5.5-7.5). Other process parameters and steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0007] Specific embodiment three: the difference between this embodiment and specific embodiment one is that activated carbon fiber, Fe 2+ , Sn 2+ The weight ratio with urea is 1: (1.5-1.9): (2-2.8): (8-9.5). Other process parameters and steps are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com