System and method for recycling NO from acetylfuran oxidized tail gas

An acetylfuran and oxidation tail gas technology, applied in the field of NO recovery, can solve the problems of wasting sodium nitrite raw material resources, incomplete absorption of nitric oxide, inability to remove nitric oxide completely, etc., so as to achieve complete absorption of nitrogen oxides and improve production. On-site and surrounding environment, the effect of reducing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

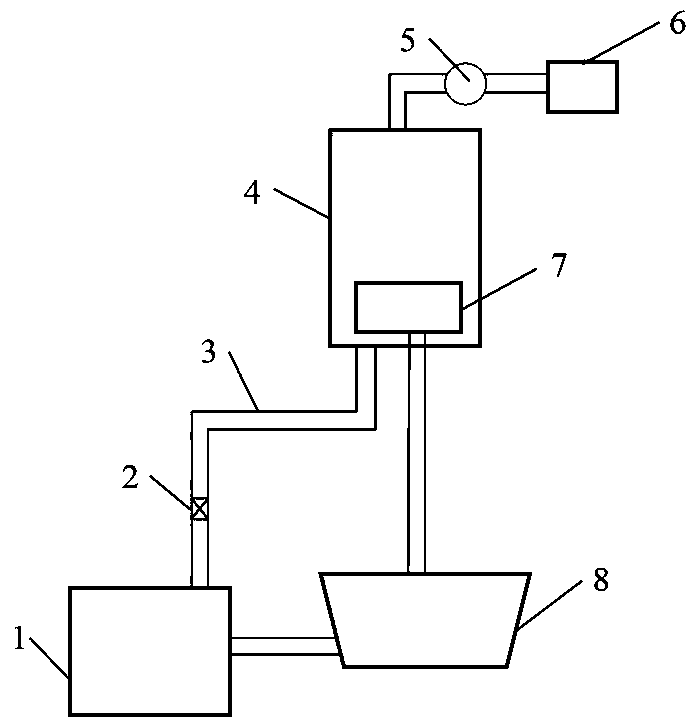

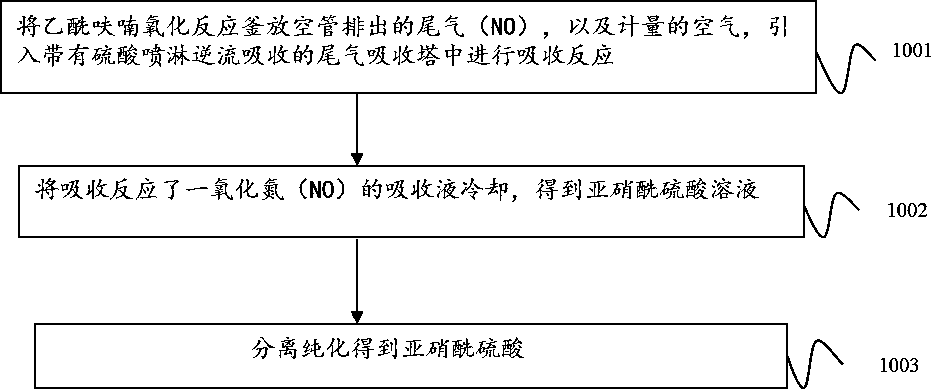

[0034] Such as figure 1 and 2 Shown, a kind of system that reclaims and utilizes nitrosylsulfuric acid NO from acetylfuran oxidation tail gas, described system comprises: oxidation reaction kettle 1, described reaction kettle is used for carrying out the oxidation reaction of acetylfuran; Absorption kettle 4, described The absorption tank is used to absorb the tail gas generated during the oxidation reaction and can spray the sulfuric acid absorbent downward from the top; the cooling device (not shown in the figure) is set in the absorption tank to cool the generated solution; emptying pipe 3, one end of the emptying pipe is connected with the oxidation reactor, and the other end is connected with the absorption reactor, for discharging the tail gas produced in the oxidation reactor; collection tank 8, the One end of the collection tank communicates with the lower part of the absorption tank for collecting the liquid generated by the reaction in the absorption tank, and the o...

Embodiment 2

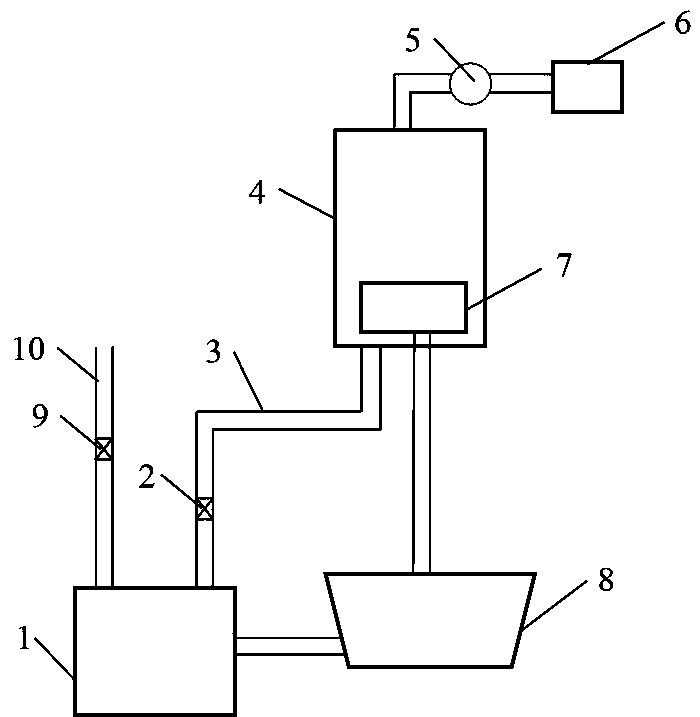

[0038] Such as figure 1 and 3 Shown, a kind of system that reclaims and utilizes nitrosylsulfuric acid NO from acetylfuran oxidation tail gas, described system comprises: oxidation reaction kettle 1, described reaction kettle is used for carrying out the oxidation reaction of acetylfuran; Absorption kettle 4, described The absorption tank is used to absorb the tail gas generated during the oxidation reaction and can spray the sulfuric acid absorbent downward from the top; the cooling device (not shown in the figure) is set in the absorption tank to cool the generated solution; emptying pipe 3, one end of the emptying pipe is connected with the oxidation reactor, and the other end is connected with the absorption reactor, for discharging the tail gas produced in the oxidation reactor; collection tank 8, the One end of the collection tank communicates with the lower part of the absorption tank for collecting the liquid generated by the reaction in the absorption tank, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com