Patents

Literature

104 results about "Constant current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

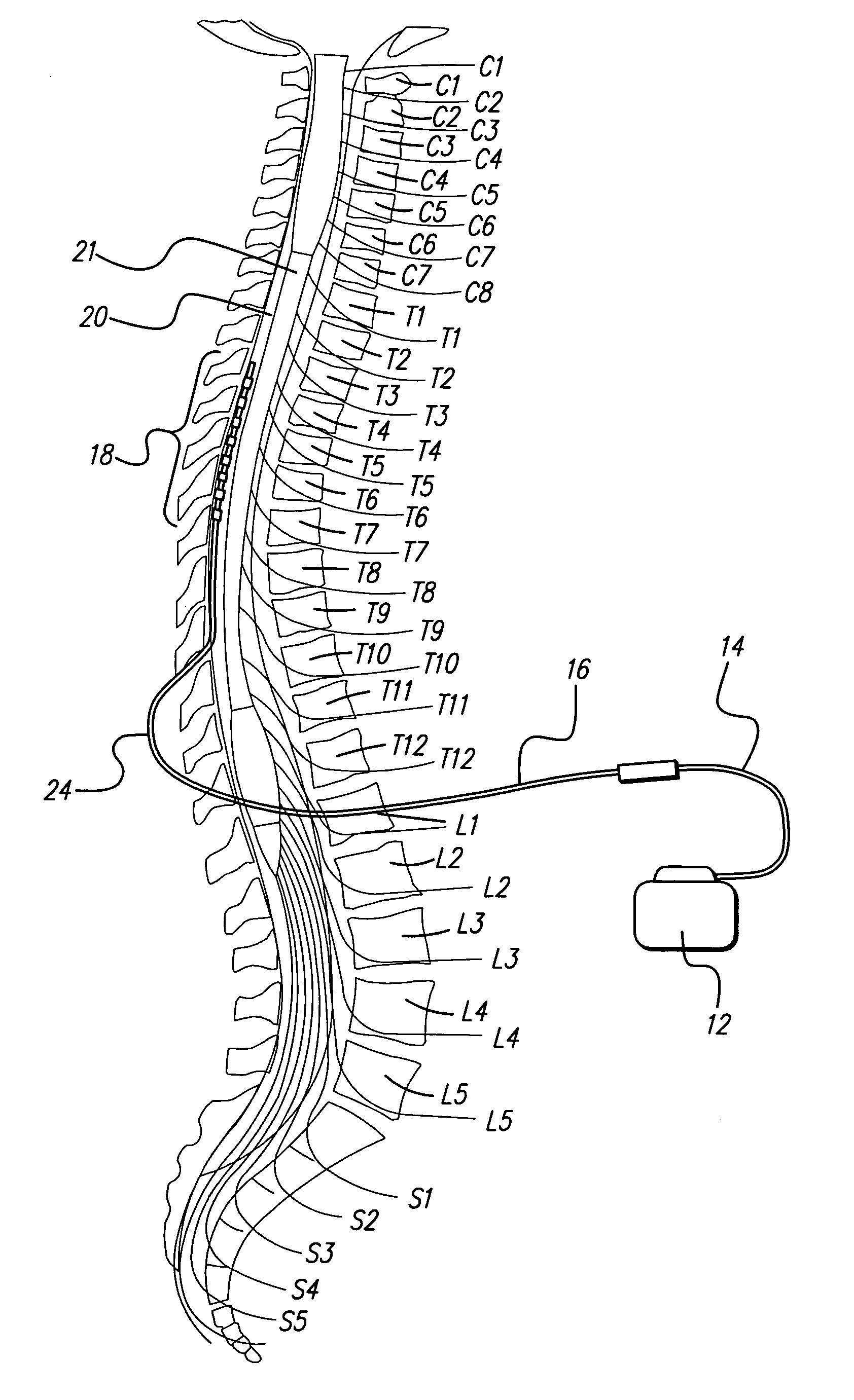

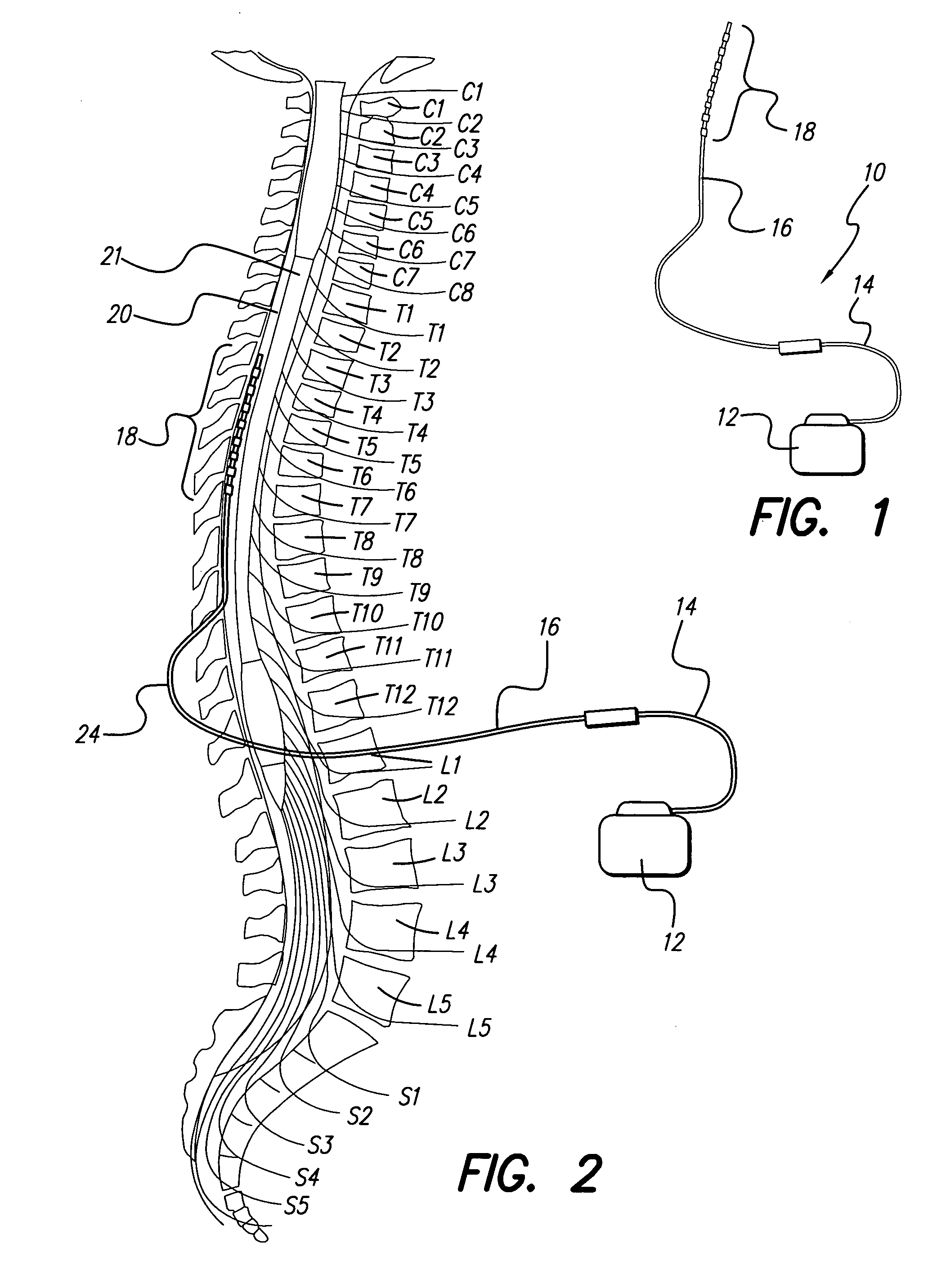

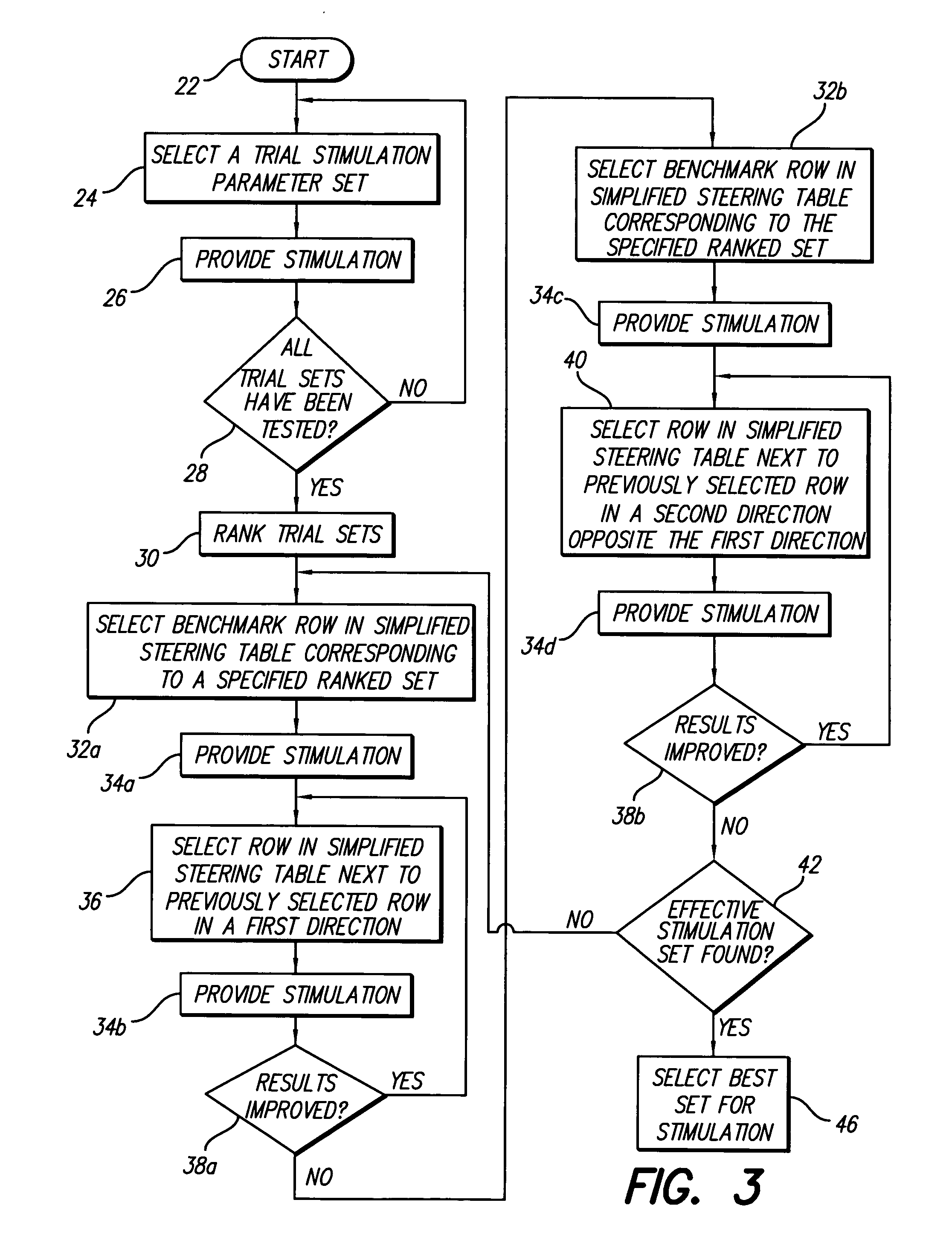

Method for optimizing search for spinal cord stimulation parameter settings

InactiveUS20050209655A1Improve search efficiencyConstant level of paresthesiaSpinal electrodesSurgeryVolumetric Mass DensityPattern perception

Methods for selecting stimulation parameter sets guide a clinician towards an effective set(s) of stimulation parameters. The clinician first evaluates the effectiveness of a small number of trial stimulation parameters sets from a Measurement Table comprising for example, four stimulation parameter sets, measuring the perception threshold and maximum threshold levels. The maximum comfortable step size and desired field shift resolution are determined, and are used along with the measured threshold levels to determine an appropriate step size to use in the current steering process. In order to maintain paresthesia at a relatively constant level during the steering process, a Superposition Equalization (SEQ) algorithm is used to compensate for the physical characteristics of the lead array, i.e., electrode separation and size. A multiplier is determined and a modifying function is used to apply this multiplier to the electrode energy output during transition to maintain a relatively constant current density.

Owner:BOSTON SCI NEUROMODULATION CORP

Method for recycling manganese and lithium from power type lithium manganate battery for electric automobile

InactiveCN102347521AReduce pollutionEasy to operateWaste accumulators reclaimingProcess efficiency improvementElectrolytic agentManganate

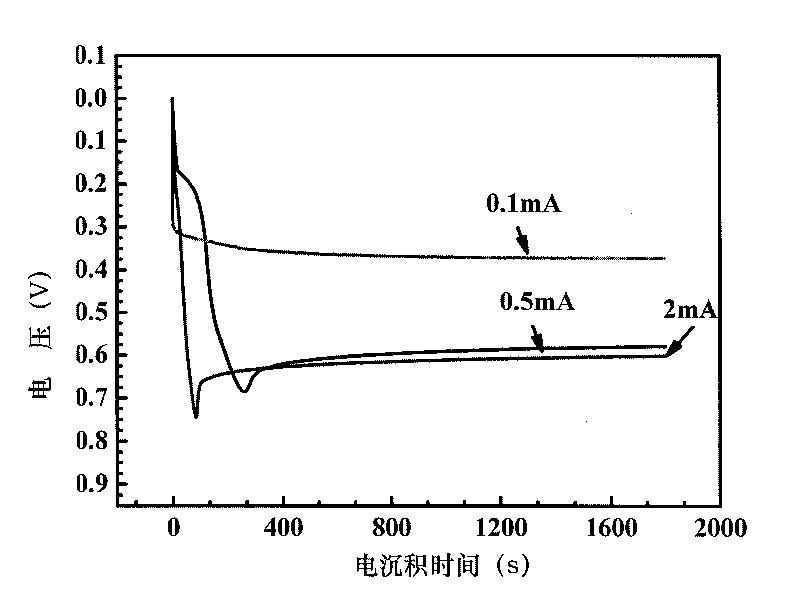

The invention discloses a method for recycling manganese and lithium from a power type lithium manganate battery for an electric automobile, which comprises the following steps of: (1) after discharging a waste and old lithium ion battery, detaching a shell to obtain an anode part; (2) removing an organic adhesive of the anode part to obtain a power type lithium manganate anode material; (3) adding acid and a reducing agent into the inorganic material obtained in the step (2), dissolving the inorganic material and filtering to remove the undissolved substance acetylene black to obtain filter liquid; (4) carrying out electrochemical deposition for 5-8 hours by using the filter liquid obtained in the step (3) as electrolyte, using a titanium sheet as a working electrode, using a graphite rod as a counter electrode and controlling the constant current density of 300-800A / m<2> and the temperature of 60-80 DEG C to obtain a manganese dioxide solid; (5) adjusting the pH of the residual liquid in the step (4) to be 9 to 10 and filtering to obtain a sediment and filter liquid; (6) adding a sodium carbonate solution with the concentration of 30-40 percent into the filter liquid obtained in the step (5) till the filter liquid is completely deposited; and filtering, washing and drying to obtain a lithium carbonate solid. MnO2 is recycled by utilizing an electrochemical deposition method, and thereby the method has the advantage of environmental protection; and the high-purity lithium carbonate solid is recycled.

Owner:GUANGDONG BRUNP RECYCLING TECH

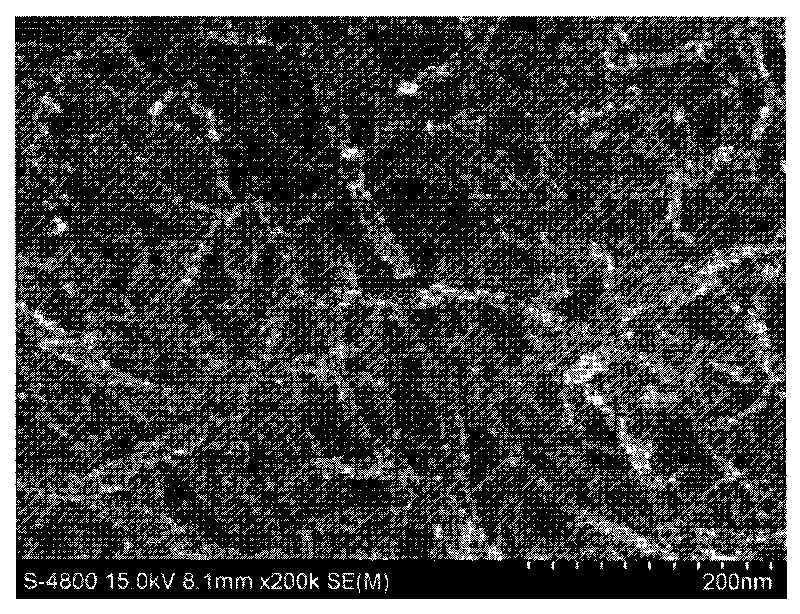

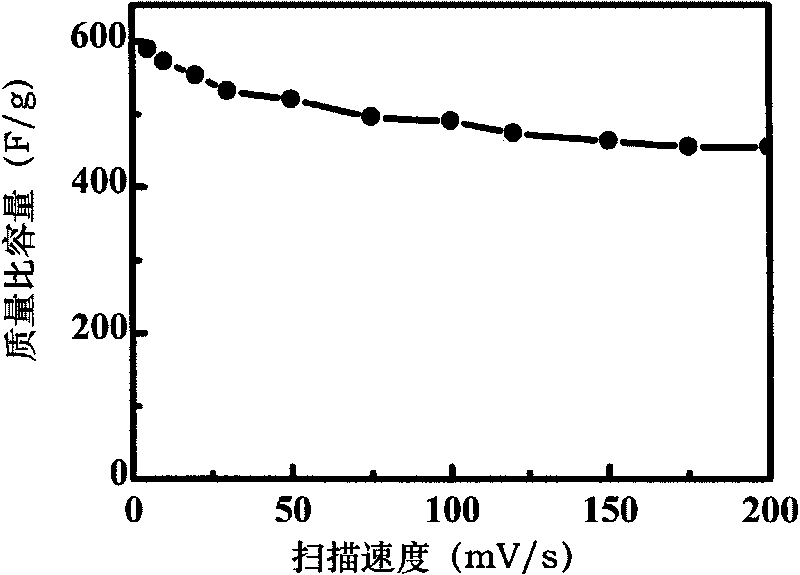

Method for preparing stannic oxide battery anode material on carbon nano tube by using electro-deposition process

The invention discloses a method for preparing a stannic oxide battery anode material on a carbon nano tube by using an electro-deposition process. The method comprises the steps of: making electro-deposition solution, treating the solution with water bath, preparing the carbon nano tube pole piece, pressing on a foam nickel base, putting the base carrying the carbon nano tube pole piece into the electro-deposition solution so as to perform vacuum treatment, and then perform the electro-deposition treatment under a constant current on the vacuumized pole piece so as to acquire the battery anode material on the carbon nano tube carrying the stannic oxide. The battery anode material prepared by using the method has higher power property and has a quality specific capacity kept between 350 and 450 F / g under a high scanning speed of 200 mV / s. The material applied in a super capacitor has higher volumetric properties, excellent cycling stability and long cycling life, first discharging specific capacity ranged between 410 and 588 F / g under a constant current density of 15 A / g, cycling times more than 5000 times and specific capacity retention rate ranged between 90 to 95 percent.

Owner:BEIHANG UNIV

Preparation method of noble metal-graphene nanometer composite

InactiveCN101797502AGood dispersionEasy to prepareCell electrodesCatalyst activation/preparationHydrazine compoundVolumetric Mass Density

The invention provides a preparation method of a noble metal-graphene nanometer composite, which comprises the steps of: oxidizing powdered graphite to prepare graphene oxide by oxidizing potassium permanganate; dispersing the graphene oxide in water; ultrasonically stripping a dispersed graphene oxide piece which is formed in water solution; reducing the graphene oxide piece with hydrazine hydrate under the existence of surface active agent to obtain graphene water solution which can be stably dispersed in water phase; centrifugally concentrating the graphene water solution; adding noble metal prodromic salt and electrolyte salt into surface active agent-containing water solution; adding water phase-dispersed graphene in proportion; adjusting PH value; reacting by means of ultrasonic electrochemistry under the density of the constant current and the intensity of ultrasound; centrifugally separating with high speed; and washing with ultrapure water to prepare the noble metal-graphene nanometer composite. The method has the advantages of convenience, speediness and controllability, etc. The prepared graphene nanometer composite has good dispersibility in water, can be stably existed for a long term, and has good electro-catalysis redox characteristic to organic matter.

Owner:NANJING UNIV

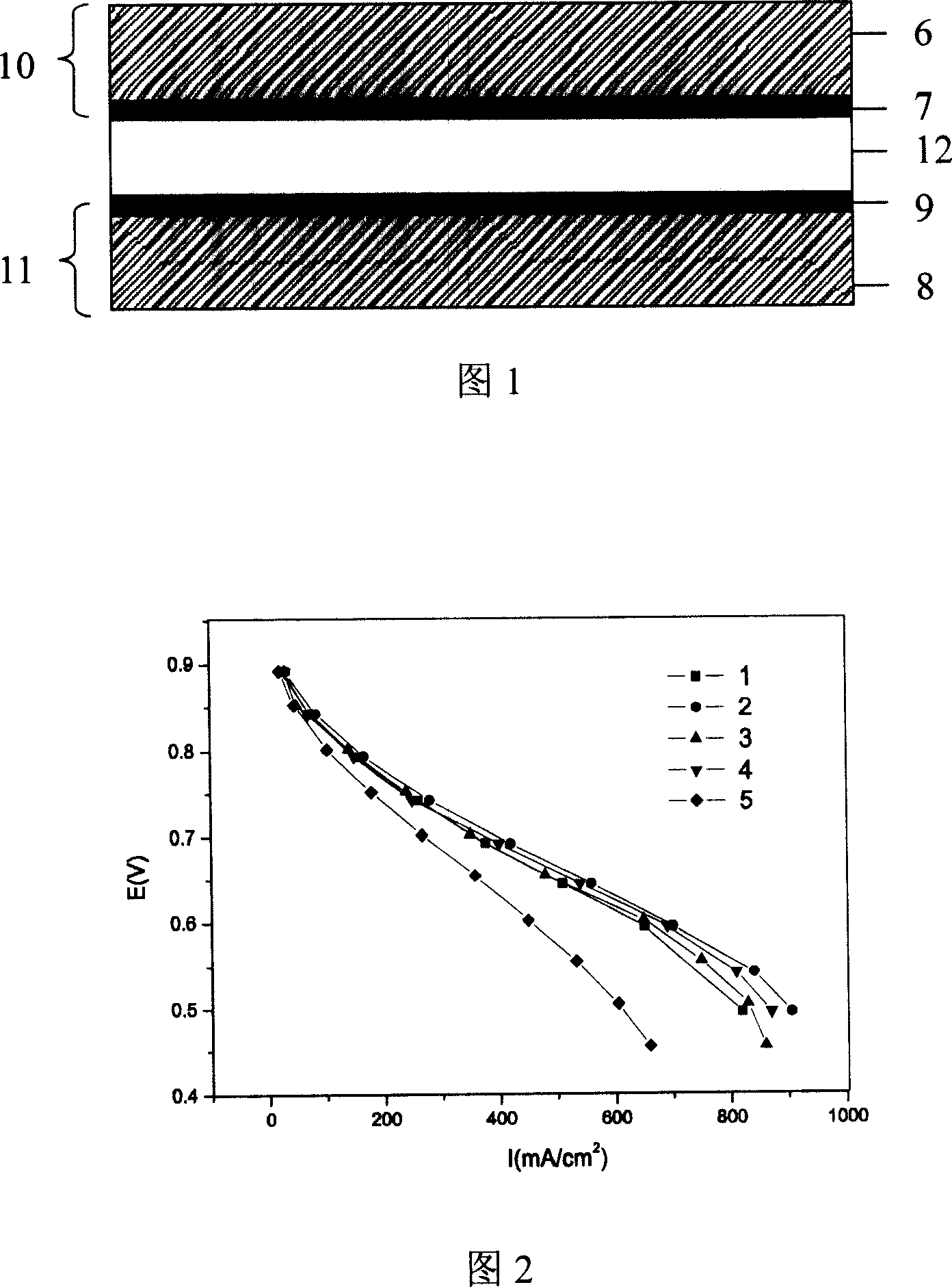

Method for activating membrane electrode of fuel cell

ActiveCN101136477AQuick activationShorten activation timeBatteries circuit arrangementsCell electrodesFuel cellsEngineering

This invention relates to an activating method for membrane electrodes of fuel cells including penetrating an anode fuel and cathode fuel into an anode chamber and a cathode chamber of the fuel battery to let it discharge including multiple discharge periods and at least one time interval among them and the battery discharges in a constant current density in each period.

