Method for coating CFx

A fluorinated graphite, coating technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve problems such as complex equipment, environmental pollution, and dangerous operation, and achieve the goal of eliminating voltage hysteresis, preventing environmental pollution, and ensuring uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

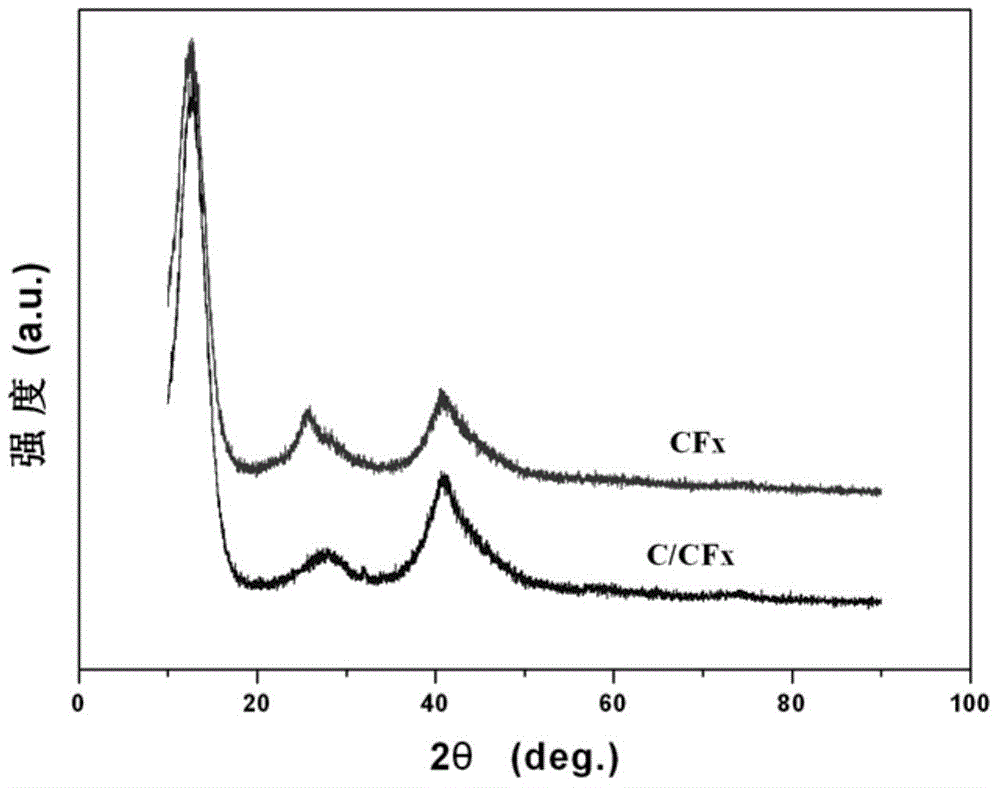

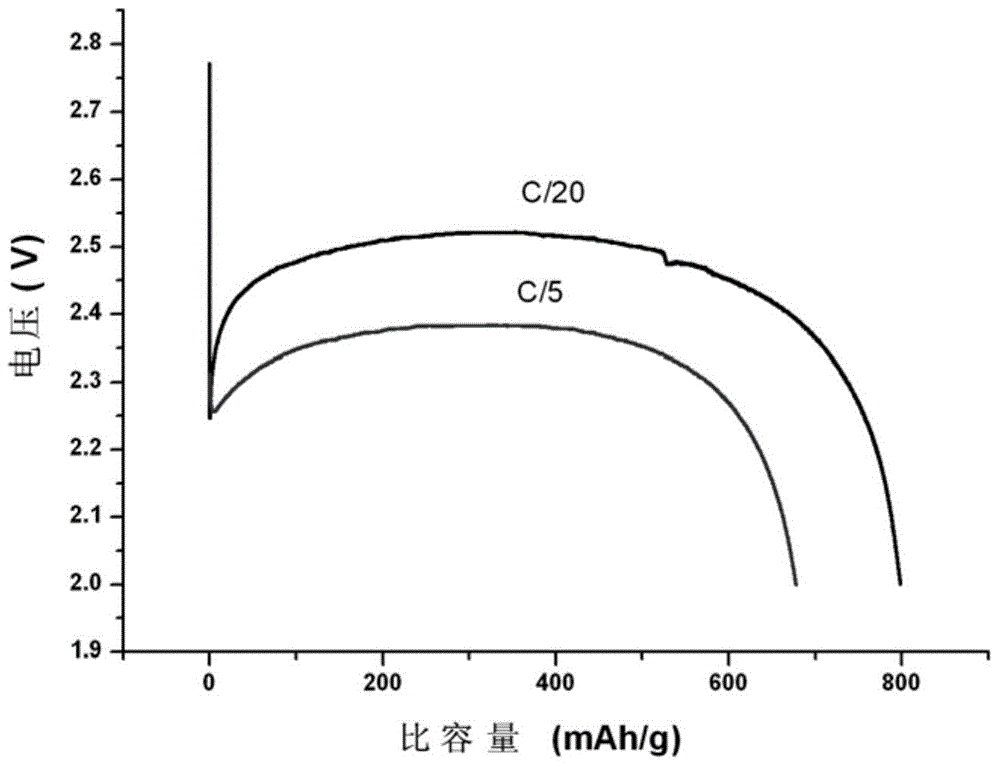

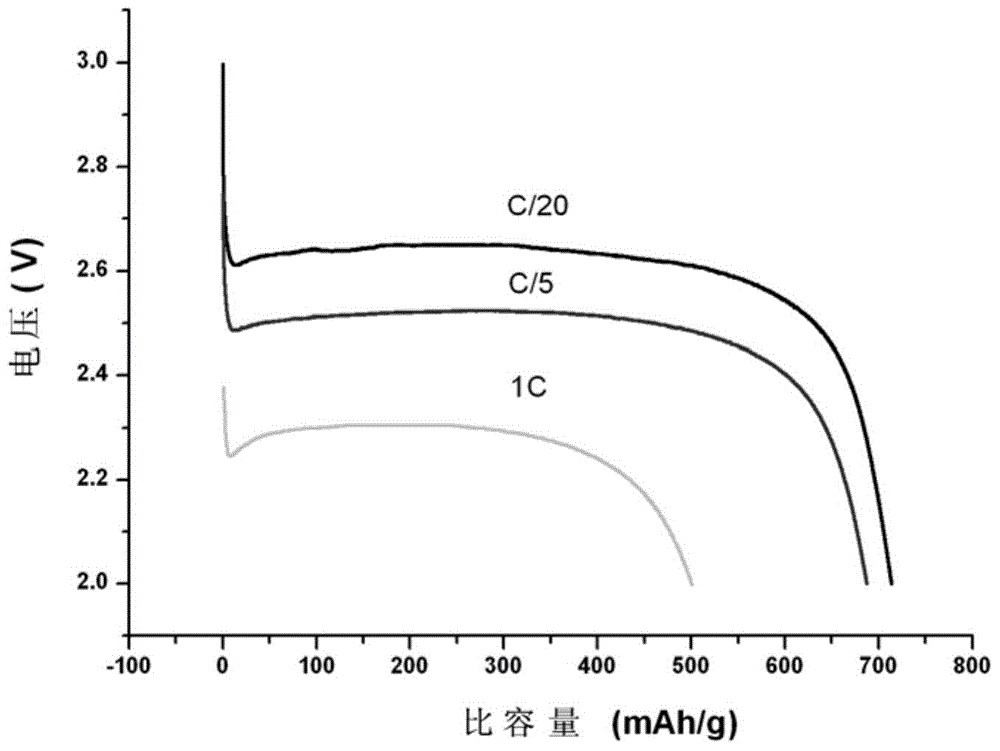

Image

Examples

Embodiment 1

[0036] Step 1 The production process of carbonaceous precursor

[0037] (1) Put LiOH into distilled water to make LiOH solution, and adjust the pH value of LiOH solution between 12 and 14;

[0038] (2) Add 100g of humic acid into the 1000ml LiOH solution prepared in step 1 (1), heat it in a water bath to 80 degrees, stir it with a stirring paddle for an hour while heating it in the water bath, use a high-speed centrifuge, run it at a speed of 5000r / min for 20min, and separate The solid insoluble matter is removed, and the obtained liquid is the alkaline solution of humic acid;

