Carbon fluoride material surface modification method and product and application thereof

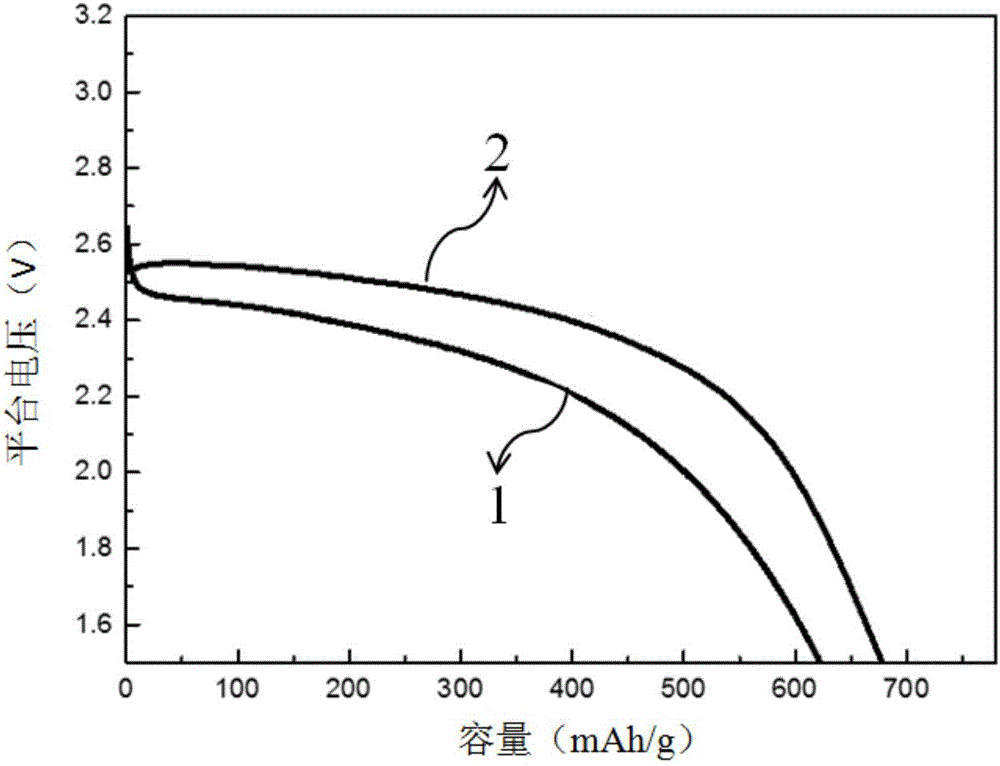

A surface modification, carbon fluoride technology, applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of inability to overcome the initial voltage hysteresis, and it is difficult to greatly improve the discharge rate of lithium-carbon fluoride batteries. , to achieve the effect of improving high-rate discharge performance and reducing voltage hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

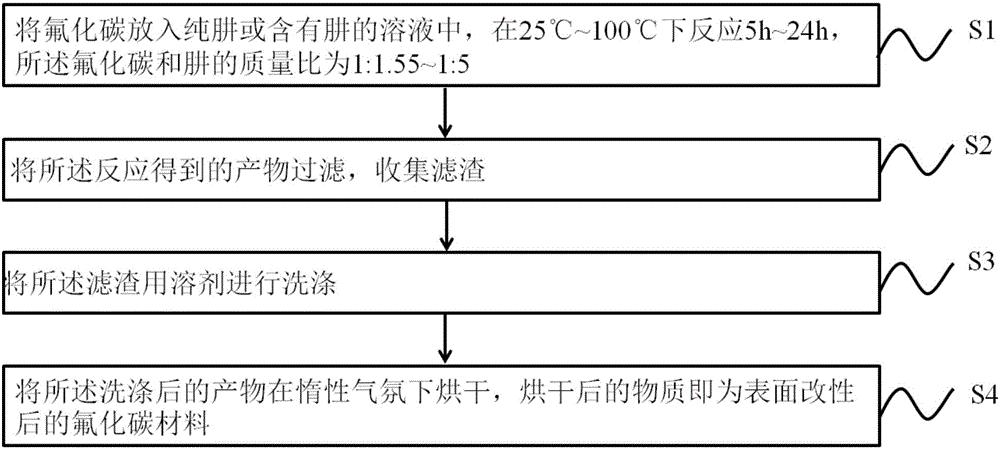

[0031] This embodiment provides a method for surface modification of carbon fluoride materials, comprising the steps of: putting 0.2 g of carbon fluoride into 20 g of ethanol solution containing hydrazine, wherein the mass percentage of hydrazine is 2%, and the React for 24 hours, and continue to stir at a rate of 10 rpm during the reaction; filter the product obtained by the reaction, and collect the filter residue; wash the filter residue with ethanol, wherein the mass ratio of the filter residue to the solvent is 3:100; The product was dried under a nitrogen atmosphere at 60°C, and the dried material was the surface-modified carbon fluoride material.

Embodiment 2

[0033] This example provides a method for surface modification of carbon fluoride materials, including the following steps: put 0.2 g of carbon fluoride into 1 g of pure hydrazine solution, react at 100 ° C for 5 hours, and continue to use 60 Stir at a speed of rpm; filter the product obtained from the reaction, and collect the filter residue; wash the filter residue with acetone, and the mass ratio of the filter residue to the solvent is 20:100; dry the washed product under an argon atmosphere at 120°C , the substance after drying is the surface-modified carbon fluoride material.

Embodiment 3

[0035] This embodiment provides a method for surface modification of carbon fluoride materials, comprising the following steps: putting 0.2 g of carbon fluoride into 4 g of an aqueous solution containing hydrazine, wherein the mass percentage of hydrazine is 11%, and reacting at 60° C. 12h, in the process of reaction, continue to stir with the speed of 30 rpm; The product obtained by reaction is filtered, collect filter residue; Filter residue is washed with water, and the mass ratio of filter residue and solvent is 10:100; The product after washing is in Drying under a nitrogen atmosphere at 90°C, the dried material is the surface-modified carbon fluoride material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com