A kind of silica-modified fluorocarbon material and preparation method thereof

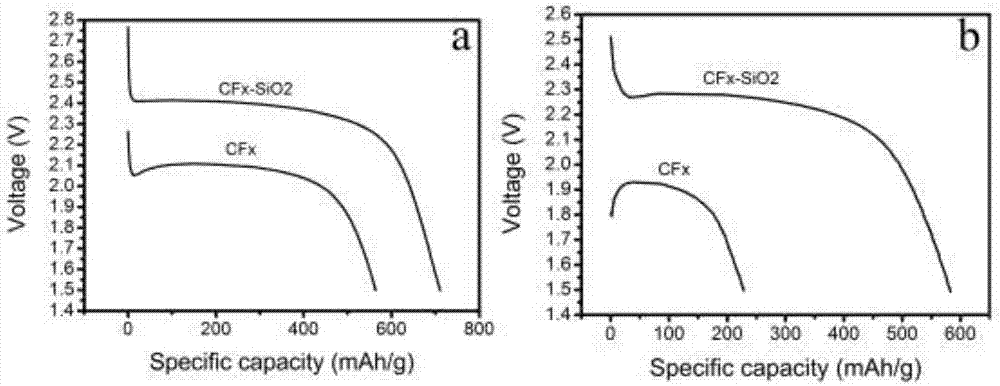

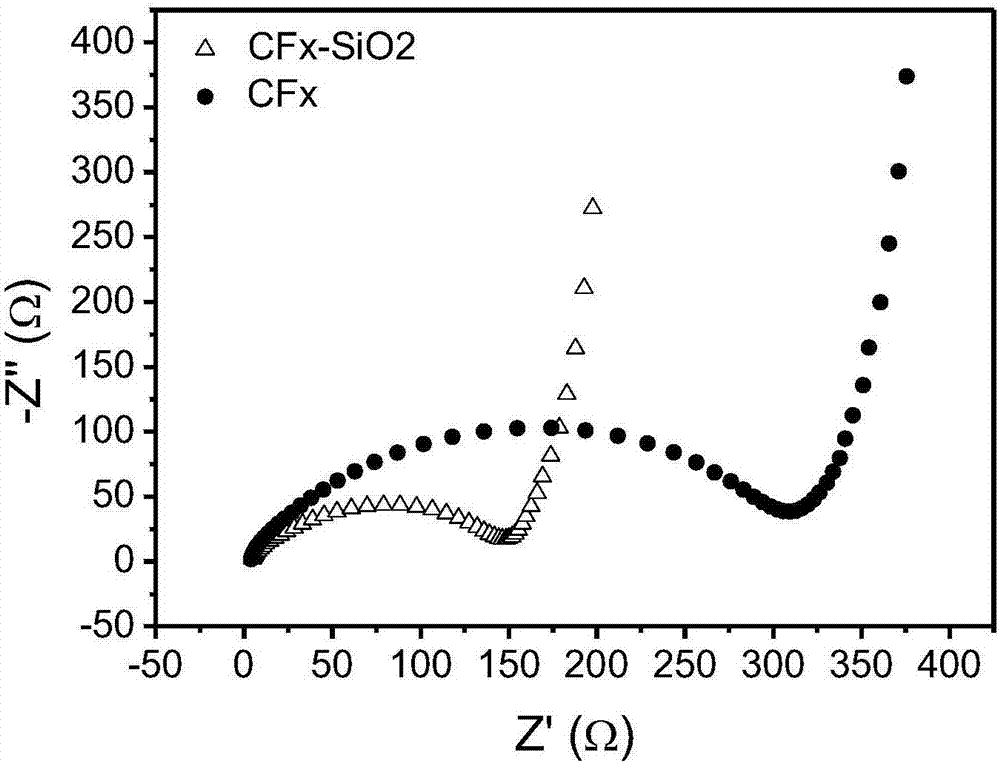

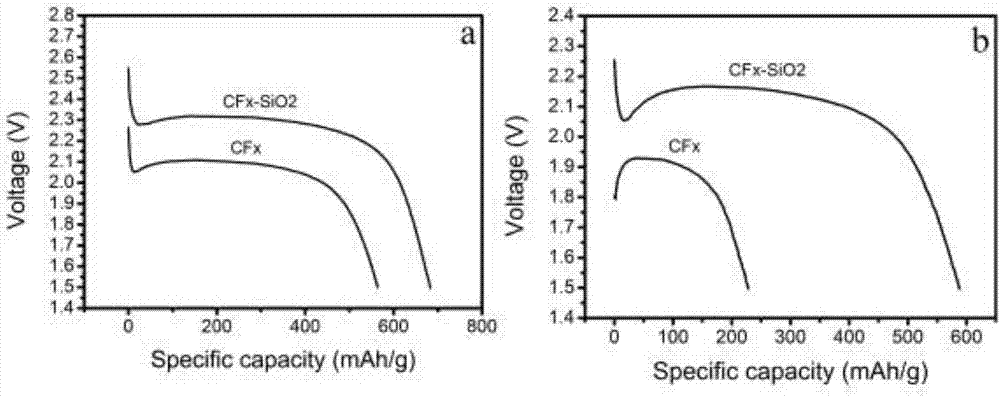

A silicon dioxide and nano silicon dioxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as insignificant effects, and achieve the effects of improving high-rate performance, increasing the discharge voltage platform, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A certain amount of surfactant was added to deionized water, then carbon fluoride was added, and stirred for 4 hours to obtain a uniform mixture. Each 10ml of water corresponds to 0.01g of surfactant and 0.2g of carbon fluoride.

[0022] Spherical nano silicon dioxide and carbon fluoride are added to the mixed solution obtained in step 3 according to a certain ratio, and stirred for 2 hours to obtain a mixed solution.

[0023] The mixture solution was filtered and washed to form a mixture.

[0024] The mixture powder was placed in an atmosphere furnace. Under an inert atmosphere, the temperature of the atmosphere furnace was raised to a constant temperature of 500° C. at a rate of 5° C. / min, and the mixture powder was calcined for 1 hour at the constant temperature. Cool down to room temperature to obtain silica-modified carbon fluoride.

[0025] Described surfactant is sodium lauryl sulfate.

[0026] The mass of the spherical nano silicon dioxide is 3% of the carbon ...

Embodiment 2

[0033] A certain amount of surfactant was added to deionized water, then carbon fluoride was added, and stirred for 4 hours to obtain a uniform mixture. Each 10ml of water corresponds to 0.01g of surfactant and 0.2g of carbon fluoride.

[0034] Spherical nano silicon dioxide and carbon fluoride are added to the mixed solution obtained in step 3 according to a certain ratio, and stirred for 2 hours to obtain a mixed solution.

[0035] The mixture solution was filtered and washed to form a mixture.

[0036] The mixture powder was placed in an atmosphere furnace, and under an inert atmosphere, the temperature of the atmosphere furnace was raised to a constant temperature of 500° C. at a rate of 5° C. / min, and the mixture powder was calcined for 1 hour at the constant temperature. Cool down to room temperature to obtain silica-modified carbon fluoride.

[0037] Described surfactant is cetyltrimethylammonium bromide.

[0038] The mass of the spherical nano silicon dioxide is 3% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com