Patents

Literature

68 results about "Anodization voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aluminium oxide nano-form photon crystal

InactiveCN1752296AThe number of layers is controllableAdjustable depthSurface reaction electrolytic coatingSurface layerLow voltage

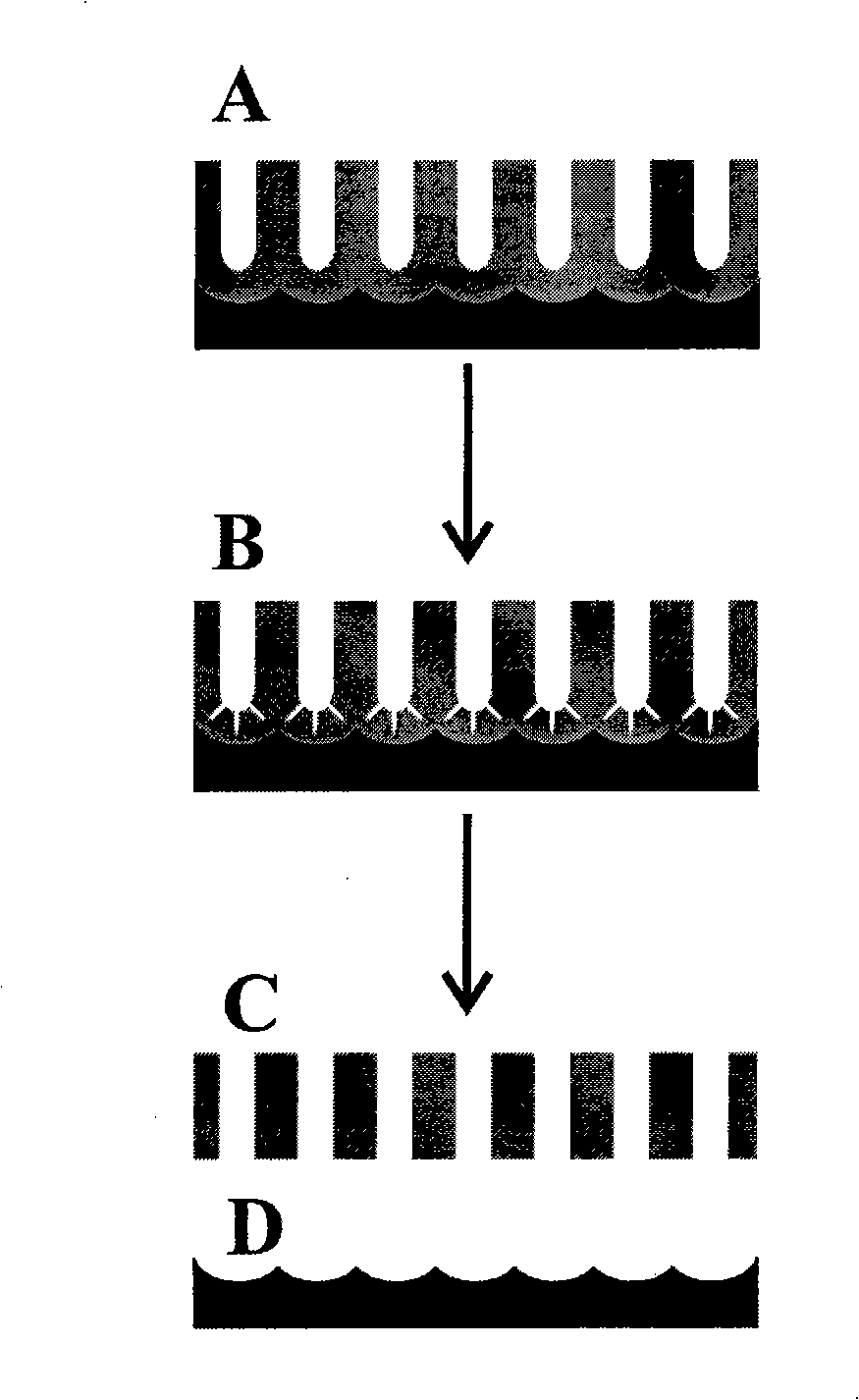

A process for preparing photon crystal from aluminium oxide nanotemplate includes such steps as dissolving the oxidized surface layer of Al sheet, and alternatively high-voltage anodizing and low-voltage anodizing more times to generate the periodic variation of aluminium oxide nanostructure on the surface of Al sheet, resulting in periodic pore structure.

