Method for extracting and separating light rare earth

A light rare earth and extraction technology, which is applied in the direction of improving process efficiency, can solve the problems of light rare earth extraction, separation, tank filling materials and large consumption of acid and alkali, so as to reduce equipment and tank filling investment, save tank filling materials, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

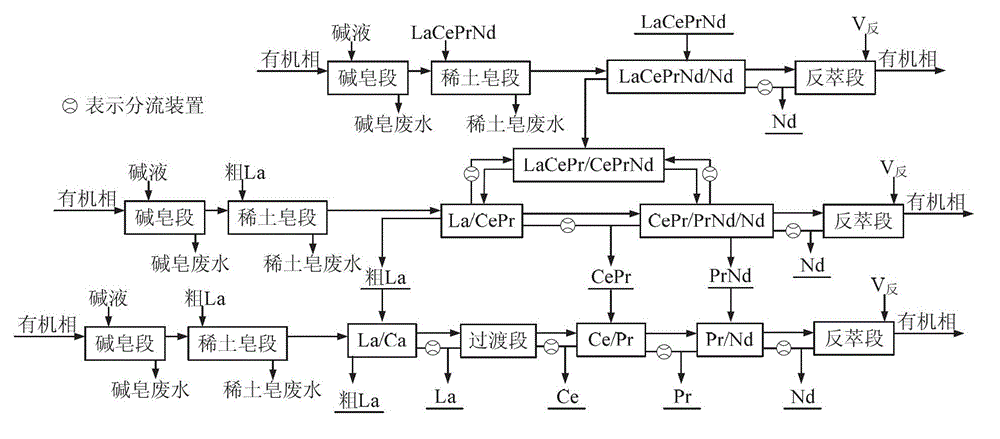

Method used

Image

Examples

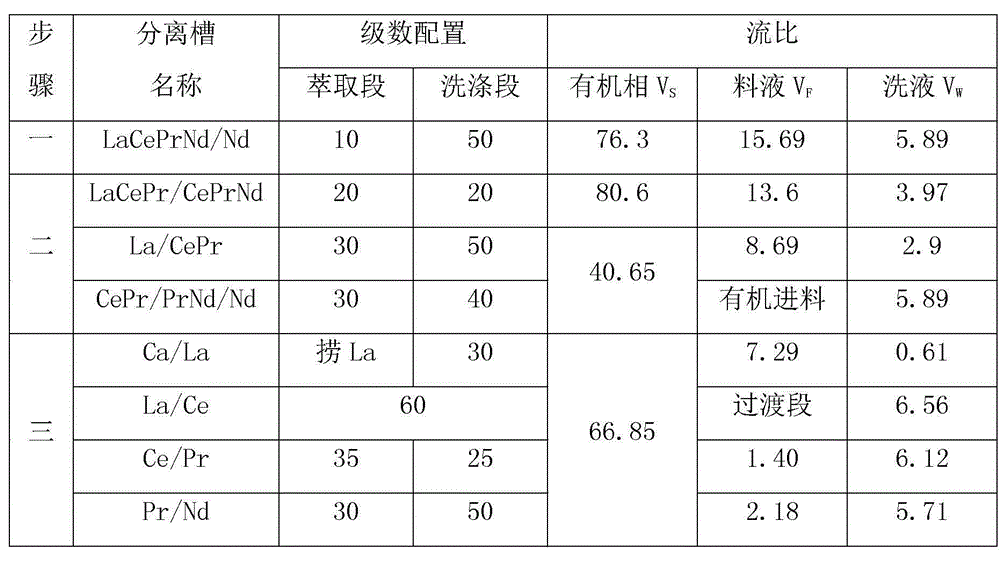

Embodiment 1

[0025] The composition of the light rare earth material is shown in the table below.

[0026] the element

La 2 o 3

CeO 2

PR 6 o 11

Nd 2 o 3

W RE / %

45.57

4.77

11.07

38.59

[0027] The above-mentioned light rare earth materials are separated into four single rare earth element products of La, Ce, Pr, and Nd, and the product quality index reaches the separation effect shown in the following table.

