Rare earth fluoride molten salt electrolysis slag treatment method

A technology of molten salt electrolysis and rare earth fluorination, which is applied in the field of rare earth, iron recovery, and fluorine recycling in rare earth fluoride molten salt slag, to achieve the effects of recovery, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

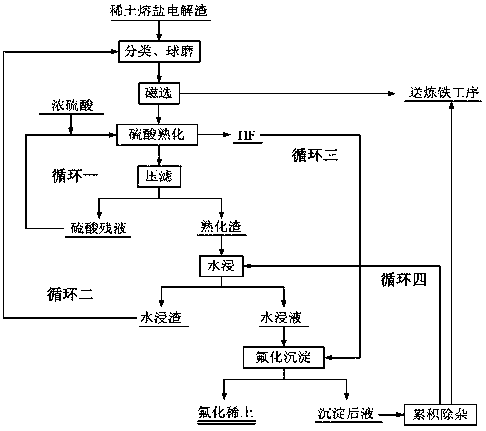

Method used

Image

Examples

Embodiment 1

[0033] The mixed rare earth fluoride molten salt electrolytic slag is used as the raw material, and its composition is as follows.

[0034] element

Nd

Pr

Dy

F

Fe

Mn

Co

Ba

content

31.9

3.76

3.04

21.46

21.49

0.066

<0.010

<0.010

element

Li

Si

Ca

Na

Mg

S

Al

C

content

2.95

0.60

0.34

0.20

0.0077

0.10

<0.010

1.7

[0035] First, grind the electrolytic slag finely with a sample mill, then sieve the slag with a particle size of 58-75 μm through a vibrating screen, take 250 g and put it in water according to the liquid-solid ratio of 20:1 and stir it thoroughly, and then use the SLon-100 magnetic separator Carry out magnetic separation, set the magnetic separation conditions as current 400 A, voltage 5.8 V, power 2.3 Kw, field strength 0.668 T, the magnetic separation tailings obtained carry out suction filtration, drying; Magnetic separation tailin...

Embodiment 2

[0038] A single fluoride rare earth molten salt electrolytic slag is used as a raw material, and its composition is as follows.

[0039] element

Nd

F

Fe

C

Ca

Mn

Co

content

38.57

20.87

24.36

1.92

0.34

<0.010

<0.010

element

Li

Si

Mg

Na

S

Al

Ba

content

3.73

1.20

<0.010

0.14

0.05

<0.010

<0.010

[0040] Firstly, the electrolytic slag was ground with a sample mill, and then the slag with a particle size of 58-75 μm was sieved through a vibrating screen. 250 g of it was placed in water according to the liquid-solid ratio of 20:1 and fully stirred, and then the SLon-100 magnetic separator was used. Perform magnetic separation, set the magnetic separation conditions as current 400 A, voltage 5.8 V, power 2.3 Kw, and field strength 0.668 T, and the obtained magnetic separation tailings are subjected to suction filtration and drying; the magnetic separation tail...

Embodiment 3

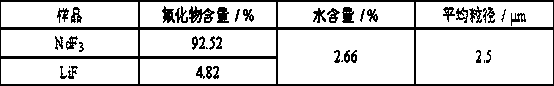

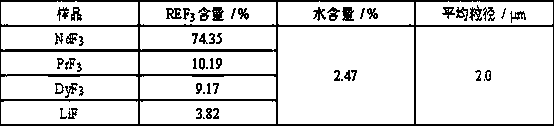

[0043] Using the molten salt electrolytic slag after ball milling in Example 1 as the raw material, the slag with a particle size of 30-50 μm was sieved through a vibrating screen, and 250 g of slag was placed in water according to a liquid-solid ratio of 20:1 and fully stirred, and then SLon- 100 magnetic separator for magnetic separation, set the magnetic separation conditions as current 400 A, voltage 5.8 V, power 2.3 Kw, field strength 0.668 T, and the obtained magnetic separation tailings were subjected to suction filtration and drying; the magnetic separation tailings were mixed with 60 % concentrated sulfuric acid is placed in a polytetrafluoroethylene beaker at a liquid-solid ratio of 5:1, and then placed in a constant temperature water bath. 140 ℃, the aging reaction is 5 h, and the stirring speed is 300 r min -1 Under the same conditions, the removal rate of F reaches 94.11%, the transformation rate of Nd reaches 94.72%, the transformation rate of Pr reaches 95.02%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com