Owner:WUHAN UNIV

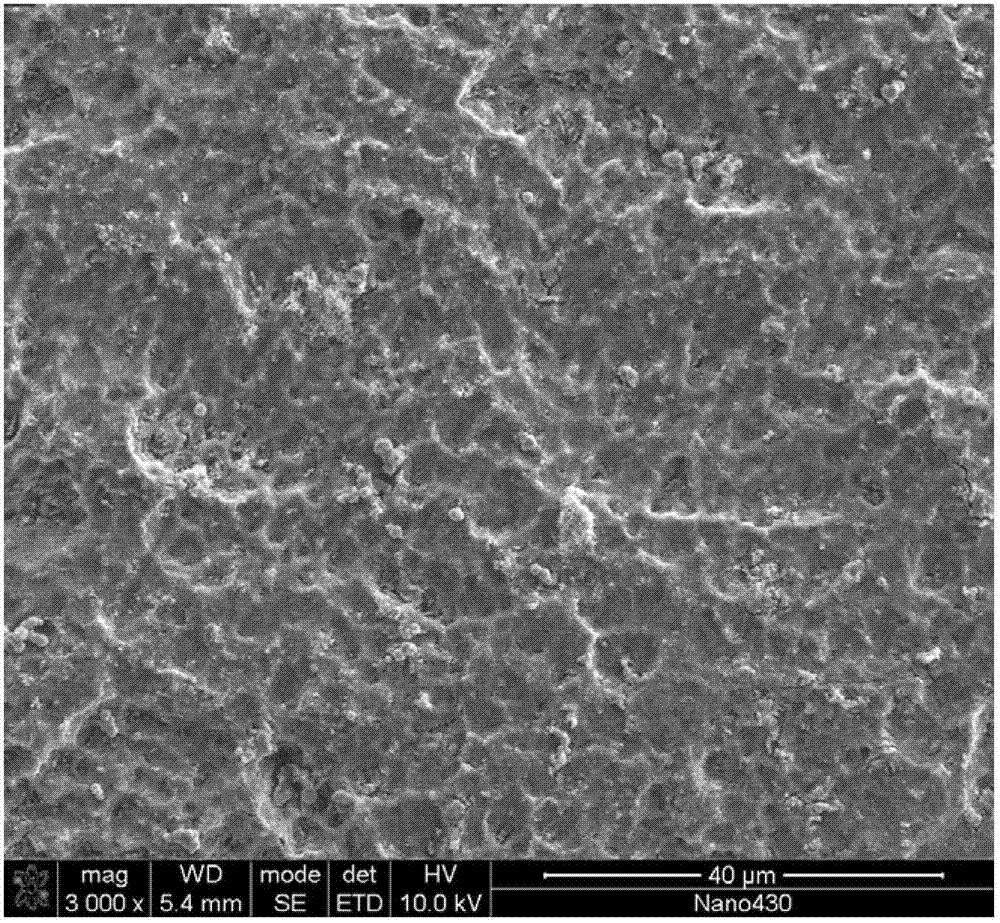

Manufacture method for chlorine-evolution dimensionally stable anode (DSA) electro-catalytic electrode with three dimensional structure

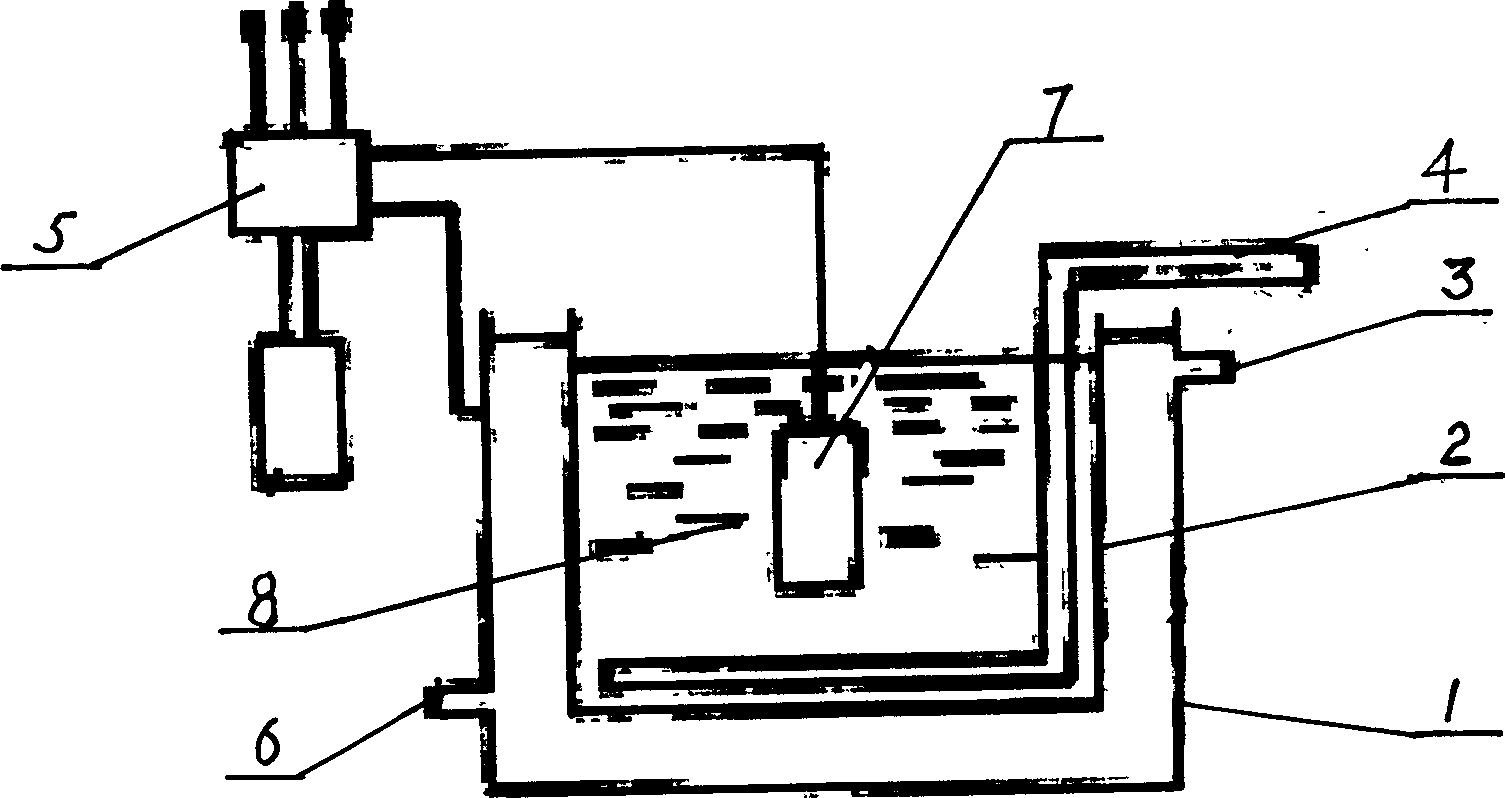

ActiveCN102766882AMild preparation conditionsAvoid impuritiesSurface reaction electrolytic coatingElectrode shape/formsNanotubeCl element

The invention discloses a manufacture method for a chlorine-evolution DSA electro-catalytic electrode with a three dimensional structure. The method includes a titanium substrate is preprocessed, and a titanium substrate titanium dioxide nanotube is manufactured; an anodic oxidation unit is used to fix the preprocessed titanium substrate on an anode and fix an iridium tantalum electrode on a cathode, the electrolyte temperature is kept in a range from 30 DEG C to 50 DEG C, the anode oxidation time is in a range from 80 minutes to 180 minutes, and the anode oxidation pressure is in a range from 15V to 35V; a hydrothermal reaction is performed; a isopropyl alcohol solution of SnCl4, SbCl3 and RuCl3 is prepared, and the titanium substrate titanium dioxide nanotube is placed in a reaction kettle vertically; the nanotube is reacted for 20h to 50h at a temperature of 100 DEG C to 250 DEG C; and thermal treatment is performed to obtain the electrode. According to the method, tedious painting and thermal decomposition processes are not included, the chlorine-evolution DSA electro-catalytic electrode with the three dimensional structure manufacture without has the advantages of being uniform and compact in surface, high in active component load, high in electrochemical activity, and long in service life.