[0039] (3) Use 1mol / L dilute hydrochloric acid to adjust the alkaline solution of humic acid produced in step 1 (2) to a pH value of 3 to 4, run it in a high-speed centrifuge at 5000r / min for 20min, separate the liquid, and wash the solid with distilled water When the pH value is 5, continue centrifugation to obtain a weakly acidic water-soluble nano-carbon precursor ACM solid; through TEM analysis, t...

Embodiment 2

[0049] Step 1 The production process of carbonaceous precursor

[0050] (1) Put LiOH into distilled water to make LiOH solution, and adjust the pH value of LiOH solution between 12 and 14;

[0051] (2) Add 100g of sulfonated asphalt into the 1000ml LiOH solution prepared in step 1 (1), heat it in a water bath to 80 degrees, stir it with a stirring paddle for one hour while heating it in the water bath, use a high-speed centrifuge, run it at a speed of 5000r / min for 20min, and separate The solid insoluble matter is removed, and the obtained liquid is the alkaline solution of sulfonated pitch;

[0052] (3) Use 1mol / L dilute hydrochloric acid to adjust the alkaline solution of sulfonated pitch produced in step 1 (2) to a pH value of 3 to 4, run it in a high-speed centrifuge at 5000r / min for 20min, separate the liquid, and wash the solid with distilled water When the pH value is 5, continue centrifugation to obtain a weakly acidic water-soluble nano-carbon precursor SCP solid; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com