Desalting method for syrup and production method for glucose syrup

A production method, the technology of glucose syrup, is applied in the field of desalinization of syrup and the production of glucose syrup, which can solve the problems of difficult control of fluid pressure balance on both sides of the membrane and fluid leakage on both sides of the membrane, so as to reduce production costs and reduce acidity. Effect of alkali consumption and reduction of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

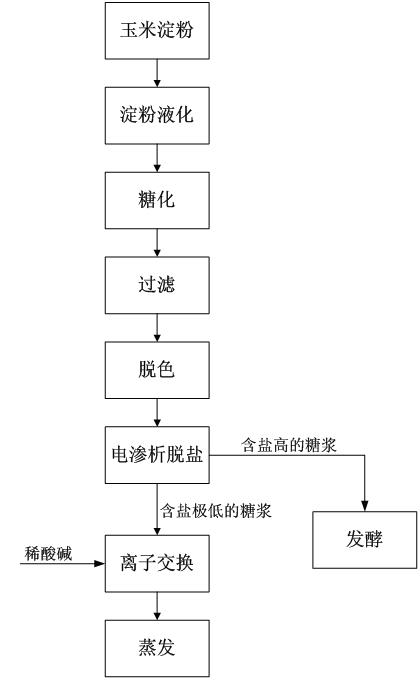

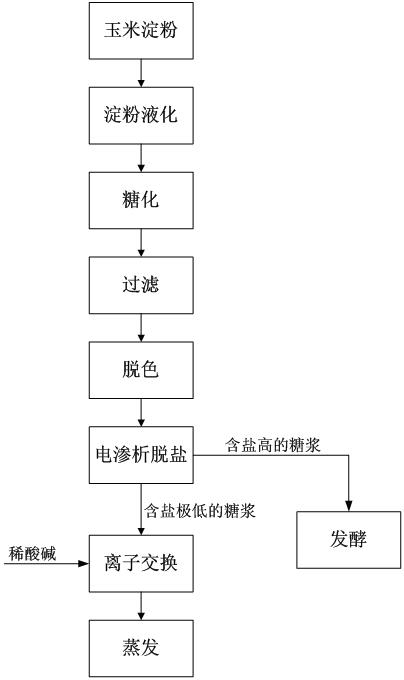

[0038] The production of glucose syrup, its concrete steps are as follows:

[0039] S1. Starch liquefaction: prepare dry starch into starch milk, pump it into the incoming tank, add sulfuric acid, adjust the pH value of the starch milk to 5.4, add 0.6 kg of liquefying enzyme per ton of dry starch, and add it to the starch milk Add liquefaction enzyme, then spray liquefaction through the injector, and enter the liquefaction reactor for 1.8hr;

[0040] S2. Saccharification: After the liquefied starch milk enters the saccharification tank after secondary flash evaporation, the saccharification enzyme is added at a ratio of 0.45 kg of saccharification enzyme per ton of dry starch, and the raw starch syrup is obtained after stirring for 42 hours;

[0041] S3, Filtration: Thin syrup is obtained after the coarse starch syrup is filtered through a vacuum drum filter;

[0042] S4, decolorization: pump dilute syrup into the decolorization tank, add activated carbon according to the rat...

Embodiment 2

[0048] The production of glucose syrup, its concrete steps are as follows:

[0049] S1. Starch liquefaction: prepare dry starch into starch milk, pump it into the incoming tank, add sulfuric acid, adjust the pH value of the starch milk to 6.0, and add 0.55 kg of liquefaction enzyme per ton of dry starch to the starch milk Add liquefaction enzyme, then spray liquefaction through the injector, and enter the liquefaction reactor for 2.0hr;

[0050] S2. Saccharification: After the liquefied starch milk enters the saccharification tank after secondary flash cooling, add the saccharifying enzyme at a ratio of 0.5 kg of saccharifying enzyme per ton of dry starch, and stir for 48 hours to obtain coarse starch syrup;

[0051] S3, Filtration: Thin syrup is obtained after the coarse starch syrup is filtered through a vacuum drum filter;

[0052] S4, decolorization: pump dilute syrup into the decolorization tank, add activated carbon according to the ratio of 3 kg of powdered activated c...

Embodiment 3

[0057] The production of glucose syrup, its concrete steps are as follows:

[0058] S1. Starch liquefaction: prepare dry starch into starch milk, pump it into the incoming tank, add sulfuric acid, adjust the pH value of the starch milk to 5.6, add 0.5 kg of liquefying enzyme per ton of dry starch, and add it to the starch milk Add liquefaction enzyme, then spray liquefaction through the injector, and enter the liquefaction reactor for 1.5hr;

[0059] S2. Saccharification: After the liquefied starch milk enters the saccharification tank after secondary flash evaporation, the saccharification enzyme is added at a ratio of 0.6 kg of saccharification enzyme per ton of dry starch, and the raw starch syrup is obtained after stirring for 36 hours;

[0060] S3, Filtration: Thin syrup is obtained after the coarse starch syrup is filtered through a vacuum drum filter;

[0061] S4, decolorization: pump dilute syrup into the decolorization tank, add activated carbon according to the rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com