Hydrogen peroxide oxidation bleaching process pH value stabilizing technology

An oxidative bleaching and hydrogen peroxide technology, applied in pulp bleaching, food science, textiles and papermaking, etc., can solve the problems of no related research work, decreased reaction efficiency, and high reaction rate, to reduce the occurrence of pollutants and increase the proportion of preparation and copying , The effect of high whiteness stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

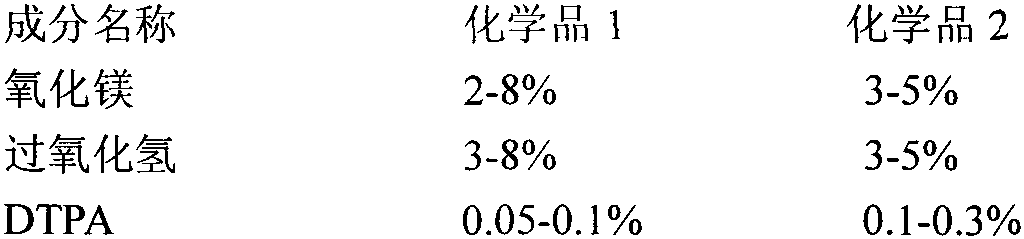

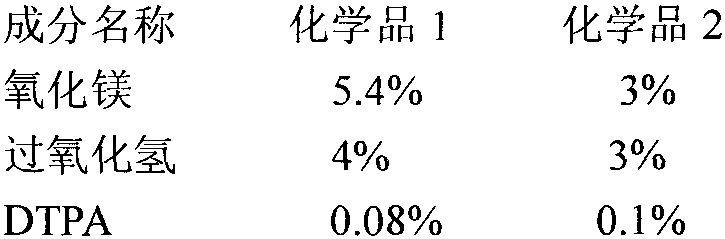

[0040] Using a hydrogen peroxide oxidative bleaching process pH stabilization technology for pulping, the selected pulping raw materials, chemicals, pulping production equipment and specific pulping process parameters are described as follows:

[0041] 1. Pulping raw materials and equipment

[0042] Commercial poplar wood chips are used in the pilot production of pulping, which are cut into 3-5 years old poplar wood by a chipper.

[0043] Magnesium base is made of magnesium oxide powder. Its physical and chemical properties are: white powder, odorless, tasteless, and non-toxic. It is a light-burned powder with high activity, slightly soluble in water, and its water suspension is weakly alkaline; hardly soluble in organic Solvent; soluble in acid and ammonium salt; commercial purity is above 85%, calcium oxide content is not more than 2%, metal ion impurity content is low (the content of ferric ion is not more than 0.2%; the content of divalent copper ion is not more than 1ppm ; Mang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com