Owner:SOUTH CHINA UNIV OF TECH +1

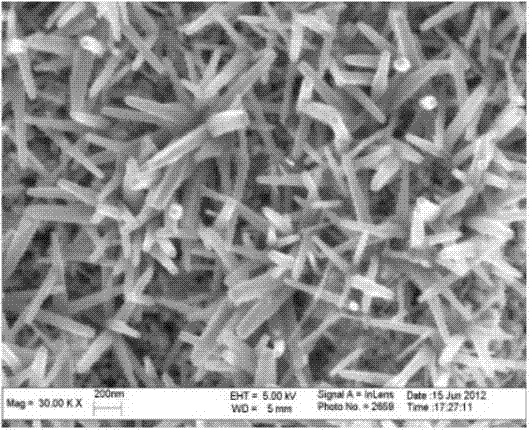

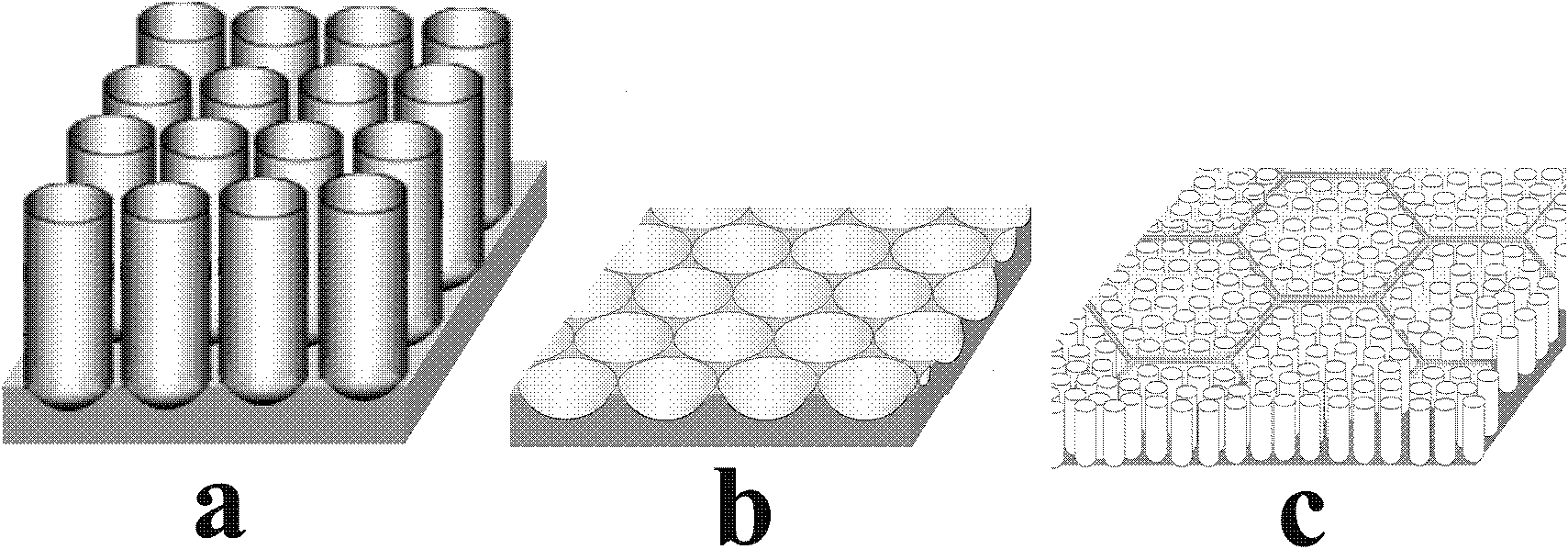

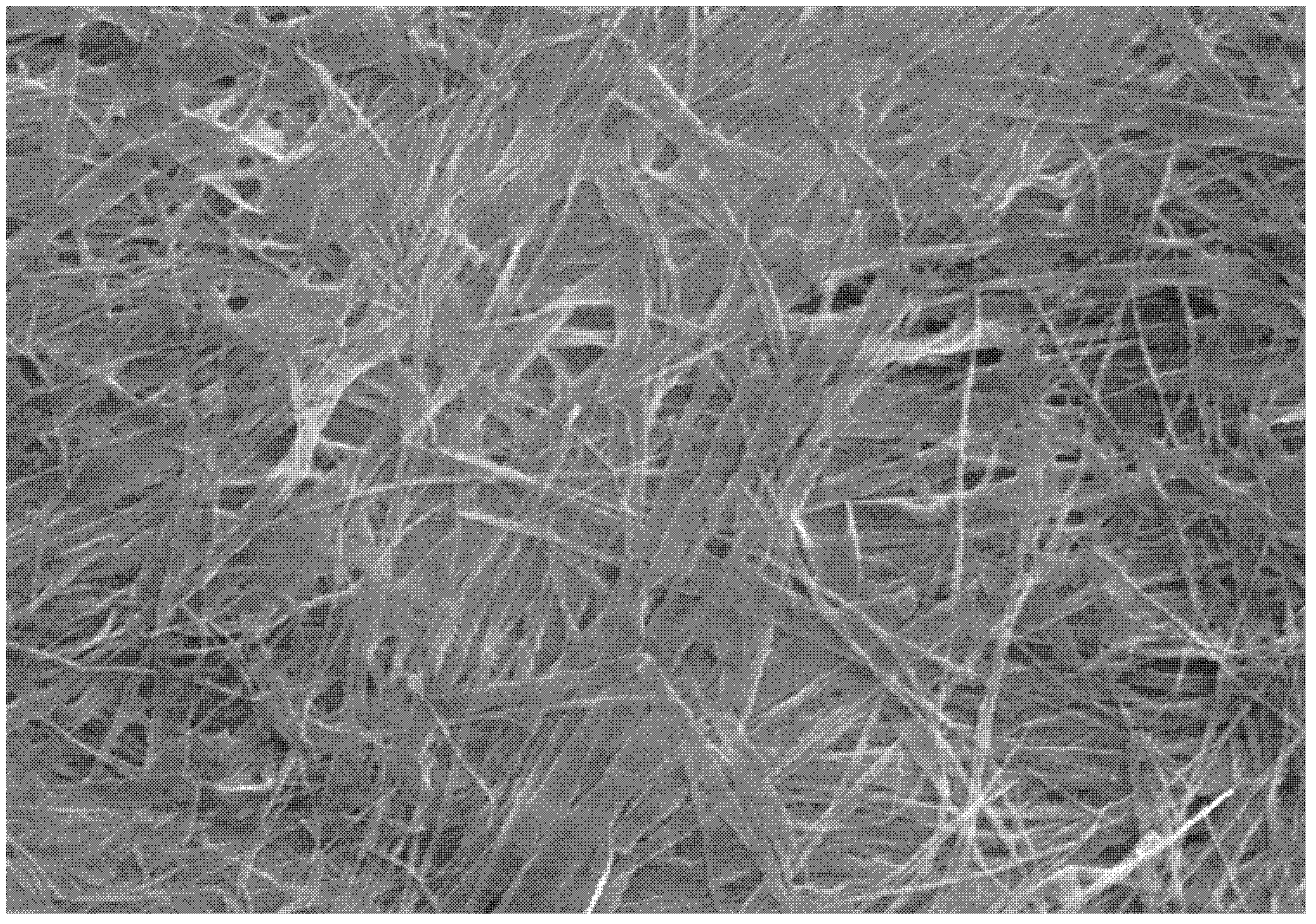

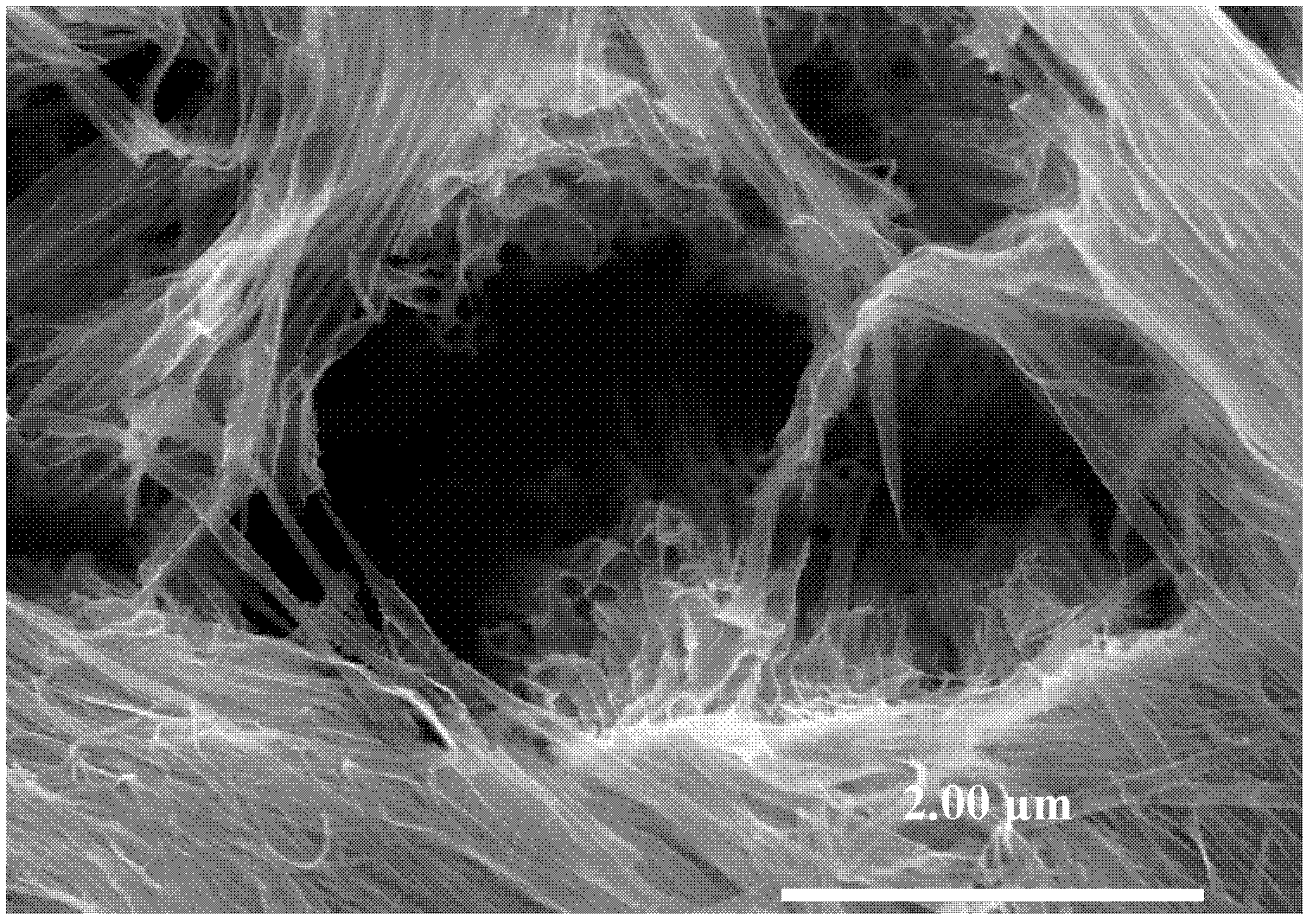

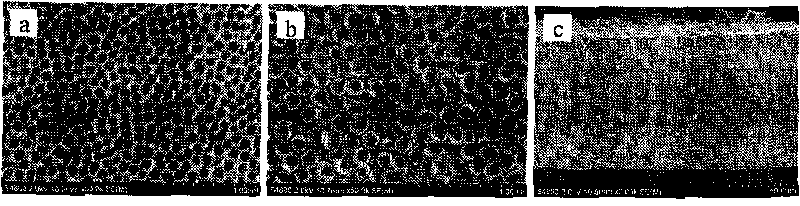

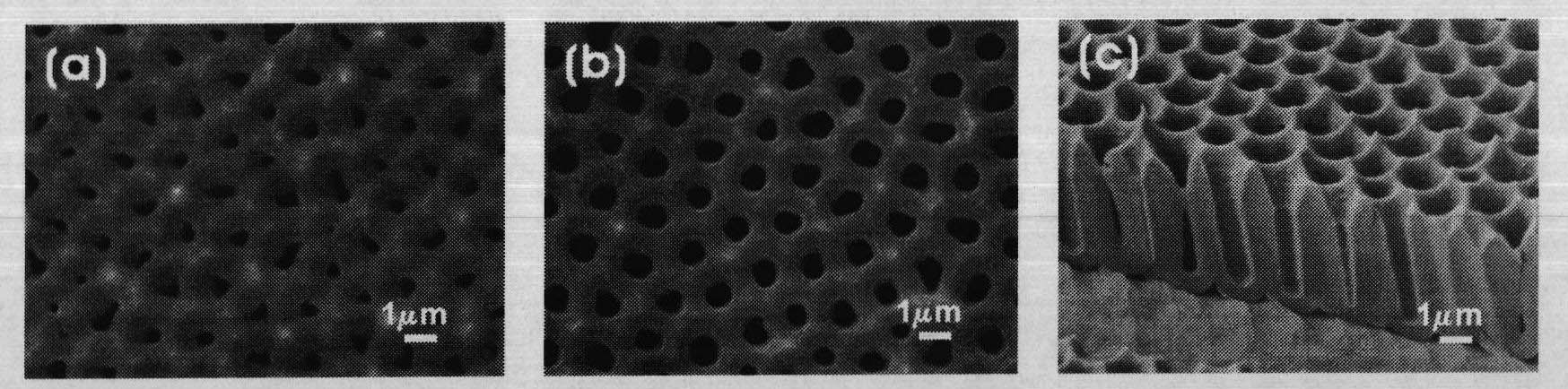

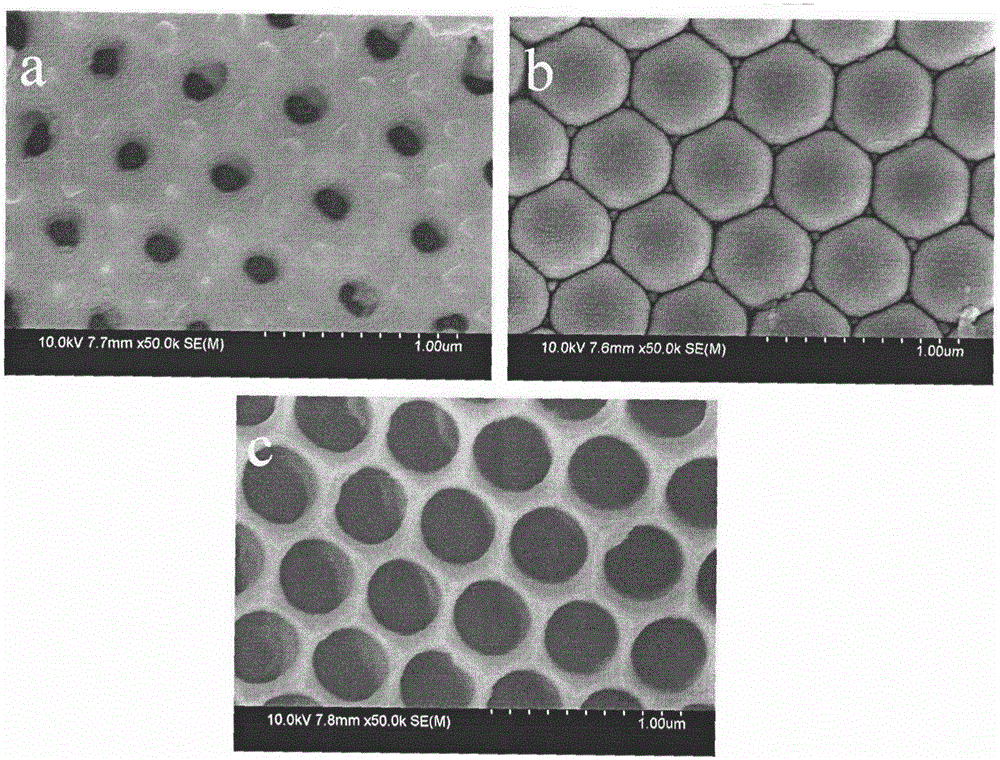