Owner:BYD CO LTD

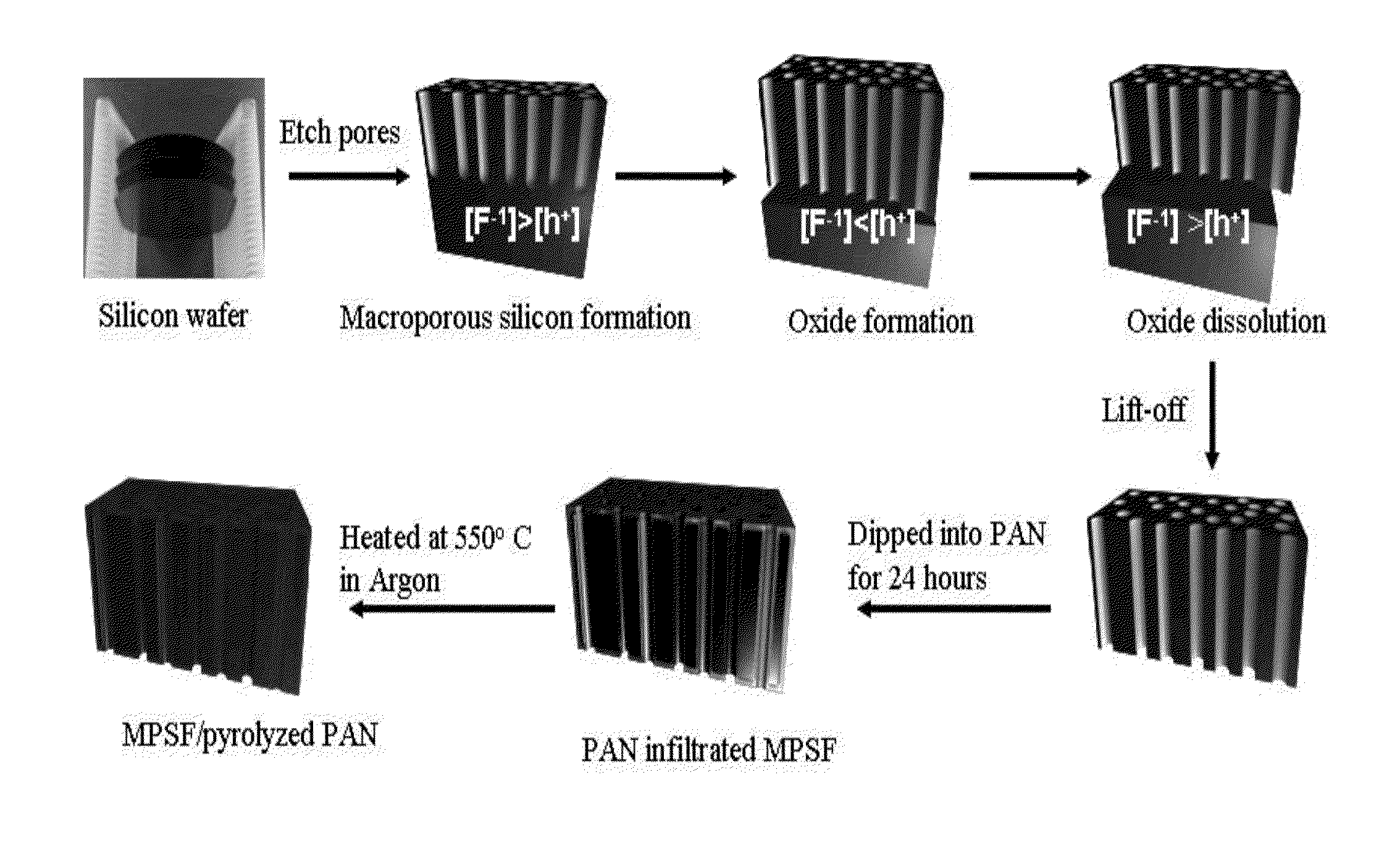

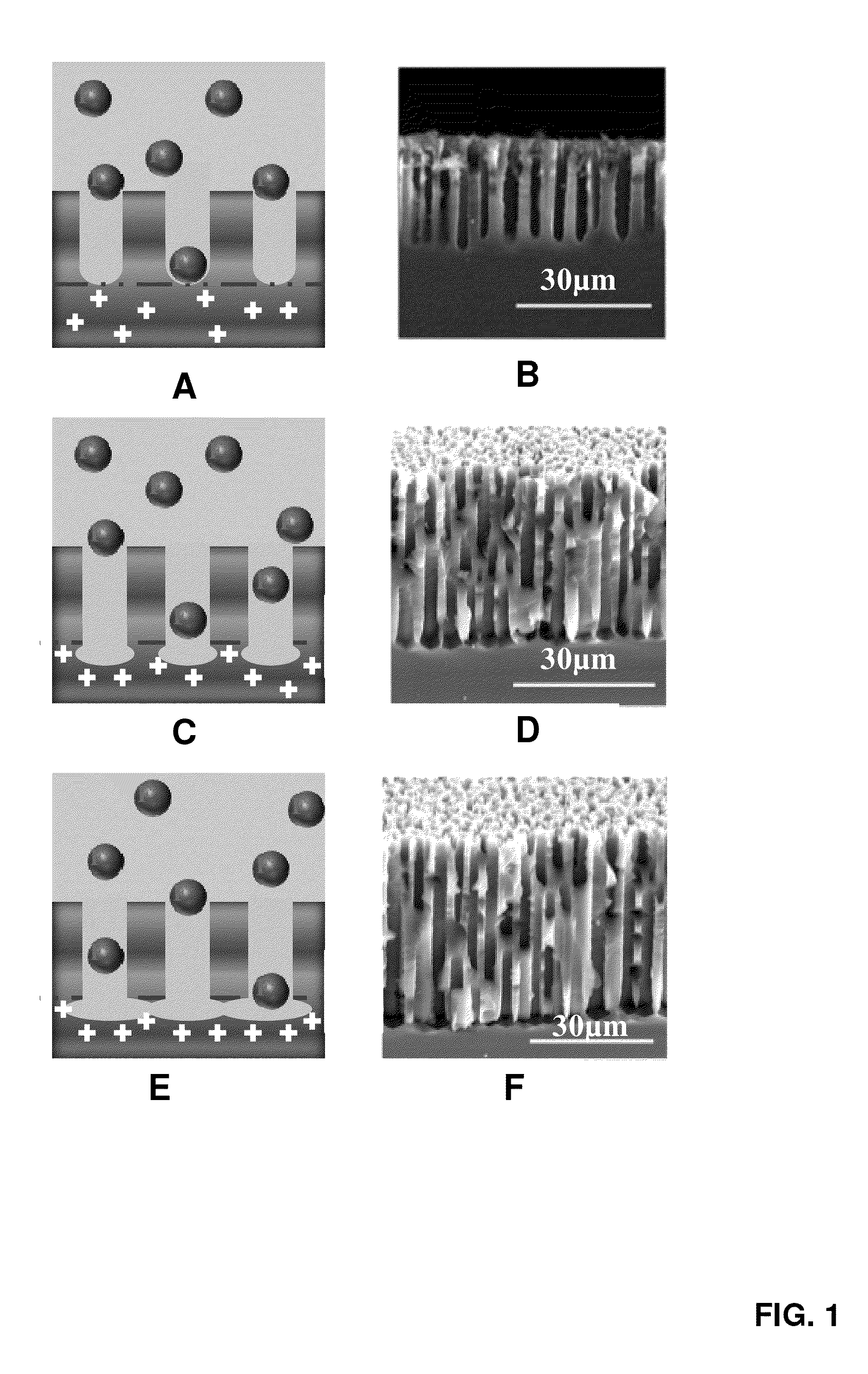

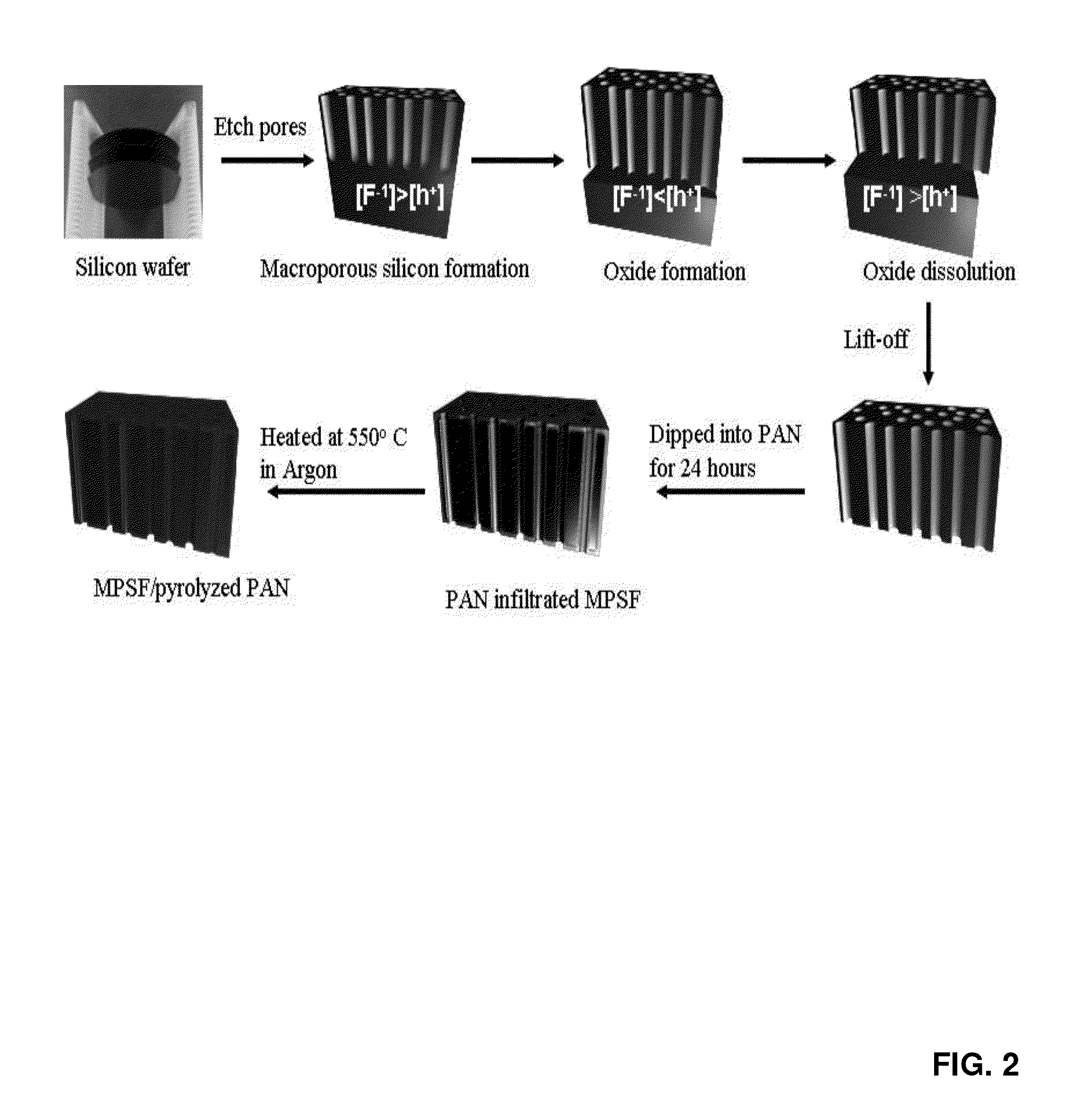

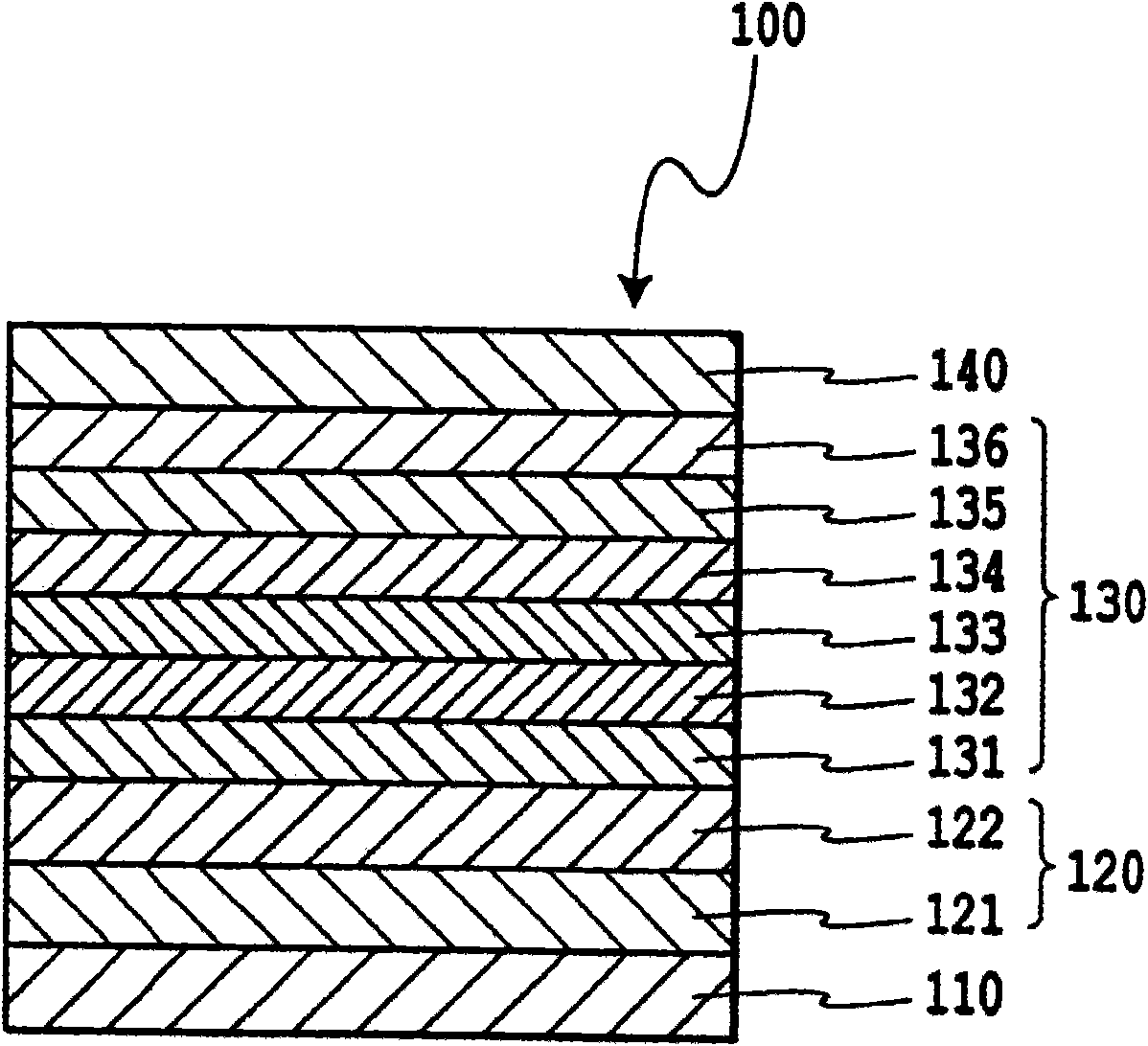

Anode battery materials and methods of making the same

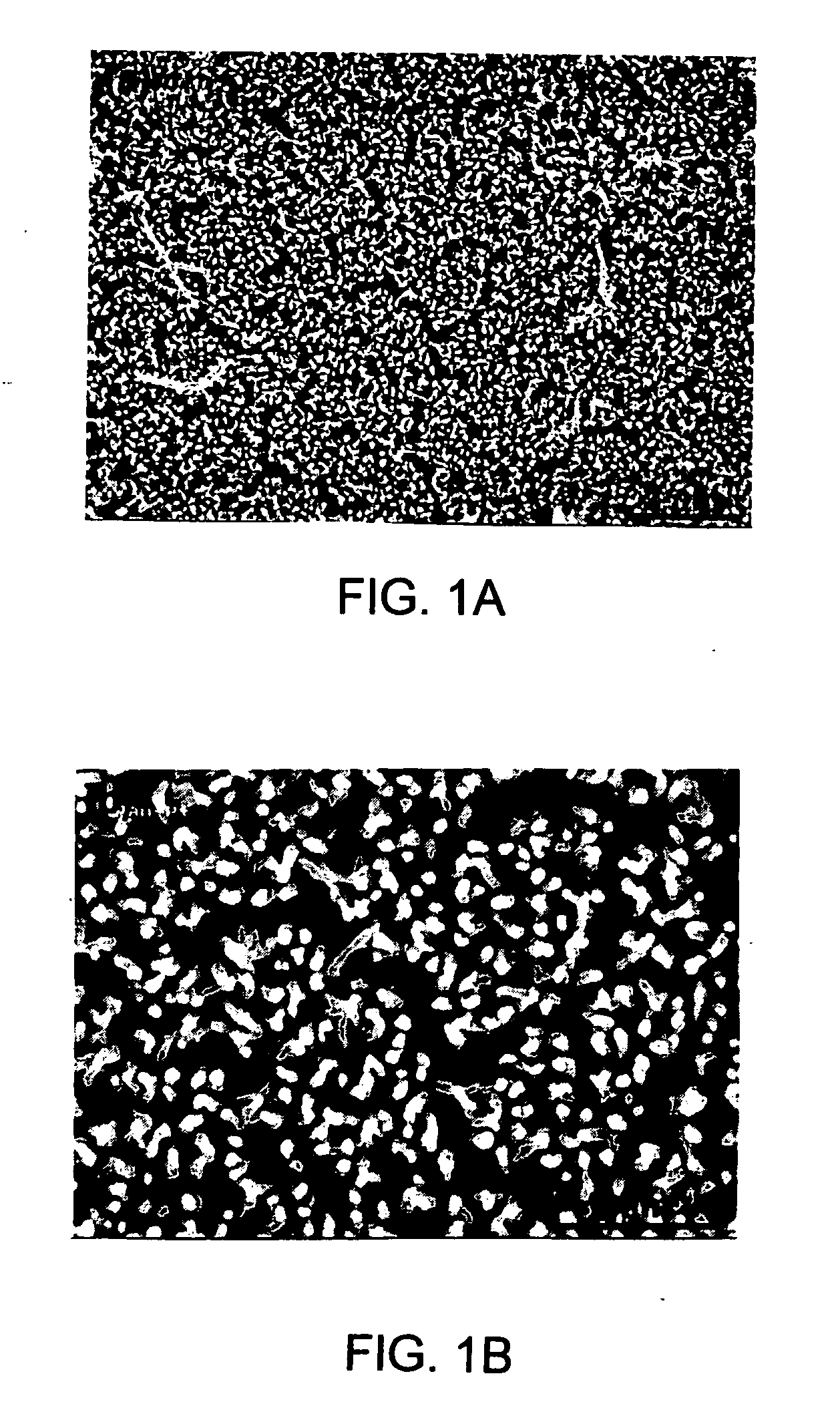

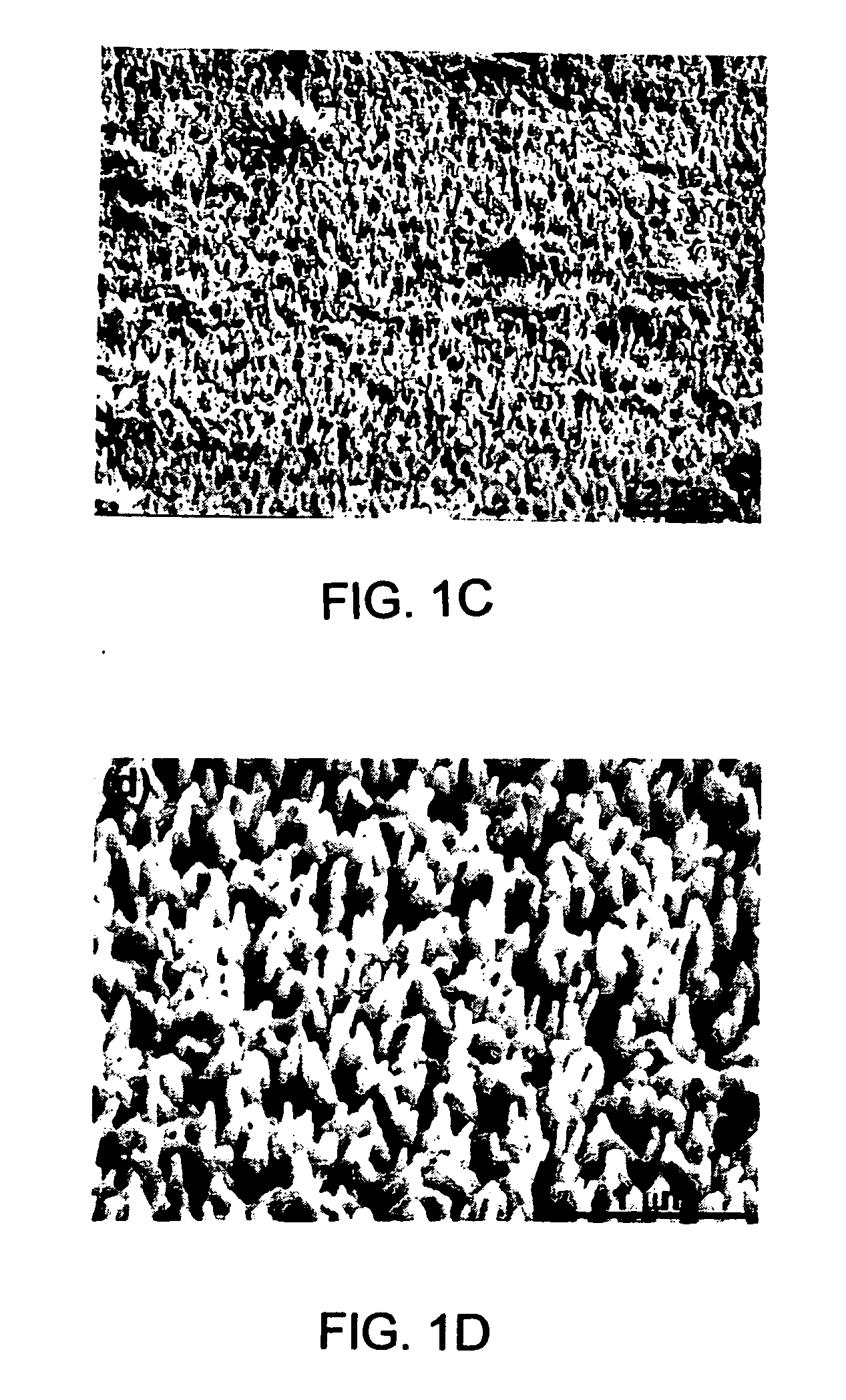

ActiveUS20130045420A1Minimal silicon material wasteImprove discharge performanceMaterial nanotechnologyElectrochemical processing of electrodesPower flowSilicon membrane

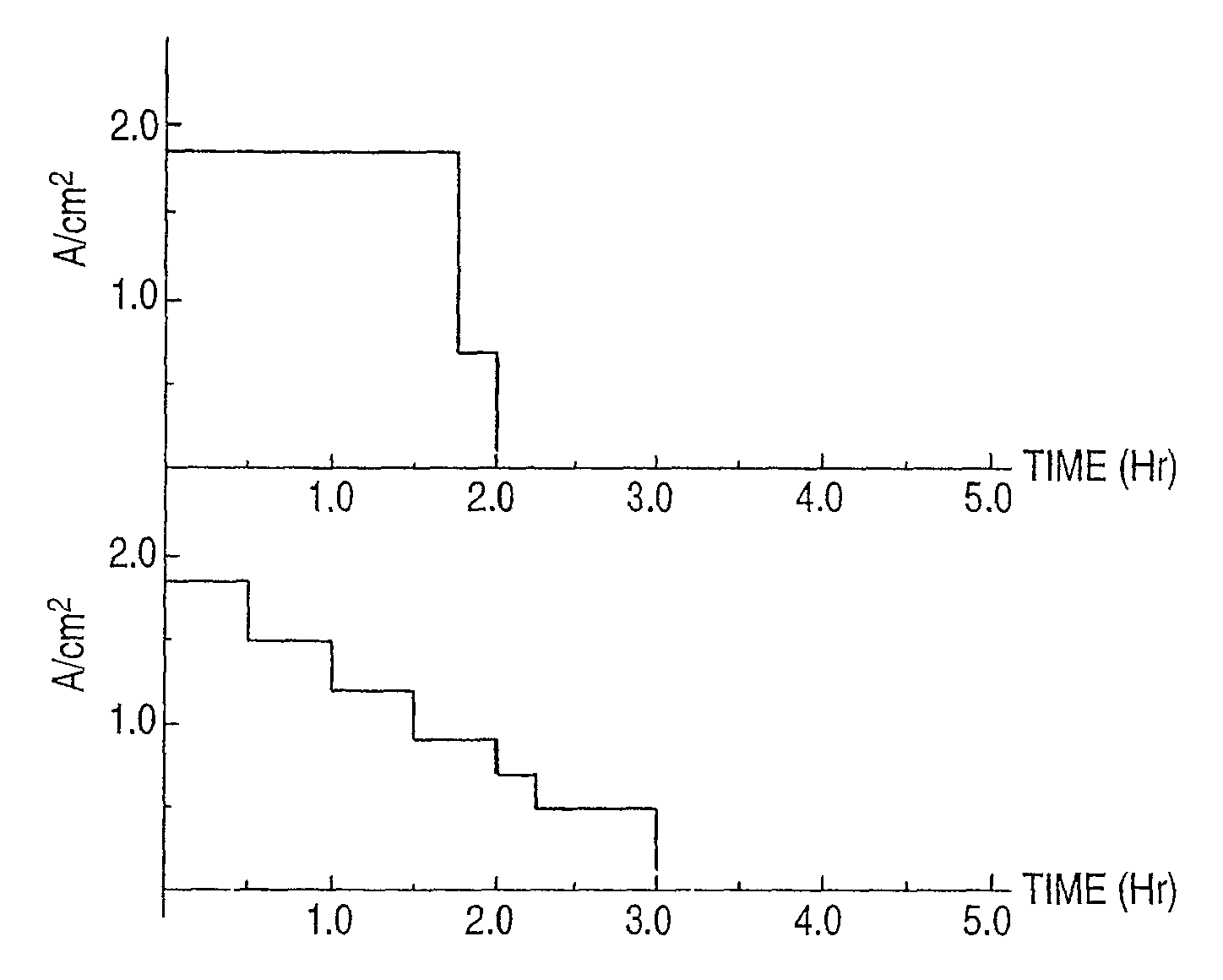

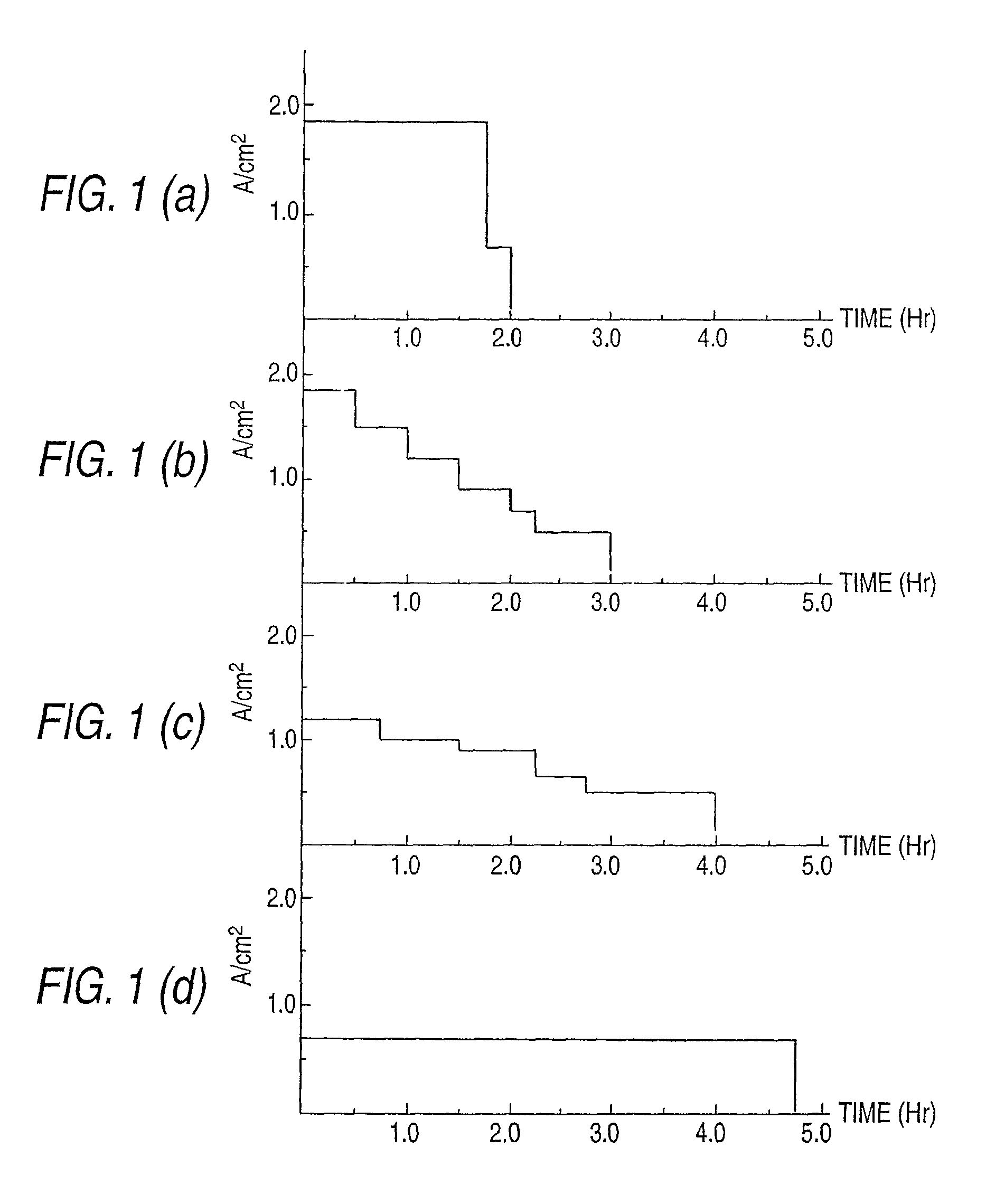

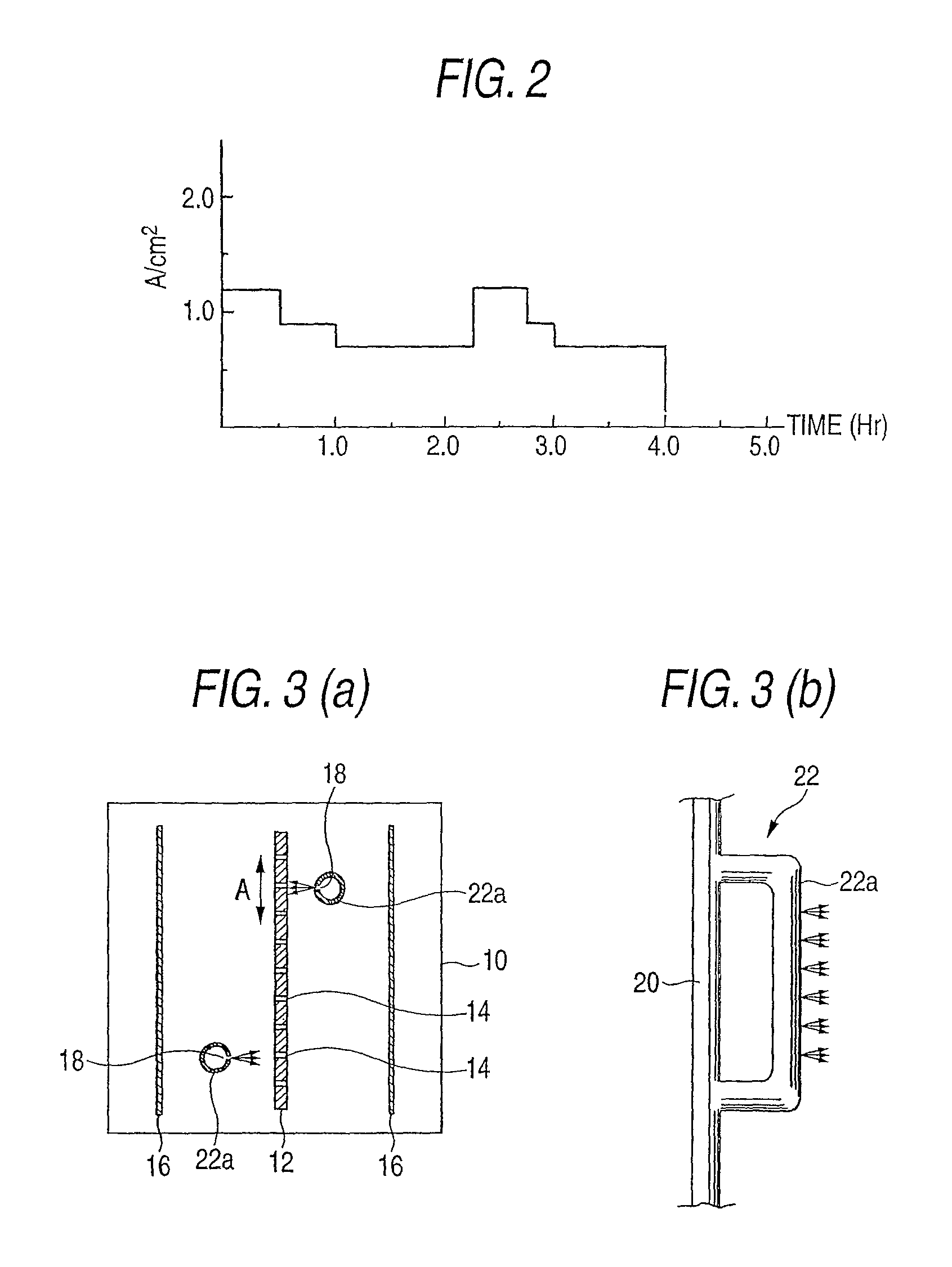

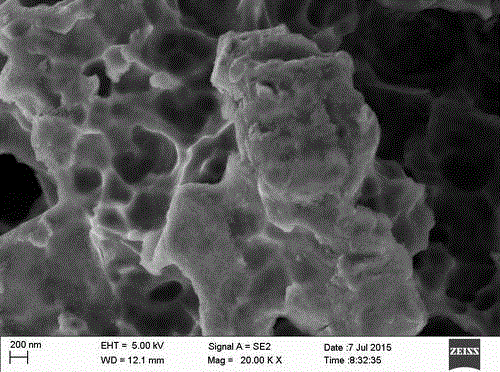

In some embodiments, the present invention provides novel methods of preparing porous silicon films and particles for lithium ion batteries. In some embodiments, such methods generally include: (1) etching a silicon material by exposure of the silicon material to a constant current density in a solution to produce a porous silicon film over a substrate; and (2) separating the porous silicon film from the substrate by gradually increasing the electric current density in sequential increments. In some embodiments, the methods of the present invention may also include a step of associating the porous silicon film with a binding material. In some embodiments, the methods of the present invention may also include a step of splitting the porous silicon film to form porous silicon particles. Additional embodiments of the present invention pertain to anode materials derived from the porous silicon films and porous silicon particles.In some embodiments, the present invention provides novel methods of preparing porous silicon films and particles for lithium ion batteries. In some embodiments, such methods generally include: (1) etching a silicon material by exposure of the silicon material to a constant current density in a solution to produce a porous silicon film over a substrate; and (2) separating the porous silicon film from the substrate by gradually increasing the electric current density in sequential increments. In some embodiments, the methods of the present invention may also include a step of associating the porous silicon film with a binding material. In some embodiments, the methods of the present invention may also include a step of splitting the porous silicon film to form porous silicon particles. Additional embodiments of the present invention pertain to anode materials derived from the porous silicon films and porous silicon particles.

