Fluorine-containing wastewater resource treatment and utilization method

A recycling and waste water technology, applied in the direction of chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of waste of resources, secondary pollution, occupation of land resources, etc., and achieve simple equipment and mild process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

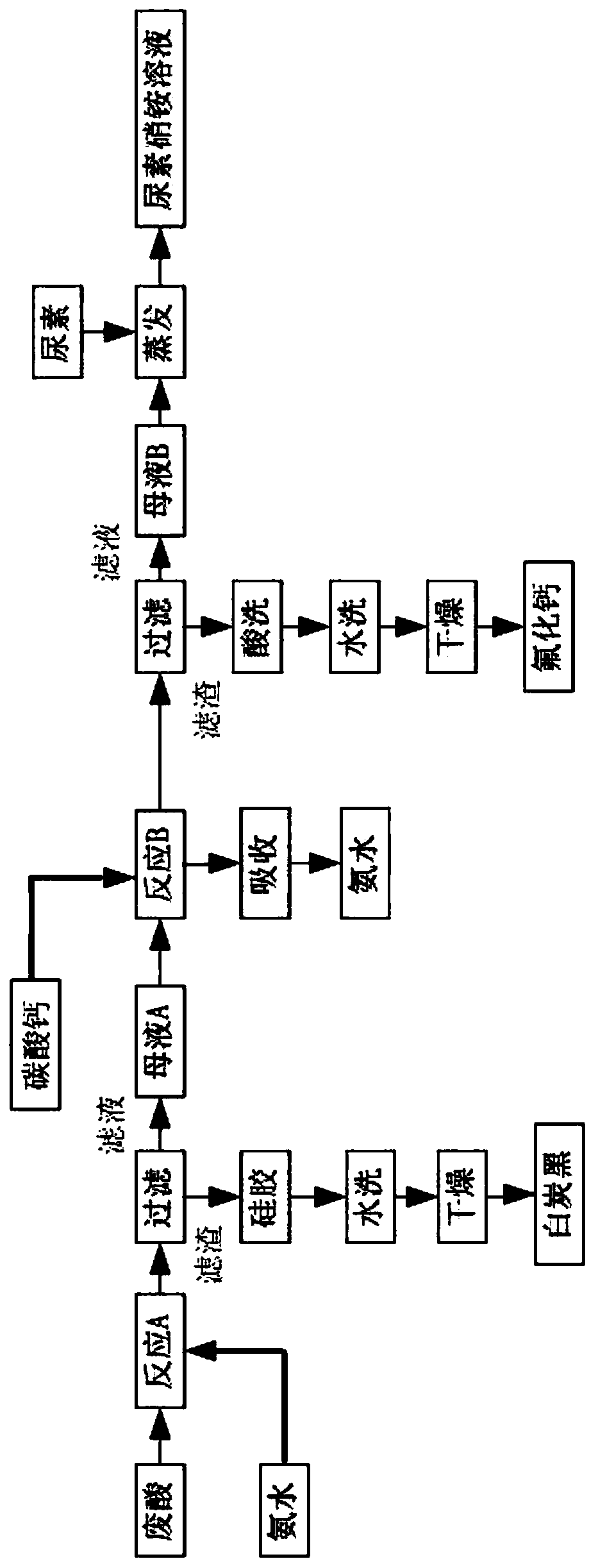

Method used

Image

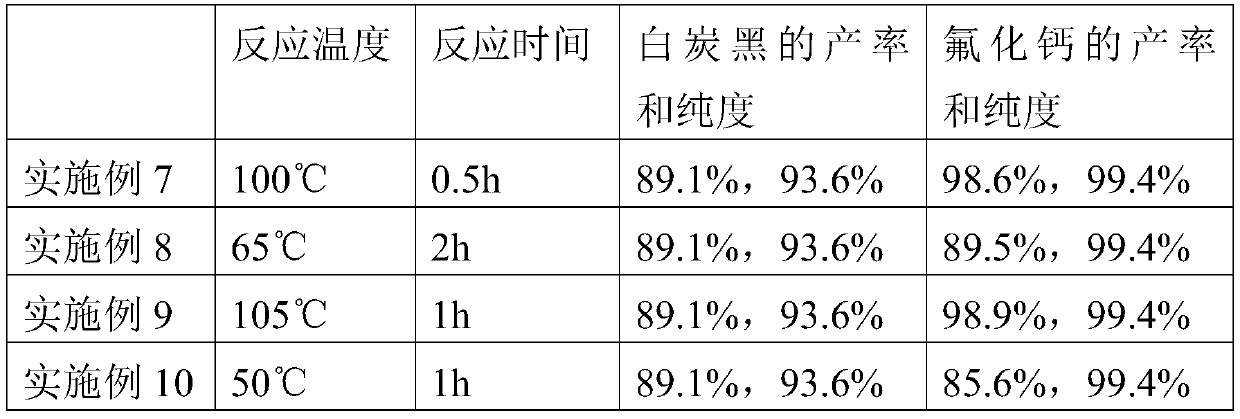

Examples

Embodiment 1

[0026] 1) Adjust the pH value of the system: take 1000mL of fluorine-containing wastewater (main components of fluorosilicic acid, hydrofluoric acid, nitric acid, fluorine content of 160g / L, silicon content of 160g / L, nitrate content of 200g / L), slowly add 1000mL of mass concentration The first precipitation agent is 28% ammonia water, the stirring reaction time is 30min, the reaction temperature is 20°C, and the pH value of the solution after the reaction is controlled to be 8.5.

[0027] 2) Step 1) After the reaction is completed, the solution is filtered to obtain mother liquor A and silica sol.

[0028] 3) The silica sol was washed with water, filtered, and dried to obtain 326.5 g of a precipitated silica product, and the washed wastewater was mixed with mother liquor A for subsequent treatment. After testing, the silicon dioxide content in the silicon dioxide product obtained in this example is 93.6%, which meets the industry standard (HG / T 3061-2009, the silicon dioxide ...

Embodiment 2

[0034] 1) Adjust the pH value of the system: take 1000mL of fluorine-containing wastewater (main components of fluorosilicic acid, hydrofluoric acid, nitric acid, fluorine content 160g / L, silicon content 160g / L, nitrate content 200g / L), slowly add 1600g A precipitant ammonium carbonate, the stirring reaction time is 30min, the reaction temperature is 20°C, and the pH value of the solution after the reaction is controlled to be 8.5.

[0035] 2) Step 1) After the reaction is completed, the solution is filtered to obtain mother liquor A and silica sol.

[0036] 3) The silica sol was washed with water, filtered, and dried to obtain 334.5 g of a precipitated silica product, and the washed wastewater was mixed with mother liquor A for subsequent treatment. After testing, in the silicon dioxide product obtained in this embodiment, the silicon dioxide content is 92.5%, which meets the industry standard (HG / T 3061-2009, the silicon dioxide content (dry product) is greater than 90%), an...

Embodiment 3-4

[0042] In Example 3-4, except that the pH value of the solution after the reaction in step 1) is different, the others are the same as in Example 1. See Table 1 for the specific pH value and the properties of the obtained product.

[0043] Table 1

[0044] pH value Silica yield and purity Calcium Fluoride Yield and Purity Example 3 7.5 67.5%,93.9% 98.2%,99.4% Example 4 13 76%,90.5% 98.2%,99.4%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com