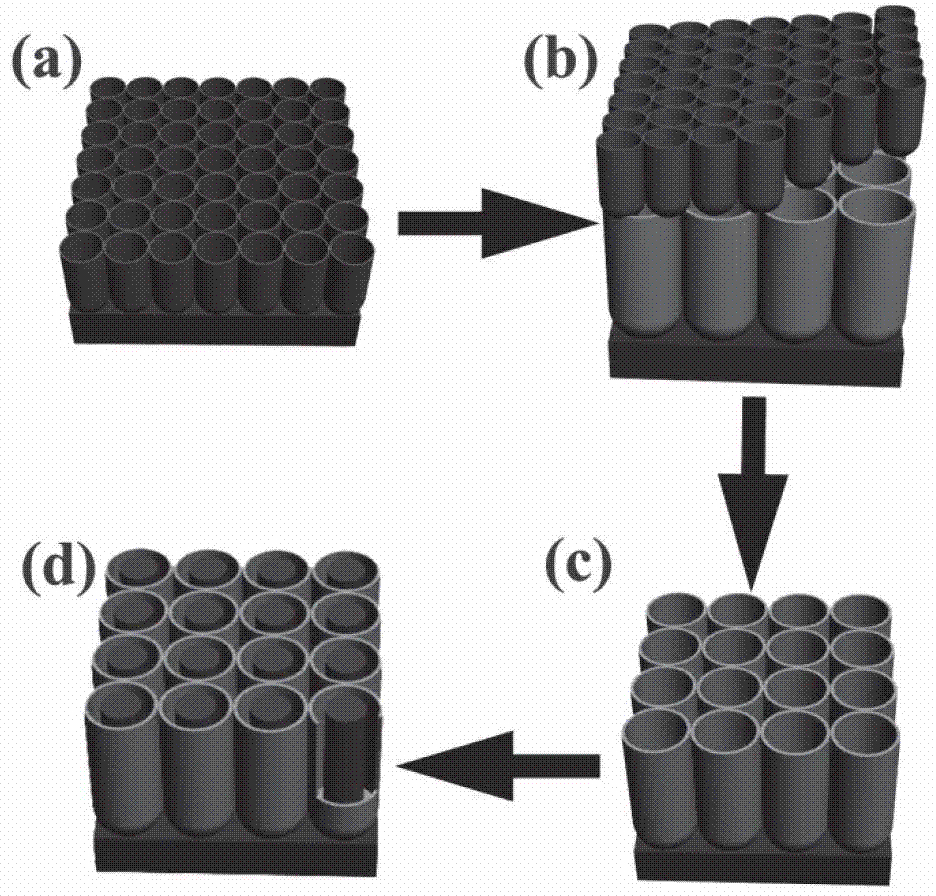

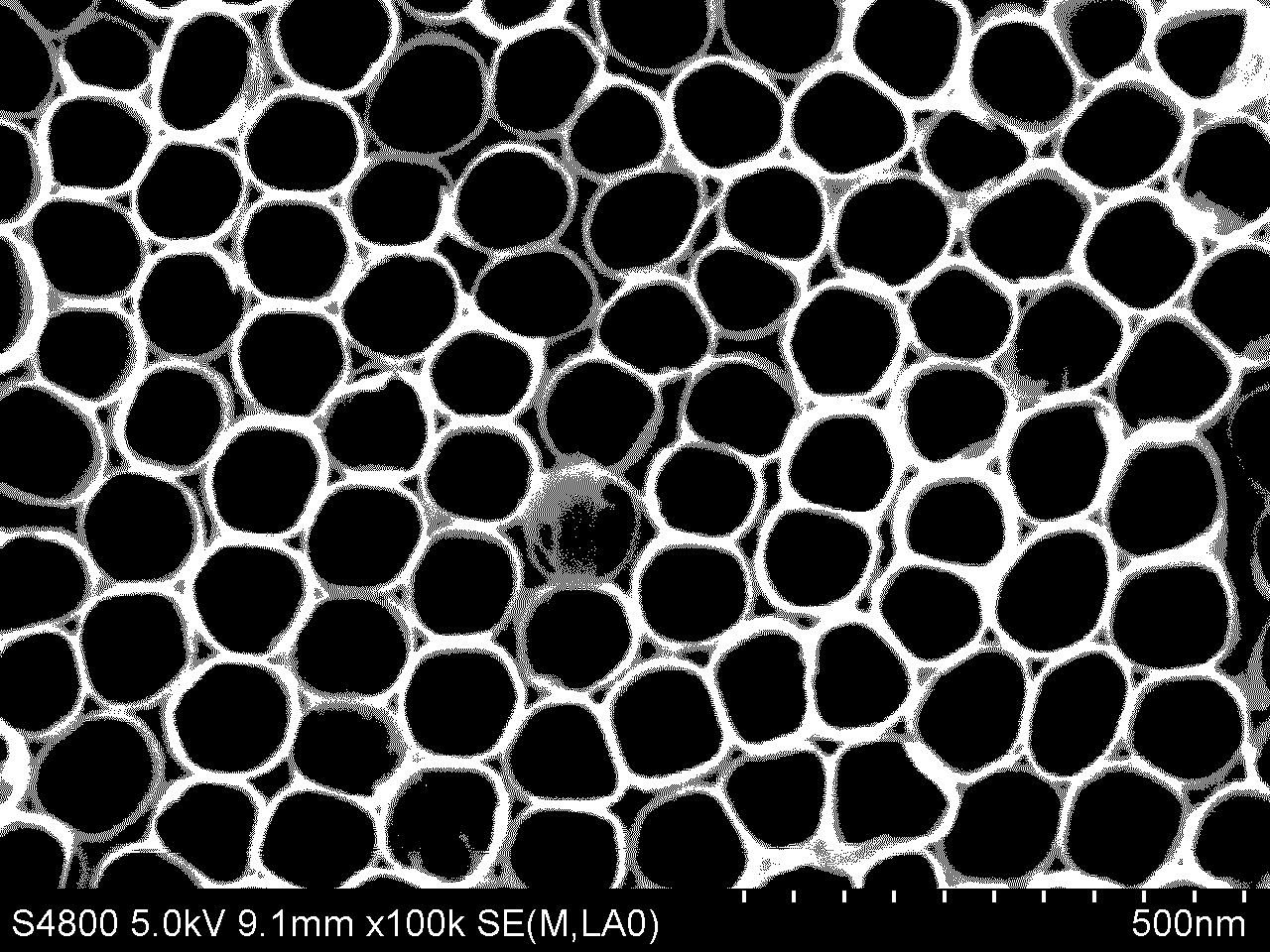

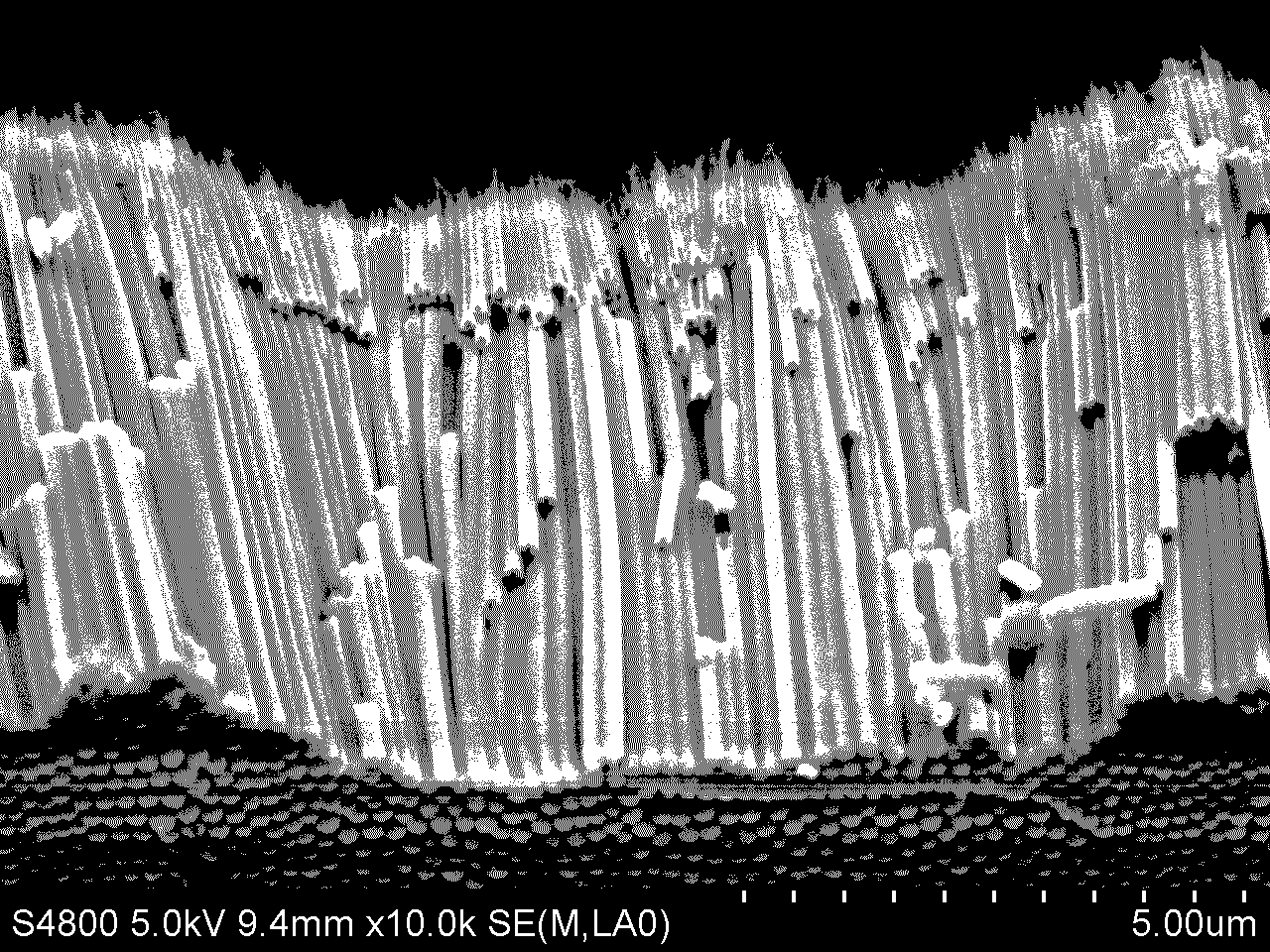

Honeycomb ordered titanium dioxide nanotube array film and preparation method thereof

InactiveCN102191529AGood size controlEasy to operatePolycrystalline material growthSurface reaction electrolytic coatingPhotonicsHoneycomb structure

The invention discloses a honeycomb ordered titanium dioxide nanotube array film and a preparation method thereof. The honeycomb ordered titanium dioxide nanotube array film consists of an upper-layer ordered structure and a lower-layer ordered structure, namely an upper-layer large-diameter regular hexagonal titanium dioxide nanopore array and a lower-layer small-diameter titanium dioxide nanotube array, wherein a low-layer nanotube orifice end is positioned in upper-layer titanium dioxide nanopores and the upper-layer nanopores are communicated so as to form a honeycomb structure. The method is easy to operate, equipment is cheap, and parameters of the structure can be effectively controlled by changing the oxidation voltage and the oxidation time of an anode; moreover, titanium dioxidewith the hierarchical structure can be widely applied to dye-sensitized solar cells, gas sensors, hydrogen preparation from water by photodecomposition, and photonic crystals.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

