Sodium-perfluorocarbon primary battery

A carbon fluoride and battery technology, applied in the field of sodium batteries, to achieve the effects of stable discharge potential, environmental friendliness, and high discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

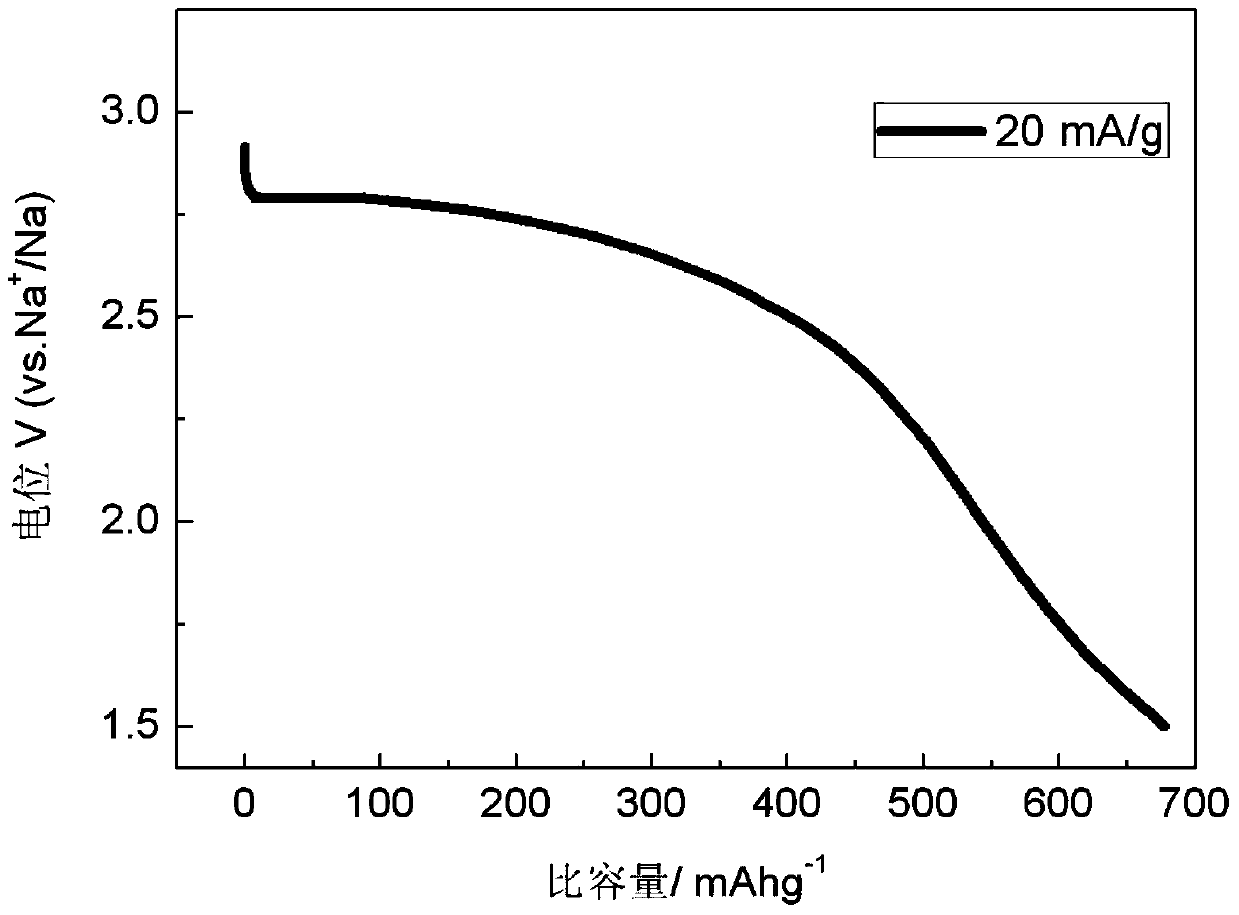

[0024] The electrochemical performance test of the sodium-carbon fluoride primary battery of the present invention is carried out by using the prepared 2025 button-type sodium battery, and the positive carbon fluoride electrode is prepared by the paste coating method. The specific steps are: according to the mass ratio of carbon fluoride positive electrode material: acetylene black: binder = 80: 10: 10, the fluorinated carbon, acetylene black and binder are ball-milled and mixed, coated on the treated aluminum foil, at 120 ℃ drying, press molding under 20MPa. A positive electrode for a sodium battery was obtained.