Owner:LOCKHEED MARTIN CORP +1

Method for etching holes by corroding aluminum foil

InactiveCN101752095AHigh densityUniform densityElectrolytic capacitorsConstant current densityMaterials science

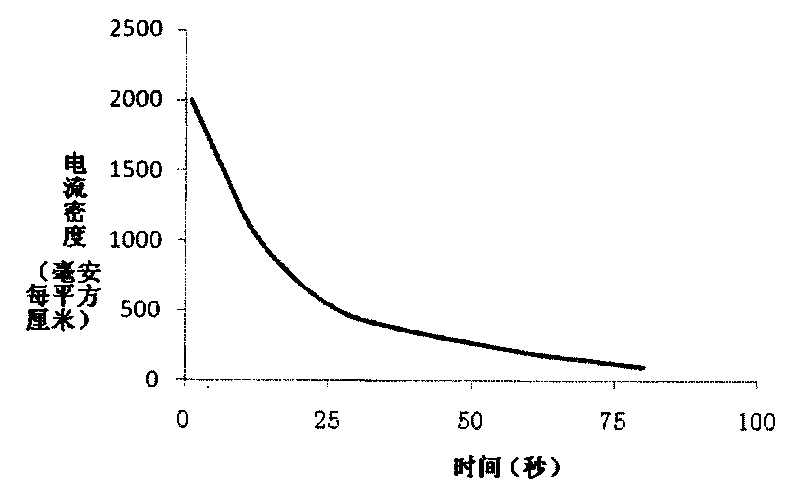

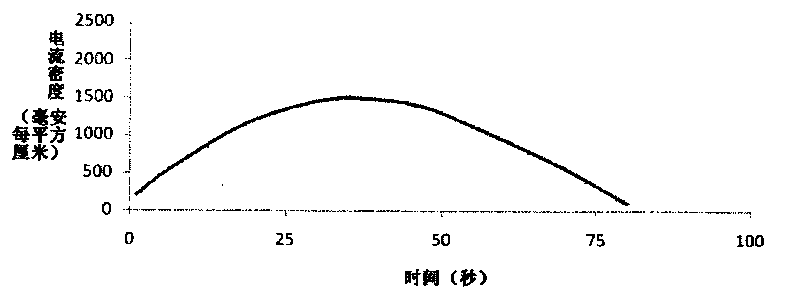

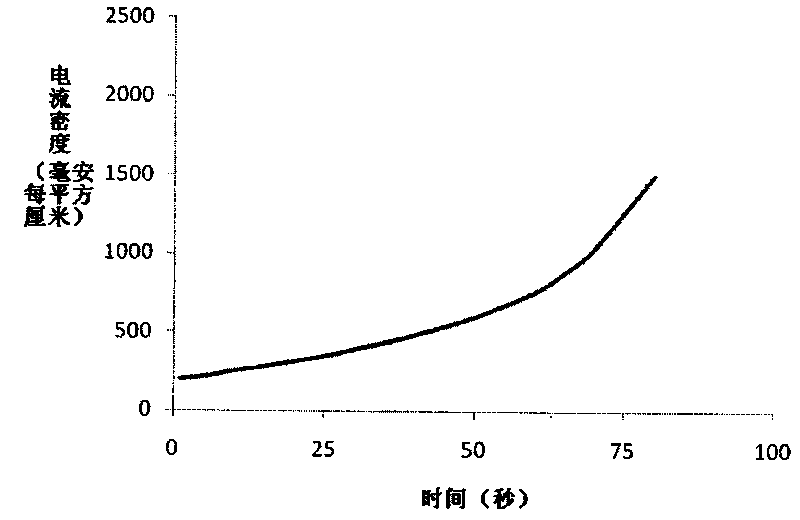

The invention discloses a method for etching holes by eroding an aluminum foil, which comprises the steps of pretreatment, first level corrosion, second level corrosion, post treatment and drying. The first level corrosion comprises the following steps of: putting the aluminum foil after the pretreatment into mixed solution of hydrochloric acid and sulfuric acid, wherein the mixed solution contains 0.5 to 1.0 N / L of aluminum, the temperature of the mixed solution is between 65 and 90 DEG C and the total acidity of the mixed solution is 5.0 to 8.0 N / L; and applying 45 to 80 seconds of direct current of which the current density changes along with the time to perform electrolytic corrosion for etching the holes in mainly three modes that: one, the current density changes from high to low along with the time; two, the current density changes from low to high and then to low again; and three, the current density changes form low to high. The hole etching mode that the current density changes from high to low along with the time improves the specific volume by 7 to 12 percent compared with the existing hole etching method with constant current density under the premise of not reducing the mechanical strength of the aluminum foil.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

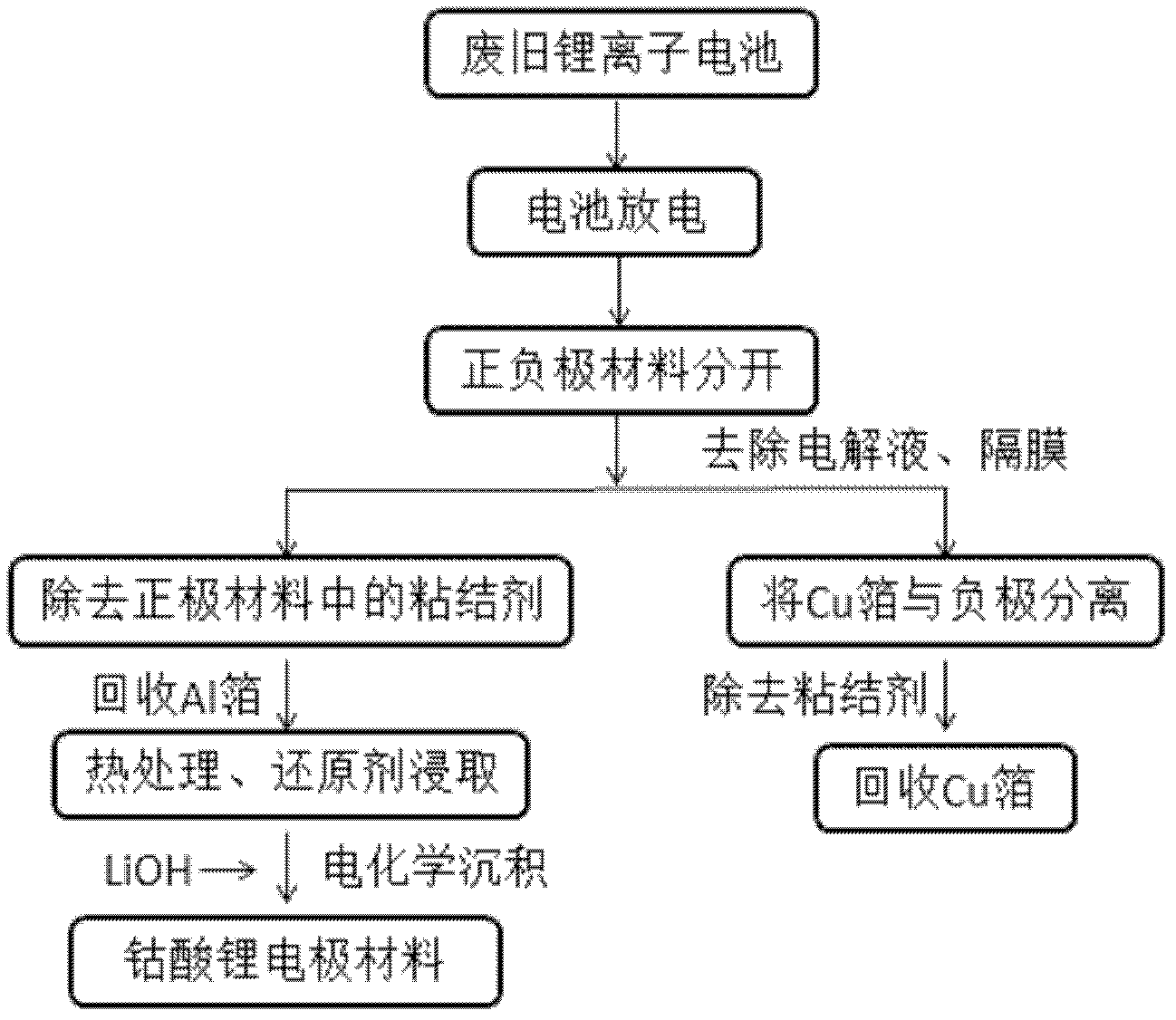

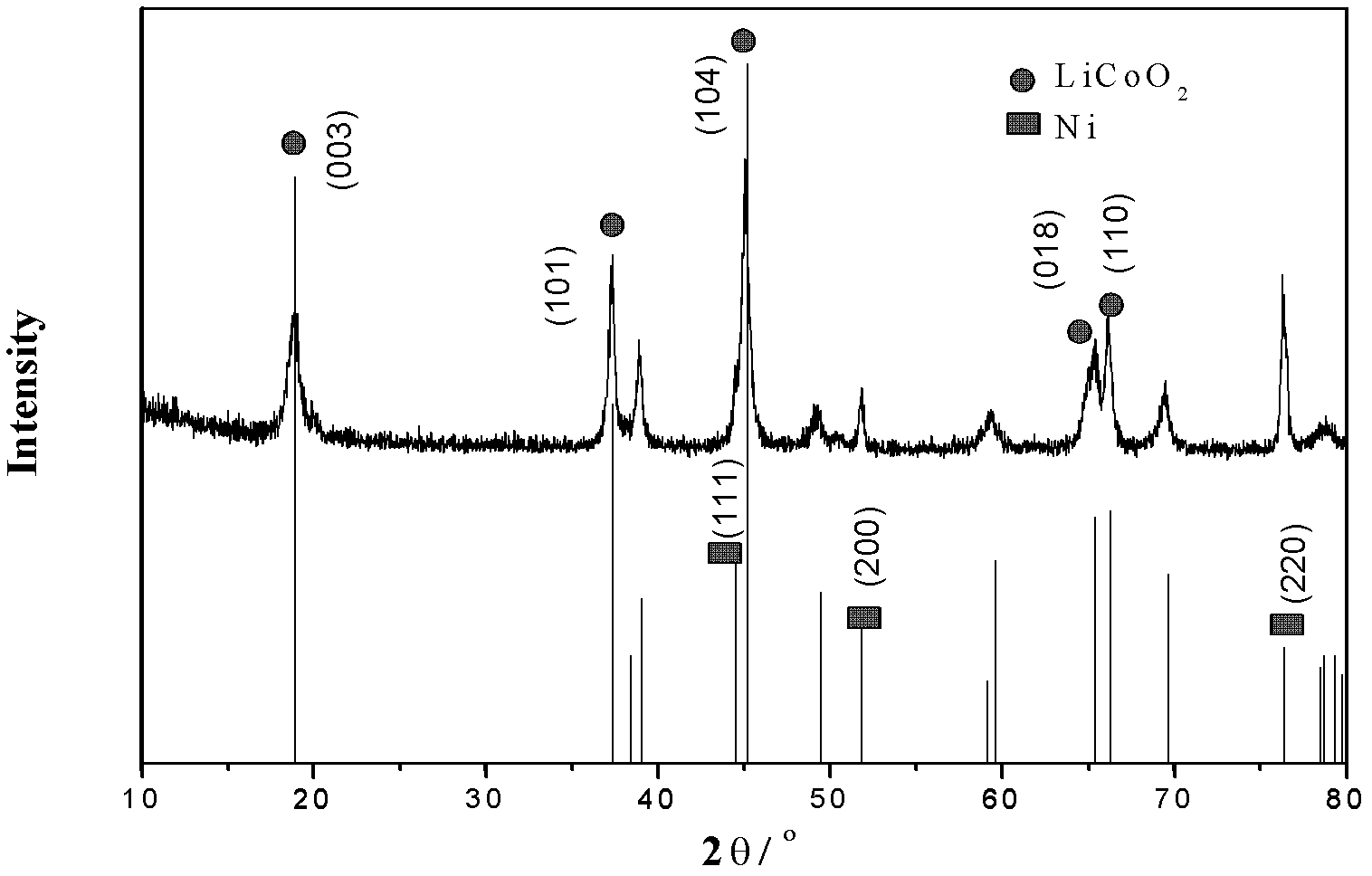

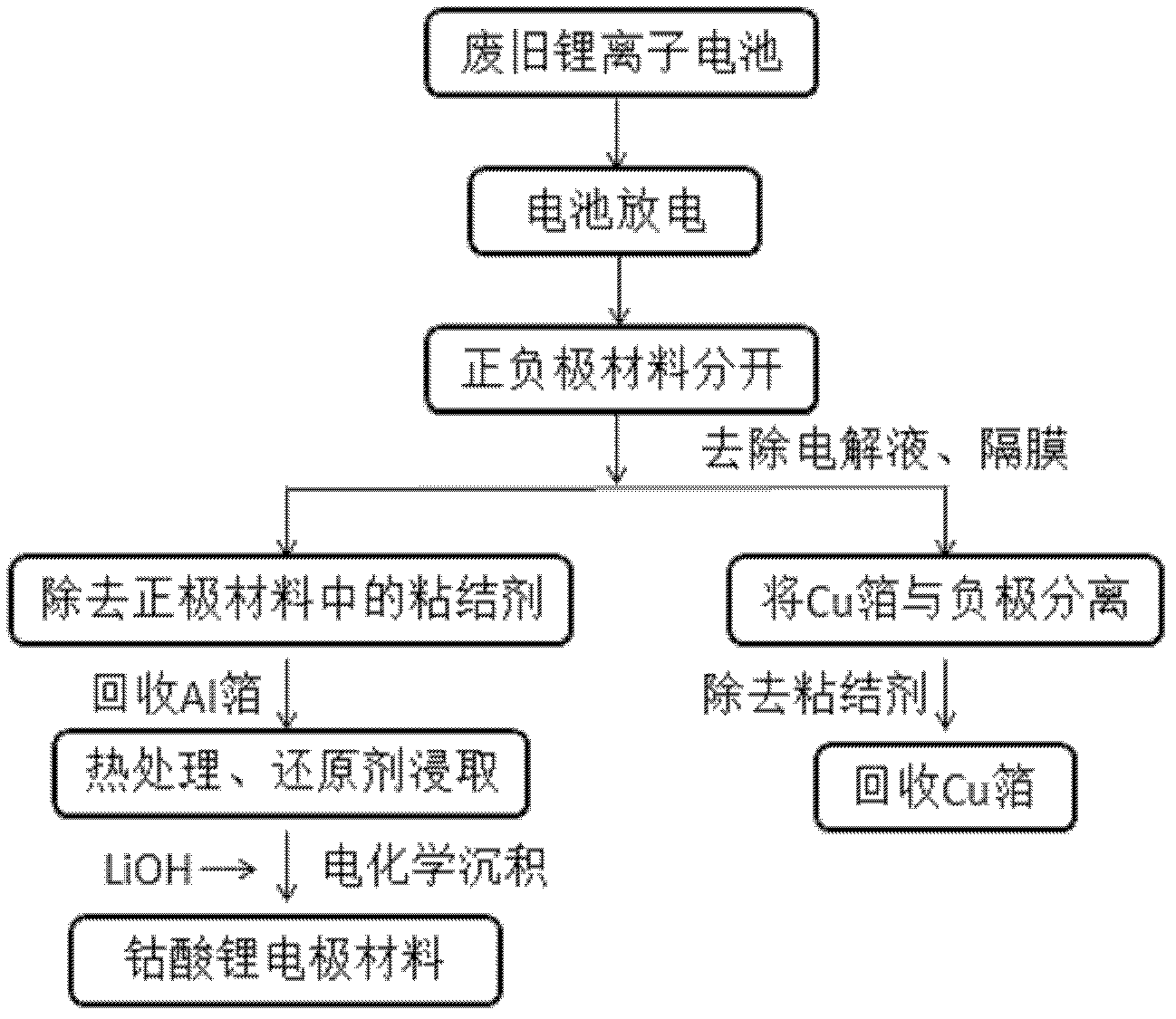

Method for recovering and regenerating positive electrode material of lithium ion battery

ActiveCN102382987ACause secondary pollutionReduce energy consumptionElectrolysis componentsWaste accumulators reclaimingFiltrationDecomposition

The invention relates to a method for recovering and regenerating a positive electrode material of a lithium ion battery and belongs to the technical field of recovery and circulating reuse of an electrode material. The method comprises the following steps: successively carrying out discharge, decomposition, an NMP (N-methyl-2-pyrrolidone) ultrasonic treatment and dissolution, filtration and firing on a waste lithium ion battery to obtain black solid powder; carrying out acid leaching on the black solid powder, and filtering to obtain a leachate solution containing Co<2+> and Li<1+>; and mixing the leachate solution with a LiOH solution to obtain electrolyte, stirring and reacting for 3-18 hours by using an electrochemical deposition technology at the constant current density of 5.0-9.0mA / cm<2> and the temperature of 30-90 DEG C, and directly synthesizing on a nickel substrate to obtain the regenerated lithium cobalt oxide positive electrode material, namely a regenerated positive electrode material of the lithium ion battery. By using the method, the recovery and regeneration of the lithium cobalt oxide positive electrode material of the waste lithium ion battery are realized; and the method has the advantages of low energy consumption, simple preparation process, short treatment period, obvious effect and no secondary environment pollution.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

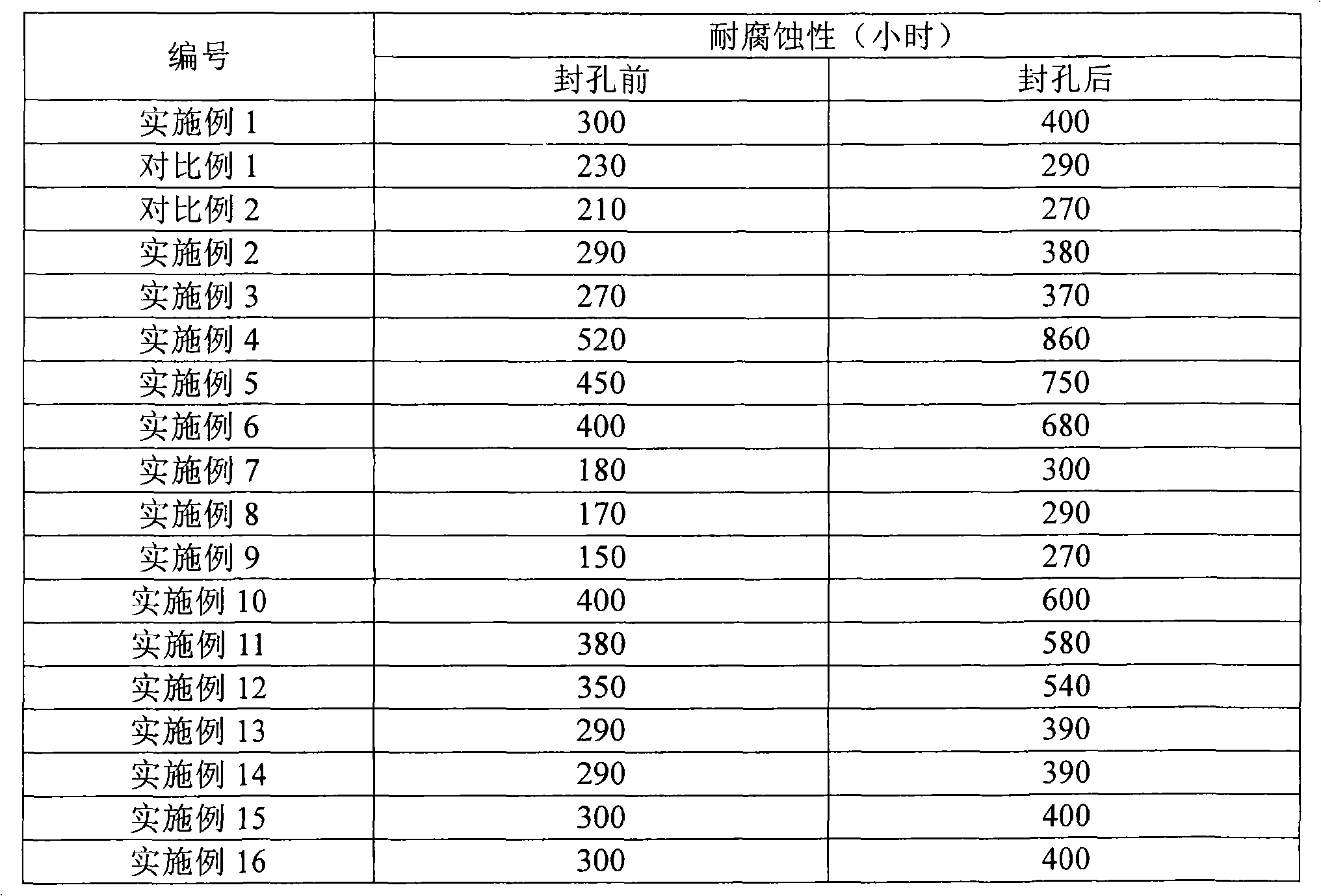

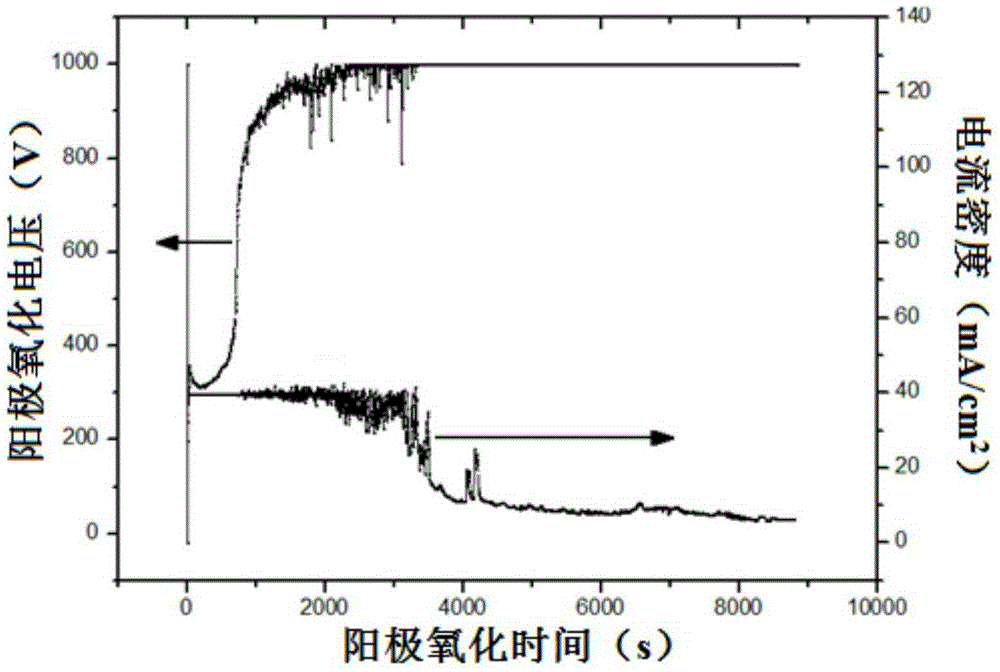

Anode oxidation method

The invention provides an anode oxidation method which comprises the following steps: under the anode oxidation condition, putting light metal material in electrolyte, using the light metal material as an anode, using the conducting material which does not react with the electrolyte as a cathode, and enabling the cathode and the anode to be respectively electrically connected with a positive electrode and a negative electrode of a power source. The anode oxidation comprises constant current density anode oxidation and constant voltage anode oxidation, wherein the current density of the constant current density anode oxidation is 0.5 to 6 amperes / square decimeter, and the voltage of the constant voltage anode oxidation is 20 to 400 volts. Compared with the light metal material which is processed by the prior anode oxidation method, the corrosion resistance of the light metal material which is processed by the anode oxidation method of the invention is greatly improved, and even the light metal material which is processed by the anode oxidation method of the invention is not post-processed by plugging, the corrosion resistance of the light metal material is also stronger.

Owner:HANGZHOU WIN WIN TECH CO LTD

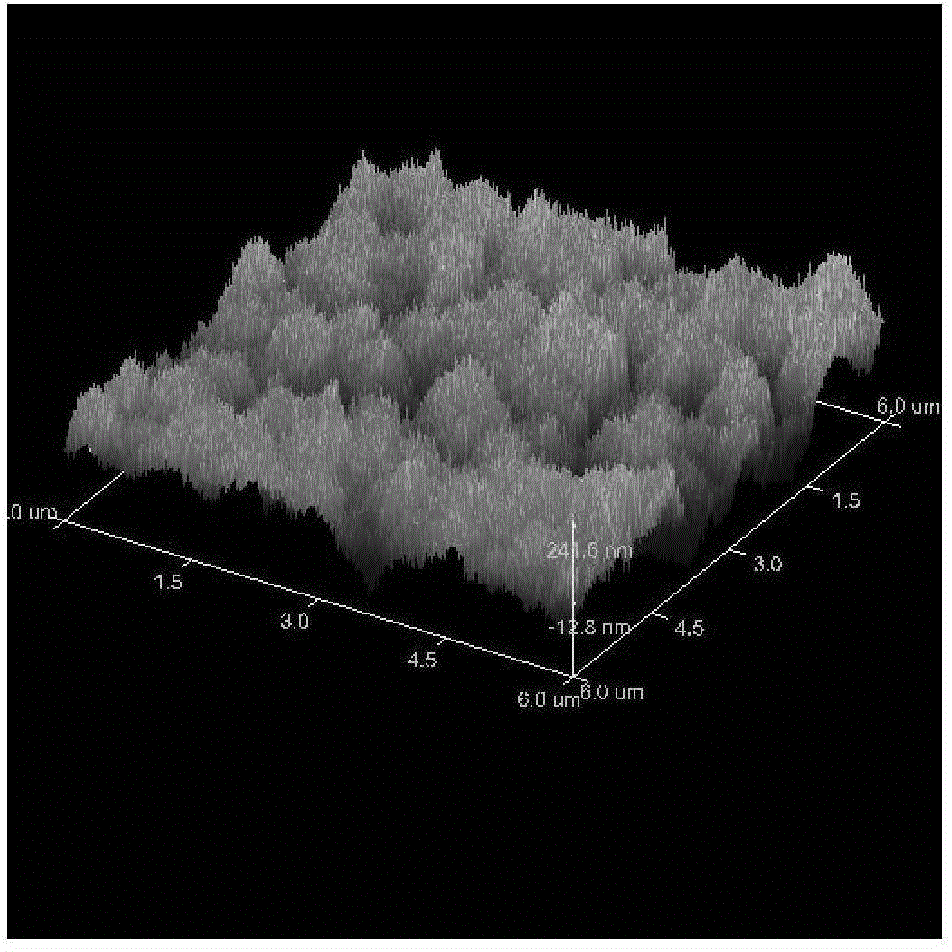

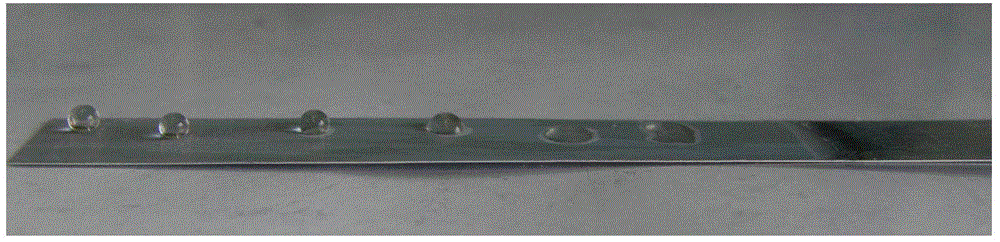

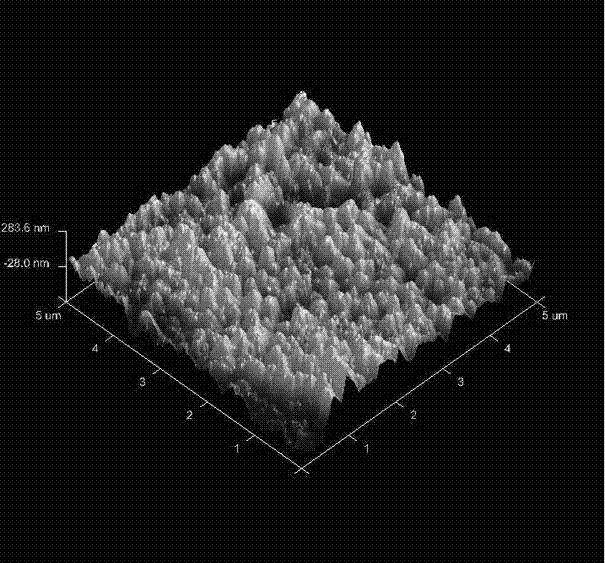

Preparing method for aluminum foil gradient wettability surface with nano coarse structure

The invention relates to a preparing method for aluminum foil gradient wettability surface with a nano coarse structure, which includes the steps as follows: stripped aluminum foil with the length of 5 to 20cm is ultrasonically cleaned, dried and immersed in NaOH water solution to be treated; phosphoric acid and glycerol mixed water solution is taken as electrolyte to perform anodic oxidation at a room temperature and under a constant current density mode, so as to achieve the nano coarse surface of the aluminum foil; the aluminum foil is tilted in an open empty container with the nano coarse surface facing upward, and under the condition of room temperature, the fluoroalkyl silane ethanol solution with the volume fraction of 0.14 to 0.24% is dripped in with the uniform velocity of 2.5 to 7.5ml / min within the time of 15 to 25min; and the aluminum foil taken out of the container is placed in a drying oven of 60 degrees C for 15min, then the gradient wettability of the nano coarse surface of the aluminum foil can be achieved, the gradient covering length is 5 to 15cm, the contact angle can be uniformly reduced from 155 degrees to lower than 5 degrees, and the progressive reducing amplitude is 10 to 30 degree / cm.