[0028] product name

Rare earth purity (%)

Non-rare earth impurities (%)

La

>99.99

CeO 2 、Pr 6 o 11 、Nd 2 o 3 All<0.002

Ce

>99.99

La 2 o 3 、Pr 6 o 11 、Nd 2 o 3 All<0.002

Pr

>99.9

La 2 o 3 , CeO 2 All 2 o 3 All<0.04

Nd

>99.9

La 2 o 3 , CeO 2 All6 o 11 <0.04

[0029] The organic phase is composed of extractant 2-ethylhexyl phosphate mono-2-ethylhexyl ester (referred to as P507) and diluent keros...

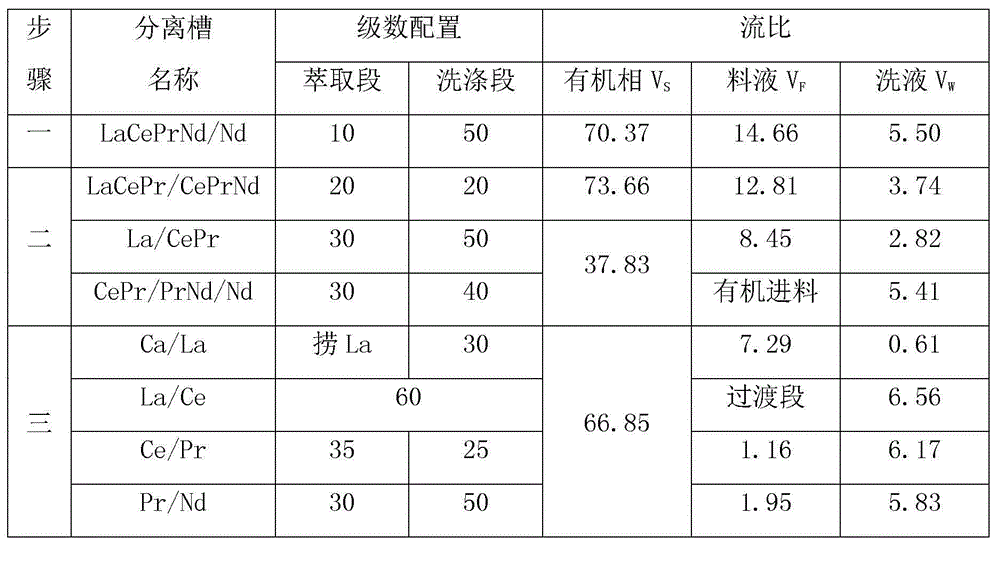

Embodiment 2

[0033] The composition of the light rare earth material is shown in the table below.

[0034] the element

La 2 o 3

CeO 2

PR 6 o 11

Nd 2 o 3

W RE / %

48.86

3.85

10.77

36.52

[0035] The above-mentioned light rare earth materials are separated into four single rare earth element products of La, Ce, Pr, and Nd, and the product quality index reaches the separation effect shown in the following table.

[0036] product name

Rare earth purity (%)

Non-rare earth impurities (%)

La

>99.99

CeO 2 、Pr 6 o 11 、Nd 2 o 3 All<0.002

Ce

>99.99

La 2 o 3 、Pr 6 o 11 、Nd 2 o 3 All<0.002

Pr

>99.9

La 2 o 3 , CeO 2 All 2 o 3 All<0.04

Nd

>99.9

La 2 o 3 , CeO 2 All6 o 11 <0.04

[0037] The organic phase is composed of extractant bis(2-ethylhexyl)phosphoric acid (referred to as P204) and diluent kerosene, the conce...

Embodiment 3

[0041] The composition of the light rare earth material is shown in the table below.

[0042] the element

La 2 o 3

CeO 2

PR 6 o 11

Nd 2 o 3

W RE / %

43.88

4.02

11.88

40.22

[0043] The above-mentioned light rare earth materials are separated into four single rare earth element products of La, Ce, Pr, and Nd, and the product quality index reaches the separation effect shown in the following table.

[0044] product name

Rare earth purity (%)

Non-rare earth impurities (%)

La

>99.99

CeO 2 、Pr 6 o 11 、Nd 2 o 3 All<0.002

Ce

>99.99

La 2 o 3 、Pr 6 o 11 、Nd 2 o 3 All<0.002

Pr

>99.9

La 2 o 3 , CeO 2 All 2 o 3 All<0.04

Nd

>99.9

La 2 o 3 , CeO 2 All6 o 11 <0.04

[0045] The organic phase is composed of extractant bis(2-ethylhexyl)phosphoric acid (referred to as P204) and diluent kerosene, the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com