Embodiment 2

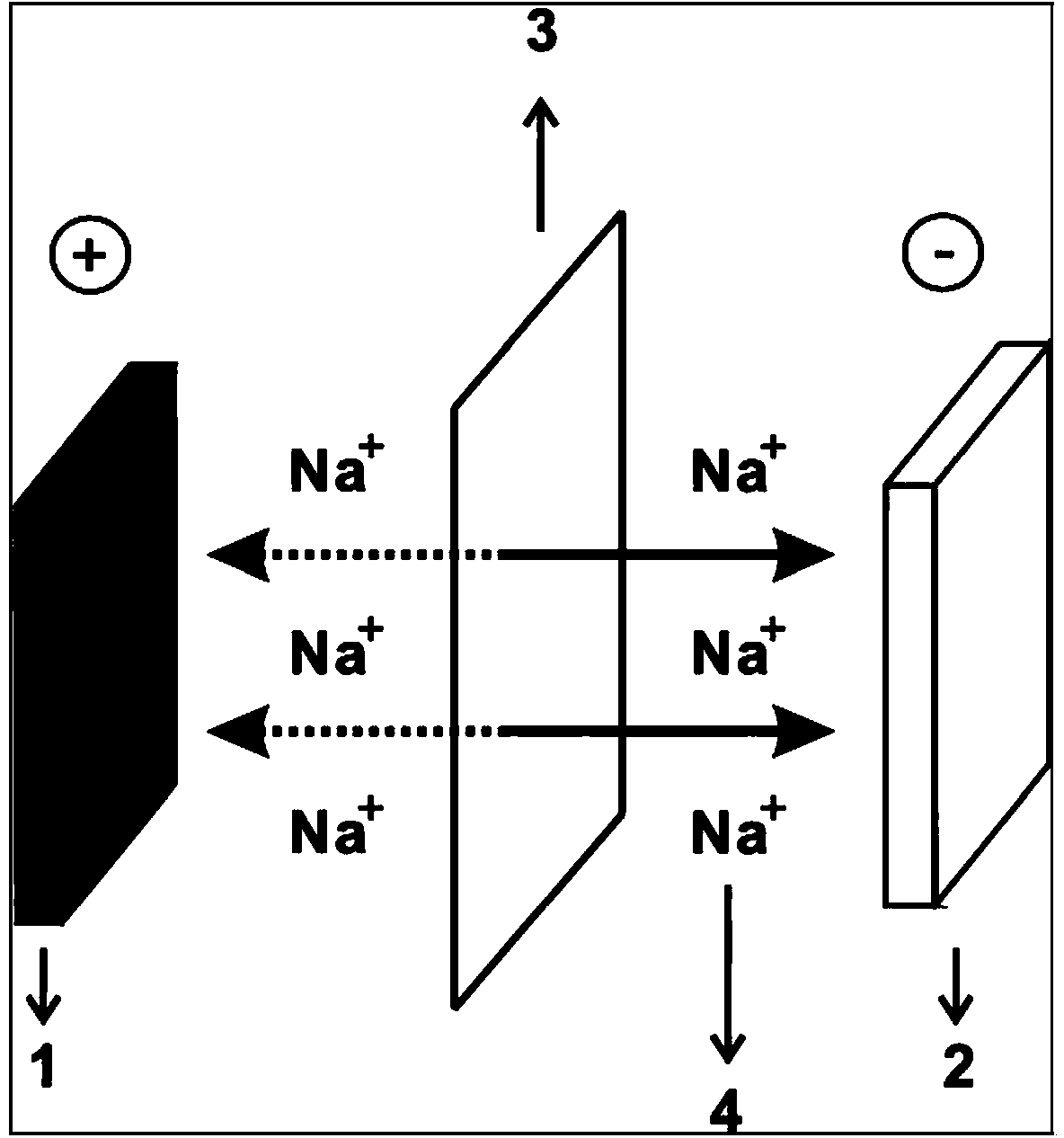

[0026] The fluorinated carbon electrode prepared in Example 1 is used as the positive pole, the sodium metal is the negative pole, the PP / PE / PP composite film Cellgard2400 is the diaphragm, and 1mol / L NaClO 4 The propylene carbonate (PC) solution is used as the electrolyte, which is assembled into a 2025 button battery. The structure principle of sodium battery is as follows: figure 1 shown. The constant current electrochemical performance test was carried out on the LAND battery test system (Wuhan Landian Electronics Co., Ltd.). Discharge cut-off potential is 1.5V (vs.Na + / Na).