Owner:SOUTHEAST UNIV

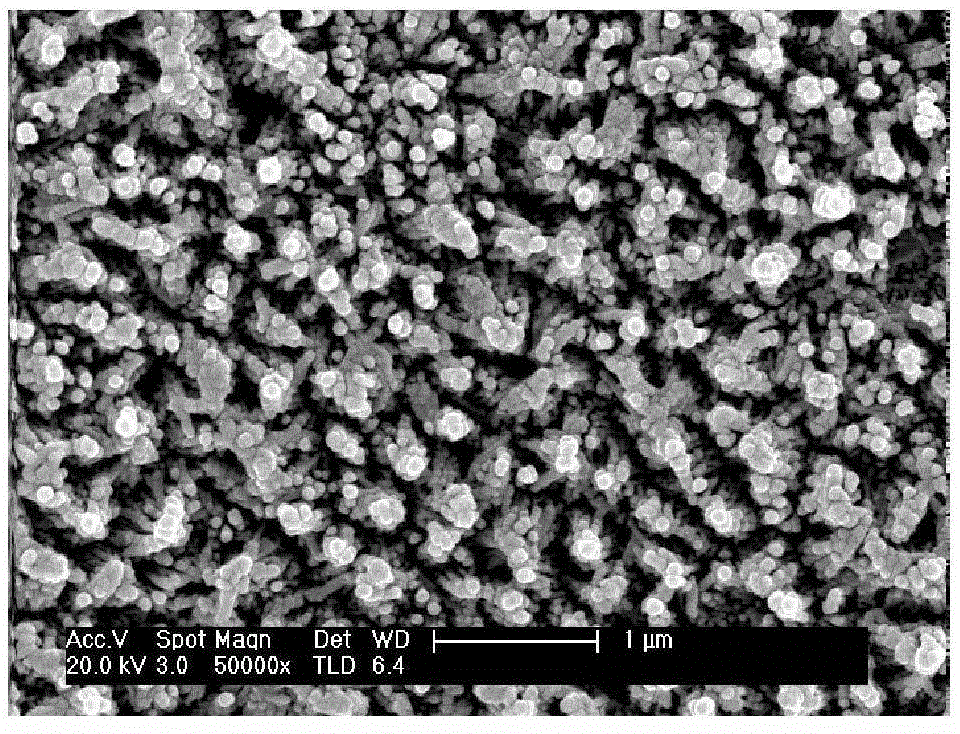

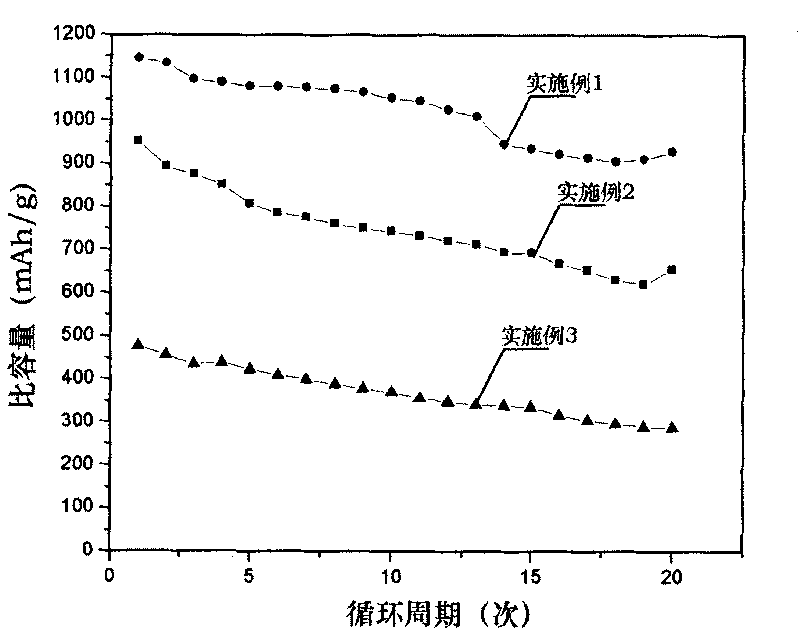

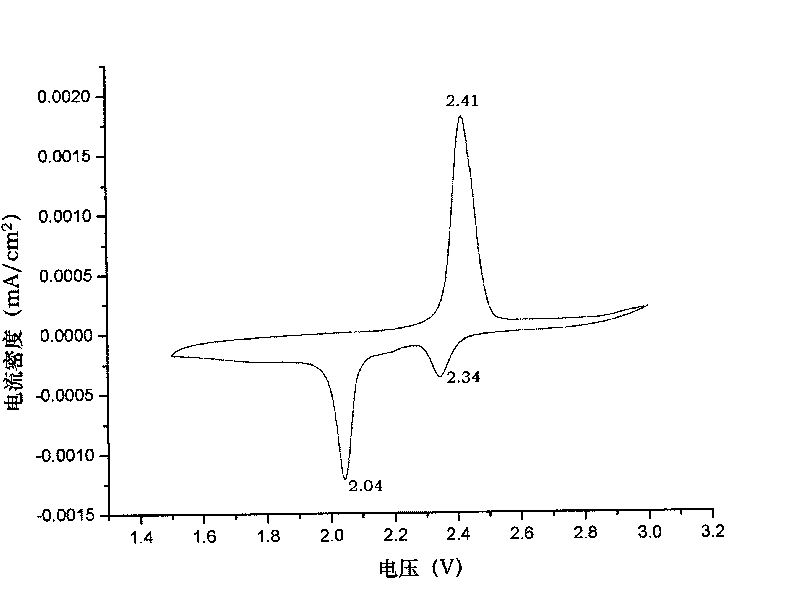

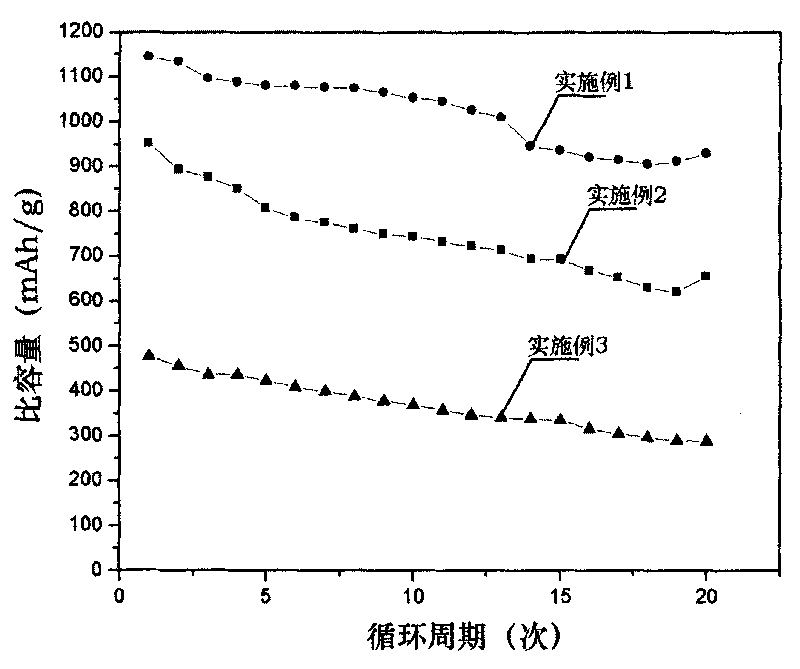

Preparation method of vulcanized conducting polymer composite anode for lithium ion battery

InactiveCN101740758AImprove conductivityHigh specific capacityCell electrodesPolymer scienceElectrical battery

The invention discloses a preparation method of a vulcanized conducting polymer composite anode for a lithium ion battery. In the method, a conducting polymer of polyaniline-pyrrole is used as a main substrate, sulphur is a main active substance, the simple substance of sulphur and the conducting polymer of polyaniline-pyrrole are compounded at different temperatures by using a co-hot method, and the granularity of the powder can reach a micron size, a submicron size and a nanometer size. The anode material prepared by the method has the initial discharge capacity of 1144 mAh / g under the conditions that the constant current density is 0.2 mA / cm<2>, the charging voltage upper limit is 3.0 V, and the charging voltage lower limit is 1.5 V, and the specific capacity still maintains 929 mAh / g after 20 times of circulation. It can be seen from a CV curve that the vulcanized conducting polymer composite anode material at 250 DEG C has high capacity reversibility and favorable cyclical stability.

Owner:BEIHANG UNIV

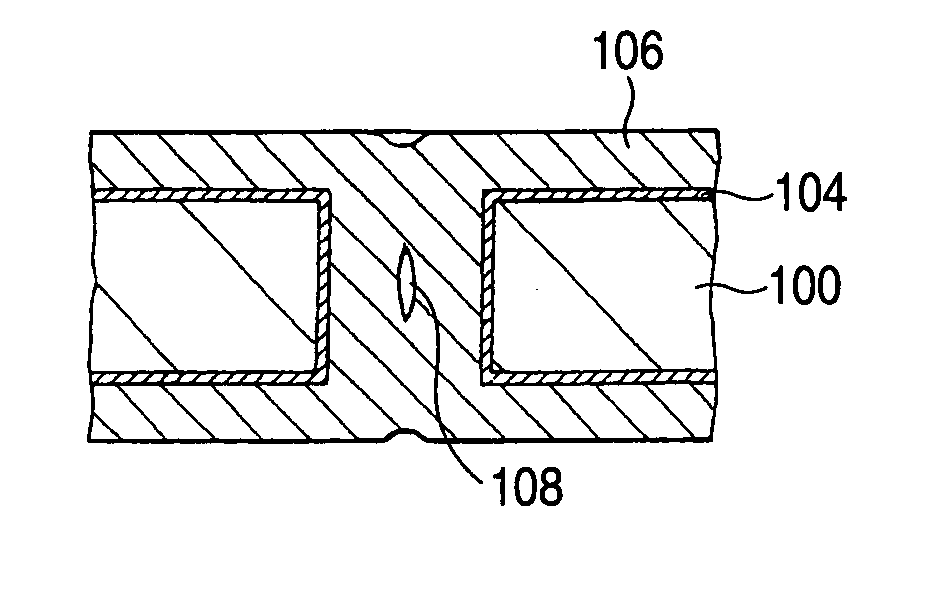

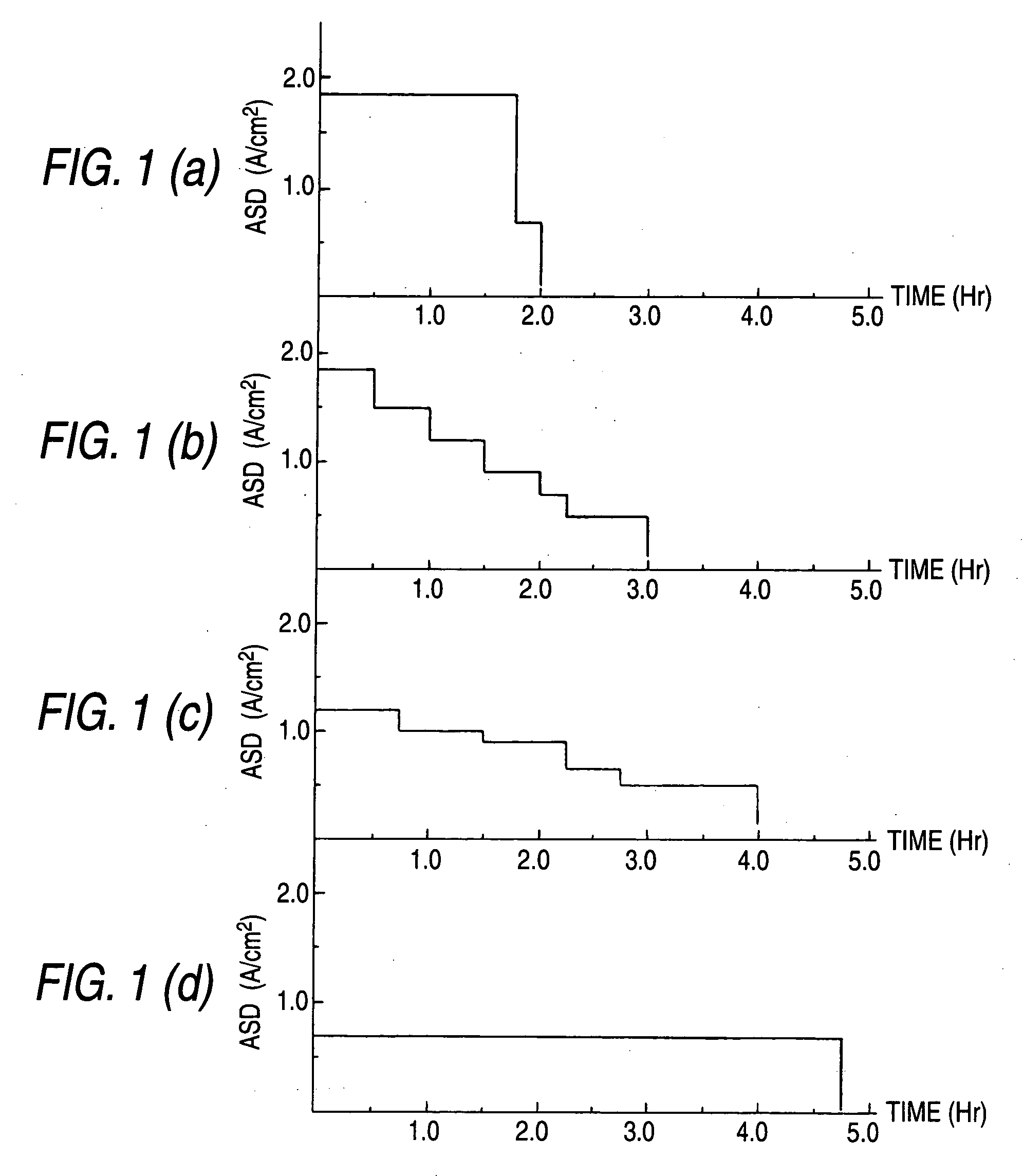

Method for filling through hole

InactiveUS20070170065A1Shorten the timeEasy to use industriallyTanksPrinted circuit aspectsHigh current densityElectrolysis

It is characterized in that in the case of filling a through hole formed in a substrate with a plated metal by electrolytic plating, the electrolytic plating is started by a high current density higher than Constant Current Density capable of fully filling the through hole when the electrolytic plating is performed with a current density held constant as a current density of the electrolytic plating, and the electrolytic plating is continued by being changed to a current density lower than the high current density by the time of reaching formation of a seam diameter in which an inside diameter does not decrease even when the electrolytic plating is continued after the electrolytic plating at the high current density is started.

Owner:SHINKO ELECTRIC IND CO LTD

Method for manufacturing high quality aluminum oxide photon crystal

InactiveCN101220510ADeep optical bandgapEasy to operateAnodisationPolycrystalline material growthNano structuringConstant current density

The invention discloses a preparing method of high quality alumina photonic crystal, and the main steps of the method are as follows: an aluminum sheet, the alumina of which is dissolved by surface treatment, is treated with anodic oxidation by high constant current density first and low constant current density then, and the step is repeated, and high quality alumina photonic crystal can be obtained. As the current density is modulated periodically, the nano structure of alumina formed on the surface of the aluminum sheet changes periodically, thus forming periodical porous structure which has the periodical dielectric structure of alumina and air, therefore, the matter has the property of photonic crystal. The method has the advantages of convenient operation and low production cost, and can produce high quality one-dimensional photonic crystal of large area, and the produced photonic crystal has controllable layer number and controllable depth and position of band gap, and has deeper optical band gap on the same number of photonic crystal layers, therefore the invention has wide application prospect in the field of manufacturing optical devices.

Owner:WUHAN UNIV

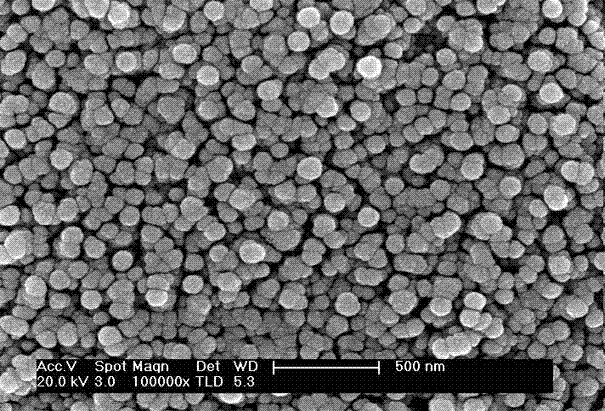

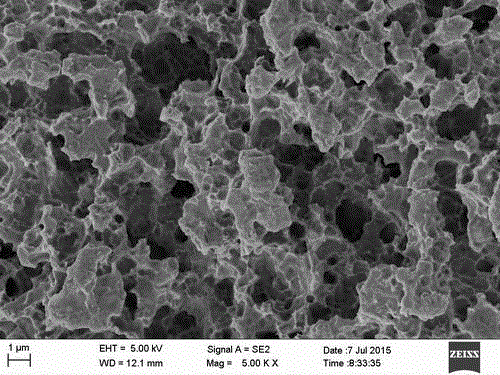

Preparation method of porous copper full-impregnated film of three-dimensional network structure

The invention relates to a preparation method of a porous copper full-impregnated film of a three-dimensional network structure. The method comprises the following steps that (1), a basic plating solution is prepared, wherein the basic plating solution comprises 1.0mol / L of H2SO4 and 0.2mol / L of CuSO4; (2), electrochemical deposition is carried out, wherein in a depositing cell, a graphite sheet serves as a positive electrode, aluminum foil serves as a negative electrode, the basic plating solution serves as electrolytes, and an electrochemistry working station is used for carrying out constant-current density electrolytic deposition to form the porous copper film on the aluminum foil; (3), vacuum annealing treatment is carried out on the porous copper film on the aluminum foil; (4), an aluminum substrate is removed, wherein aluminum foil obtained after vacuum annealing treatment is placed in alkali liquor to have a reaction, the aluminum foil is removed, and the porous copper full-impregnated film of the three-dimensional network structure is obtained. Compared with the prior art, the porous copper full-impregnated film of the three-dimensional network structure is even in bore diameter and stable in structure and has the good filtering separation function, and meanwhile due to the large specific area, and the good toughness, the film can be used as a good catalyst carrier.

