Compulsory internal recycle fluorination electrolysis reactor

A technology of a reactor and a reactor, which is applied in the field of electrolysis reactors for organic electrochemical synthesis, can solve problems such as affecting production safety, leakage of corrosive liquids, etc., and achieves the effects of stable electrolysis reaction environment, uniform flow, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

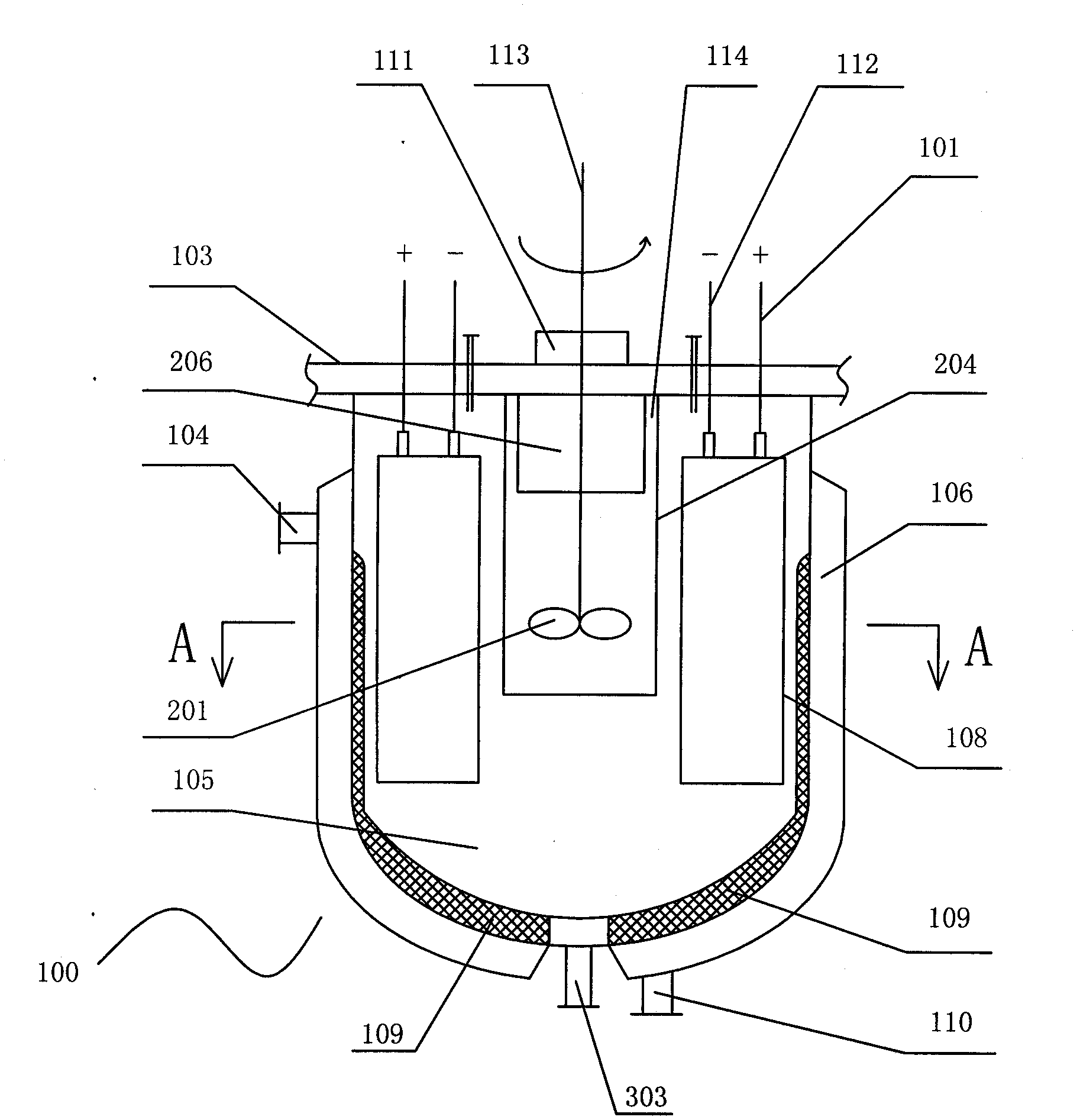

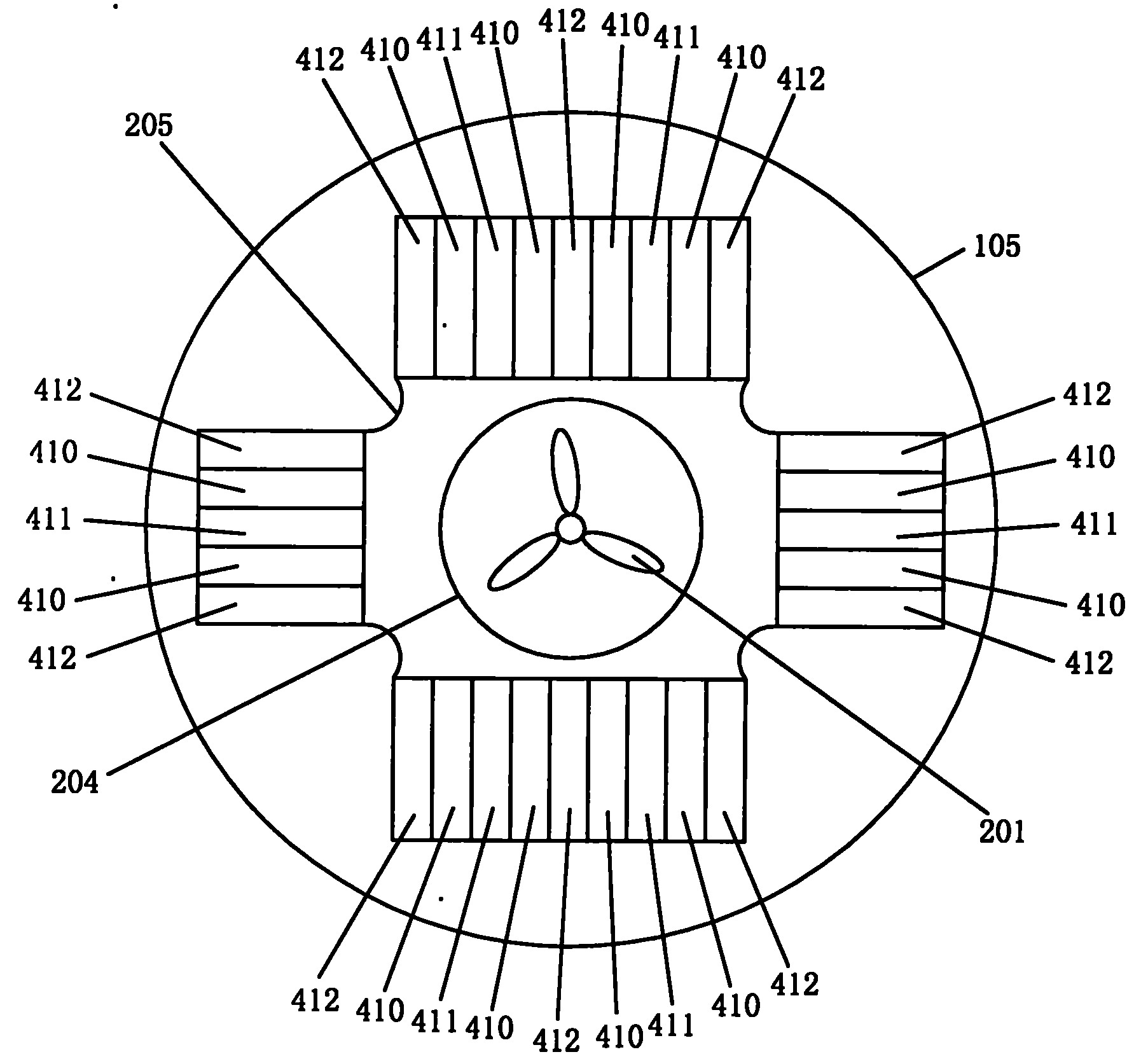

