Modified adsorbent and applications of modified adsorbent in ultra-high purity methyl fluoride preparation

A monofluoromethane and adsorbent technology, applied in the field of modified adsorbents, can solve the problems of requiring many raw materials, complex processes, and low purity of HFC-41, and achieve high adsorption efficiency, no secondary pollution, and large adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

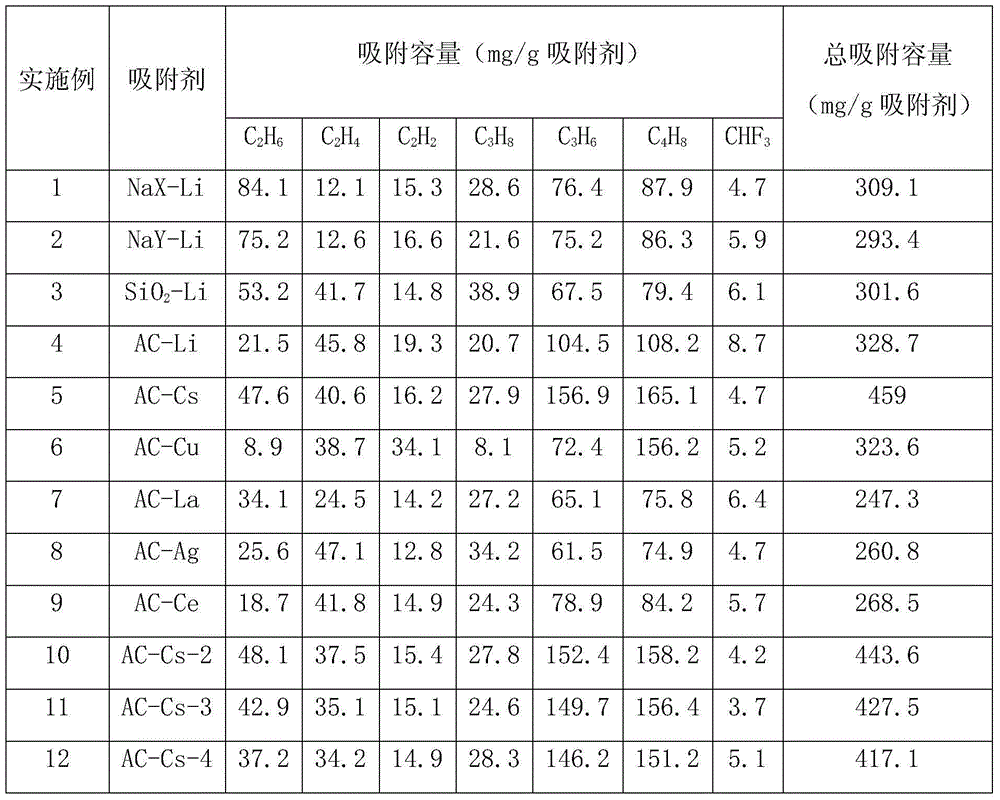

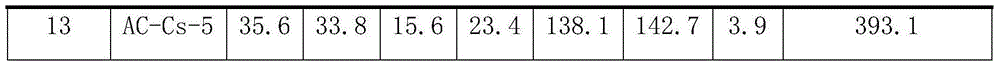

Examples

Embodiment 1

[0032] Weigh 10g of NaX molecular sieve raw powder, mix it with 0.1mol / L LiCl solution at a solid-to-liquid ratio of 1:3, and stir at 80°C for 4h. Filter molecular sieves, and add fresh LiCl solution with a concentration of 0.1mol / L at a solid-to-liquid ratio of 1:3 again for ion exchange. This process is repeated 4 times to ensure that Na + completely by Li + exchange. Filter the solid, wash with distilled water until Cl-free -1 . Dry at 110°C for 8 hours. Take a certain amount of sample in the gas-solid phase adsorption device, at 350 ° C, N 2 In-situ activation in the atmosphere for 2 hours, after cooling down, feed the raw material gas HFC-41 for adsorption and removal of impurities.

Embodiment 2

[0034] Weigh 10g of NaY molecular sieve raw powder, mix it with 0.1mol / L LiCl solution at a solid-to-liquid ratio of 1:3, and stir at 80°C for 4h. Filter molecular sieves, and add fresh LiCl solution with a concentration of 0.1mol / L at a solid-to-liquid ratio of 1:3 again for ion exchange. This process is repeated 4 times to ensure that Na + completely by Li + exchange. Filter the solid, wash with distilled water until Cl-free -1 . Dry at 110°C for 8 hours. Take a certain amount of sample in the gas-solid phase adsorption device, at 350 ° C, N 2 In-situ activation in the atmosphere for 2 hours, after cooling down, feed the raw material gas HFC-41 for adsorption and removal of impurities.

Embodiment 3

[0036] Weigh 10gSiO 2 and 20g LiCl solid, placed in a ball mill to grind for 60min, then take it out, and bake it at 350°C for 8h to promote LiCl on SiO 2 The surface is dispersed. Take a certain amount of sample in the gas-solid phase adsorption device, at 350 ° C, N 2 In-situ activation in the atmosphere for 2 hours, after cooling down, feed the raw material gas HFC-41 for adsorption and removal of impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com