Owner:TONGJI UNIV

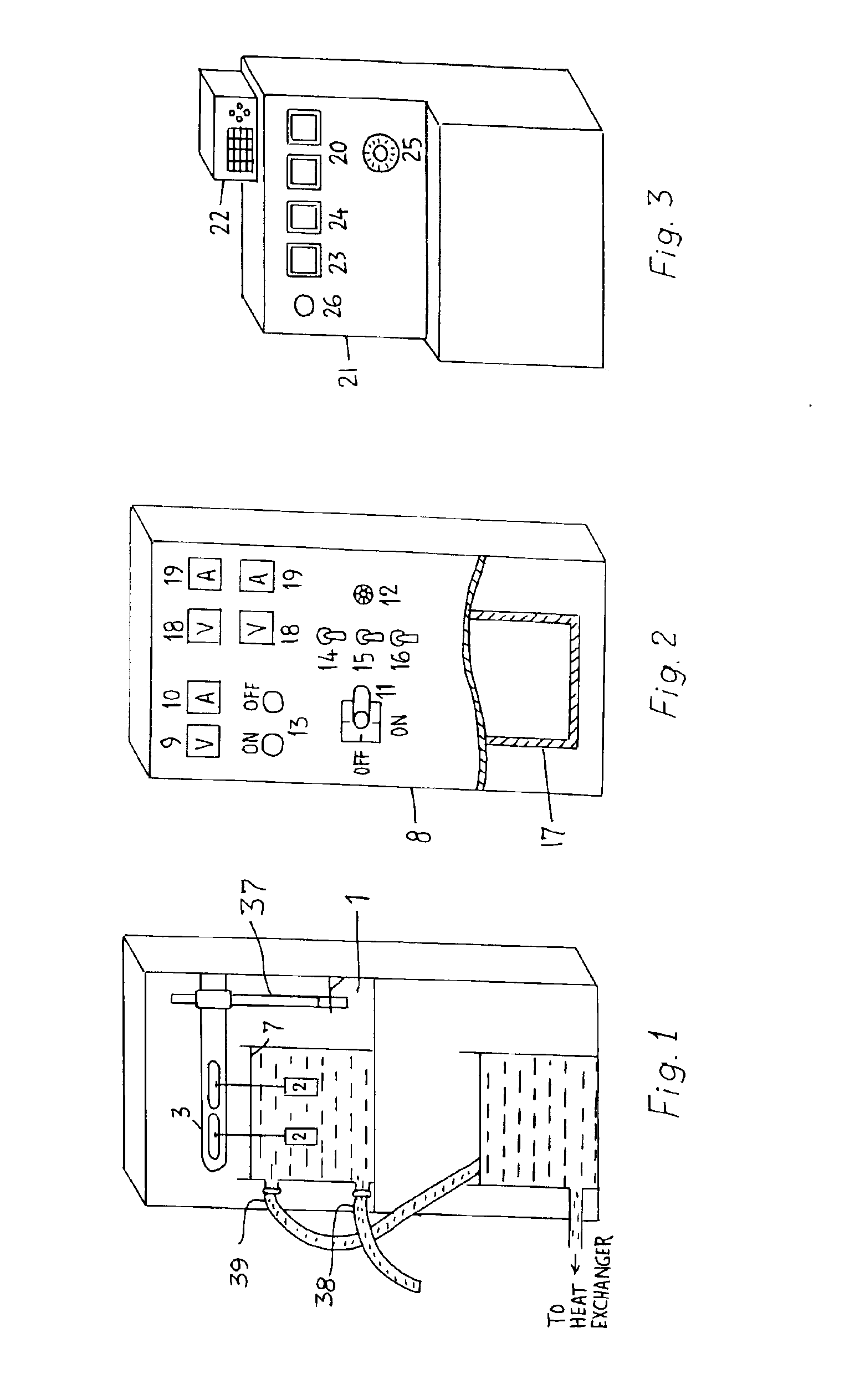

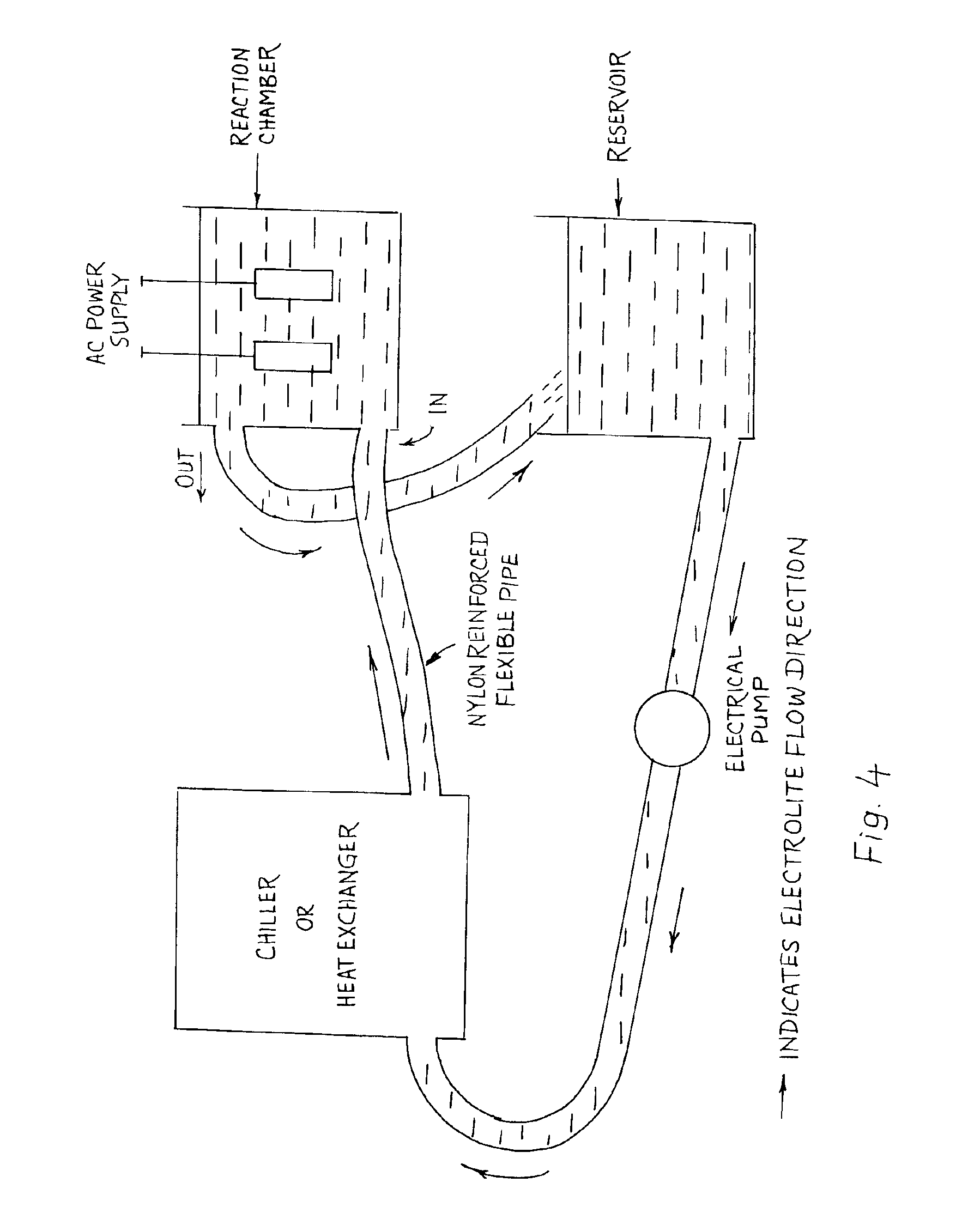

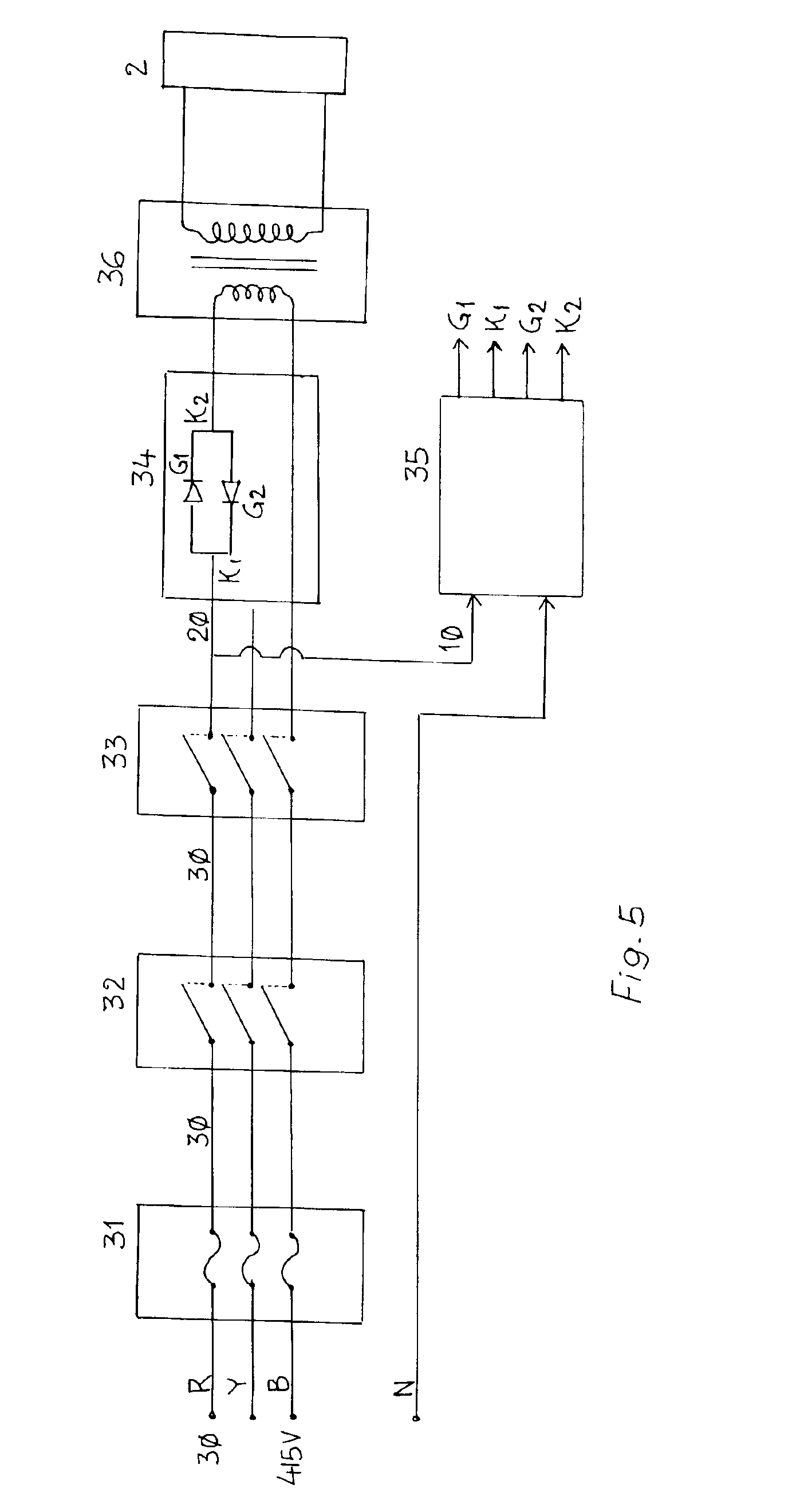

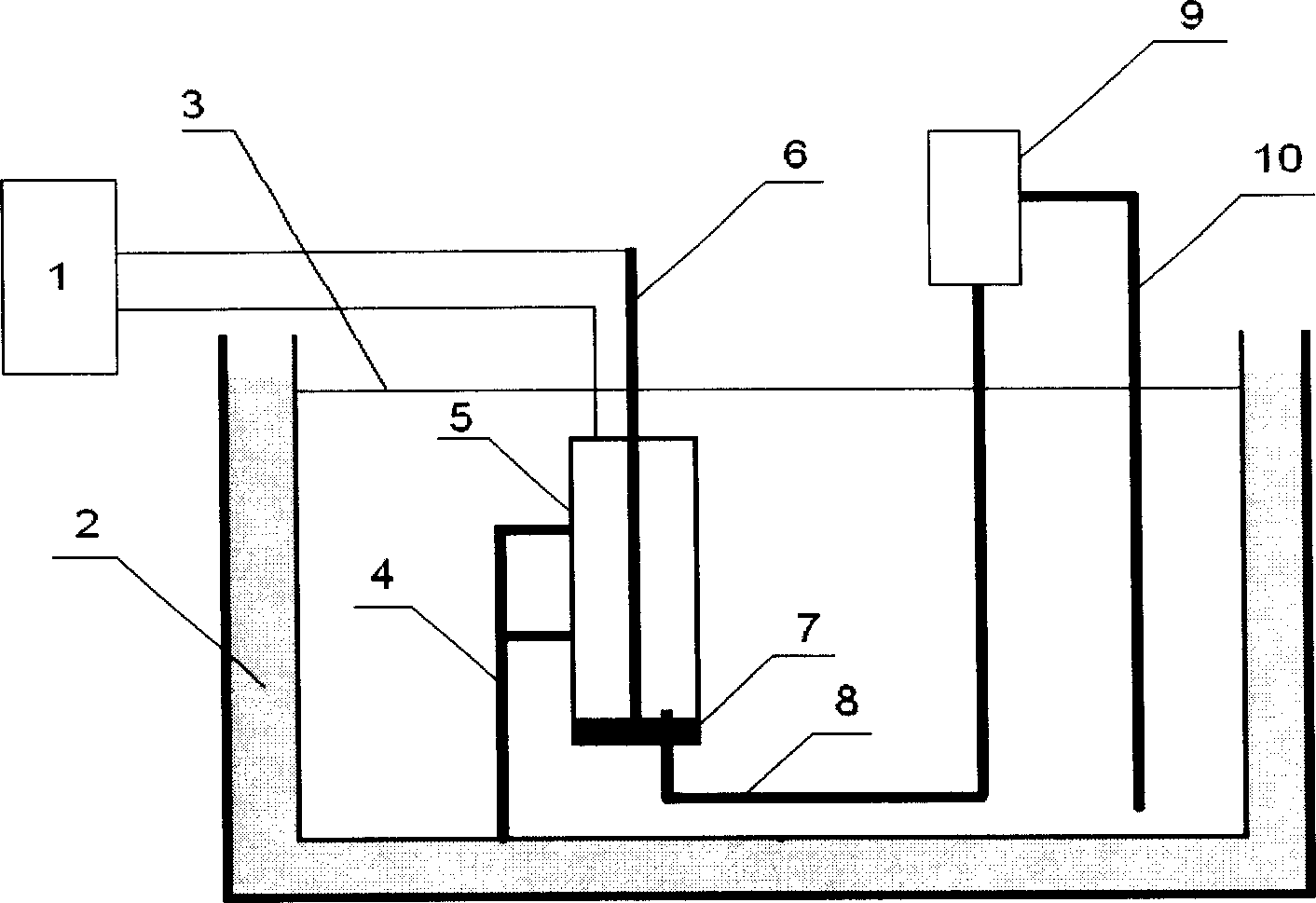

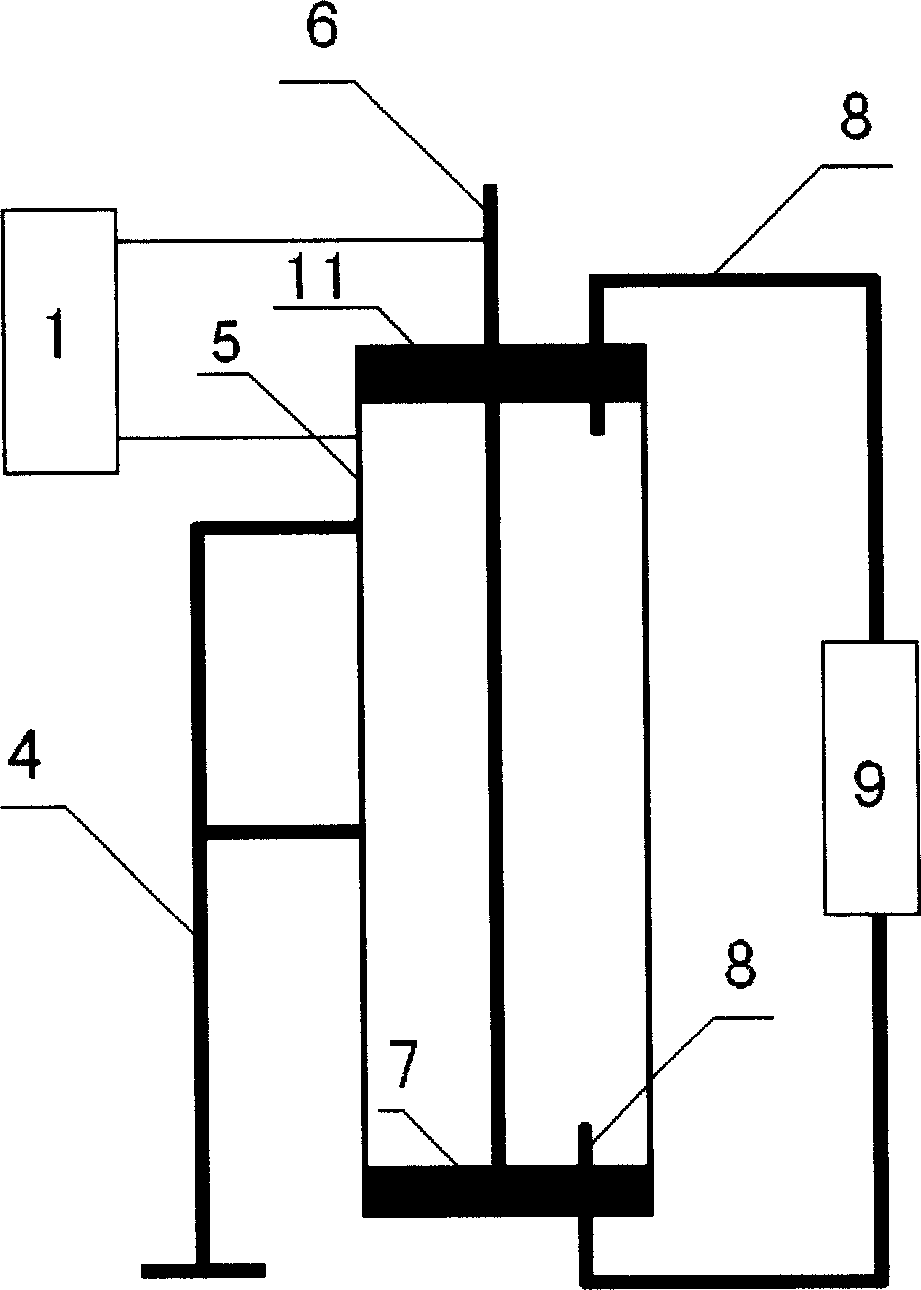

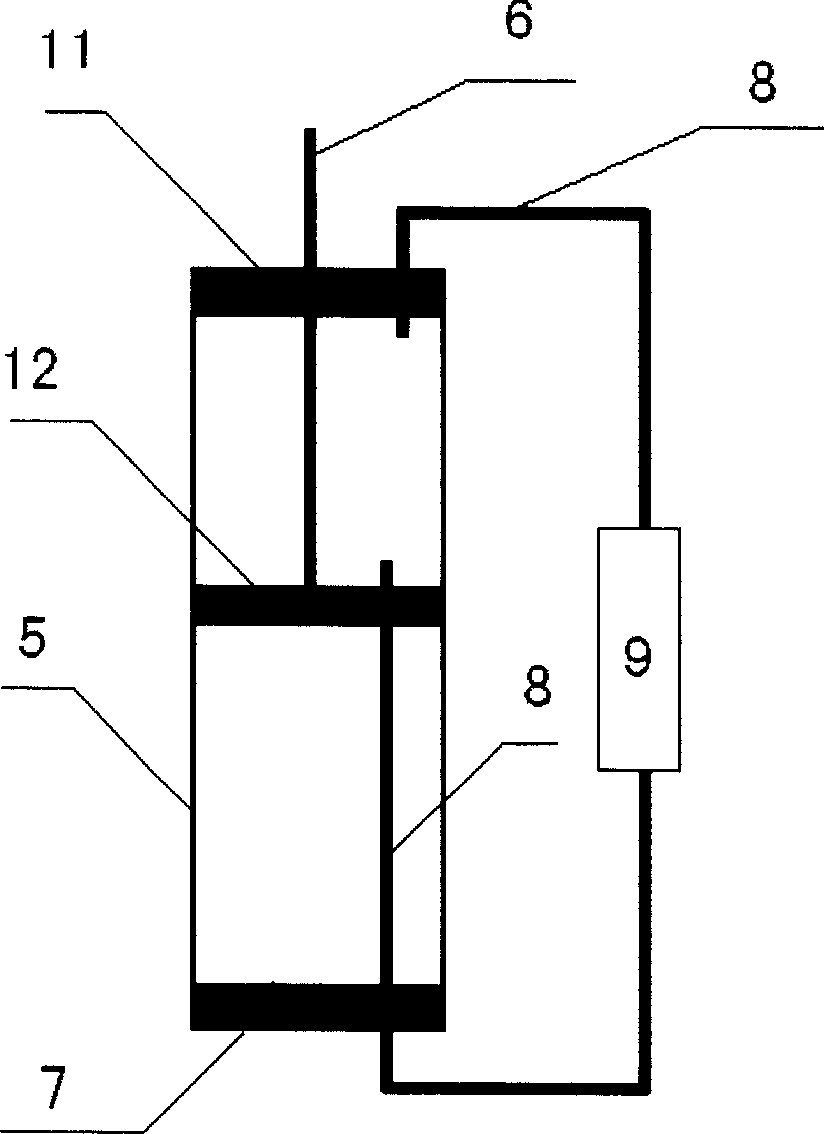

Process for forming coatings on metallic bodies and an apparatus for carrying out the process

InactiveUS6893551B2Protect the surfaceEconomical and simpleCellsAnodisationCeramic compositeVolumetric Mass Density

A process for forming oxide based dense ceramic composite coatings on reactive metal and allow bodies involves suspension of at least two reactive metal or alloy bodies in a non-metallic, non-conducting, non-reactive chamber in such a way that it causes either partial or full immersion of the bodies in a continuously circulating electrolyte. Thyristor controlled, modified shaped wave multiphase alternating current power supply is applied across the bodies where in each body is connected to an electrode. Electric current supplied to the bodies is slowly increased to a particular value till the required current density is achieved and the maintained at the same level throughout the process. Visible arcing at the surface of the immersed regions of the bodies is identified when the applied electric potential crosses 60V. Electric potential is further increased gradually to compensate the increasing resistance of the coating. Electrolyte composition is regulated through the changes in pH and conductivity of the electrolytic solution, Thickness of the coating formed on the bodies is monitored by the time for which the electrical power at constant current density is supplied to the bodies. The contains obtained are found to exhibit higher density and excellent wear.

Owner:M S INT ADVANCED RES CENT FOR POWDER METALLURGY & NEW METERIALS ARCI

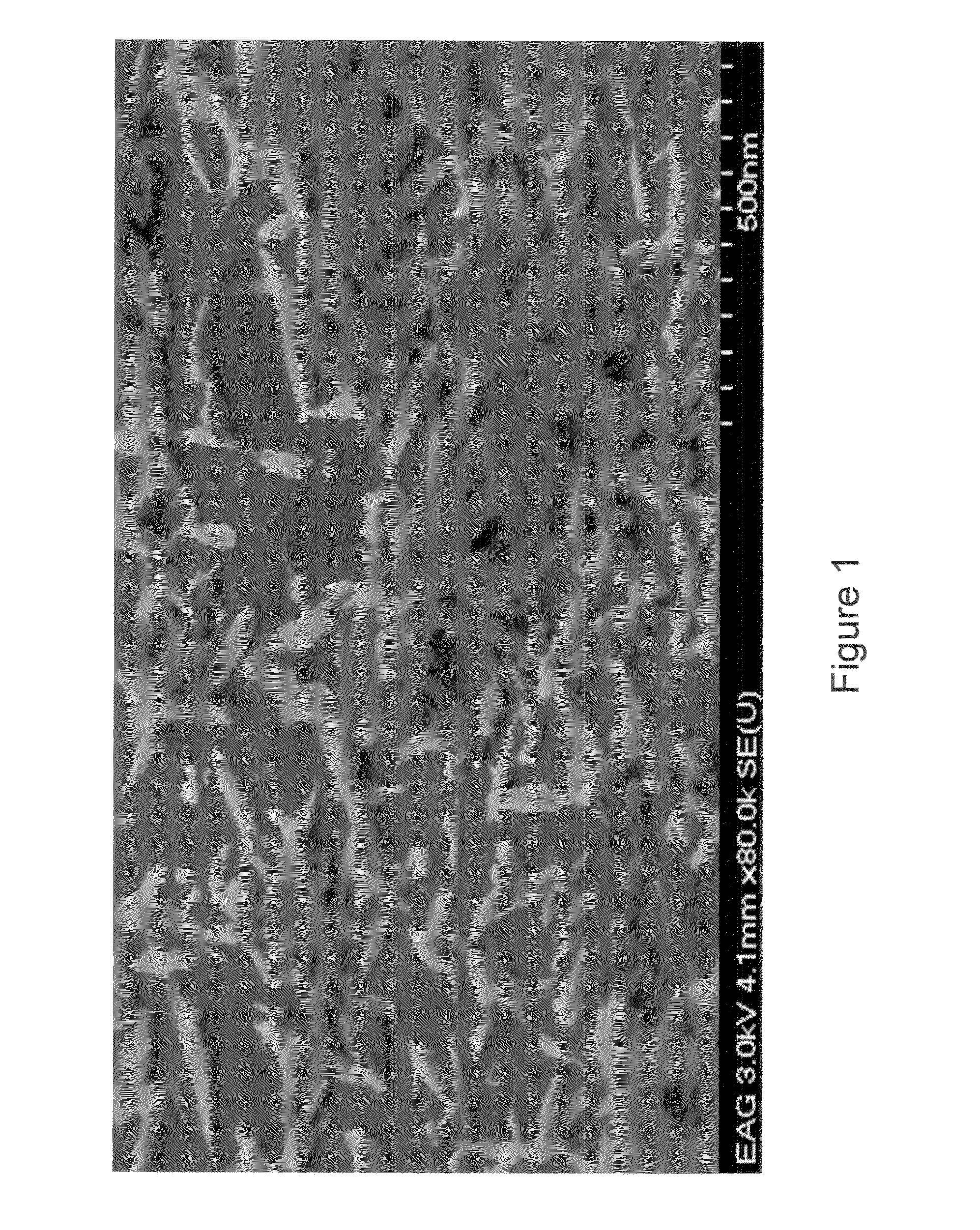

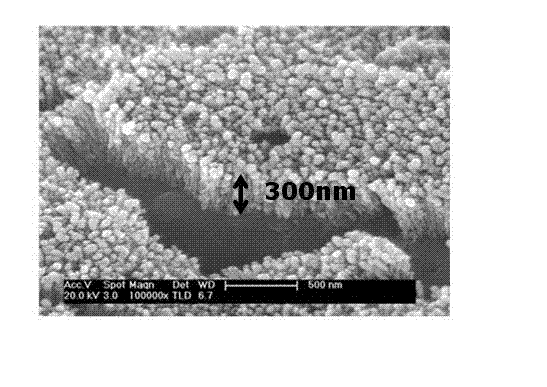

Methods of depositing discrete hydroxyapatite regions on medical implants

InactiveUS20110089041A1Enhanced in-growth capabilityFull mechanical loadability is achieved can be reducedElectrolytic inorganic material coatingElectrolytic organic material coatingCalcium biphosphatePhosphate ion

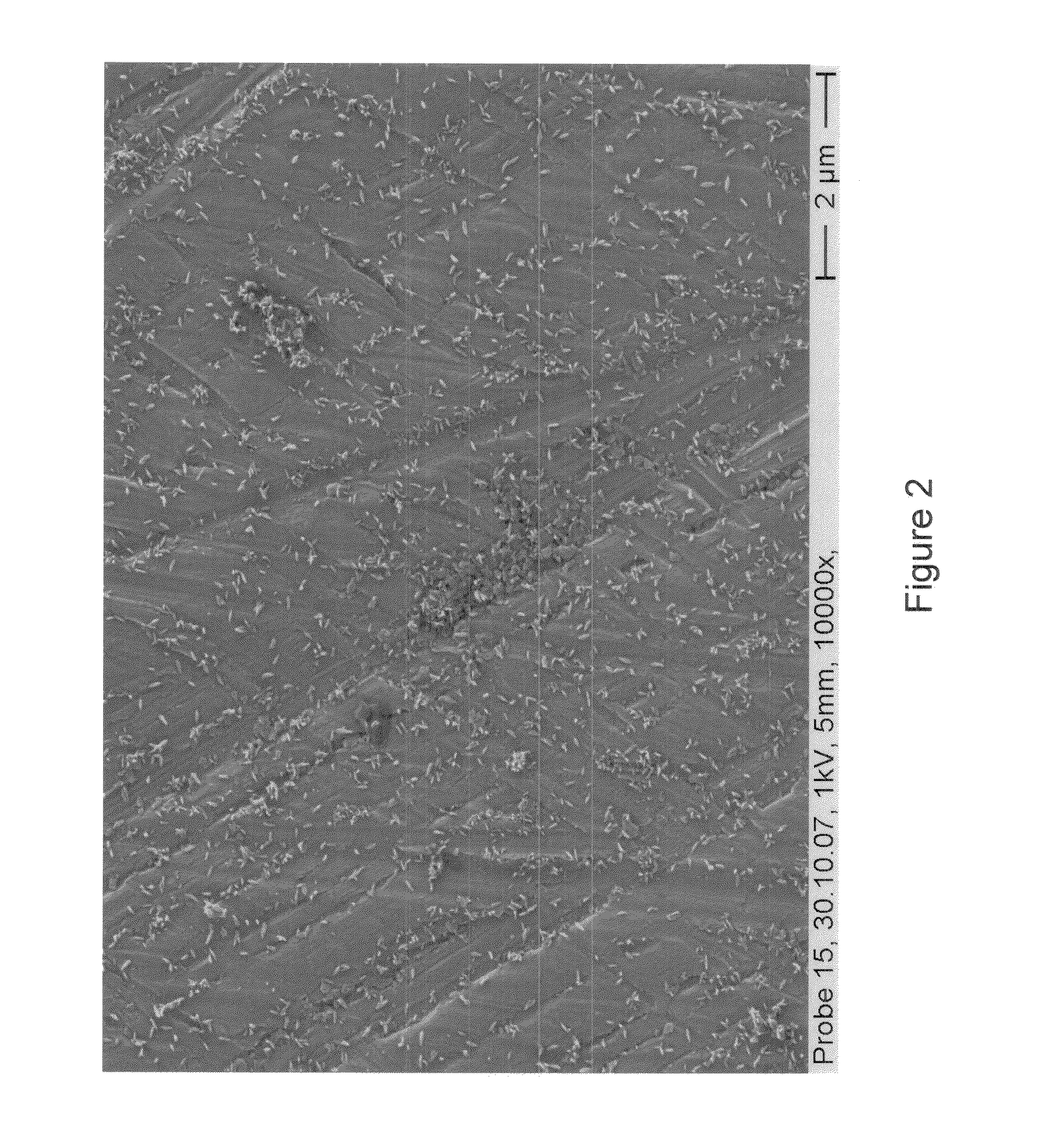

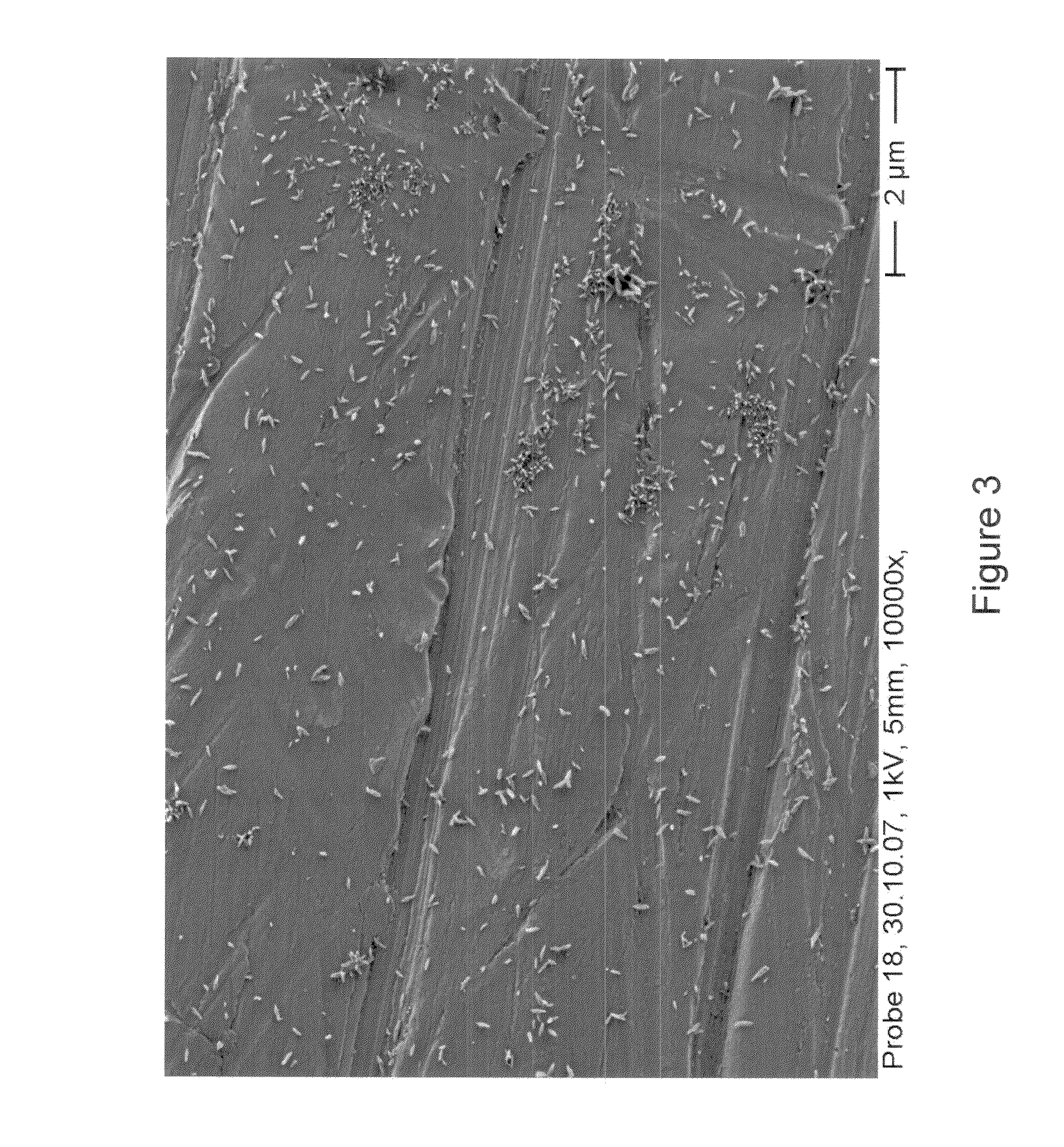

A method for electrochemically depositing discrete regions of calcium phosphate onto a medical implant. The method includes providing an implant including at least one area having a metallic surface. At least a portion of the metallic surface is contacted with an electrolyte solution comprising calcium ions and phosphate ions. The metallic surface is used as a cathode, and an electrical potential is applied between the cathode and the electrolyte solution. The electrical potential is applied with a constant current density of from about 10 to about 50 mA / cm2 for a period of time of from about 1 to about 20 minutes. A plurality of discrete regions of needle-shaped hydroxyapatite crystals are electrochemically deposited onto the metallic surface.

