Surface-modified carbon fluoride material, and method and application thereof

A kind of fluorinated carbon and fluorinated carbon technology, applied in the field of surface modified fluorinated carbon materials, can solve the problems that it is difficult to greatly increase the discharge rate of lithium-carbon fluoride batteries, and cannot overcome the defects of initial voltage hysteresis. Large rate discharge performance, the effect of reducing voltage hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

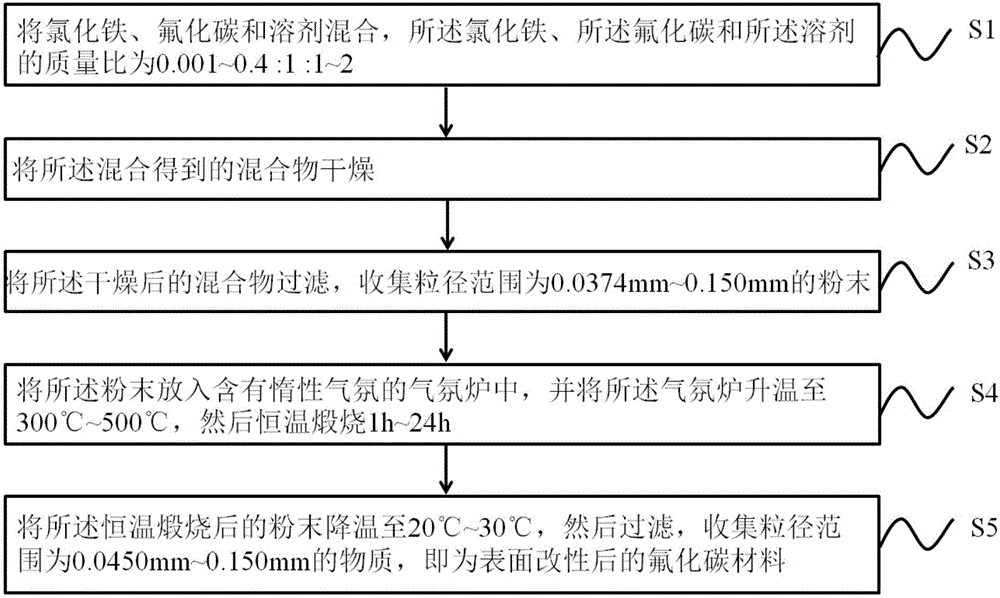

[0033] This embodiment provides a method for surface modification of carbon fluoride materials, including the following steps: 0.2g of ferric chloride, 4g of carbon fluoride and 6g of ethanol are mixed in a ball mill, the mixing time is 12h, and the mixing speed is 300 rpm; dry the mixed mixture, the drying time is 10h, and the drying temperature is 25°C; the dried mixture is filtered through a 100-325 mesh sieve, and the powder with a particle size range of 0.0450mm~0.150mm is collected ; Put the filtered powder into an atmosphere furnace containing nitrogen, raise the atmosphere furnace to 300°C at a heating rate of 5°C / min, and then calcinate at a constant temperature for 5 hours; The powder after constant temperature calcination is cooled at a rate of 2°C / min Reduce the temperature to 25°C; filter the cooled powder with a 100-325 mesh sieve, and collect the material with a particle size ranging from 0.0450mm to 0.150mm, which is the fluorocarbon material after surface modifi...

Embodiment 2

[0035] This embodiment provides a method for surface modification of carbon fluoride materials, which includes the following steps: 0.4g of ferric chloride, 10g of carbon fluoride and 14g of ethanol are mixed in a ball mill, the mixing time is 12h, and the mixing speed is 200 rpm; dry the mixed mixture, the drying time is 10h, and the drying temperature is 30℃; the dried mixture is filtered through a 100-325 mesh sieve, and the powder with a particle size range of 0.0450mm~0.150mm is collected ; Put the filtered powder into an atmosphere furnace containing argon, raise the atmosphere furnace to 450°C at a heating rate of 5°C / min, and then calcinate at a constant temperature for 5 hours; cool the temperature-calcined powder at a temperature of 10°C / min The rate is reduced to 25°C; the cooled powder is filtered with a 100-325 mesh sieve, and the material with a particle size ranging from 0.0450mm to 0.150mm is collected, which is the fluorocarbon material after surface modificatio...

Embodiment 3

[0037] This embodiment provides a method for surface modification of carbon fluoride materials, including the following steps: mixing 0.2 g of ferric chloride, 0.5 g of carbon fluoride, and 1 g of isopropanol in a ball mill. The mixing time is 24 hours. The speed of the mixture is 100 rpm; the mixed mixture is dried, the drying time is 10h, and the drying temperature is 30℃; the dried mixture is filtered with a 100-400 mesh sieve, and the collected particle size range is 0.0374mm~0.150 mm powder; put the filtered powder into an atmosphere furnace containing nitrogen, raise the atmosphere furnace to 300°C at a heating rate of 3°C / min, and then calcinate at a constant temperature for 24h; the powder after constant temperature calcination is heated at 2°C / min The cooling rate is reduced to 25°C; the cooled powder is filtered with a 100-325 mesh sieve, and the material with a particle size ranging from 0.0450mm to 0.150mm is collected, which is the surface-modified fluorocarbon mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com