Method for manufacturing high quality aluminum oxide photon crystal

A technology of photonic crystals and alumina, which is applied in the field of electrochemistry, can solve the problems that periodic changes in hole density cannot obtain a one-dimensional multilayer film structure, and achieve the effects of wide application prospects, convenient operation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

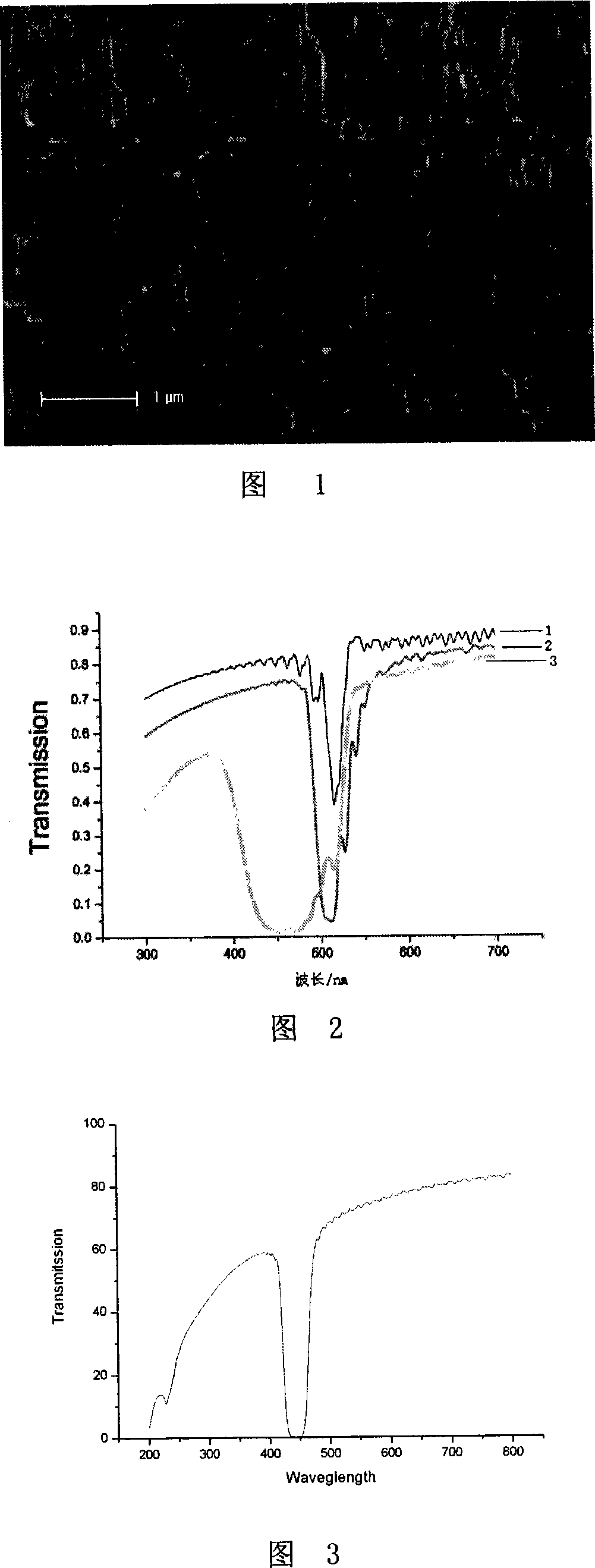

Image

Examples

Embodiment 1

[0024] At an ambient temperature of 22 degrees Celsius, follow the steps below:

[0025] (1) Cut an aluminum sheet with a thickness of 0.2mm into a shape of 2.5cm×3cm, first degrease the aluminum sheet with acetone, and then wash it with 0.1mol / L dilute sulfuric acid and 0.1mol / L dilute sodium hydroxide solution The aluminum sheet. In the electrolyte solution of 80wt% absolute alcohol and 20wt% perchloric acid mixed solution, the treated aluminum sheet was used as anode, and the platinum sheet was used as cathode, and was electrochemically polished with 16v voltage for 3 minutes.

[0026] (2) Use 0.3mol / L sulfuric acid as the electrolyte, use the polished aluminum sheet as the anode, and the platinum sheet as the cathode, and anodize the aluminum sheet for 6 hours at a voltage of 20v.

[0027] (3) Use a mixed solution of 6 wt% phosphoric acid and 1.8 wt% chromic acid to dissolve the aluminum oxide film formed on the surface of the aluminum sheet.

[0028] (4) Use 0.3mol / L su...

Embodiment 2

[0031] At an ambient temperature of 22 degrees Celsius, follow the steps below:

[0032] (1) Cut an aluminum sheet with a thickness of 0.2 mm into a shape of 2.5 cm × 3 cm, first degrease the aluminum sheet with acetone, and then wash the aluminum sheet with 0.1 mol / L dilute sulfuric acid and 0.1 mol / L dilute sodium hydroxide solution aluminum sheet. In the electrolyte of 80wt% absolute alcohol and 20wt% perchloric acid mixed solution, the cleaned aluminum sheet was used as the anode, and the platinum sheet was used as the cathode, and was electrochemically polished with a voltage of 16v for 3 minutes.

[0033] (2) Use 0.3mol / L sulfuric acid as the electrolyte, the polished aluminum sheet as the anode, and the platinum sheet as the cathode, and anodize the aluminum sheet for 6 hours at a voltage of 20v.

[0034] (3) Use a mixed solution of 6 wt% phosphoric acid and 1.8 wt% chromic acid to dissolve the aluminum oxide film formed on the surface of the aluminum sheet.

[0035] ...

Embodiment 3

[0038] At an ambient temperature of 22 degrees Celsius, follow the steps below:

[0039] (1) Cut an aluminum sheet with a thickness of 0.2 mm into a shape of 2.5 cm × 3 cm, first degrease the aluminum sheet with acetone, and then wash the aluminum sheet with 0.1 mol / L dilute sulfuric acid and 0.1 mol / L dilute sodium hydroxide solution aluminum sheet. In the electrolyte solution of 80wt% absolute alcohol and 20wt% perchloric acid mixed solution, the treated aluminum sheet was used as anode, and the platinum sheet was used as cathode, and was electrochemically polished with 16v voltage for 3 minutes.

[0040] (2) Use 0.3mol / L sulfuric acid as the electrolyte, the polished aluminum sheet as the anode, and the platinum sheet as the cathode, and anodize the aluminum sheet for 6 hours at a voltage of 20v.

[0041] (3) Use a mixed solution of 6 wt% phosphoric acid and 1.8 wt% chromic acid to dissolve the aluminum oxide film formed on the surface of the aluminum sheet.

[0042] (4) Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com