Embodiment 3

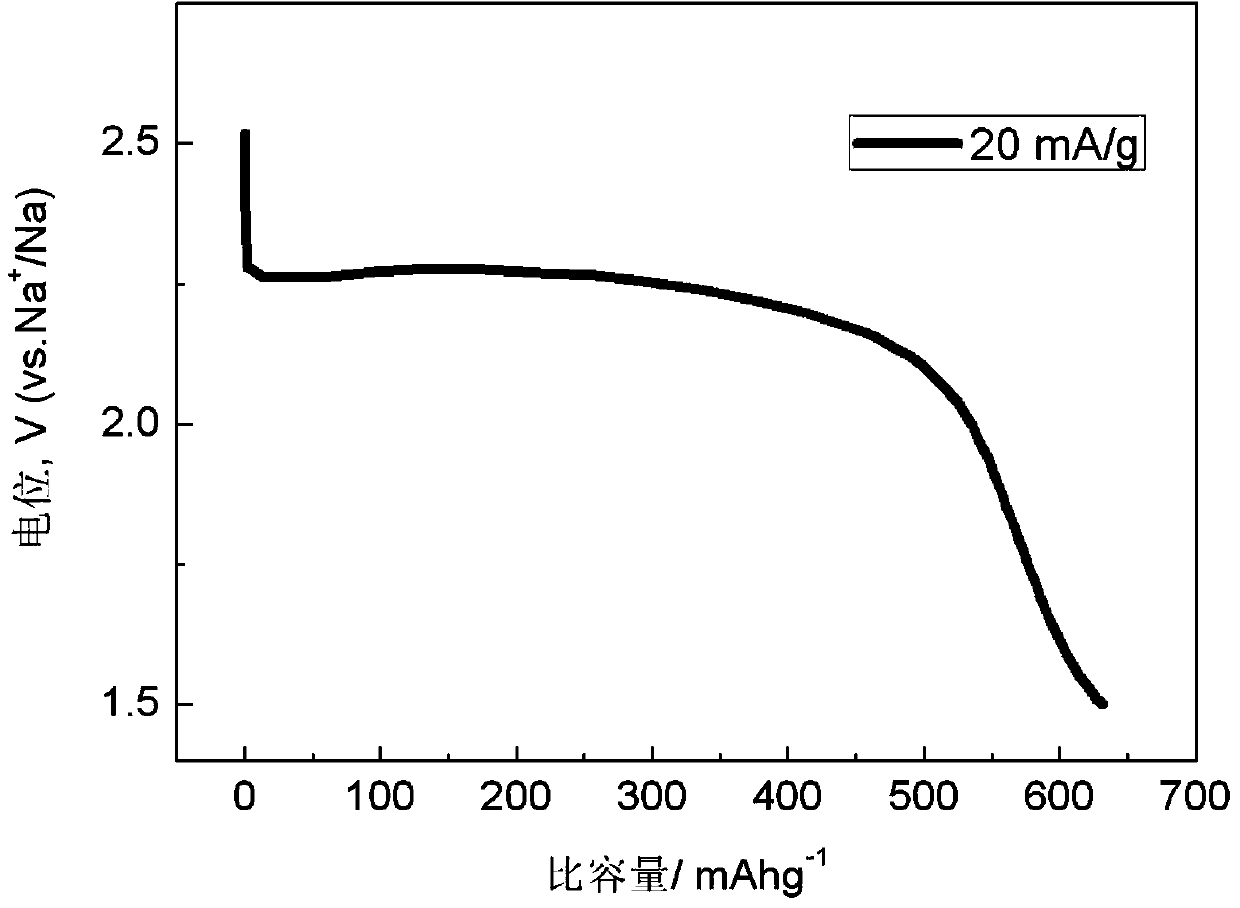

[0028] Using fluorinated carbon fiber (F / C=0.75) as the positive electrode active material, referring to Example 1, a positive electrode for a sodium battery was prepared. Referring to Example 2, the sodium battery preparation and electrochemical performance test were carried out. Test results such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com