Owner:BIOMET MFG CORP

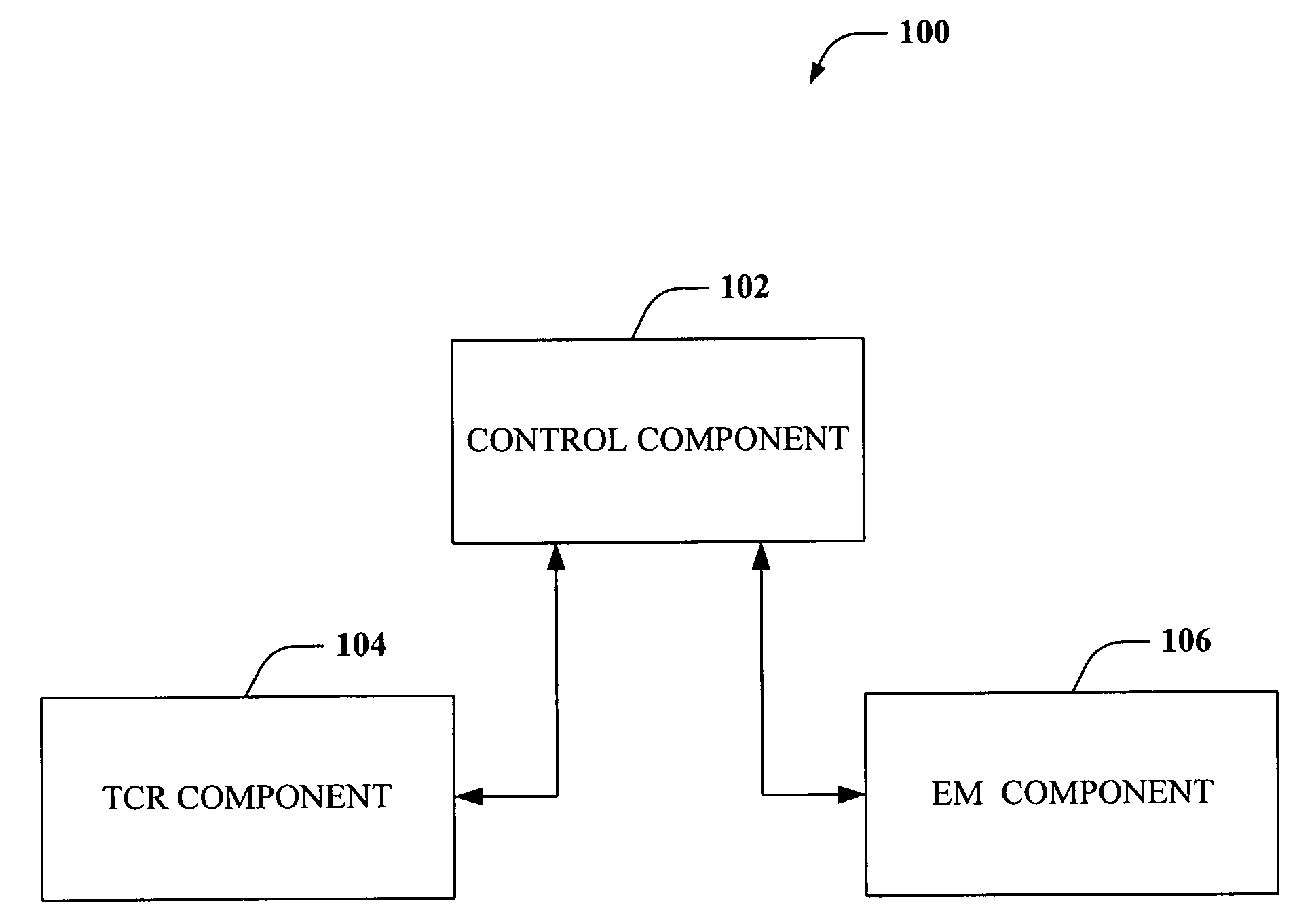

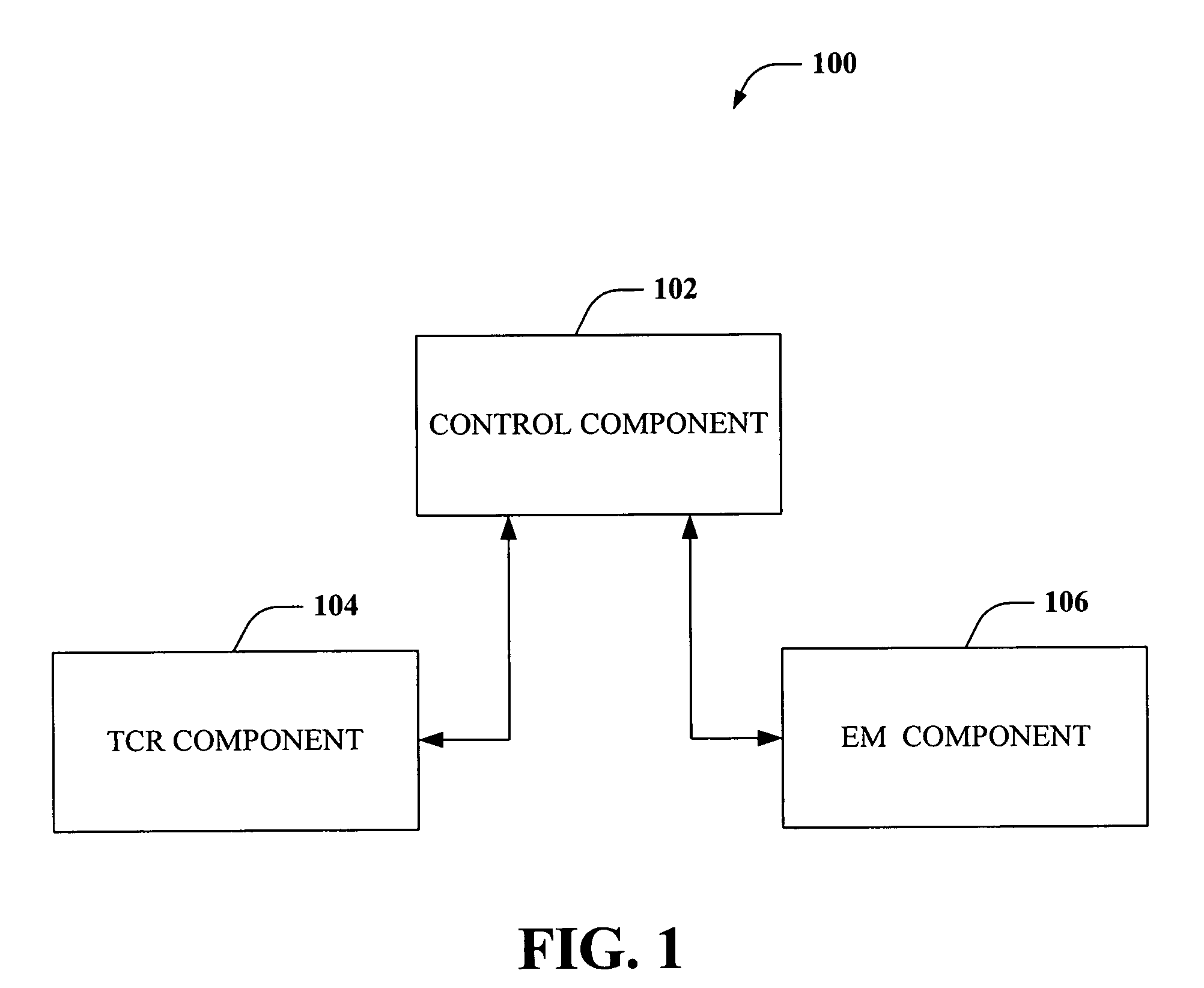

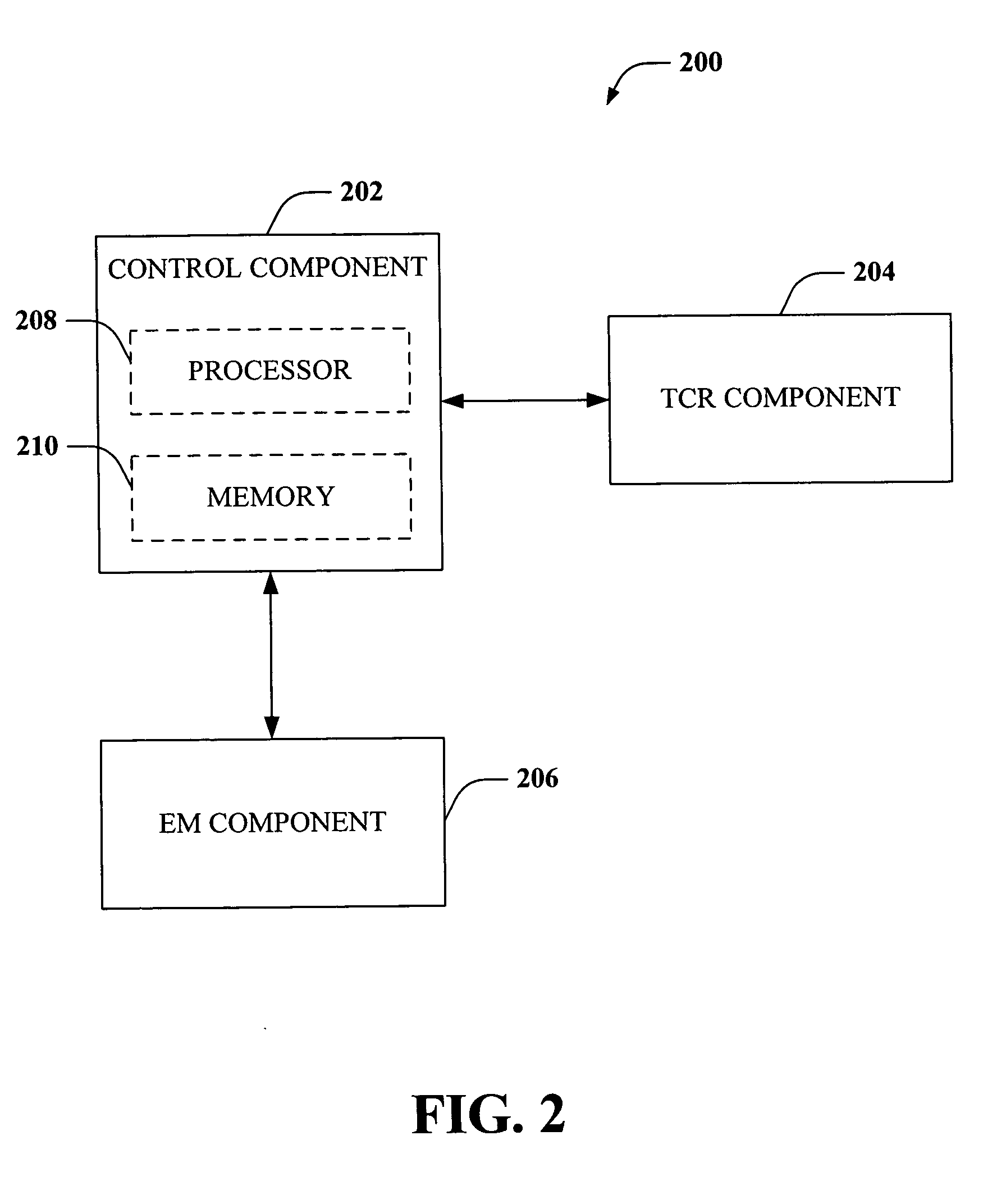

Predicting EM reliability by decoupling extrinsic and intrinsic sigma

InactiveUS7146588B1Improve isolationQuantify impactResistance/reactance/impedenceDetecting faulty computer hardwareWafer fabricationIntrinsics

Systems and methods are disclosed that facilitate predicting electromigration (EM) reliability in semiconductor wafers via decoupling intrinsic and extrinsic components of EM reliability. Electrical cross-sections of wafer test lines can be determined and individual currents can be forced through the test lines to force a constant current density across a test wafer. An EM reliability test can be performed to determine a purely intrinsic component of EM reliability. A single current can then be applied to all test lines and a second EM reliability test can be performed to determine total EM reliability. Standard deviations, or sigma, of failure distributions can be derived for each EM test. Intrinsic sigma can be subtracted from total sigma to yield an extrinsic sigma associated with process variation in wafer fabrication. Sigmas can then be utilized to predict EM reliability when process variations are adjusted, without application of a damaging package-level EM test.

Owner:ADVANCED MICRO DEVICES INC

Method for preparing aluminum alloy colored composite film

ActiveCN101831681AImprove performanceNot easy to decomposeAnodisationComposite electrolyteComposite film

The invention discloses a method for preparing an aluminum alloy colored composite film. The method comprises pretreatment and direct-current electrolytic coloring; the direct-current electrolytic coloring adopts composite electrolyte consisting of H2SO4, CuSO4, EDTA and water, wherein the H2SO4 is 1,000 to 1,200g / L, the CuSO4 is 200 to 300g / L, the EDTA is 40 to 55g / L, the balance is water, and the pH value of the solution is less than or equal to 4.5; the coloring is performed at the constant current density of 0.5 to 0.6A / cm<2> and the temperature of between 20 and 30 DEG C, and the area ratio of a cathode to an anode is (1.5-2): 1; and a direct-current anode oxidation step can be added before the direct-current electrolytic coloring. The method has the advantages of simple preparation process, safe production operation and low production cost; and the obtained colored film has good corrosion resistance, and meets the decorative requirement.

Owner:苏州盛泽科技创业园发展有限公司

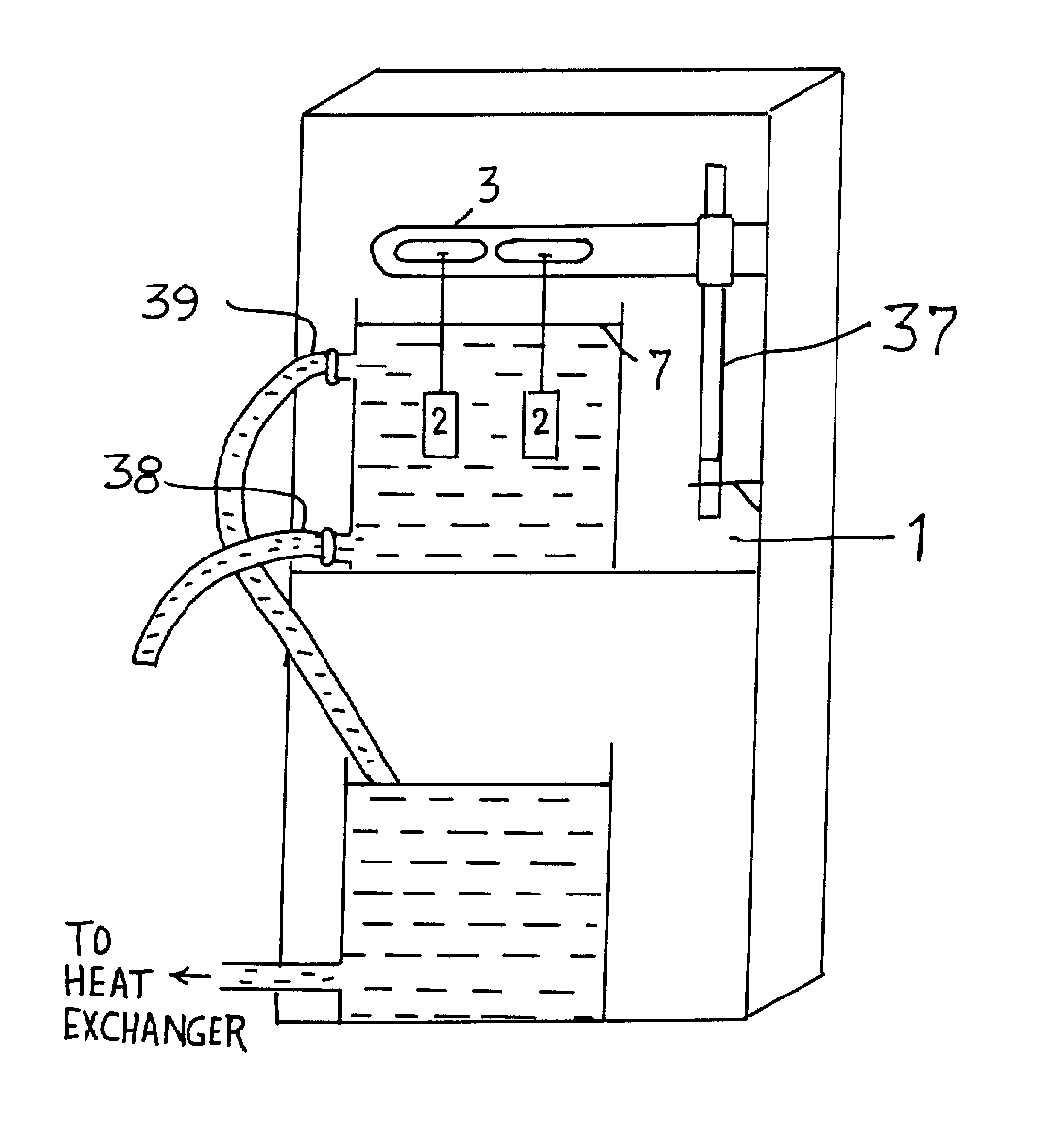

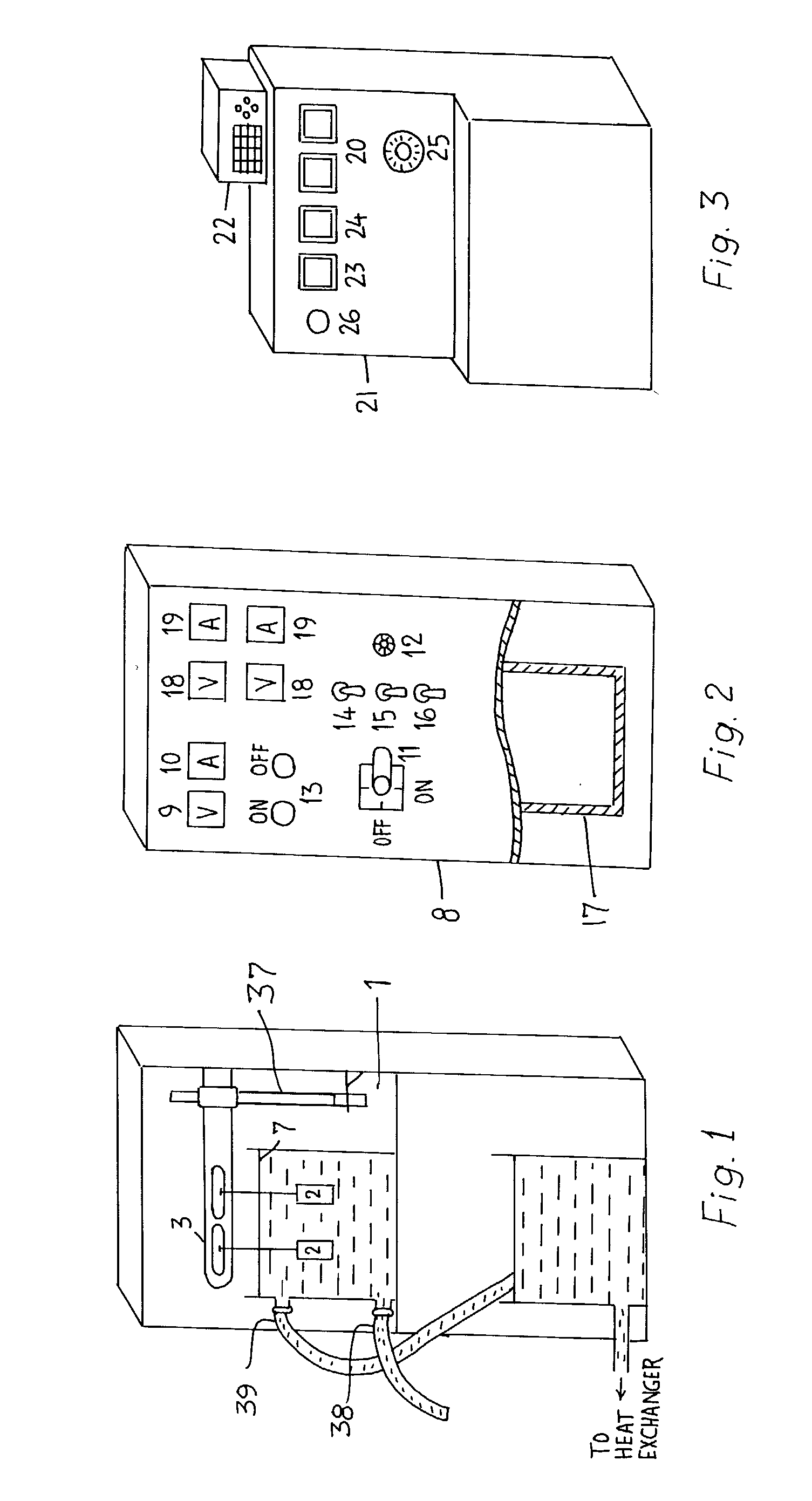

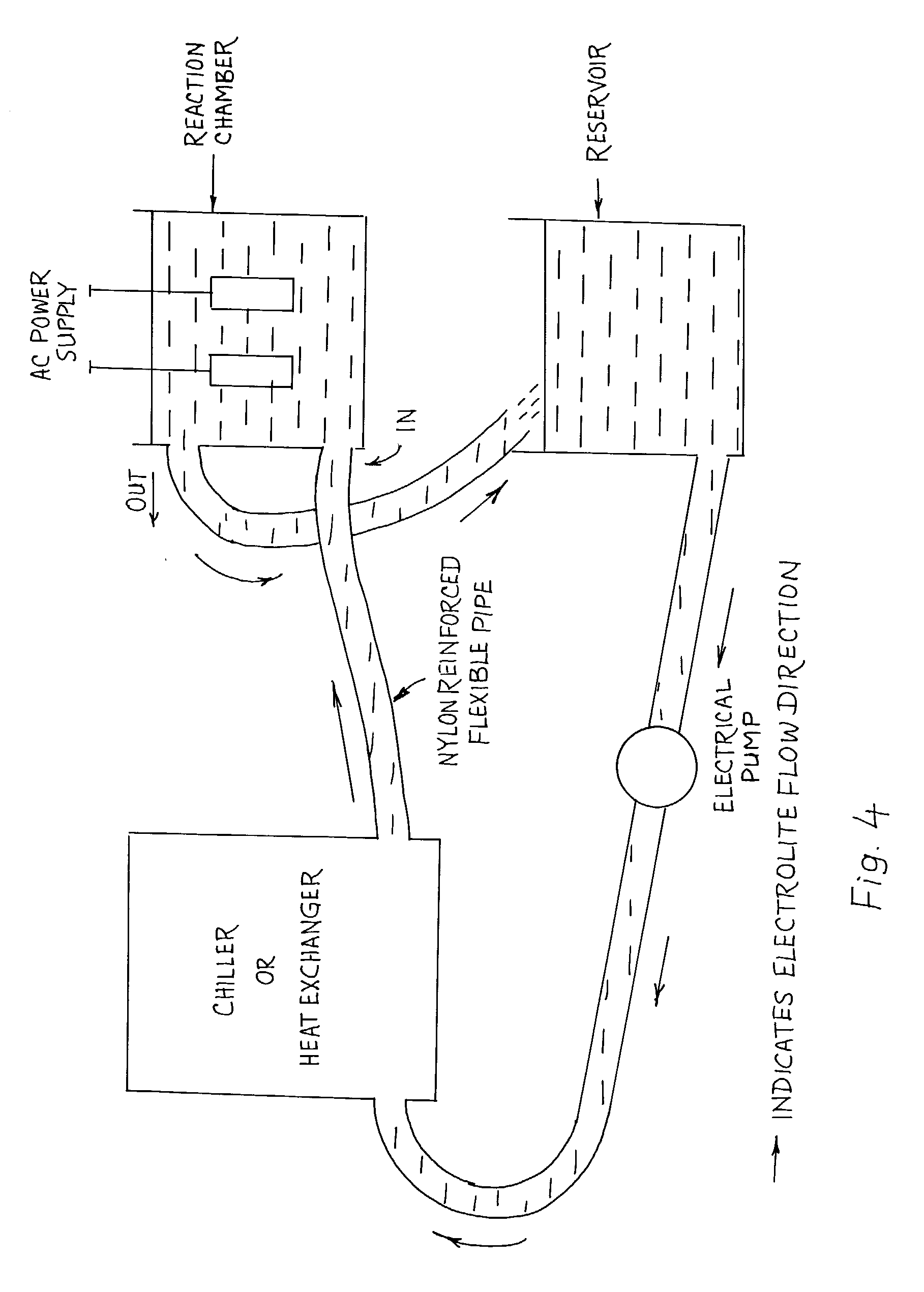

Process for forming coatings on metallic bodies and an apparatus for carrying out the process

InactiveUS20030094377A1Protect the surfaceEconomical and simpleCellsAnodisationCeramic compositeVolumetric Mass Density

This invention disclosed in this application relates to a process for forming oxide based dense ceramic composite coatings on reactive metal and alloy bodies. The process involves suspension of at least two reactive metal or alloy bodies in a non-metallic, non-conducting, non-reactive chamber in such a way that it causes either partial or full immersion of the said bodies in a continuously circulating electrolyte. Thyristor controlled, modified shaped wave multiphase alternating current power supply is applied across the said bodies where in each body is connected to an electrode. Electric current supplied to the said bodies where in each body is connected to an electrode. Electric current supplied to the said bodies is slowly increased to a particular value till the required current density is achieved and the maintained at the same level throughout the process. Visible arcing at the surface of the immersed regions of the said bodies is identified when the applied electric potential crosses 60V. Electric potential is furthr increased gradually to compensate the increasing resistance of the coating. Electrolyte composition is regulated through the changes in pH and conductivity of the electrolytic solution. Thickness of the coating formed on the said bodies is monitored by the time for which the electrical power at constant current density is supplied to the said bodies. The invention also relates to an apparatus for carrying out the above defined process. The coatings obtained according to the present invention are found to exhibit higher density and excellent wear resistance.

Owner:M S INT ADVANCED RES CENT FOR POWDER METALLURGY & NEW METERIALS ARCI

Pipe surface ceramizing treatment process

InactiveCN1706990ASolve the problem of ceramicizationAvoid influenceElectroforming processesPulsed DCMetallic materials

The surface ceramizing treatment process for pipe of non-valve metal or non-metal includes the following steps: 1. forming valve metal layer of 50-150 micron thickness in the inner and outer surface of the pipe through composite filming process; and 2. fixing electrode rod connected to negative pole of DC power source in the inner cavity of the pipe, connecting the pipe to the positive pole of the power source, soaking the pipe into alkali treating liquid inside treating tank, and maintaining constant current density to treat for proper period. The treatment process of the present invention is suitable for the surface ceramizing of pipe unsuitable for being ceramized in micro plasma process and has the problem of ceramizing the inner surface of pipe solved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

