Semiconductor-level quartz crucible and production method thereof

A technology of a quartz crucible and a manufacturing method, applied in manufacturing tools, glass manufacturing equipment, glass molding and other directions, can solve problems such as multiple micro-bubbles, crystal pulling failure, wire breakage, etc. The effect of reducing the degree of devitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

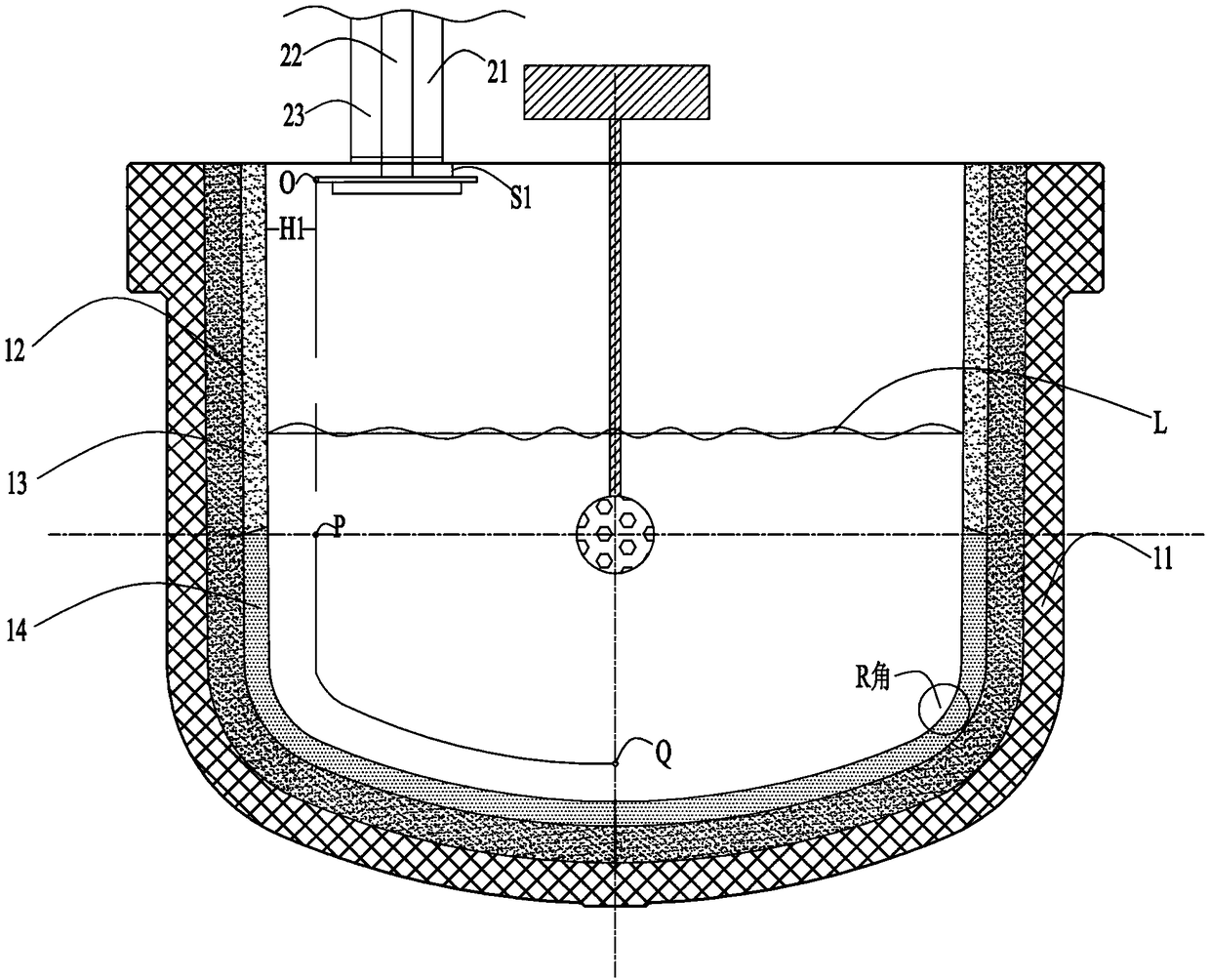

[0062] Preparation of raw materials: Weigh high-purity quartz sand, high-efficiency isolation quartz sand, and high-purity artificially synthesized amorphous quartz sand that are qualified in quality and meet the requirements of the production process. The mass ratio of amorphous quartz sand is 3:1:1;

[0063] Loading: After preparing the three raw materials, pre-set the high-purity quartz sand inside the first blanking barrel 21 of the melting machine, set the high-efficiency isolation quartz sand inside the second blanking barrel 22, and place the high-purity synthetic non- The crystalline quartz sand is pre-set inside the third blanking cylinder 23 of the melting machine, and the blanking sequence is sequentially set as the first blanking cylinder 21, the second blanking cylinder 22, and the third blanking cylinder 23;

[0064] Material molding preparation: after the charging is completed, the quartz crucible body 11 is set on the crucible mold, and the crucible mold is set...

