Industrial novel method for synthesizing graphite fluoride

A technology of fluorinated graphite and graphite, which is applied in the petroleum industry, lubricating compositions, electrical components, etc., and can solve problems such as difficulty in increasing fluorine content, poor quality of fluorinated graphite, and low output of fluorinated graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

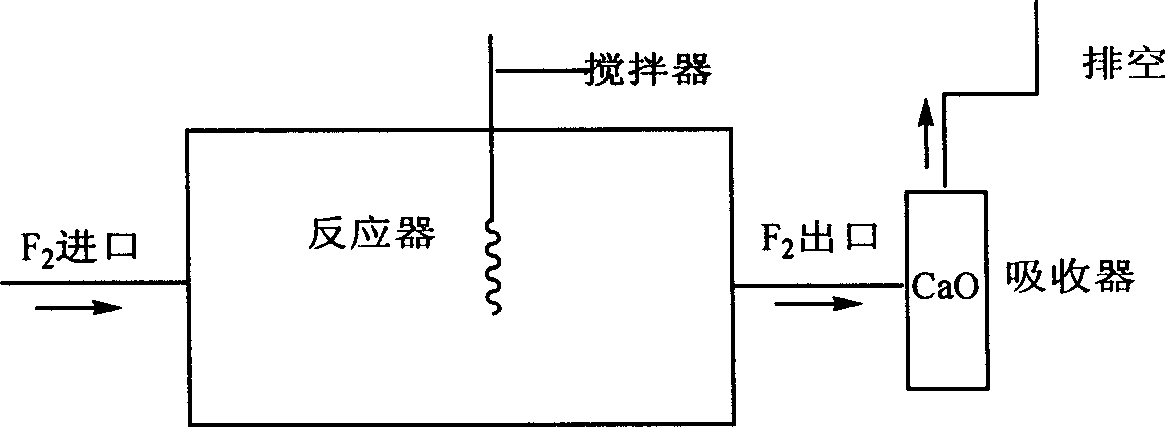

Image

Examples

example 1

[0008] Add 500 microns and 600 kg of graphite into the reaction vessel, spread evenly on the reaction plates of each layer, heat the reactor to a temperature of 200 to 300 degrees, vacuumize the reaction system, and remove the air from the reaction system. Raise the temperature to 500 to 600 degrees, slowly introduce fluorine gas, control the flow rate of fluorine gas added by the fluorine gas flow meter to 3 to 50 liters per minute, continue to react at this flow rate for 5 to 10 hours, stop heating, let the reaction The kettle is naturally cooled to a temperature below 300 degrees, and nitrogen gas is introduced into the cooled reaction vessel to drive away the residual fluorine gas in the reaction vessel, and the reaction ends. Open the reaction kettle, take out the solid powder in the reaction kettle according to the color classification, and obtain the product. The total weight of the product is 1500 kg, the black color is 300 kg, the fluorine content is 50% to 55%, and th...

example 2

[0010] Add graphite 50 microns and 600 kg into the reaction vessel, spread evenly on the reaction plates of each layer, heat the reactor to a temperature of 200 to 300 degrees, vacuumize the reaction system, and clean the reaction system twice. Raise the temperature to 500 to 600 degrees, slowly introduce fluorine gas, control the flow rate of fluorine gas added by the fluorine gas flow meter to 3 to 50 liters per minute, continue to react at this flow rate for 5 to 10 hours, stop heating, let the reaction The kettle is naturally cooled to a temperature below 300 degrees, and nitrogen gas is introduced into the cooled reaction vessel to drive away the residual fluorine gas in the reaction vessel, and the reaction ends. Open the reaction kettle, take out the solid powder in the reaction kettle according to the color classification, and obtain the product. The total weight of the product is 1500 kg, the black color is 300 kg, the fluorine content is 50% to 55%, and the gray to of...

example 3

[0012] Add graphite 10 microns and 600 kg into the reaction vessel, spread it evenly on the reaction plates of each layer, heat the reactor to a temperature of 200 to 300 degrees, vacuumize the reaction system, and remove the air from the reaction system. Raise the temperature to 500 to 600 degrees, slowly introduce fluorine gas, control the flow rate of fluorine gas added by the fluorine gas flow meter to 3 to 50 liters per minute, continue to react at this flow rate for 5 to 10 hours, stop heating, let the reaction The kettle is naturally cooled to a temperature below 300 degrees, and nitrogen gas is introduced into the cooled reaction vessel to drive away the residual fluorine gas in the reaction vessel, and the reaction ends. Open the reaction kettle, take out the solid powder in the reaction kettle according to the color classification, and obtain the product. The total weight of the product is 1500 kg, the black color is 300 kg, the fluorine content is 50% to 55%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com