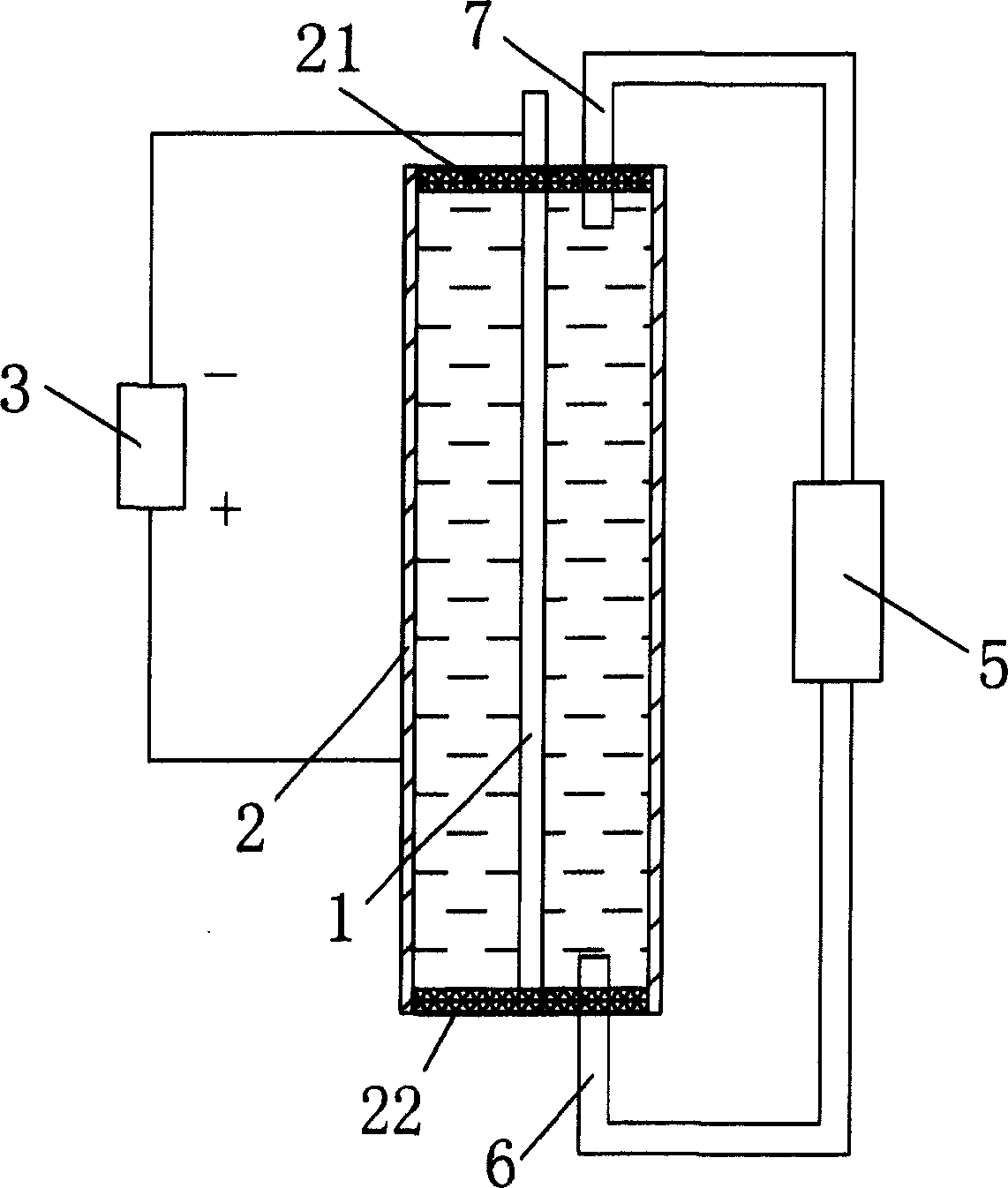

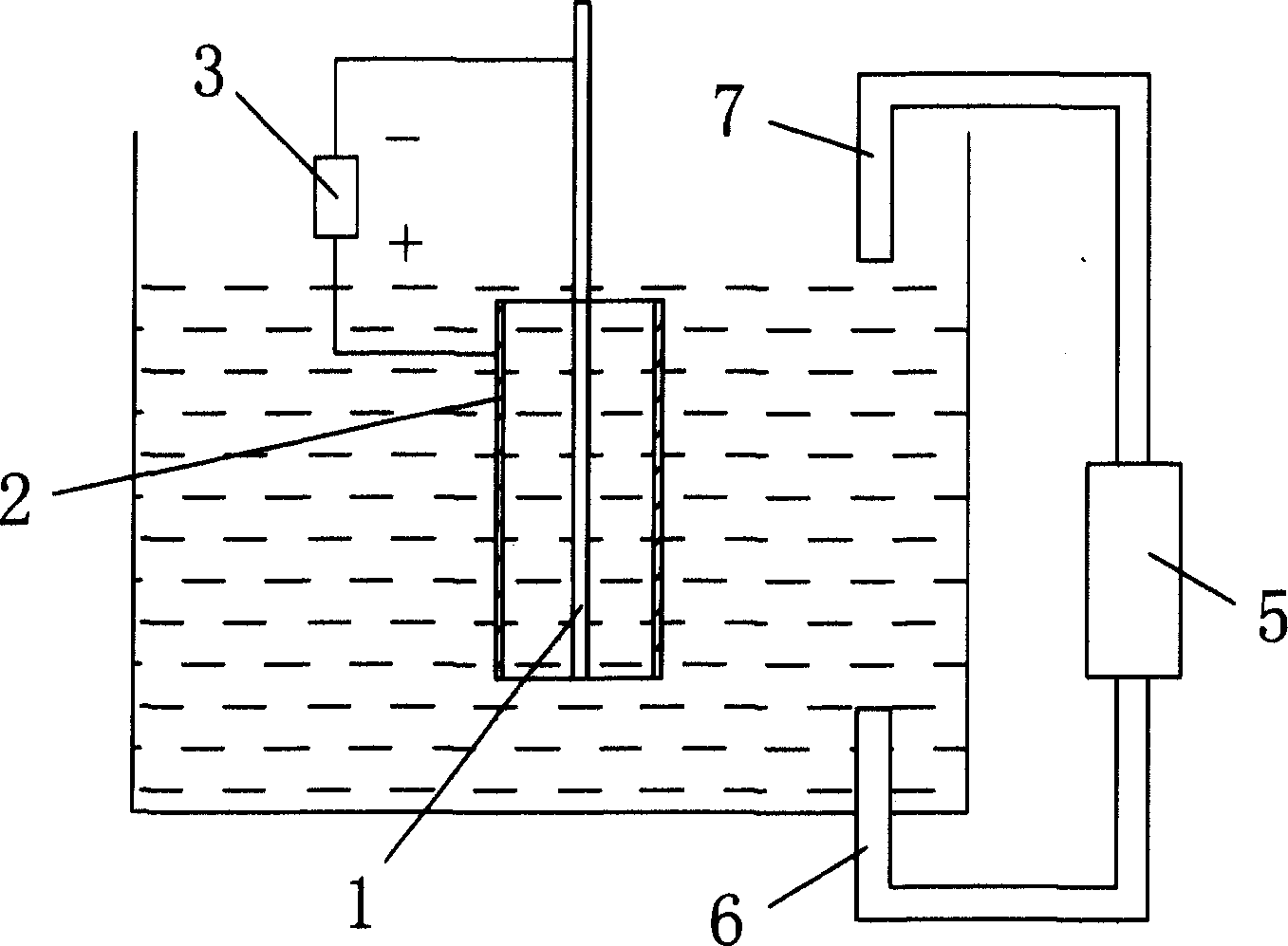

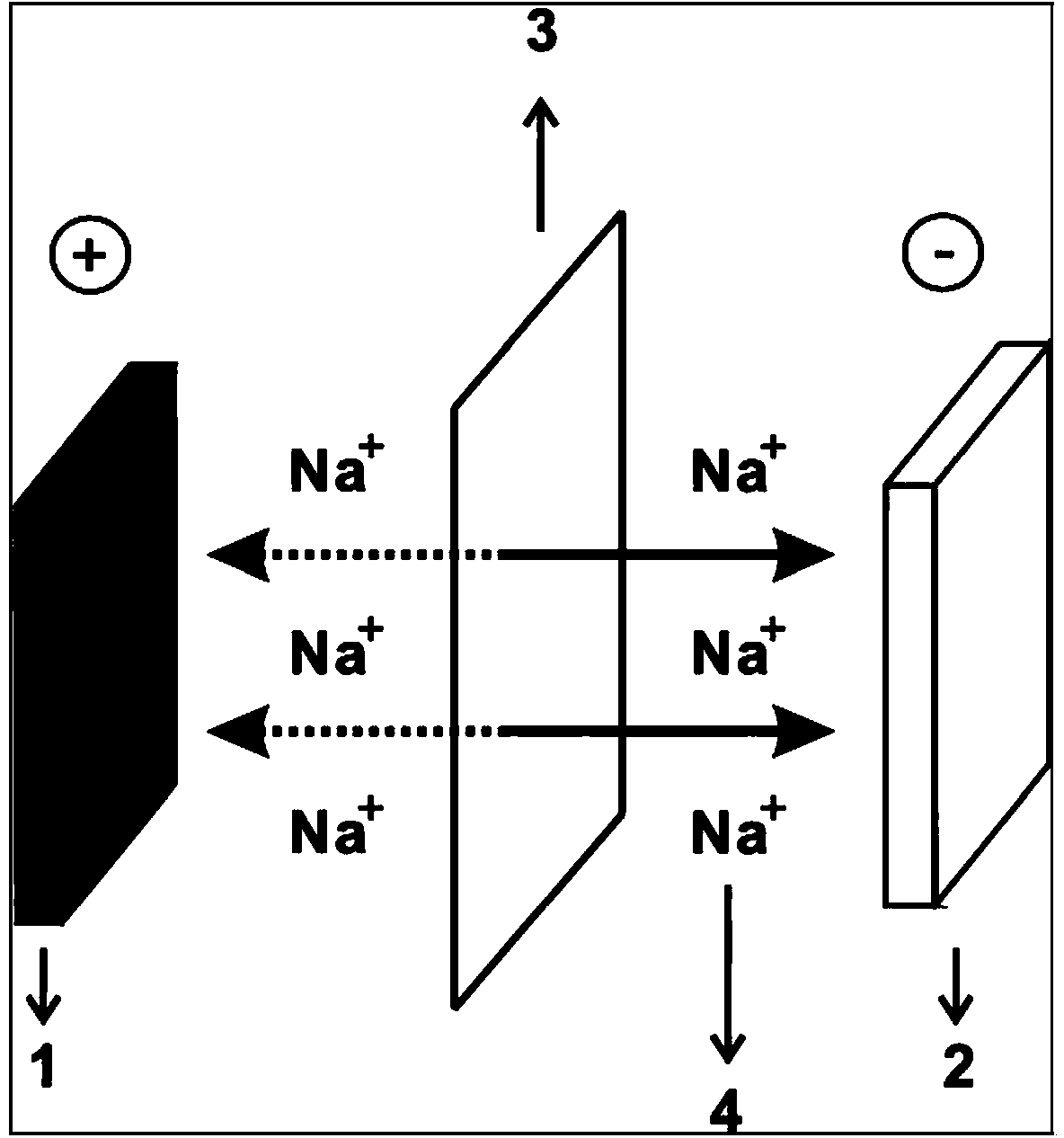

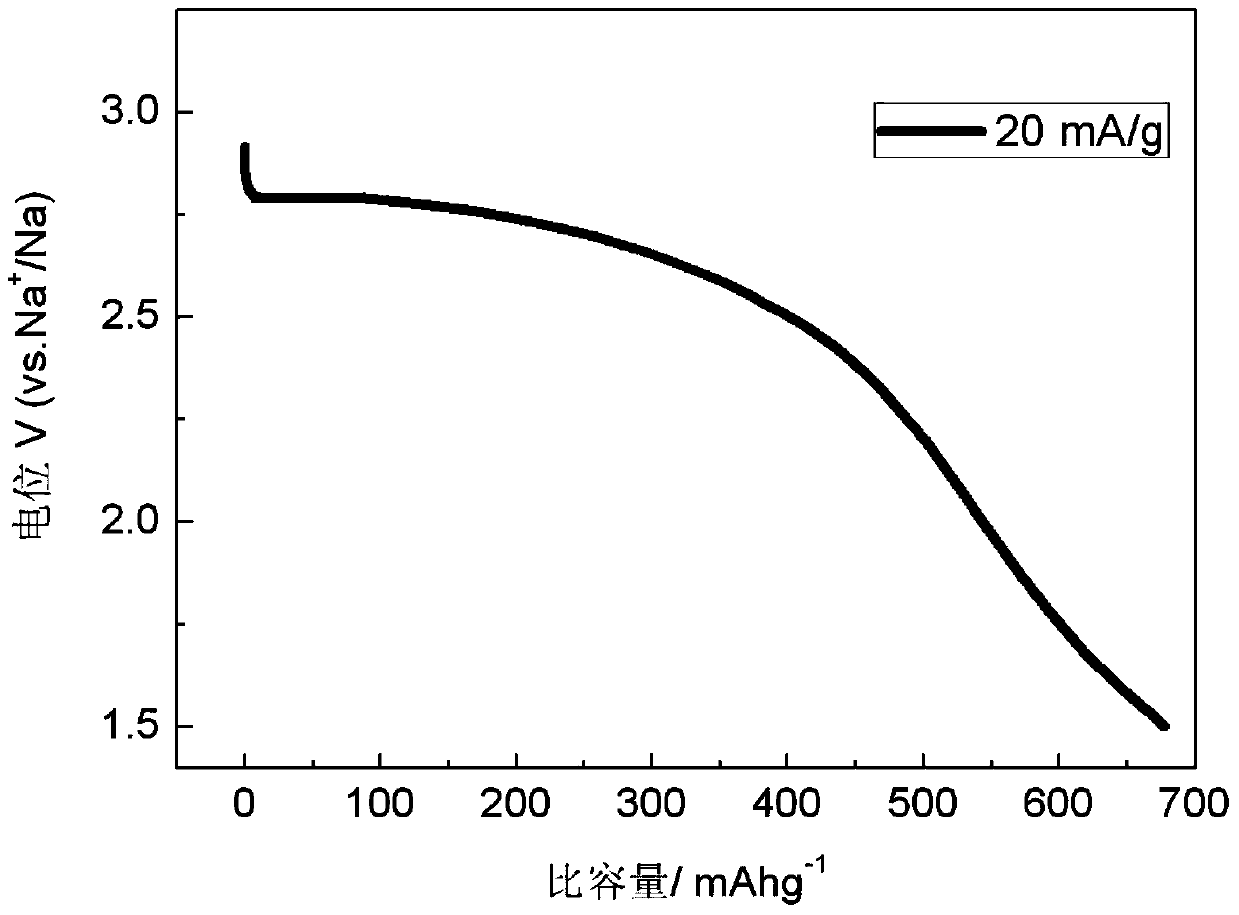

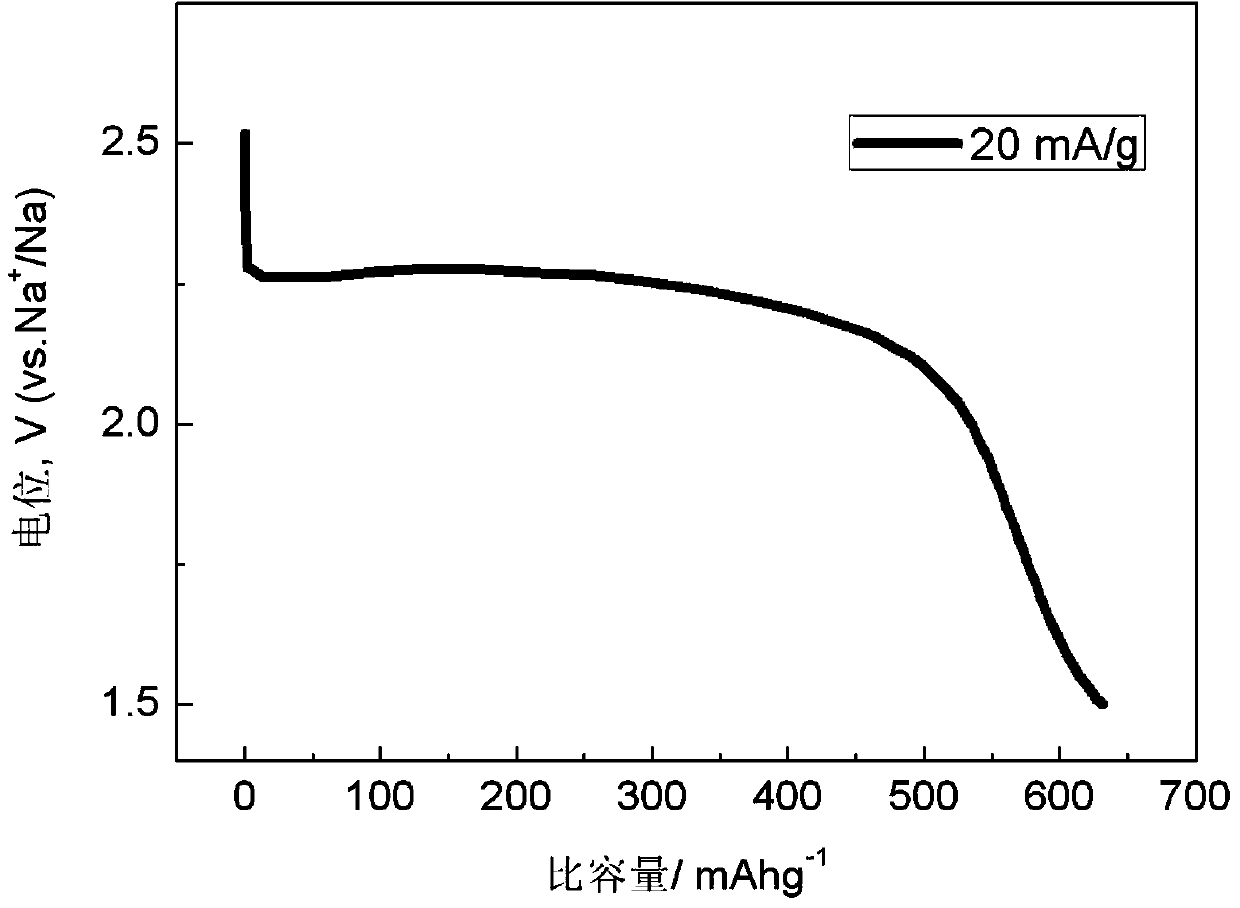

Sodium-perfluorocarbon primary battery

ActiveCN103700858AImprove discharge capacityDischarge potential is stablePrimary cellsPrimary cell electrodesFiberCarbon monofluoride

The invention discloses a sodium-perfluorocarbon primary battery and relates to a sodium battery. The sodium-perfluorocarbon primary battery is provided with a positive electrode, a negative electrode, a diaphragm and an electrolyte solution, wherein the positive electrode takes perfluorocarbon as an active substance; a main body of the perfluorocarbon is (CFx), and x is ranged from 0.2-1.2; the active substance comprises 20-100 percent of perfluorocarbon by mass; the electrolyte consists of a solvent, an electrolyte and an additive. The commercial perfluorocarbon, including carbon monofluoride, fluoride petroleum coke, fluoride carbon nano tube, fluoride carbon fibers, fluoride graphene and the like, is used as a main body active substance of the positive electrode of the sodium-perfluorocarbon primary battery; the sodium metal is used as the negative electrode; the electrolyte solution which takes an organic solution as the solvent and contains the sodium salt electrolyte and the diaphragm form a primary battery system which discharges at the constant current density of 20mA / g, and the mass specific capacity can be more than 800mAh / g. The sodium-perfluorocarbon primary battery has the characteristics of high discharging capacity, steady discharging level, environment friendliness and the like.

Owner:XIAMEN UNIV +1

Electrosynthesis of nanofibers and nano-composite films

InactiveUS20060021879A1Material nanotechnologySurface reaction electrolytic coatingComposite filmNanofiber

A method for producing an array of oriented nanofibers that involves forming a solution that includes at least one electroactive species. An electrode substrate is brought into contact with the solution. A current density is applied to the electrode substrate that includes at least a first step of applying a first substantially constant current density for a first time period and a second step of applying a second substantially constant current density for a second time period. The first and second time periods are of sufficient duration to electrically deposit on the electrode substrate an array of oriented nanofibers produced from the electroactive species. Also disclosed are films that include arrays or networks of oriented nanofibers and a method for amperometrically detecting or measuring at least one analyte in a sample.

Owner:BATTELLE MEMORIAL INST

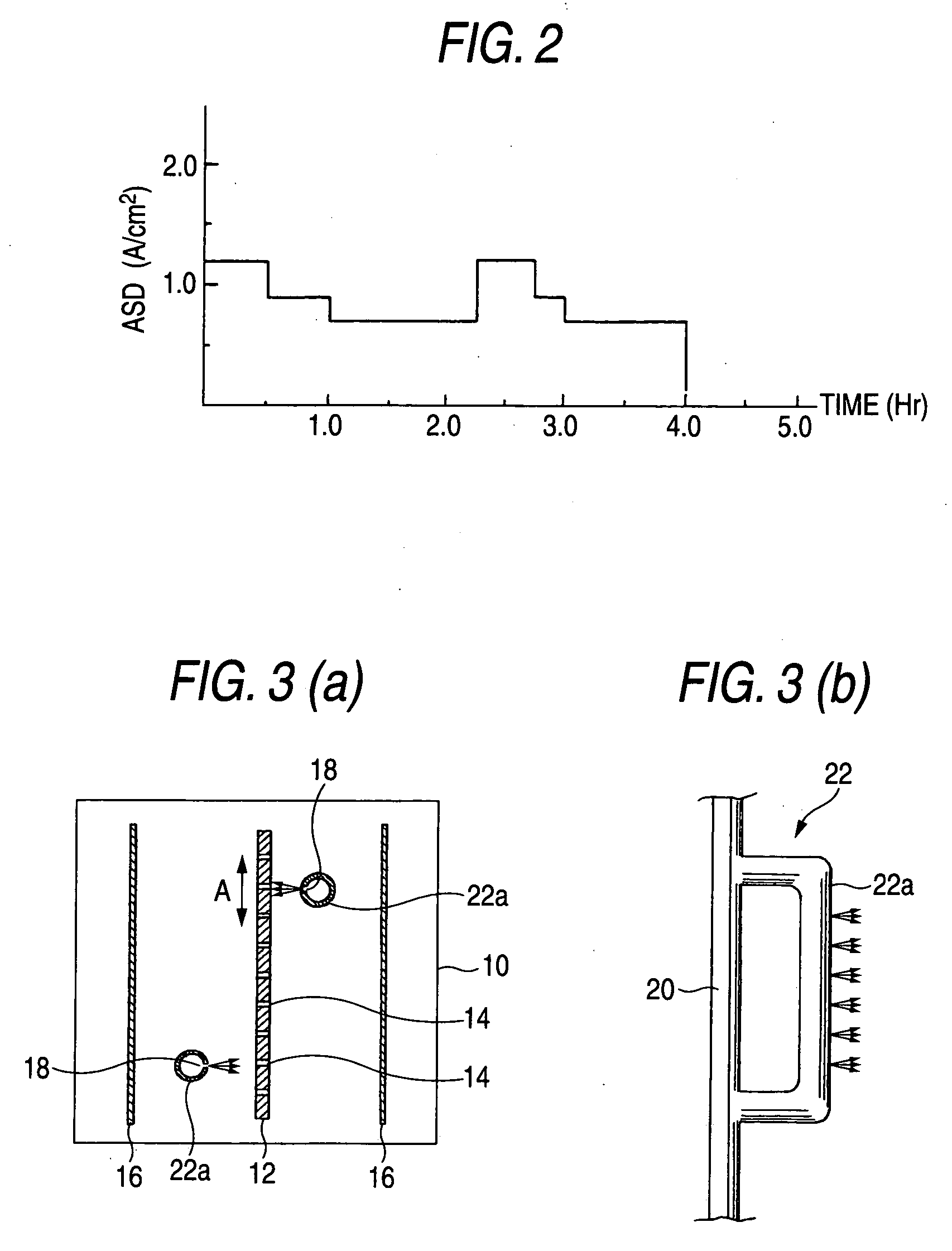

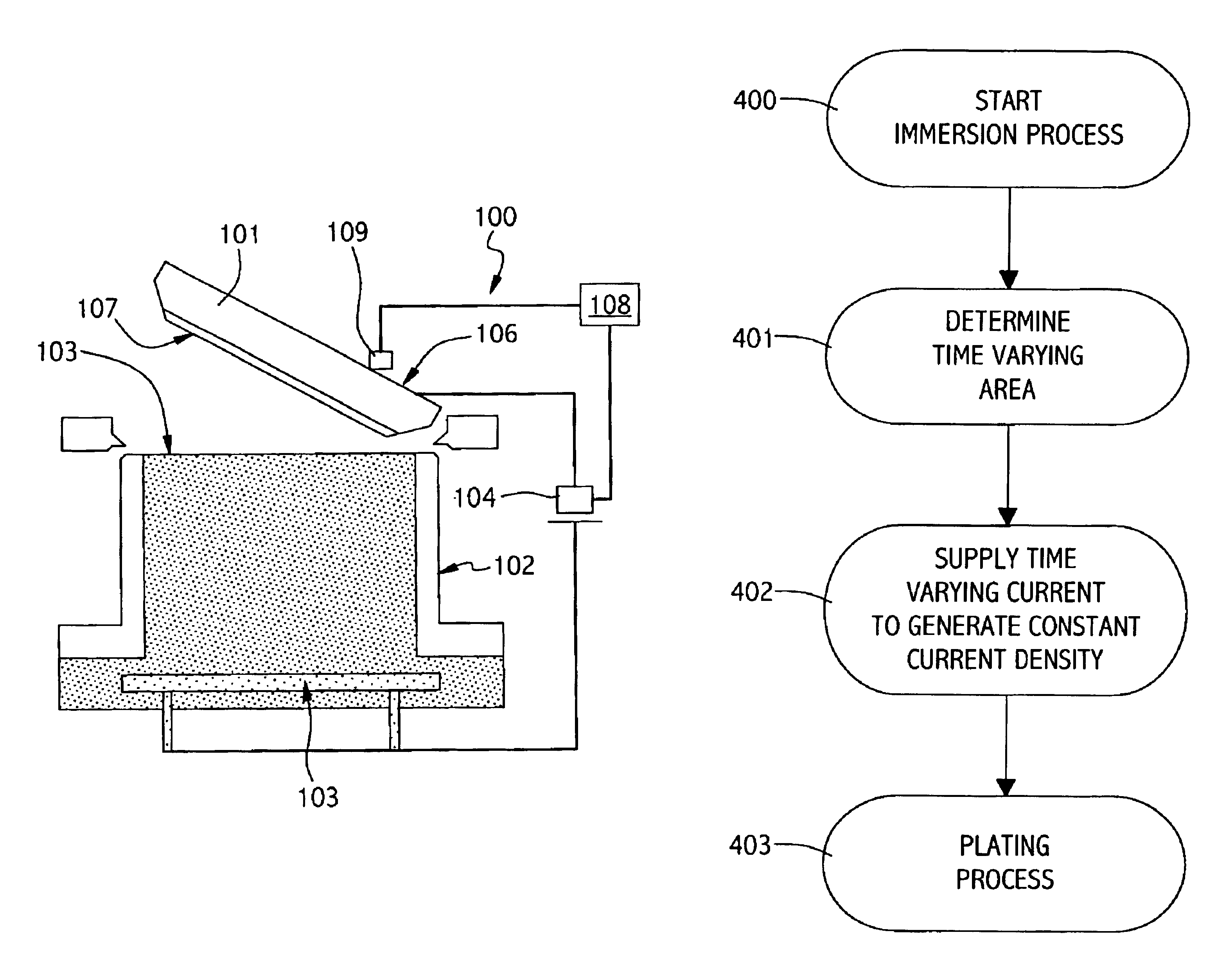

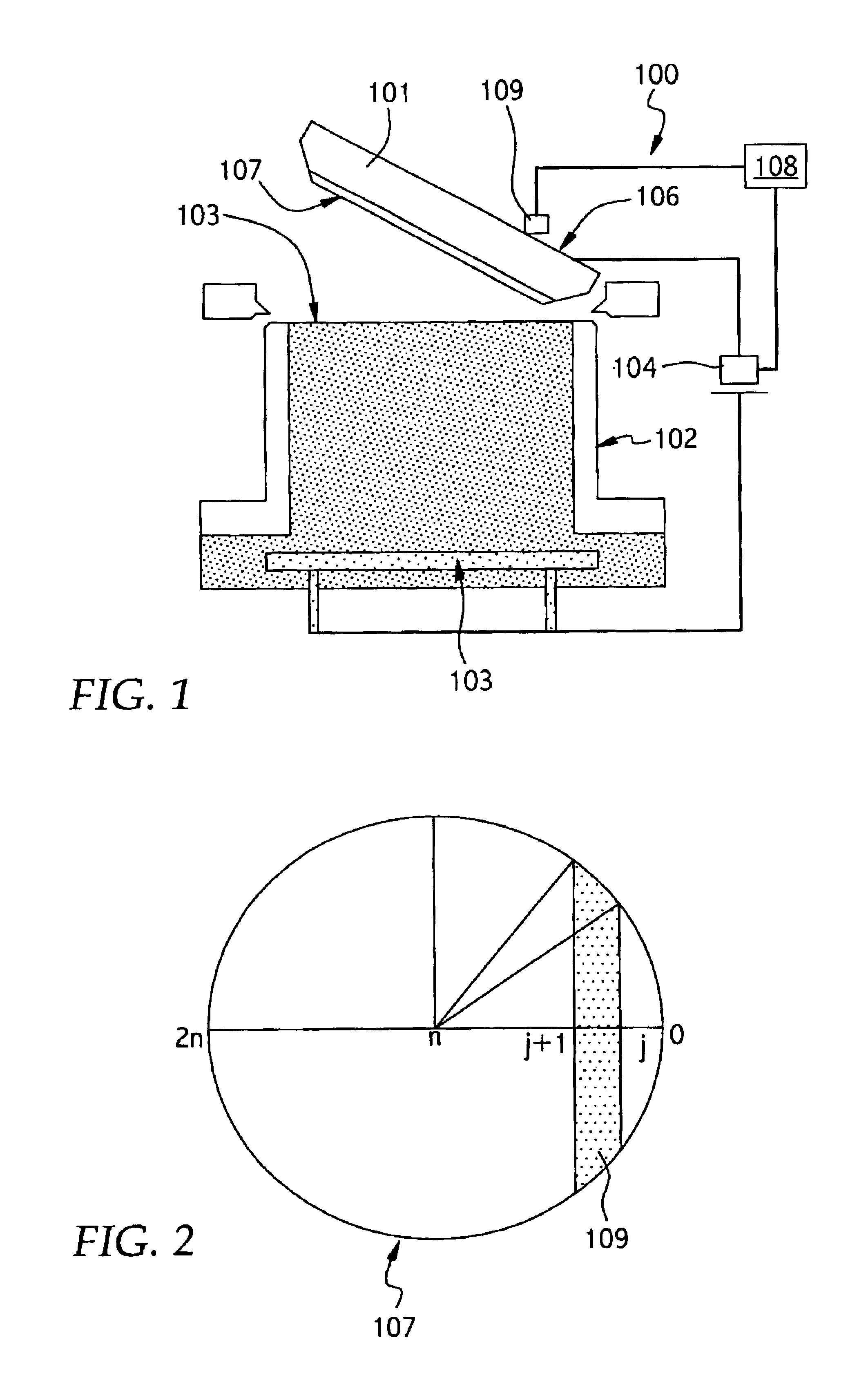

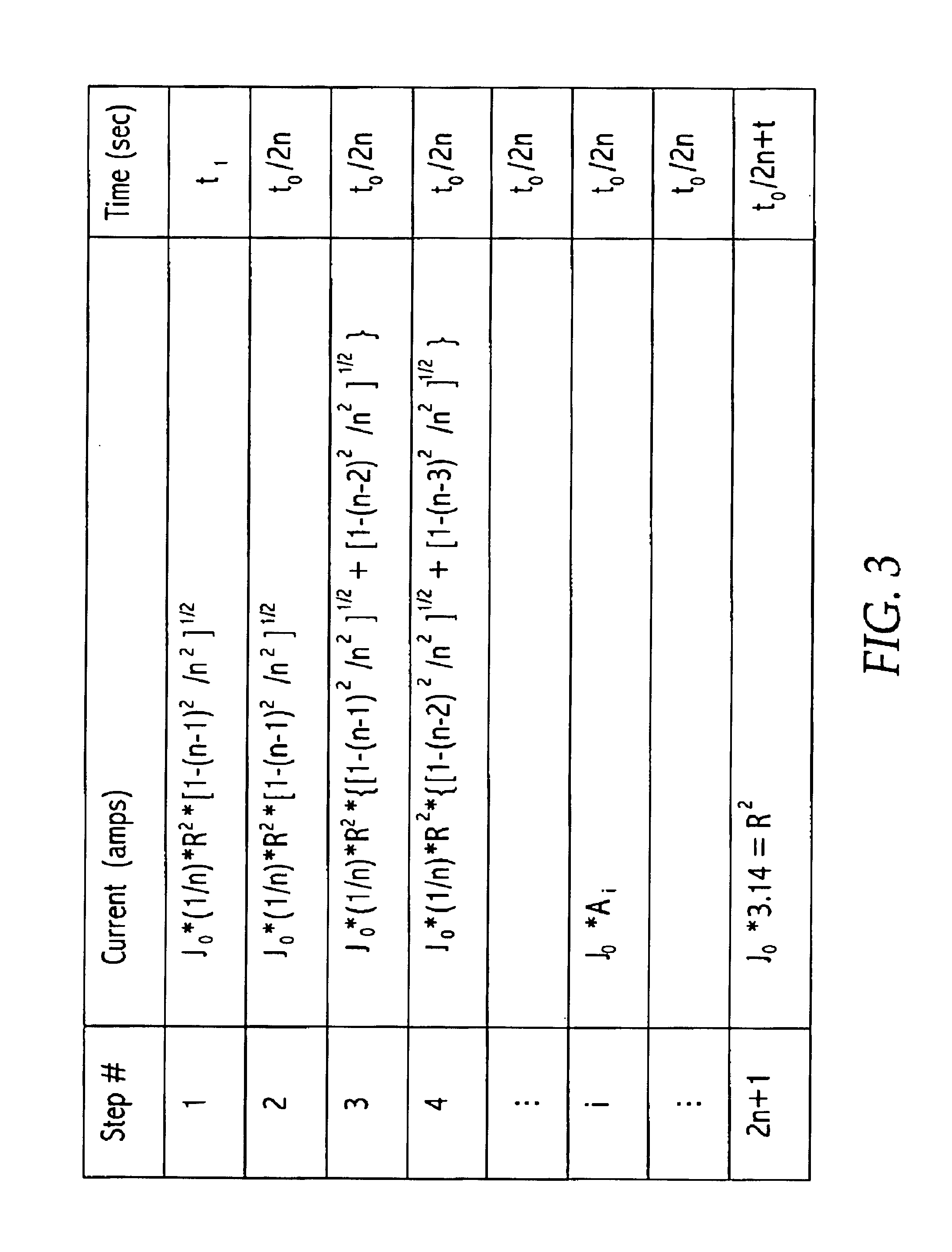

Method for regulating the electrical power applied to a substrate during an immersion process

InactiveUS6911136B2Maintain densityCellsMachining electric circuitsConstant current densityElectrical and Electronics engineering

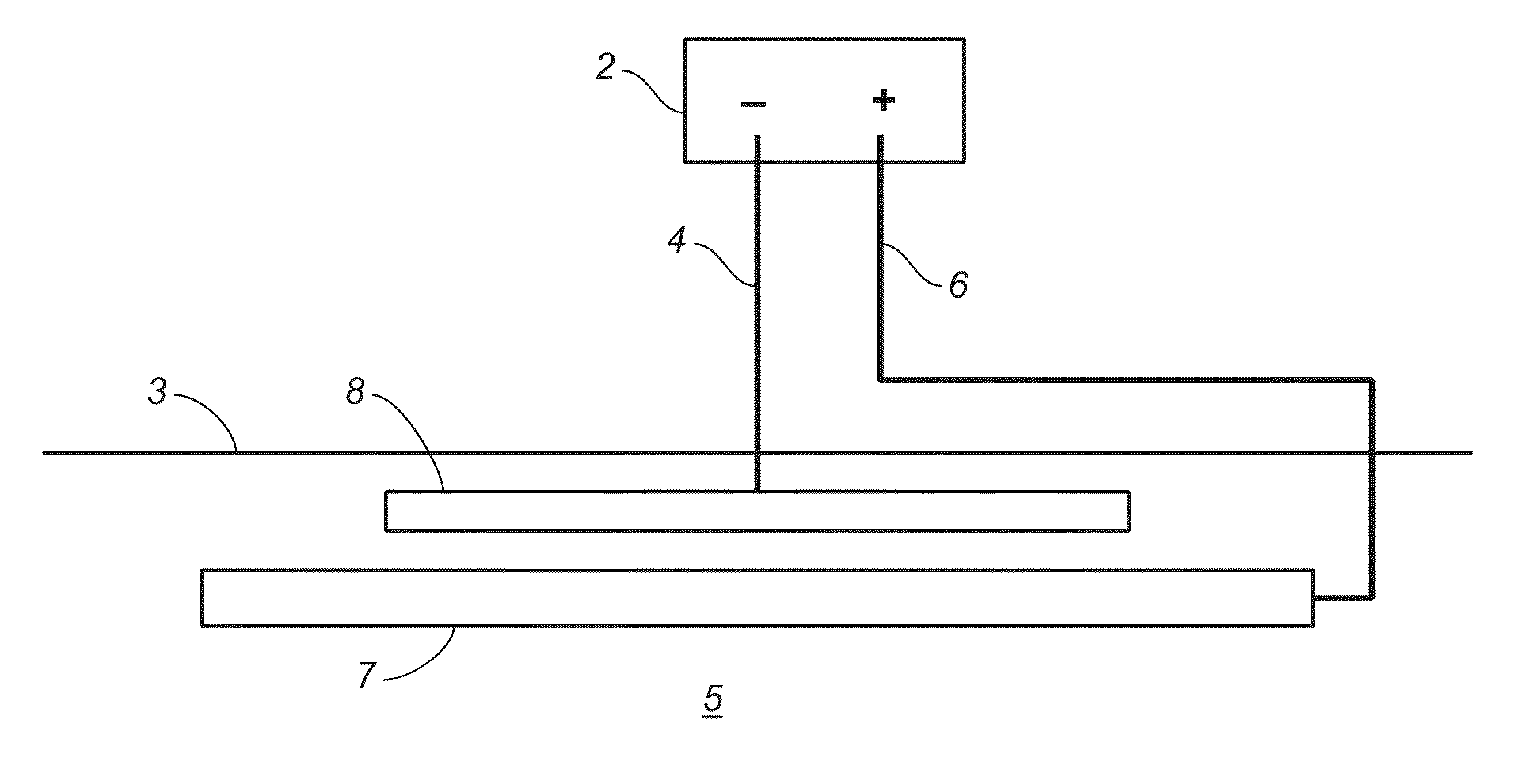

A method and apparatus for providing a uniform current density across an immersed surface of a substrate during an immersion process. The method includes the steps of determining a time varying area of an immersed portion of the substrate during the immersion process, and supplying a time varying current to the substrate during the immersion process, wherein the time varying current is proportional to the time varying area and is configured to provide a constant current density to the immersed portion of the substrate.

