Automatic rare earth oxide fluorination transformation system

A rare earth oxide and fluorination technology, applied in the direction of rare earth metal halide, rare earth metal fluoride, etc., can solve the problems of affecting the development of enterprises, low consumption and yield of fluorinated products, low production efficiency, etc., and save labor costs. , to achieve sustainable recycling and improve the effect of fluorination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

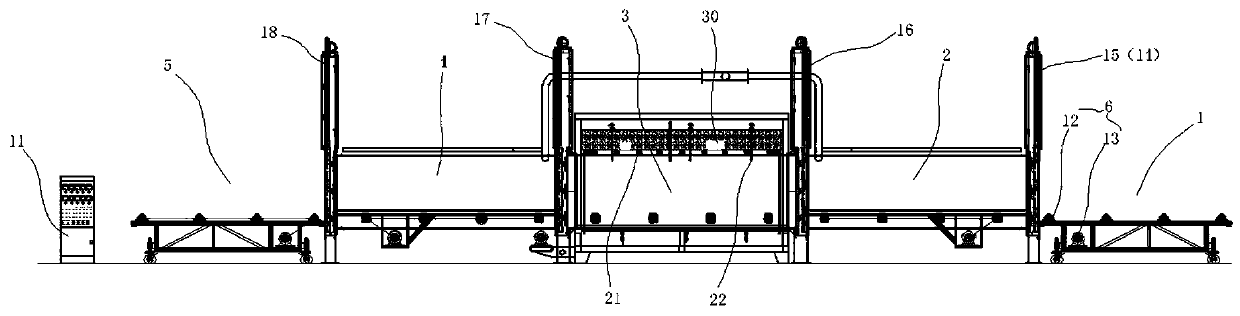

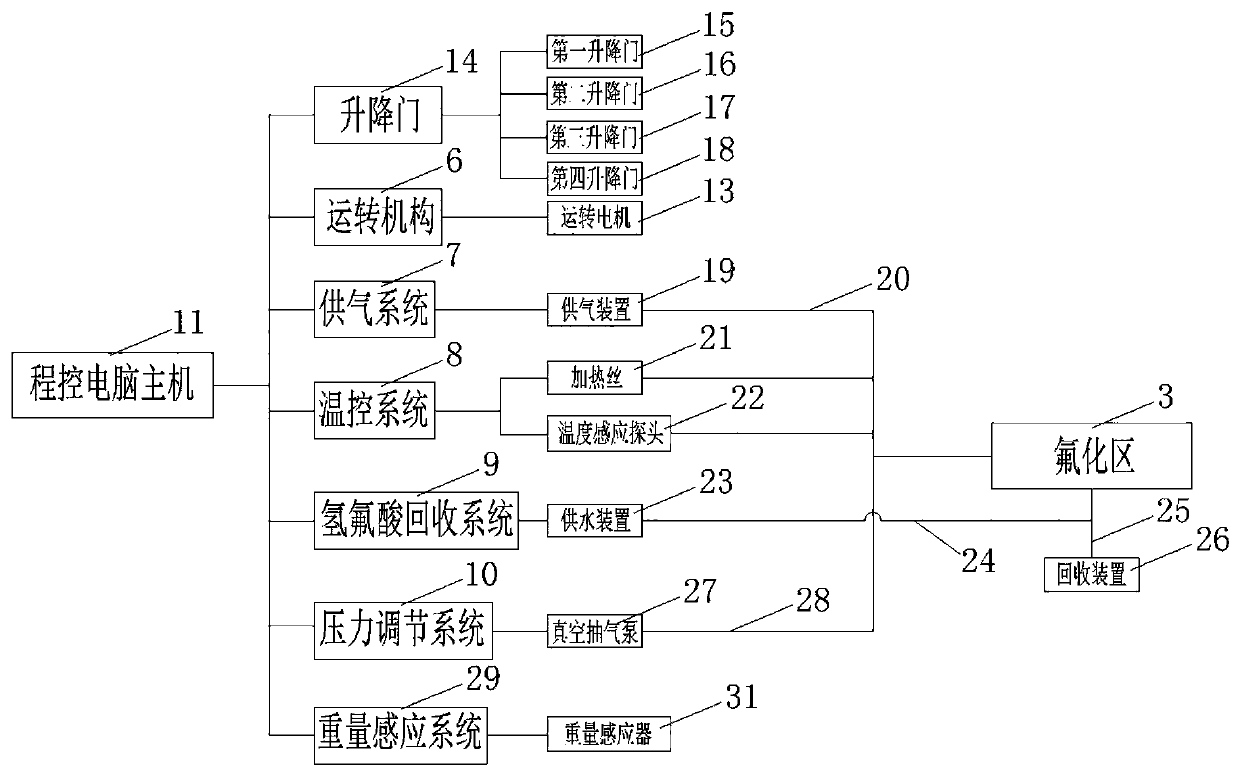

[0019] refer to Figure 1 ~ Figure 2 , an automatic rare earth oxide fluorination transformation system, including a feeding area 1, a material preparation area 2, a fluorination area 3, a cooling area 4 and a discharge area 5 arranged in sequence, wherein the feeding area 1 is used for rare earth oxides manual feeding, the preparation area 2 is used to prepare the incoming rare earth oxides for subsequent use, and the fluorination area 3 is a key area for reacting rare earth oxides and hydrogen fluoride gas under heating, The cooling zone 4 is the zone where the product is cooled to the temperature of the process condition, and finally the product is discharged and sorted through the unloading zone 5 . In order to ensure the whole process of automatic work, the feeding area 1, the material preparation area 2, the fluorination area 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com