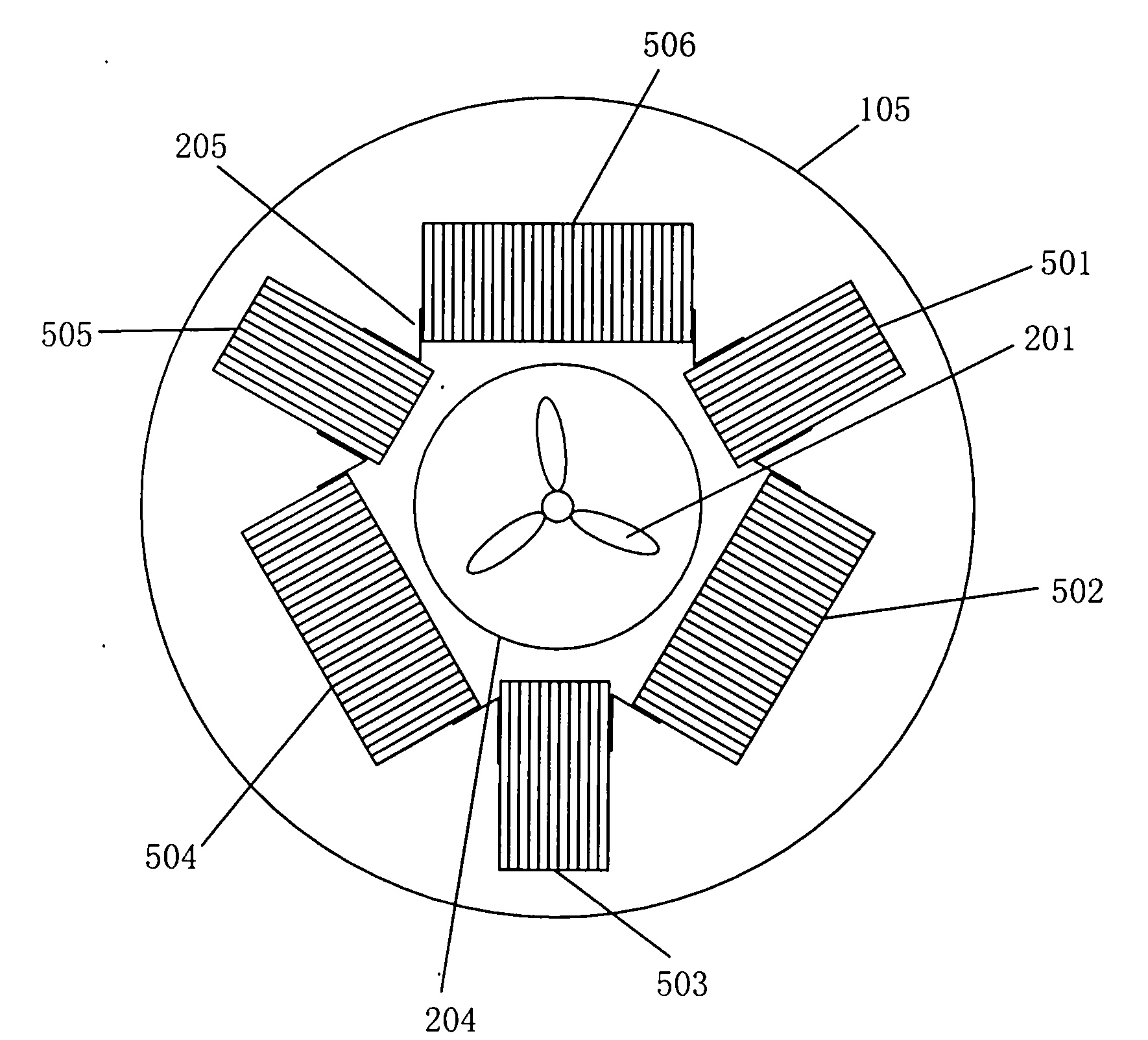

[0030] Example as figure 1 As shown, a reactor 100 for fluorination electrolysis, which includes a reactor 105 with an inner cavity, a pair of cathode and anode lead-out ends, a plurality of anode plates and cathode plates that are insulated from each other and arranged in the inner cavity of the reactor , are respectively connected to an external power supply through corresponding polarity electrode leads; and, the reactor 100 also includes a stirrer 201, a rotating shaft 113 and a motor (not shown in the figure). A kettle cover 103 is arranged above the reactor 105 for sealing the reactor 105, and a sealing device 111 can also be provided to ensure the sealed state of the reactor and enhance the safety degree; The jacket 106 is used to cool the reactor, and the cooling jacket 106 can be cooled by liquid, specifically, the inflow and outflow of cooling liquid or circulating cooling can be realized through the input pipe 104 and the output pipe 110 .

[0031] Each anode plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com