Owner:APPLIED MATERIALS INC

Preparation method of aluminium foil bionic nanostructured super-hydrophobic anti-condensation functional surface

The invention relates to a treatment method of an aluminium foil bionic nanostructured super-hydrophobic anti-condensation functional surface. The method comprises the following steps: firstly performing ultrasonic cleaning of an aluminium foil with acetone and deionized water, blowing to dry, soaking the aluminium foil into a 1 mol / L NaOH aqueous solution for treatment for 30-60 s, cleaning with ethanol and deionized water in order, blowing to dry so as to keep in reserve; soaking the pretreated aluminium foil in liquid which adopts a mixed aqueous solution of phosphoric acid and glycerol as an electrolyte, performing anodization under a room-temperature condition in a constant current density mode for 120-150 min; after the anodization is completed, taking the aluminium foil out, cleaning with ethanol and deionized water, blowing to dry; soaking the anodized aluminium foil in liquid stearic acid at 70 DEG C for 1 h, rinsing in hot ethanol with a temperature of 70 DEG C, curing in an oven with a temperature of 80 DEG C for 30 min so as to prepare the aluminium foil bionic nanostructured super-hydrophobic anti-condensation functional surface. The invention has a simple preparation process, no pollution, less substrate damage, excellent surface quality, and is applicable to popularization and application.

Owner:SOUTHEAST UNIV

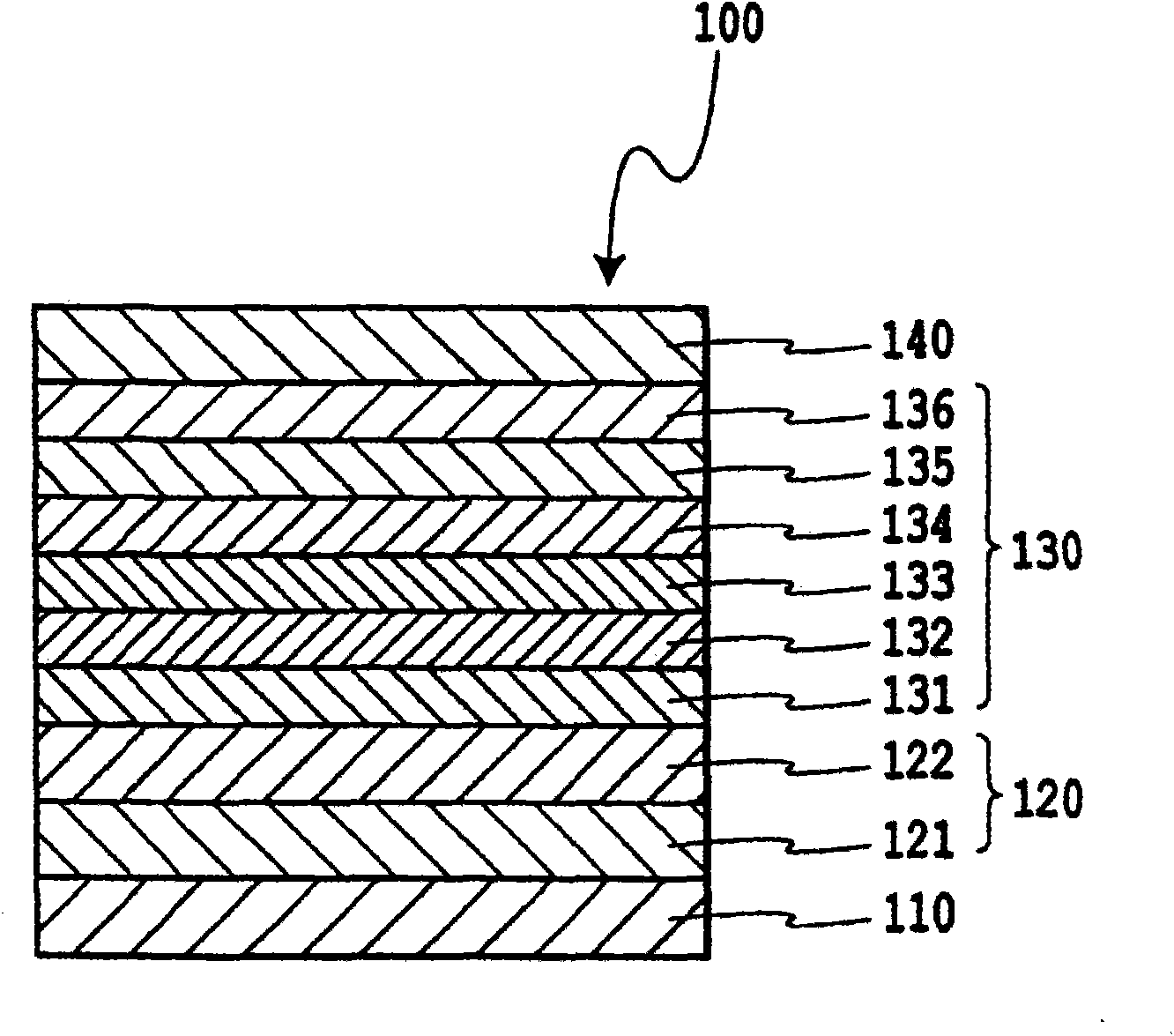

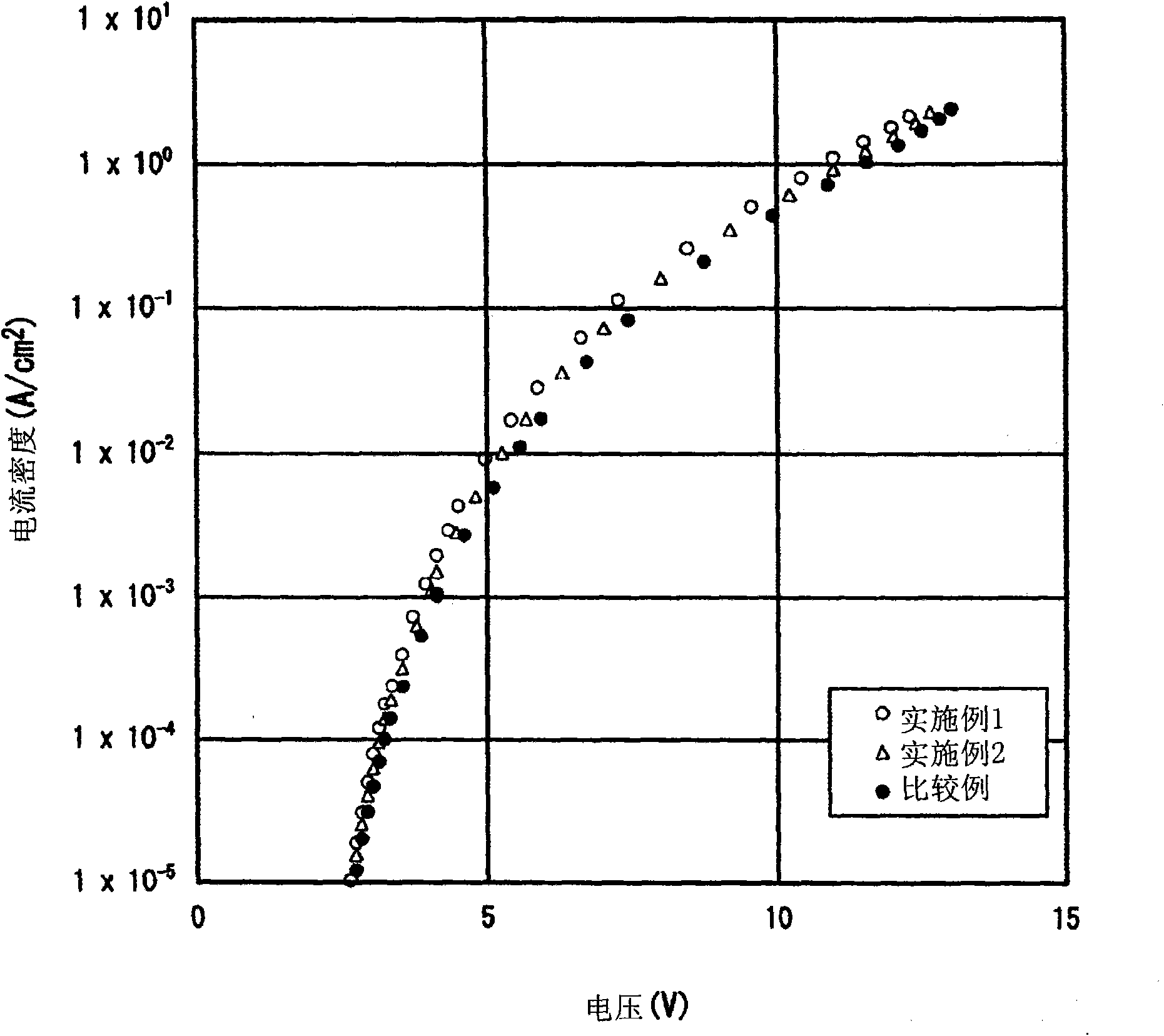

Organic EL element having cathode buffer layer

InactiveCN101855741AReduce the driving voltageImprove qualityElectroluminescent light sourcesSolid-state devicesElectron injectionTransport layer

An organic EL element includes a cathode, a cathode buffer layer composed of a HAT derivative, an electron injection transport layer, and a light emitting layer arranged in this order from the substrate side. The organic EL element has remarkable advantages that (1) the electron injection transport performance of the electron injection transport layer is prevented from being deteriorated by oxygen and / or moisture adsorbed to the cathode and supply of electrons to the light emitting layer is assured, (2) the drive voltage of the organic EL element is reduced, (3) an increase of the drive voltage for giving a constant current density with the passage of the drive time is prevented, and (4) current leakage and occurrence of a pixel defect are suppressed, and the quality and fabrication yield of the organic EL element are improved.

Owner:SHARP KK

Method and device for internal wall ceramic treatment of steel and iron pipe casting

InactiveCN1769526ASolve the problem of ceramic treatmentTightly boundAnodisationSuperimposed coating processPower flowPulsed DC

This invention discloses the ceramic processing method for the steel tube wall, fist choosing the steel tube with the metal aluminium layer on its wall, then fasting the electrode pole on the lumen of the steel tube, wherein the electrode pole connects with the cathode of the impulse dc source, the exterior surface of the steel tube connects with the positive pole of the power, keeping the cavity of the steel tube in the alkaline lyes, adjusting the pressure of the power to keep it invariable. This invention also discloses the devices of this method, which includes steel tube, impulse dc source, electrode pole and handling fluid circle device, the steel tube connects with the anode of the power, one end of the electrode pole connects with the cathode of the power, another in the lumen of the steel tube, and the handling fluid circle device keeps the temperature and the chroma of the handling fluid unform. This method also can produce the ceramic layer which can endure high temperature and wearing and eroding, and has long longevity, and the structure of the device is simple, it is easy to install and take down.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for filling through hole

InactiveUS7909976B2Shorten the timeEasy to useTanksPrinted circuit aspectsHigh current densityElectrolysis

It is characterized in that in the case of filling a through hole formed in a substrate with a plated metal by electrolytic plating, the electrolytic plating is started by a high current density higher than Constant Current Density capable of fully filling the through hole when the electrolytic plating is performed with a current density held constant as a current density of the electrolytic plating, and the electrolytic plating is continued by being changed to a current density lower than the high current density by the time of reaching formation of a seam diameter in which an inside diameter does not decrease even when the electrolytic plating is continued after the electrolytic plating at the high current density is started.

Owner:SHINKO ELECTRIC IND CO LTD

Preparation method of durable underwater ultra oleophobic surface of titanium alloy matrix

The invention discloses a preparation method of a durable underwater ultra oleophobic surface of a titanium alloy matrix, and belongs to the technical field of surface treatments of metallic materials. The preparation method comprises the following steps: performing electro chemical etching on the surface of a titanium alloy piece under a constant current density in a neutral electrolyte consisting of NaCl and H2O2 so as to prepare micron-grade concave pits and a cavity structure; after the electro chemical etching is completed, putting the titanium alloy piece into deionized water so as to perform ultrasonic cleaning; and taking out the titanium alloy piece after the ultrasonic cleaning, and placing the taken titanium alloy piece into water so as to obtain the underwater ultra oleophobic surface of the titanium alloy matrix. A contact angle between the prepared underwater ultra oleophobic surface on the titanium alloy matrix and dichloromethane in the water is 158.9 degrees, a rolling angle is smaller than 10 degrees, and the surface has good characteristics of underwater durability and corrosion resistance. The method is simple in technology, low in cost and pollution-free to environment and can be used for underwater oil pollution resistance and underwater corrosion resistance of the titanium alloy surface.

Owner:DALIAN UNIV OF TECH

Electro-Depositing Metal Layers of Uniform Thickness

InactiveUS20130252020A1Eliminates convective flowMinimizing electrolyte mixingCellsThin material handlingConstant current densityElectroplating

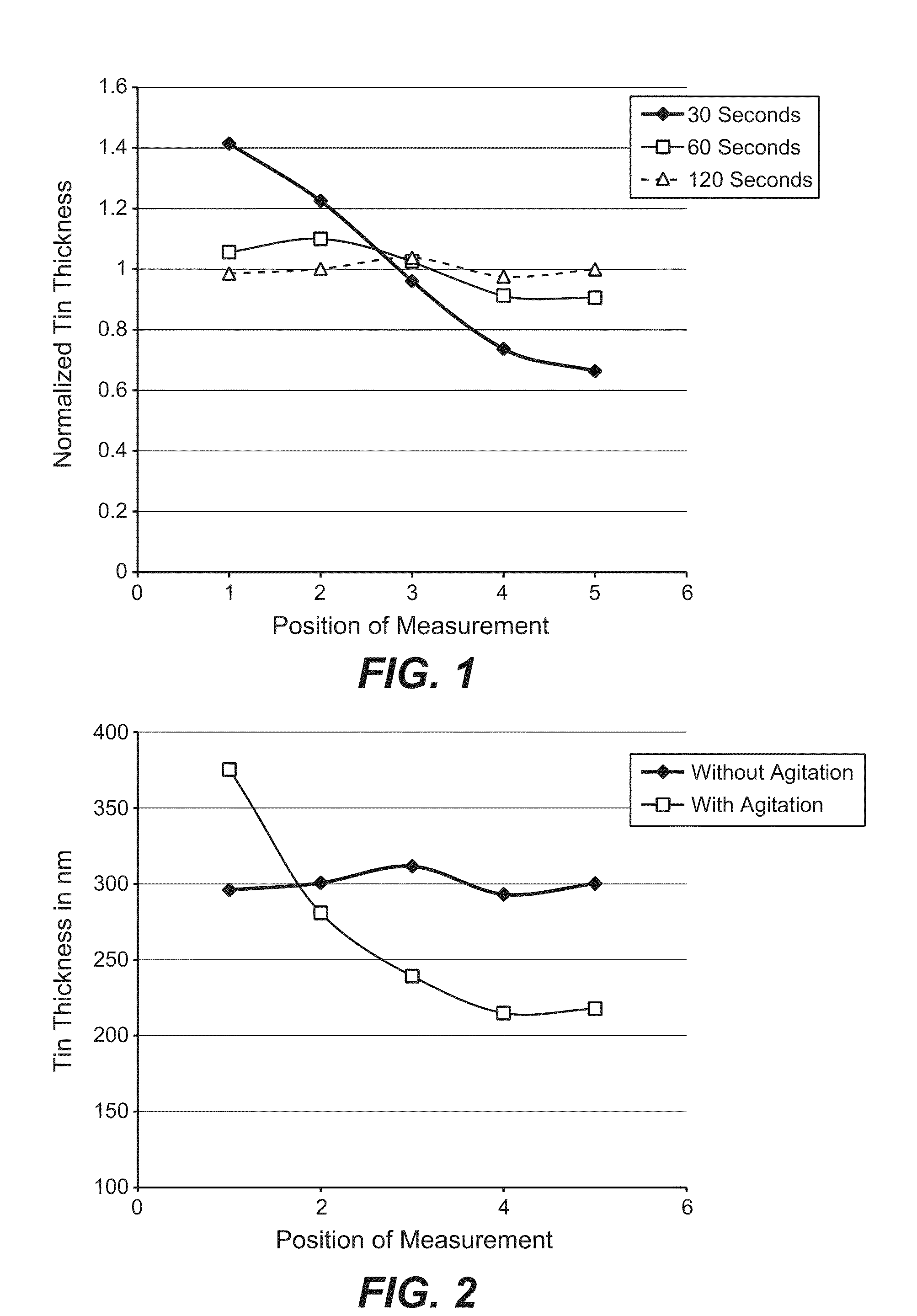

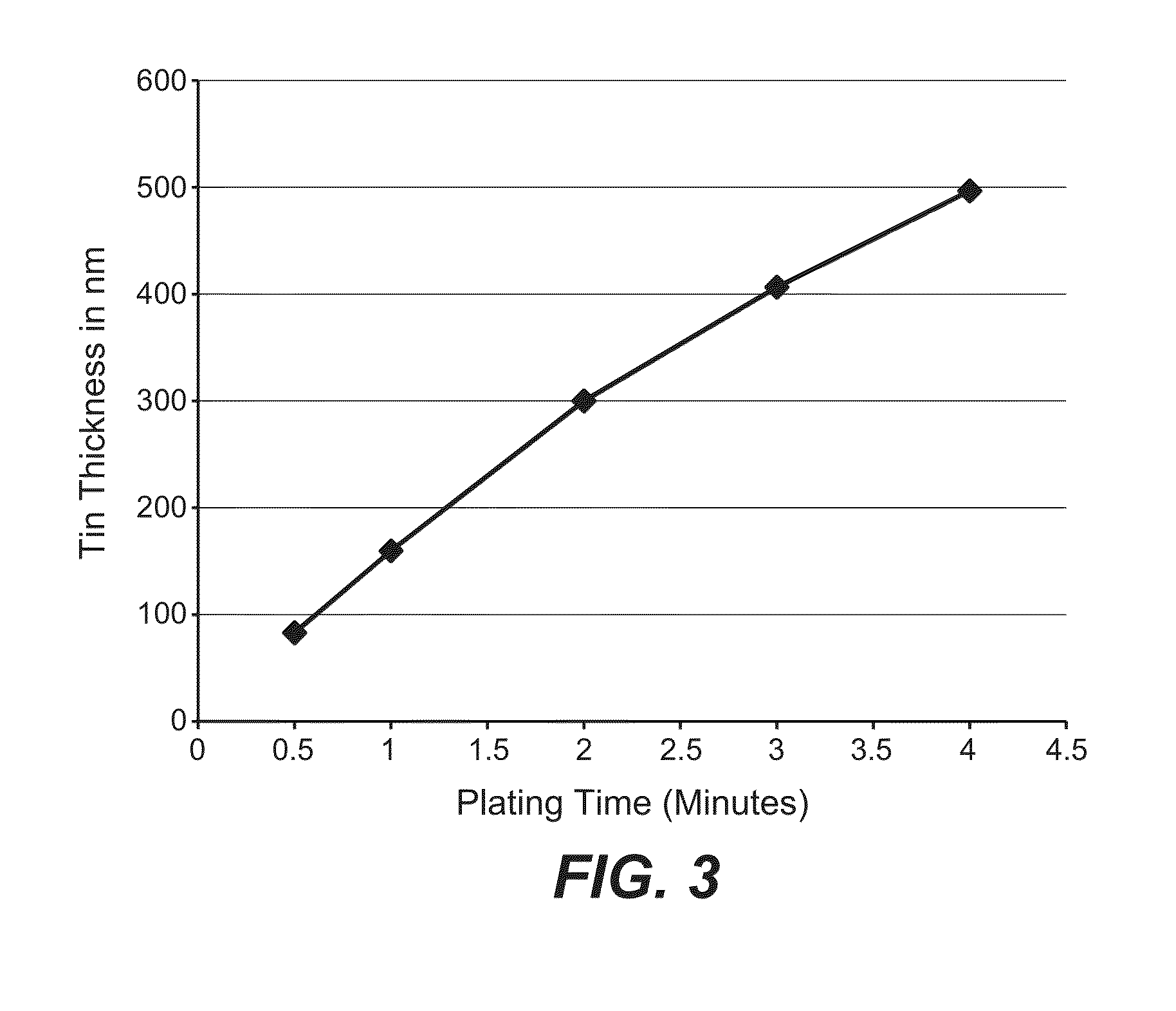

The invention is an apparatus and method for forming highly uniform layers of metal on a substrate by electro-deposition. The substrate is electroplated in a bath composed of a quiescent (i.e., no external agitation) electrolyte solution using an effective constant current density carefully selected to match the chemical composition of the electrolyte.

Owner:TECHNIC INC

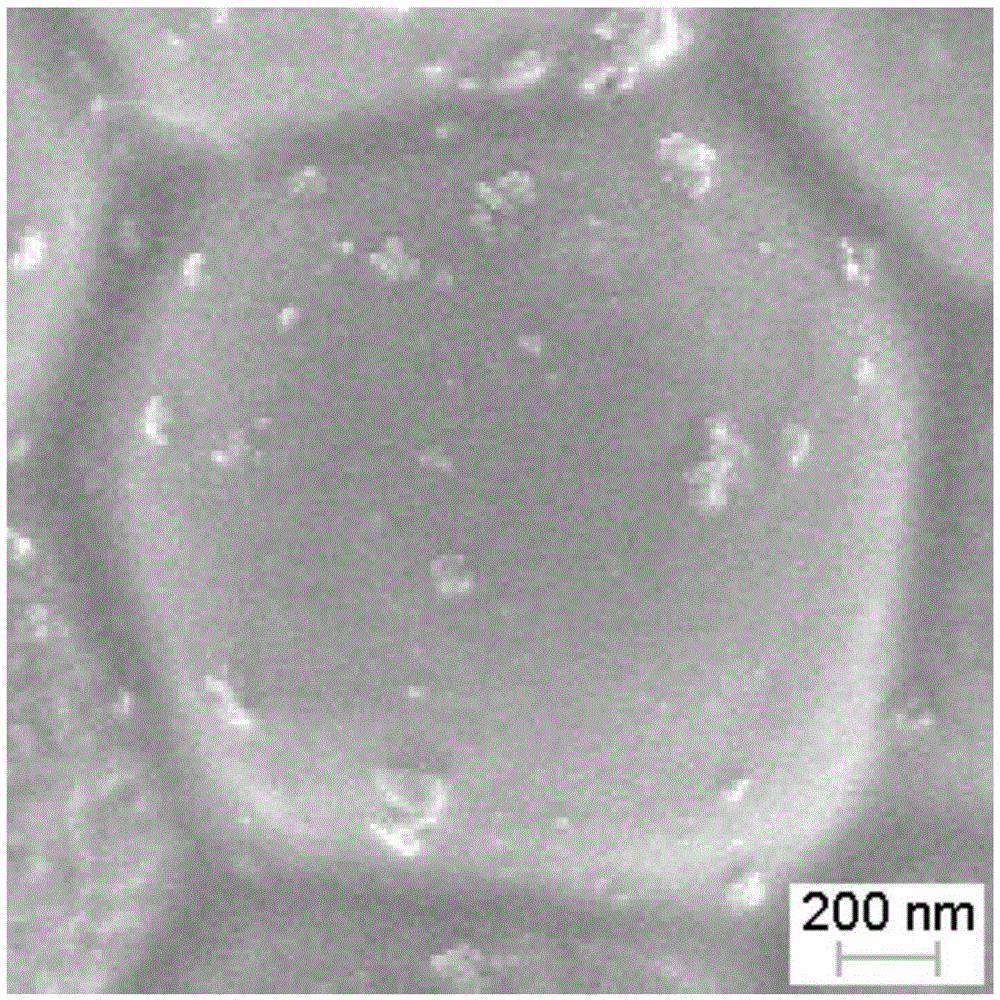

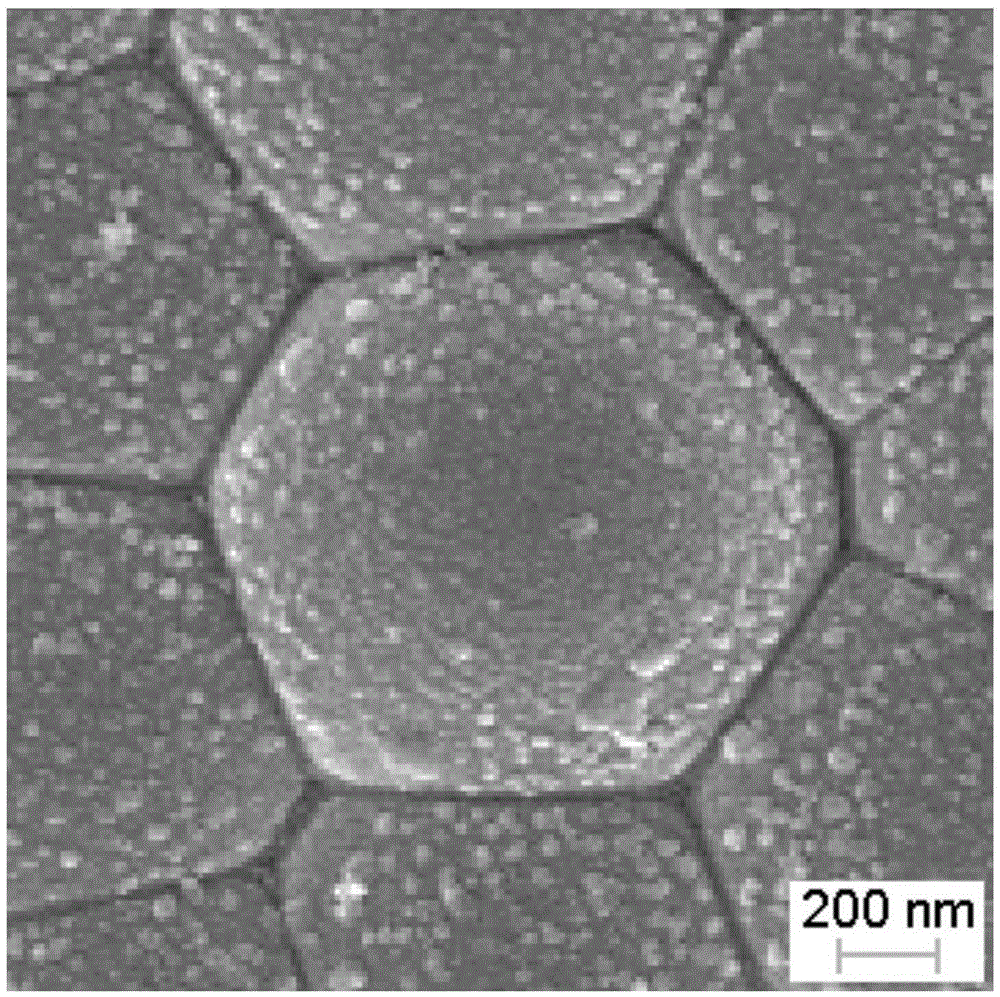

Method for preparing large-hole-interval porous anodic alumina membrane at high voltage

InactiveCN105297106ASuppress breakdownAchieving controllable equipmentSurface reaction electrolytic coatingConstant current densityHigh voltage

The invention discloses a method for preparing a large-hole-interval porous anodic alumina membrane at high voltage. The method includes the steps that a high pure aluminum sheet is subjected to electrochemical polishing after being washed; the polished aluminum sheet serves as an anode, graphite serves as a cathode, the anode oxidation process is performed while an oxalic acid-ethanol-water mixed solution serves as an electrolyte, and high anode oxidization voltage is obtained by performing self-adaption boosting under constant current density; a sample obtained through anode oxidization is soaked in a saturated copper chloride solution, then the large-hole-interval porous anodic alumina membrane is obtained, and the average hole interval of the prepared porous anodic alumina membrane is regulated and controlled by adjusting the ethanol adding proportion, the anode oxidization voltage and the current density. The large hole interval size of the prepared porous anodic alumina membrane is adjustable so that the porous anodic alumina membrane can serve as a template to synthesize various functional submicron and micron materials. Meanwhile, the large-hole-interval porous anodic alumina membrane has the advantages that raw materials are easy to obtain, operation is easy, cost is low, and repeatability is good, and feasibility is improved when the large-hole-interval porous anodic alumina membrane is applied to production.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com