Waste discharging treatment system for trimanganese tetraoxide production

A manganese tetraoxide and treatment system technology, which is applied in the field of waste treatment system for manganese tetraoxide production, can solve problems such as environmental pollution, low recovery rate of manganese element, incomplete purification of waste water, etc., so as to improve the treatment effect, Sufficient recovery and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

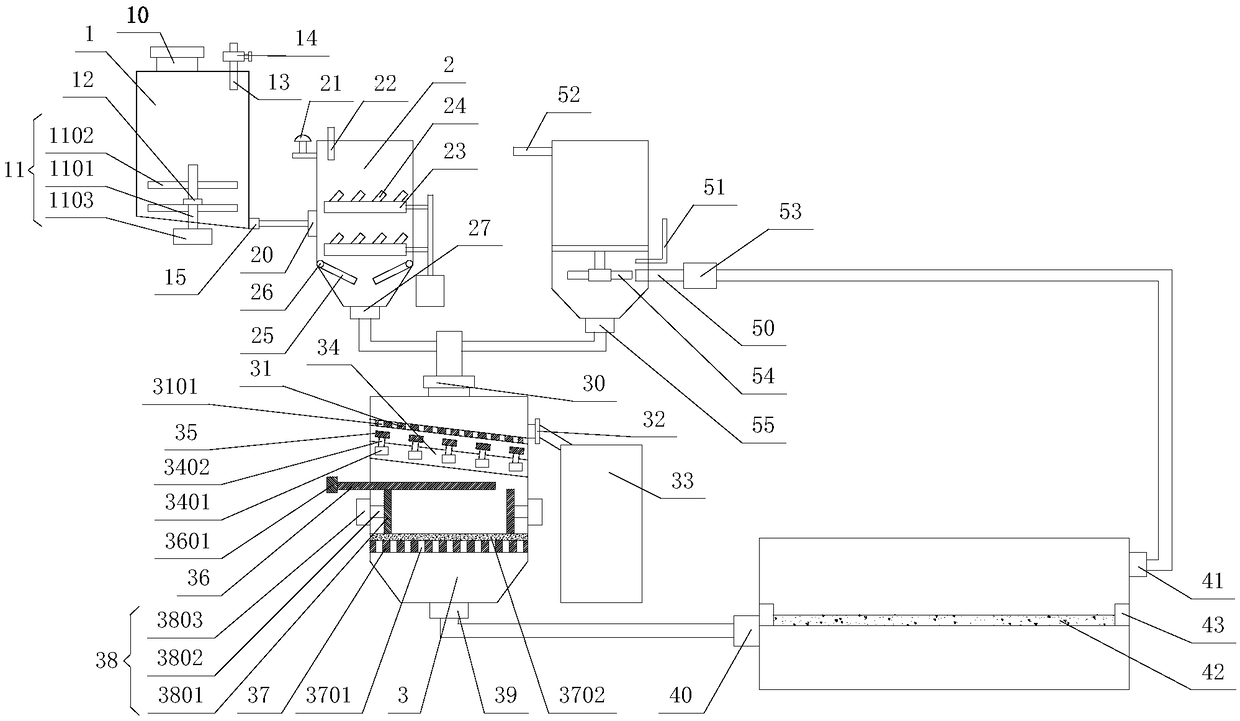

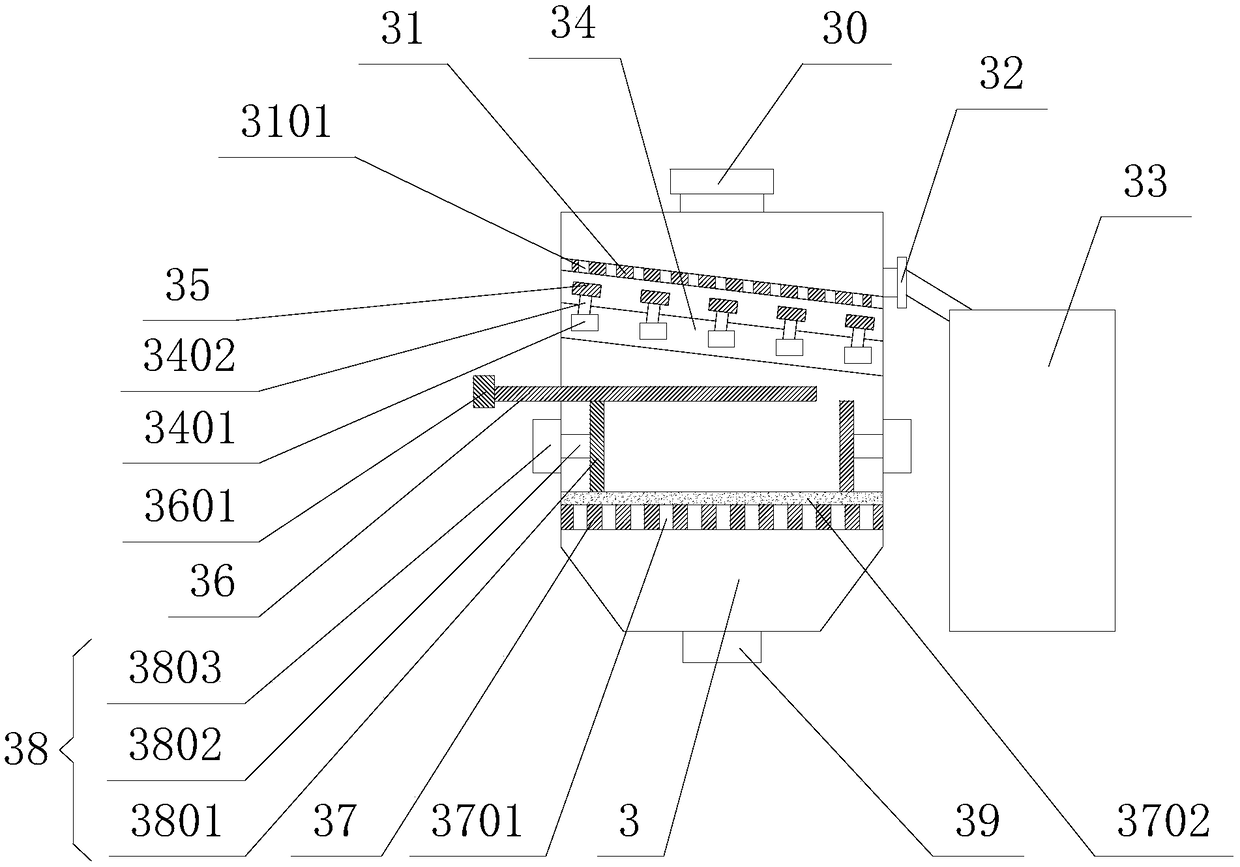

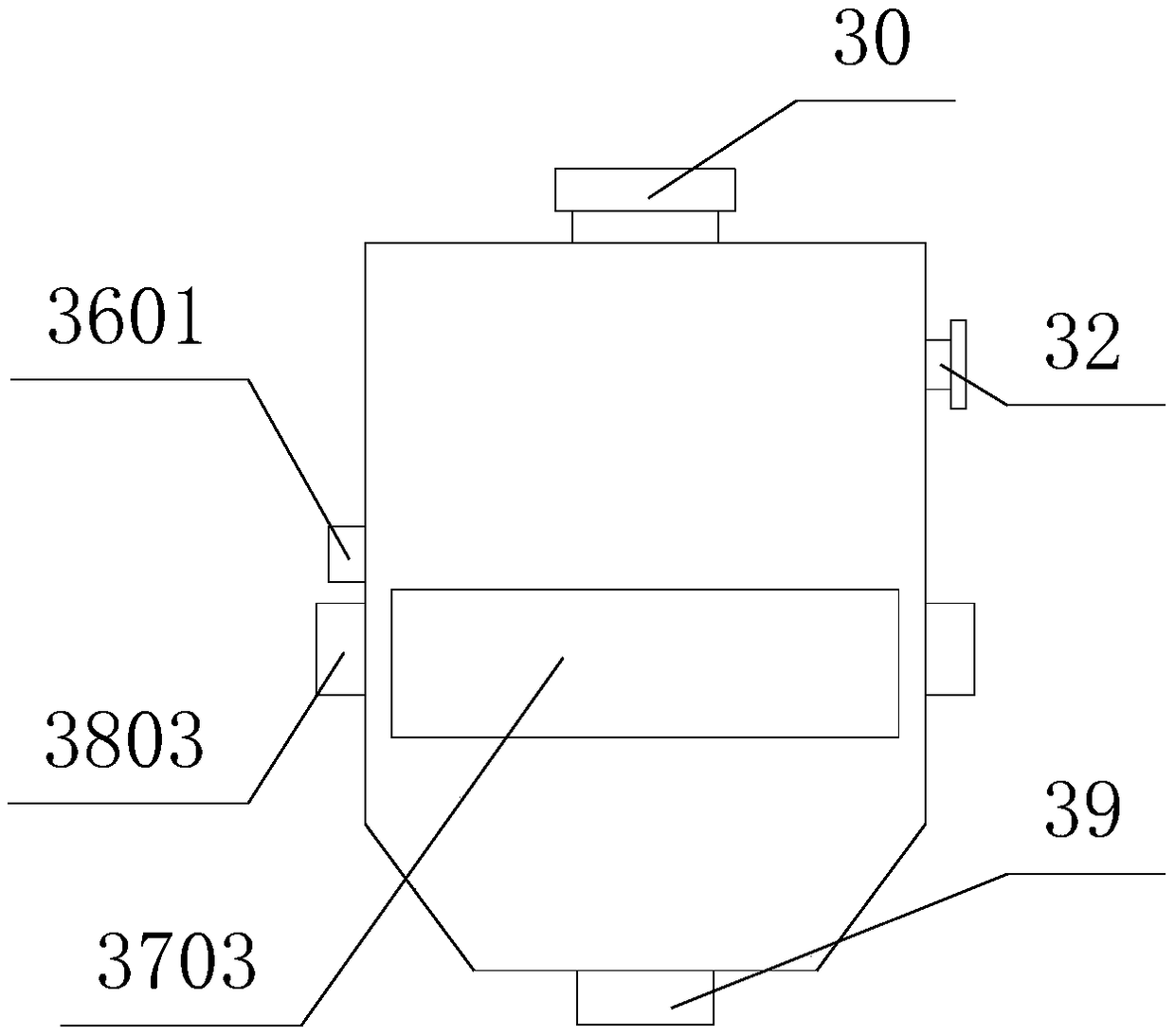

[0032] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the waste treatment system for manganese tetraoxide production provided in this embodiment includes a collection tank 1, an oxidation tank 2, a pressure filter tank 3, a sedimentation tank 4 and a manganese precipitation tank 5;

[0033] The top of the collection tank 1 is provided with a collection wastewater inlet 10, and the bottom is provided with a collection wastewater outlet 15. The collection tank 1 is provided with a stirring device 11, a pH sensor 12 and a liquid level sensor. The stirring device 11 includes a stirring shaft 1101 , stirring blade 1102 and driving motor 1103, the top of the stirring shaft 1101 is vertically positioned at the center line of the collection tank 1, and the bottom end extends out of the collecting tank 1 and is connected with the driving motor 1103, and the stirring blade 1102 is provided with multiple groups, Multiple sets of stirring blades 1102 are evenly distrib...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, except that the inclination angle of the aeration head 24 is changed, and the angle between the aeration head 24 and the horizontal plane is 30 degrees.

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 1, except that the inclination angle of the aeration head 24 is changed, and an included angle of 60 degrees is formed between the aeration head 24 and the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com