Clean production technology and method for lithium sulfate

A clean production and production method technology, applied in the direction of lithium sulfate/sulfite, etc., to achieve the effect of simple impurity removal process, reduction of impurity types and impurity content, and increase of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

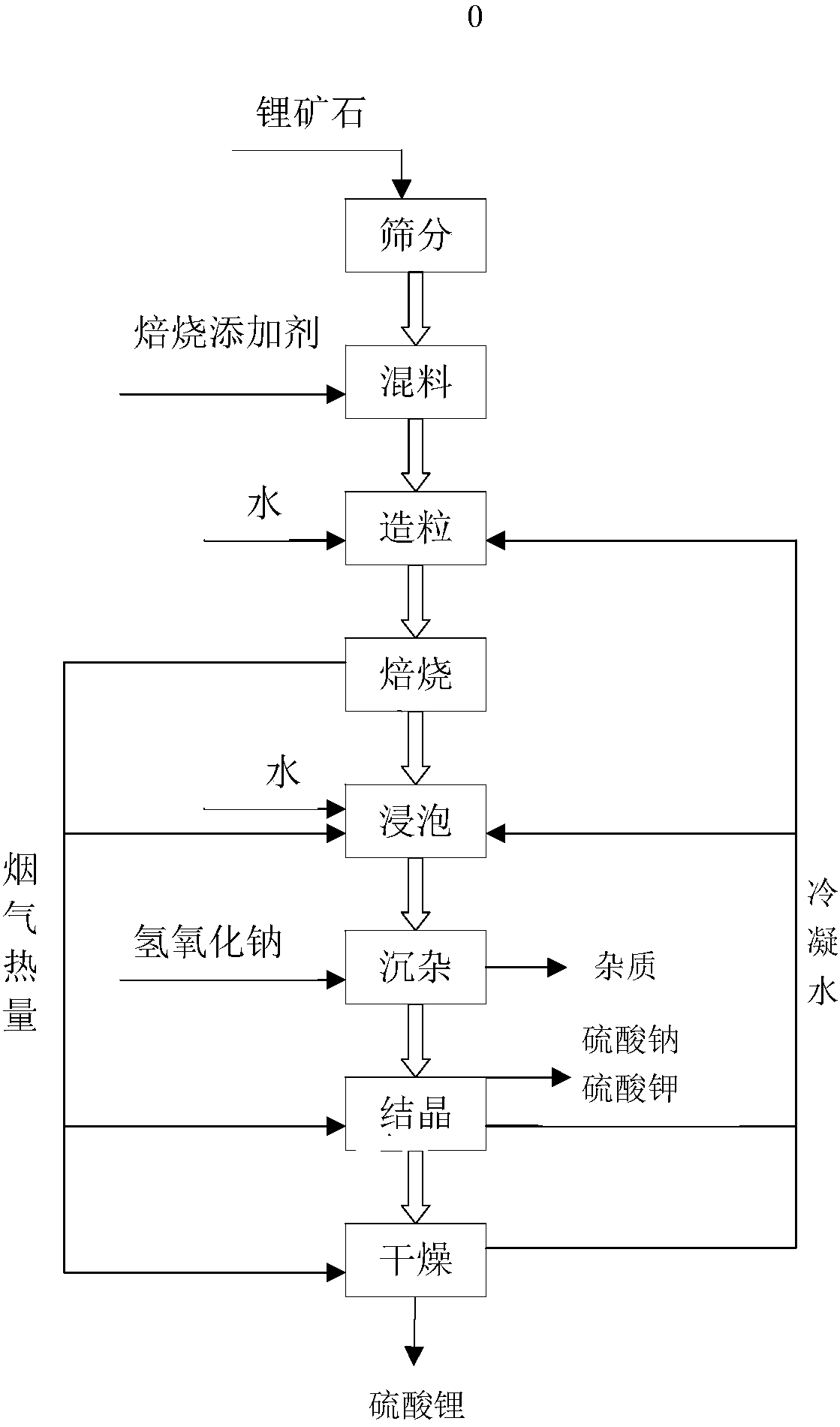

Image

Examples

Embodiment Construction

[0022] The invention has simple technological process, small amount of acid and alkali, material and energy recycling, realizes recycling of industrial waste water, zero discharge, and crystallizes potassium sulfate and sodium sulfate as supplementary additives, which is a typical practical clean production technology. The following is illustrated with specific examples:

[0023] 1. Screening: Screen the lepidolite ore with a 100-mesh iron sieve. If there are large particles, crush the large particles and sieve to obtain lepidolite ore powder that meets the requirements.

[0024] 2. Mixing: Mix the sieved lepidolite and roasting additive according to the mass ratio of 1:0.5, and stir evenly.

[0025] 3. Granulation: Stir the mixture with an appropriate amount of water, and granulate with a granulator to form a ball with a diameter of 10mm.

[0026] 4. Roasting: put the pellets into a roasting kiln for roasting, the roasting temperature is 920°C, and the roasting time is 20 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com