Method for extracting and separating high-purity dysprosium oxide and terbium oxide from terbium-dysprosium rare earth enrichment matters

A rare earth enrichment and terbium oxide technology, which is applied in the field of rare earth separation, can solve the problems of high commissioning cost, high acid-base consumption, and large amount of terbium element pressing, so as to reduce commissioning costs, save one-time investment, and reduce investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

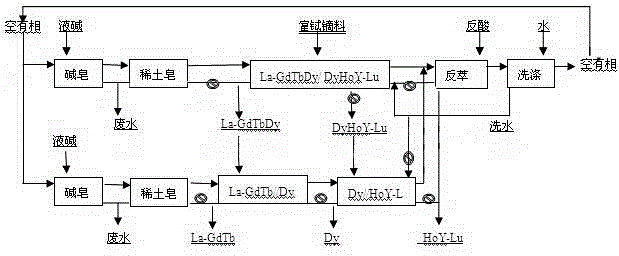

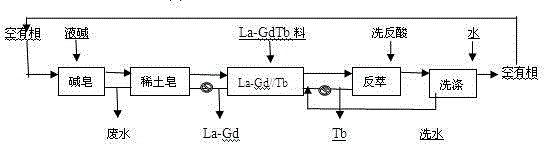

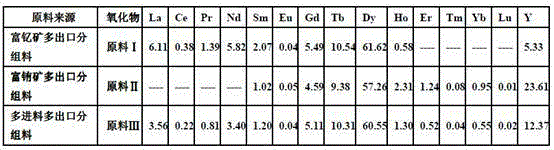

[0021] Implementation example 1: with raw materials Ⅰ As the feed solution of terbium-dysprosium enrichment, ① firstly pre-group in molar fraction of 0.55:0.45, extract part of the aqueous phase La~GdTbDy material to make rare earth soap, and then separate into two intermediate feed liquids, La~GdTbDy and DyHoY~; ② Middle The feed liquid directly enters the series separation process linkage, and after drawing out part of the aqueous phase La~GdTb material to make rare earth soap, it is then separated into: La~GdTb, HoY~ two pure enrichments and high-purity Dy products; ③ The separated intermediate products La~GdTb feed liquid, and then enter the La~Gd / / Tb two-outlet separation process to separate into La~Gd pure enrichment and high-purity Tb products. If the process uses high-grade pure hydrochloric acid as wash-back acid, the precipitant is purified Oxalic acid can produce fluorescent grade high-purity terbium oxide products (see the process flow figure 1 , figure 2 ).

...

Embodiment 2

[0028] Example 2: Using raw material II as the feed liquid of the terbium-dysprosium enrichment, 1. firstly pre-group by molar fraction of 0.6:0.4, draw out part of the aqueous phase ~SmEuGdDy material to make rare earth soap, and then separate it into ~SmEuGdTbDy and DyHo~LuY two The intermediate feed liquid; ②The intermediate feed liquid directly enters the series separation process linkage, and part of the water phase ~SmEuGdTb material is extracted to make rare earth soap, and then separated into: ~SmEuGdTb, HoY~ two pure enrichments and high-purity Dy products; ③Separation The intermediate product ~SmEuGdTb feed liquid, and then enter the ~SmEuGd / / Tb two-outlet separation process to separate into ~SmEuGd pure enrichment and high-purity Tb products. Refined oxalic acid can produce fluorescent-grade high-purity terbium oxide products (see the process flow figure 1 , figure 2 ).

[0029] The organic phase consists of extractant: bis(2-ethylhexyl)2-ethylhexylphosphoric aci...

Embodiment 3

[0035] Example 3: Using the raw material III as the feed liquid of the terbium-dysprosium enrichment, ① firstly pre-group by molar fraction of 0.5:0.5, and extract part of the aqueous phase La~GdDy materials to prepare rare earth soap, and then separate into La ~GdTbDy and DyHo~LuY two intermediate feed liquids; ②The intermediate feed liquid directly enters the series separation process, and part of the aqueous phase La~GdTb material is extracted to make rare earth soap, and then separated into: La~GdTb, Ho~LuY two pure rich Aggregates and high-purity Dy products; ③ separated intermediate products La ~GdTb feed liquid, and then enter the La~Gd / / Tb two-outlet separation process to separate into La~Gd pure concentrates and high-purity Tb products. If the process uses high-grade pure hydrochloric acid as the washing and reverse acid, the precipitating agent uses refined oxalic acid It can produce fluorescent grade high-purity terbium oxide products (see the process flow figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com