Process for preparing xylitol by using corn core or agriculture and forestry castoff

A technology of agricultural and forestry waste and xylitol, which is applied in the field of xylitol production, and can solve the problem of low recovery rate of xylitol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

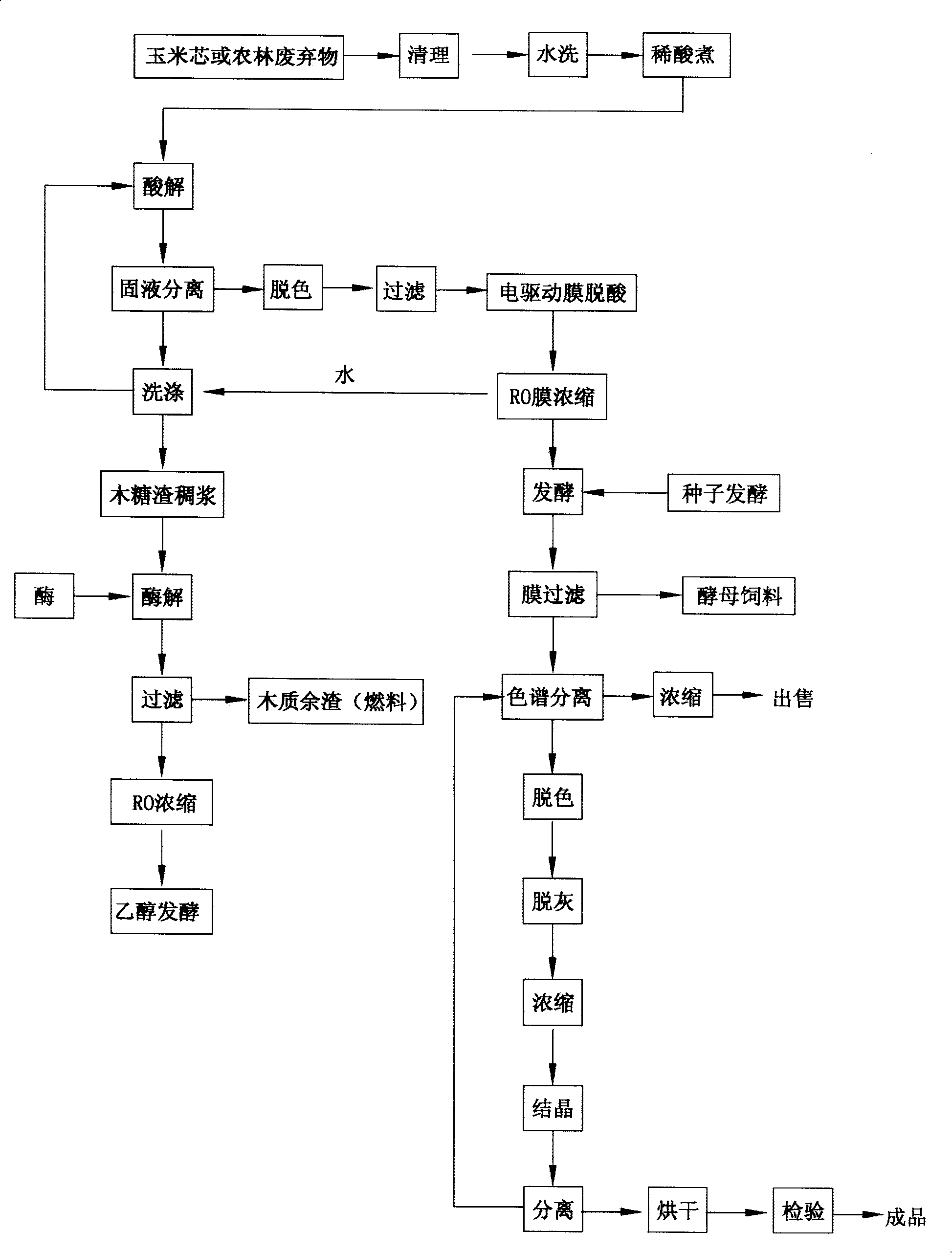

Method used

Image

Examples

Embodiment 1

[0062] The pretreatment of embodiment 1. corncob

[0063] Take 100Kg corncobs, manually pick out the large and small impurities, add tap water, turn them manually, and clean the soil and dust on the surface of the corncobs. Then drain the sewage and measure the moisture content of the corn cob. Put the corn cob into the 1000L sugar reactor, then add 0.1% H 2 SO 4 Solution 600Kg, in 600Kg dilute acid solution, 0.1% sulfuric acid is 0.61Kg, water is 599.39Kg (the moisture inhaled when the corn cob is washed with water should also be deducted), heated to 80°C while stirring, staying for 1 hour, releasing dilute sour water.

[0064] The enamel kettle (manufactured by Zibo Industrial Enamel Factory) is anchored and stirred at a speed of 60 rpm, and the jacket is heated and cooled.

Embodiment 2

[0065] Embodiment 2. the acid hydrolysis of corncob

[0066] Then according to the weight ratio of corn cob:dilute acid solution=1:6, add 0.8% H 2 SO 4Solution 600kg, in 600kg of dilute acid solution, 98% sulfuric acid is 4.9Kg, water is 595.1Kg (note that after 0.1 dilute pickling, the total amount of water that is more than the moisture contained in commercial corn cobs should be deducted), under the condition of stirring Heating to 110°C and keeping it for 2 hours, the acidolysis ends.

[0067] The condition of enamel still is with embodiment 1

Embodiment 3

[0068] Example 3. Acid hydrolysis of corn stalks

[0069] Corn stalks are pulverized (through a 3mm sieve), and 0.8% H 2 SO 4 Solution 600kg, in the dilute acid solution of 600kg, 98% sulfuric acid is 4.9Kg, and water is 595.1Kg, is heated to 110 ℃ under the situation of stirring, keeps 2 hours, and acidolysis finishes.

[0070] The condition of enamel still is with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com