Zero discharge system for treating flue gas of boiler and method

A boiler flue gas, zero emission technology, applied in the field of air pollution control, can solve the problems of sewage, dust secondary pollution, high water consumption, secondary pollution, etc., achieve high denitrification efficiency, low operating cost, and reduce treatment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

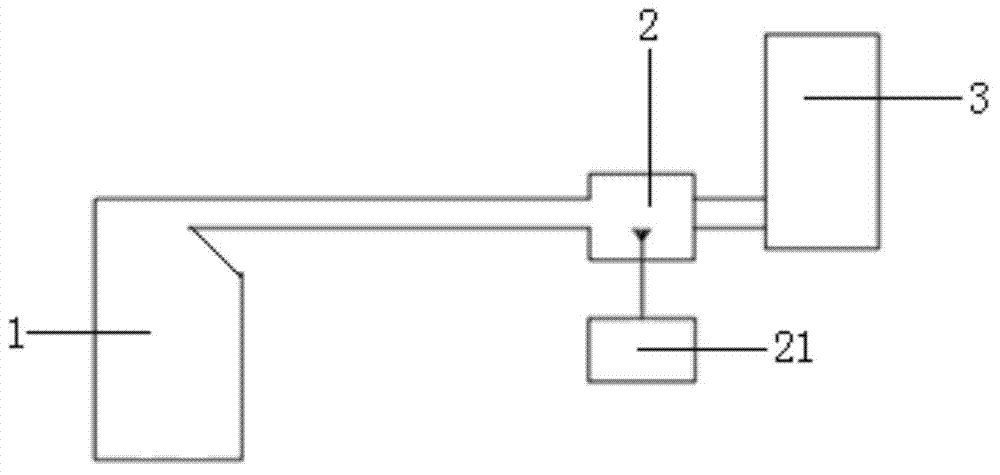

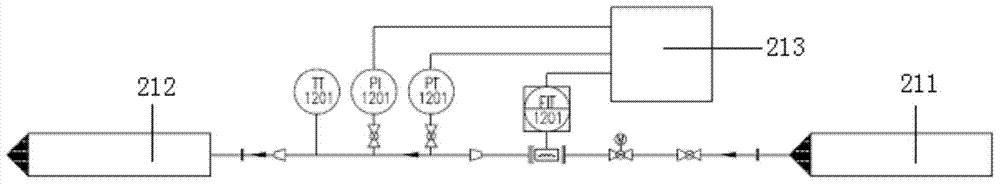

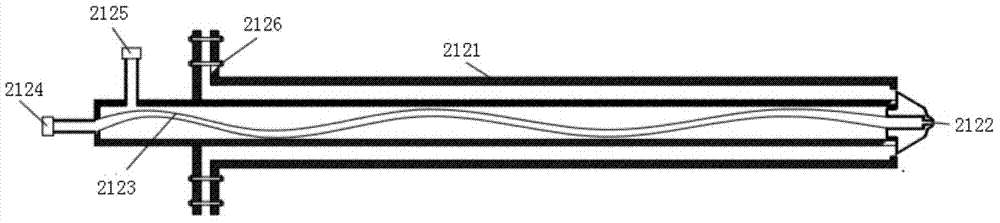

[0036] With the above-mentioned treatment system and method of the present invention, the flue gas of a certain thermoelectric boiler is treated, and in the flue gas to be treated: NO X The concentration is 100mg / m 3 , Smoke content is 200mg / m 3 , SO X The concentration is 800mg / m 3 . In this embodiment, the attached image 3 The shown system and method process the flue gas, wherein, the ozone preparation and distribution unit 21 is provided with four spray guns 212, and is arranged on the inner peripheral wall of the oxidation reactor 2 at equal intervals along the radial direction, and the oxidation reactor 2 The reaction temperature inside is controlled at 120°C, the total amount of ozone injected into the oxidation reactor 2 by four spray guns 212 and the NO in the flue gas X , SO X The molar ratio of the ozone is 1.2:1, and the residence time of ozone in the oxidation reactor 2 is 0.3s. NO in flue gas X , SO X In the oxidation reactor 2, it is oxidized into high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com