Method for measuring alumina in aluminium fluoride

A medium-alumina, determination method technology, applied in chemical analysis and detection of substances, determination of alumina content in aluminum fluoride products, can solve problems such as cost increase, slow detection speed, measurement numerical analysis error, etc., and achieve savings Cost, analysis error reduction, and the effect of improving the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The aluminum fluoride sample was ground until it passed through a 74 μm sieve, baked in an oven at 105°C for 2 hours, and then cooled to room temperature in a desiccator.

[0031] Put the platinum crucible in a high-temperature furnace and burn at 1000°C for 30 minutes, take out the platinum crucible and cover, put it in a desiccator, cool to room temperature, and weigh.

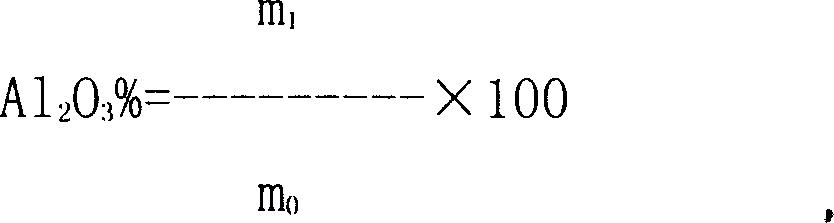

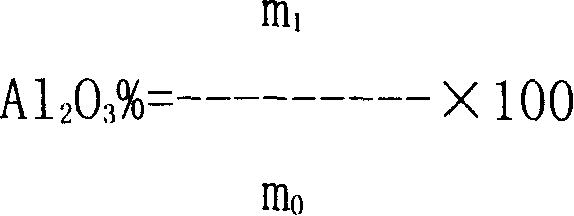

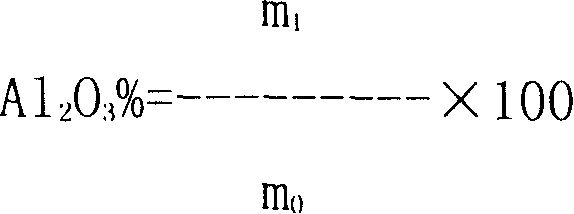

[0032] Weigh 1.0000g sample, place the sample in a 400ml beaker, add 150ml water, stir with a glass rod to distribute the sample evenly at the bottom of the beaker, cover the watch glass, heat and boil for 20min (stir constantly and keep the original volume), then Add 50ml H 3 BO 3 -NaOH solution, continue to heat and boil for 15min (stir continuously and maintain the original volume), filter with slow filter paper, transfer all the precipitate to the filter paper, wash with hot water until neutral (tested with phenolphthalein ethanol solution), put the precipitate together with the filter paper Put...

Embodiment 2

[0036] The aluminum fluoride sample was ground until it passed through a 74 μm sieve, baked in an oven at 110°C for 2 hours, and then cooled to room temperature in a desiccator.

[0037] Put the platinum crucible in a high-temperature furnace and burn at 1000°C for 30 minutes, take out the platinum crucible and cover, put it in a desiccator, cool to room temperature, and weigh.

[0038] Weigh 0.5000g sample, place the sample in a 400ml beaker, add 150ml water, stir with a glass rod so that the sample is evenly distributed on the bottom of the beaker, cover the watch glass, heat and boil for 15min (stir constantly and keep the original volume), then Add 30ml H 3 BO 3 -NaOH solution, continue to heat and boil for 15min (stir continuously and maintain the original volume), filter with slow filter paper, transfer all the precipitates to the filter paper, wash with hot water until neutral (check the pH of the filtrate to about 7 with PH test paper), Put the precipitate together w...

Embodiment 3

[0042] Weigh 1.60g of aluminum fluoride trihydrate and place it in a 400ml beaker, add 0.0500g of alumina, add 150ml of water, stir with a glass rod so that the sample is evenly distributed on the bottom of the beaker, cover with a watch glass, heat and boil for 20min (stir continuously and keep the original volume), then add 50ml H 3 BO 3 -NaOH solution, continue to heat and boil for 15min (stir continuously and maintain the original volume), filter with medium-speed filter paper, transfer all the precipitate to the filter paper, wash with hot water until neutral (tested with phenolphthalein ethanol solution), put the precipitate together with the filter paper Put it into a platinum crucible with constant weight, ash it on an electric furnace, move it into a high-temperature furnace at 1000°C, burn it for 30 minutes, take it out, put it in a desiccator, cool it to room temperature, and weigh it.

[0043] After 5 measurements, the recovery of alumina was between 0.0490 and 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com