Preparation method and application of two-dimensional Ti3C2Tx modified carbon fluoride composite positive electrode material

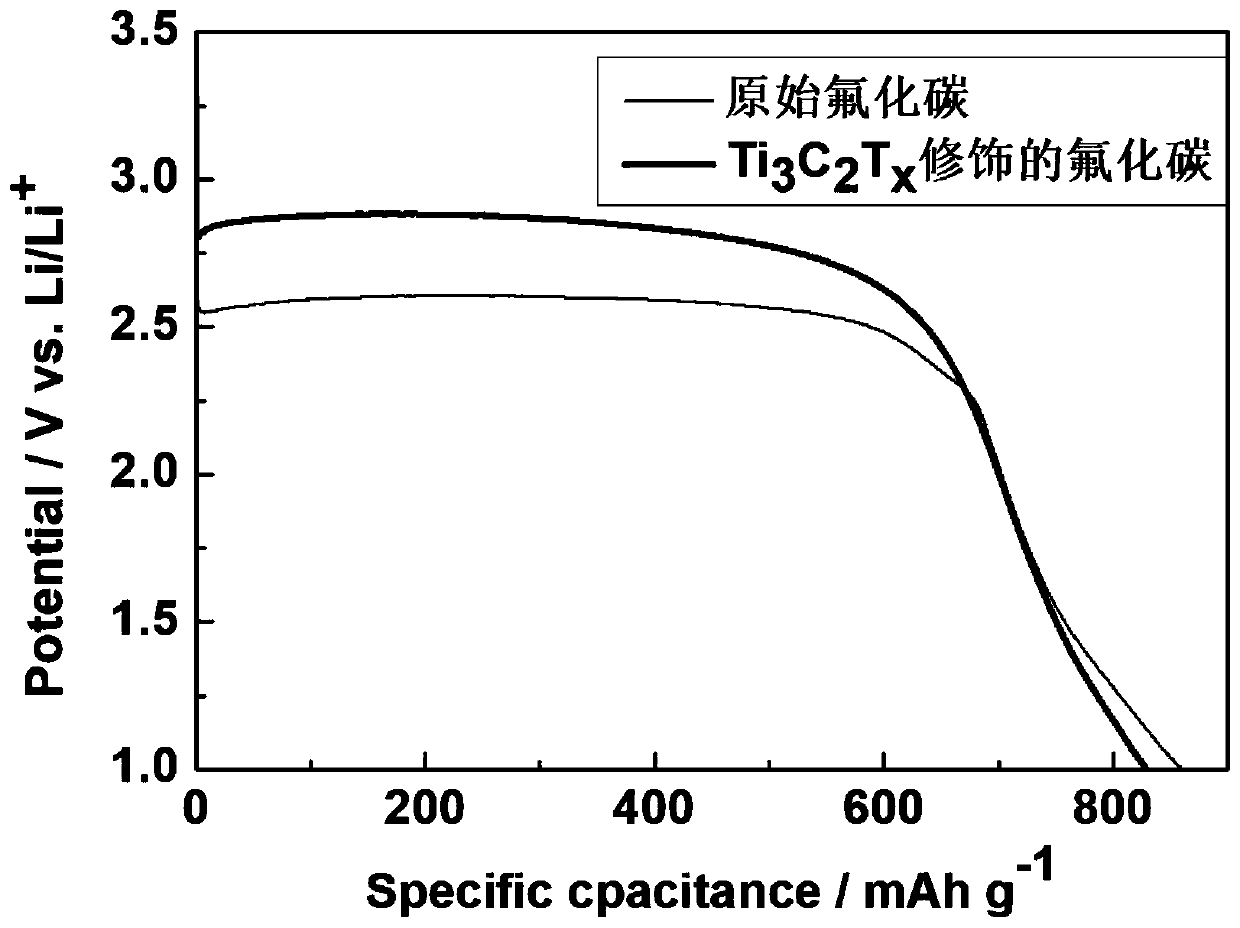

A composite cathode material, carbon fluoride technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of limited large-scale application, poor rate performance, serious heat generation, etc., to achieve easy large-scale production, electrical conductivity Excellent performance, the effect of improving the discharge voltage platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A two-dimensional Ti 3 C 2 T x The preparation method of the modified carbon fluoride composite cathode material,

[0025] (1) Weigh 1gCF x (i.e. fluorinated carbon) positive electrode material, slowly poured into a mixed solution containing deionized water and ethanol (volume ratio of deionized water and ethanol 2:1), wherein deionized water is 20ml, ethanol is 10ml; ultrasonic stirring 6h to get mixed CF x suspension;

[0026] (2) Add 0.05g Ti 3 C 2 T x Adding to the suspension in step (1), under the protection of argon, ultrasonically stirred for 6 hours to obtain a mixed suspension;

[0027] (3) The suspension in step (2) is suction filtered, and washed 4 times with deionized water to obtain a mixture;

[0028] (4) freeze-drying the mixture of step (3) for 36 hours to obtain a composite material;

[0029] (5) Put the composite material obtained in step (4) in a tube furnace, heat up to 150°C for 3 hours at a rate of 5°C / min under the protection of argon, a...

Embodiment 2

[0031] A two-dimensional Ti 3 C 2 T x The preparation method of the modified carbon fluoride composite cathode material,

[0032] (1) Weigh 1gCF x (i.e. fluorinated carbon) positive electrode material, slowly poured into a mixed solution containing deionized water and ethanol (volume ratio of deionized water and ethanol 2:1), wherein deionized water is 20ml, ethanol is 10ml; ultrasonic stirring 6h to get mixed CF x suspension;

[0033] (2) Add 0.05g Ti 3 C 2 T x Adding to the suspension in step (1), under the protection of argon, ultrasonically stirred for 12 hours to obtain a mixed suspension;

[0034] (3) The suspension in step (2) is suction filtered, and washed 4 times with deionized water to obtain a mixture;

[0035] (4) freeze-drying the mixture of step (3) for 36 hours to obtain a composite material;

[0036] (5) Put the composite material obtained in step (4) in a tube furnace, heat up to 150°C for 3 hours at a rate of 5°C / min under the protection of argon, ...

Embodiment 3

[0038] A two-dimensional Ti 3 C 2 T x The preparation method of the modified carbon fluoride composite cathode material,

[0039] (1) Weigh 1g CF x (i.e. fluorinated carbon) positive electrode material, slowly poured into a mixed solution containing deionized water and ethanol (volume ratio of deionized water and ethanol 2:1), wherein deionized water is 20ml, ethanol is 10ml; ultrasonic stirring 6h to get mixed CF x suspension;

[0040] (2) Add 0.05g Ti 3 C2 T x Adding to the suspension in step (1), under the protection of argon, ultrasonically stirred for 24 hours to obtain a mixed suspension;

[0041] (3) The suspension in step (2) is suction filtered, and washed 4 times with deionized water to obtain a mixture;

[0042] (4) freeze-drying the mixture of step (3) for 36 hours to obtain a composite material;

[0043] (5) Put the composite material obtained in step (4) in a tube furnace, heat up to 150°C for 3 hours at a rate of 5°C / min under the protection of argon, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com