System and method for debugging half-speed steam turbine protection system of nuclear power plant

A half-speed steam turbine and protection system technology, applied in the field of nuclear power plants, can solve problems such as failure to meet the requirements of commissioning, immature research and application of key commissioning technologies, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

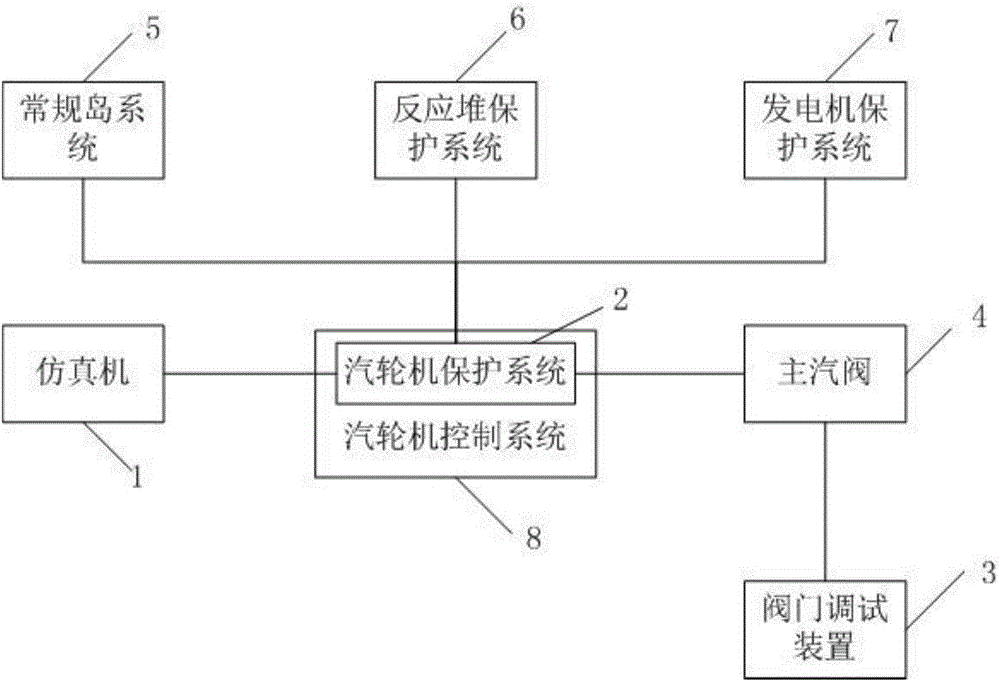

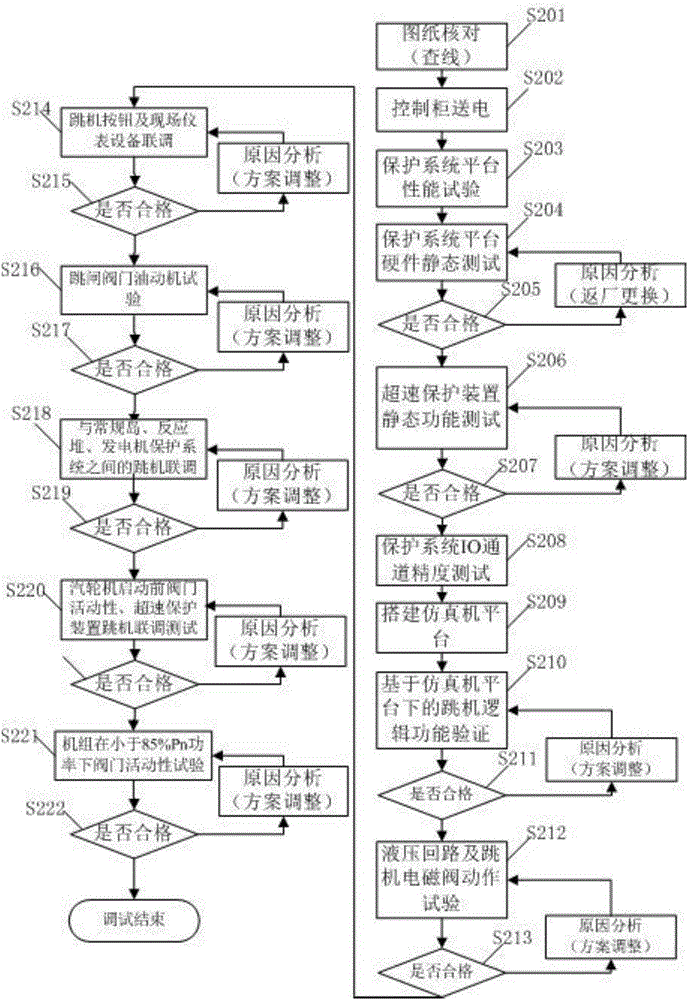

[0076] An embodiment of the present invention provides a system for debugging a half-speed steam turbine protection system in a nuclear power plant, see figure 1 , the system consists of:

[0077] The simulator 1 is connected to the steam turbine protection system 2, and is used to simulate and send a plurality of operating parameters of the steam turbine to the steam turbine protection system 2, so as to test the protection action of the steam turbine protection system 2; and,

[0078] The valve debugging device 3 is connected with the main steam valve 4 of the steam turbine, and is used to simulate the control signal of the steam turbine protection system 2 to the main steam valve 4, and test the opening and closing of the main steam valve 4 to test the main steam valve 4. Whether the action of valve 4 matches that of the steam turbine protection system 2.

[0079] It should be noted that the simulator can simulate various working conditions of the steam turbine, such as ha...

Embodiment 2

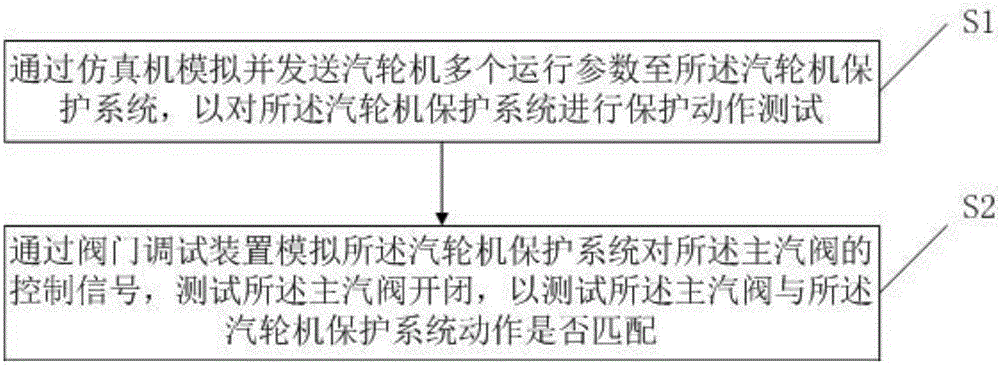

[0143] The embodiment of the present invention provides a method for debugging the half-speed steam turbine protection system of a nuclear power plant, which can be applied to the system for debugging the half-speed steam turbine protection system of a nuclear power plant in the above embodiment, see image 3 ,include:

[0144] S1. Simulate and send a plurality of operating parameters of the steam turbine to the steam turbine protection system through a simulator, so as to perform a protection action test on the steam turbine protection system;

[0145] S2. Simulating the control signal of the steam turbine protection system to the main steam valve through the valve debugging device, and testing the opening and closing of the main steam valve, so as to test whether the action of the main steam valve matches the action of the steam turbine protection system.

[0146] Further, the multiple operating parameters of the steam turbine are simulated and sent to the steam turbine prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com