Embodiment 2

[0070] Preparation of raw materials: Weigh high-purity quartz sand, high-efficiency isolation quartz sand, and high-purity artificially synthesized amorphous quartz sand that are qualified in quality and meet the requirements of the production process. The mass ratio of amorphous quartz sand is 5:1:1;

[0071] Loading: After preparing the three raw materials, pre-set the high-purity quartz sand inside the first blanking barrel 21 of the melting machine, set the high-efficiency isolation quartz sand inside the second blanking barrel 22, and place the high-purity synthetic non- The crystalline quartz sand is pre-set inside the third blanking cylinder 23 of the melting machine, and the blanking sequence is sequentially set as the first blanking cylinder 21, the second blanking cylinder 22, and the third blanking cylinder 23;

[0072] Material molding preparation: after the charging is completed, the quartz crucible body 11 is set on the crucible mold, and the crucible mold is set...

Embodiment 3

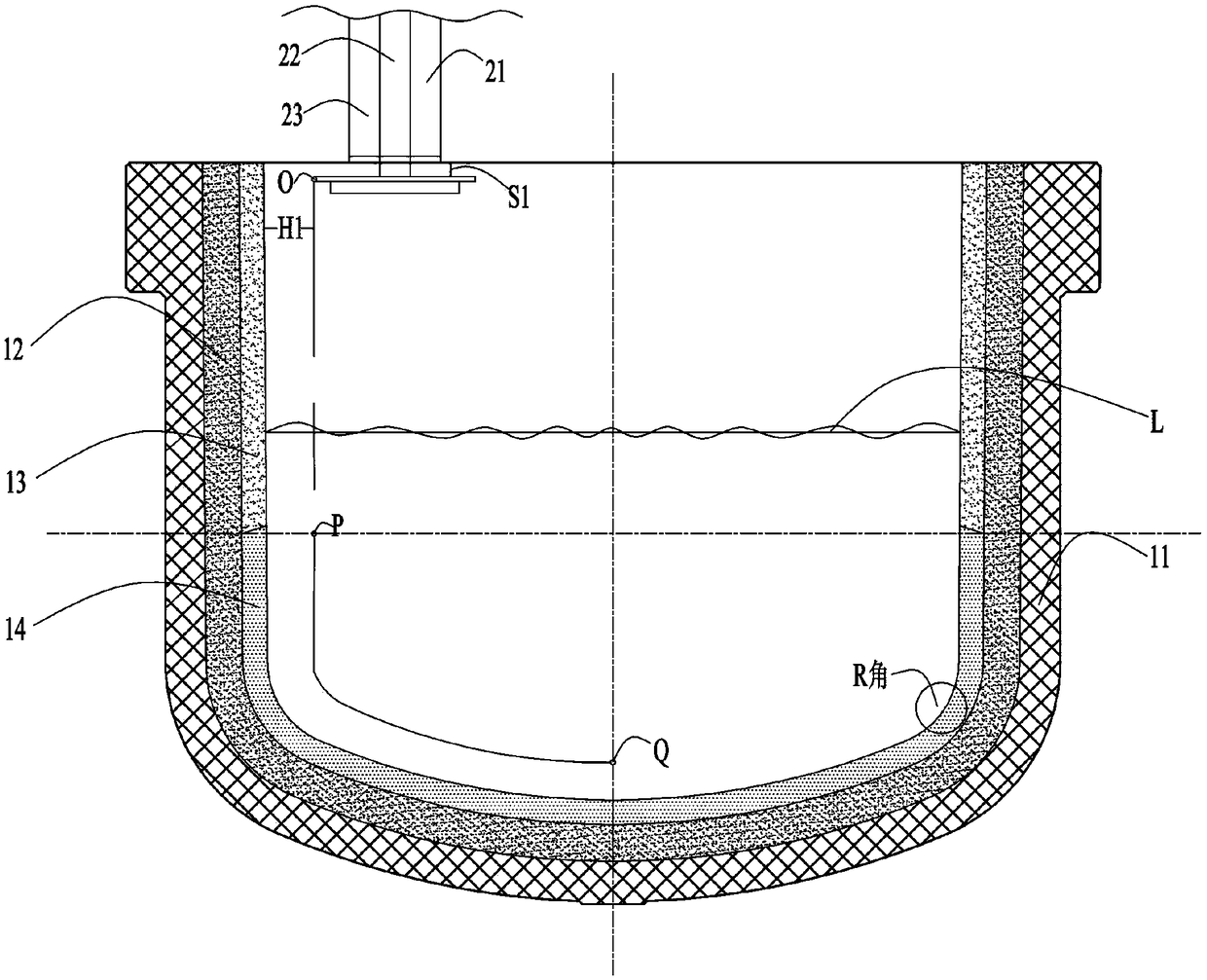

[0079] A semiconductor-grade quartz crucible, comprising a quartz crucible body 11, a first protective layer 12, a second protective layer 13, and a third protective layer 14, the first protective layer 12 is arranged on the inner surface of the quartz crucible body 11, the The second protective layer 13 is arranged on the upper surface of the first protective layer 12, the third protective layer 14 is arranged on the lower surface of the first protective layer 12, and the height of the second protective layer 13 is the same as that of the third protective layer. The height of the layer 14 is the same, the thickness of the second protective layer 13 is the same as that of the third protective layer 14, and the second protective layer 13 and the third protective layer 14 are in contact with the surface of the first protective layer 12 , forming a complete and smooth layer.

[0080] The thickness of the first protective layer 12 is 8 mm, the thickness of the second protective la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com