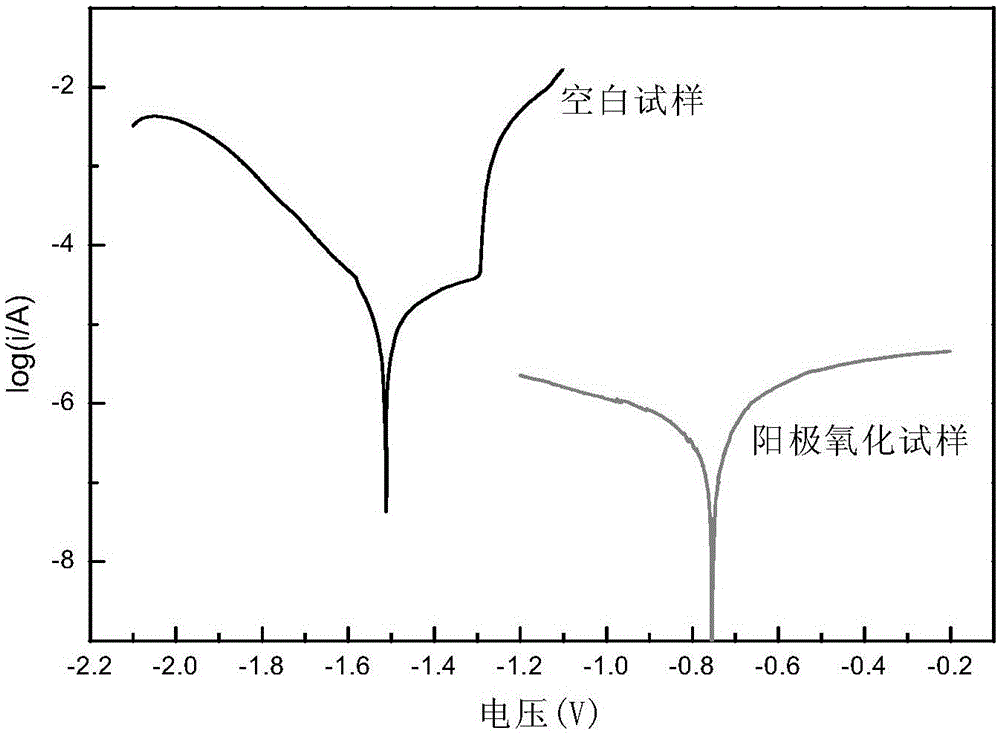

Titanium and titanium alloy surface anodic oxidation coloring method

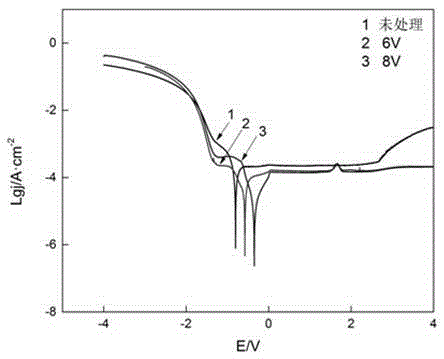

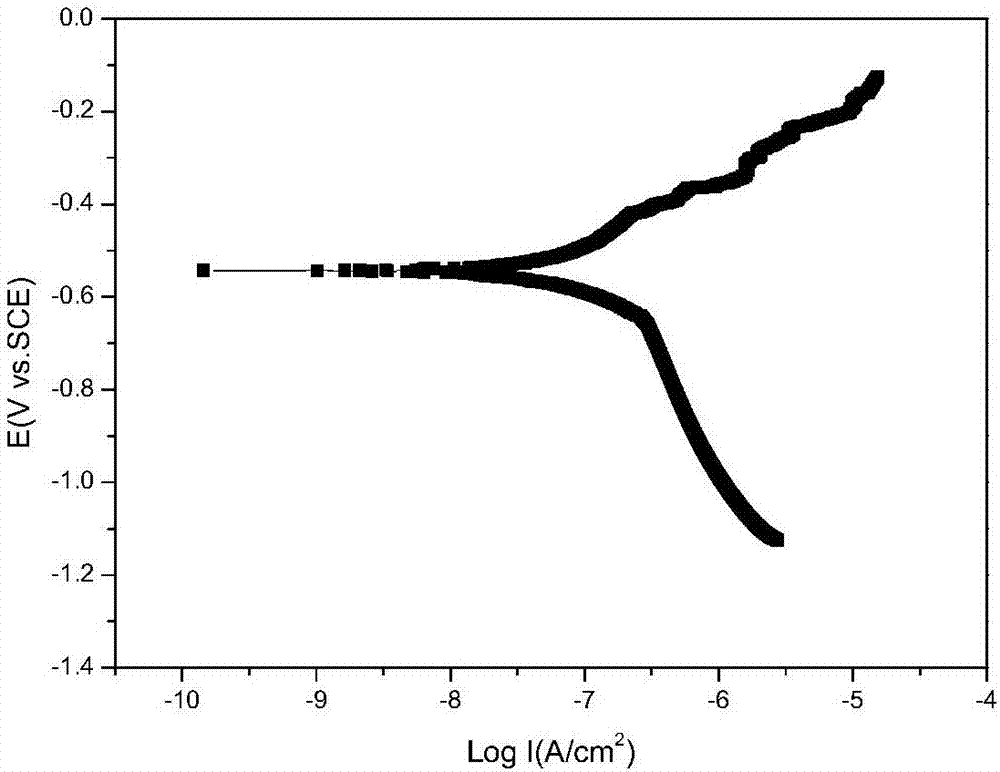

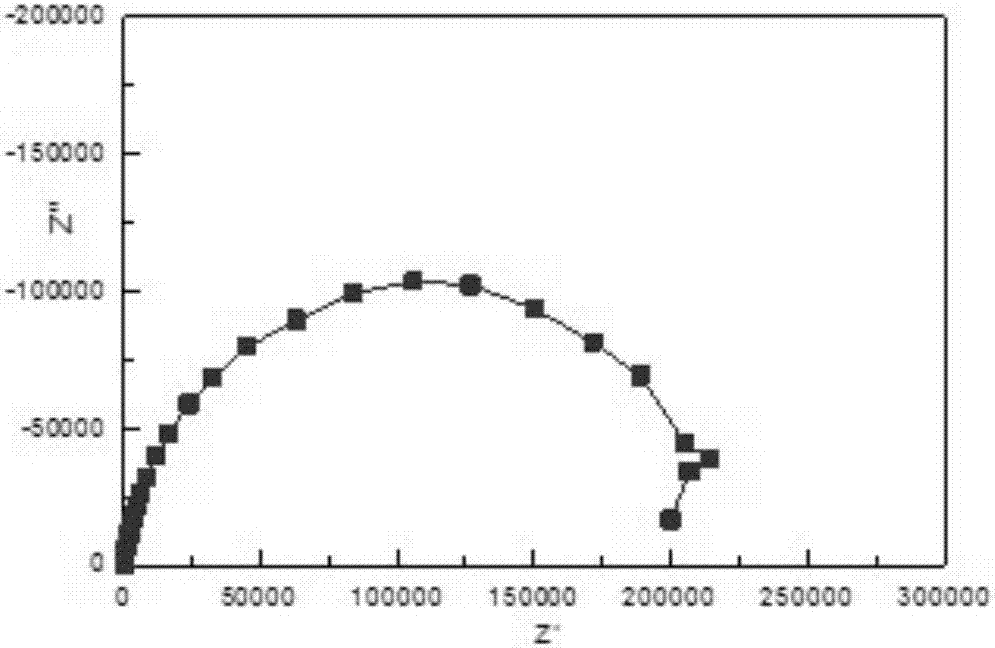

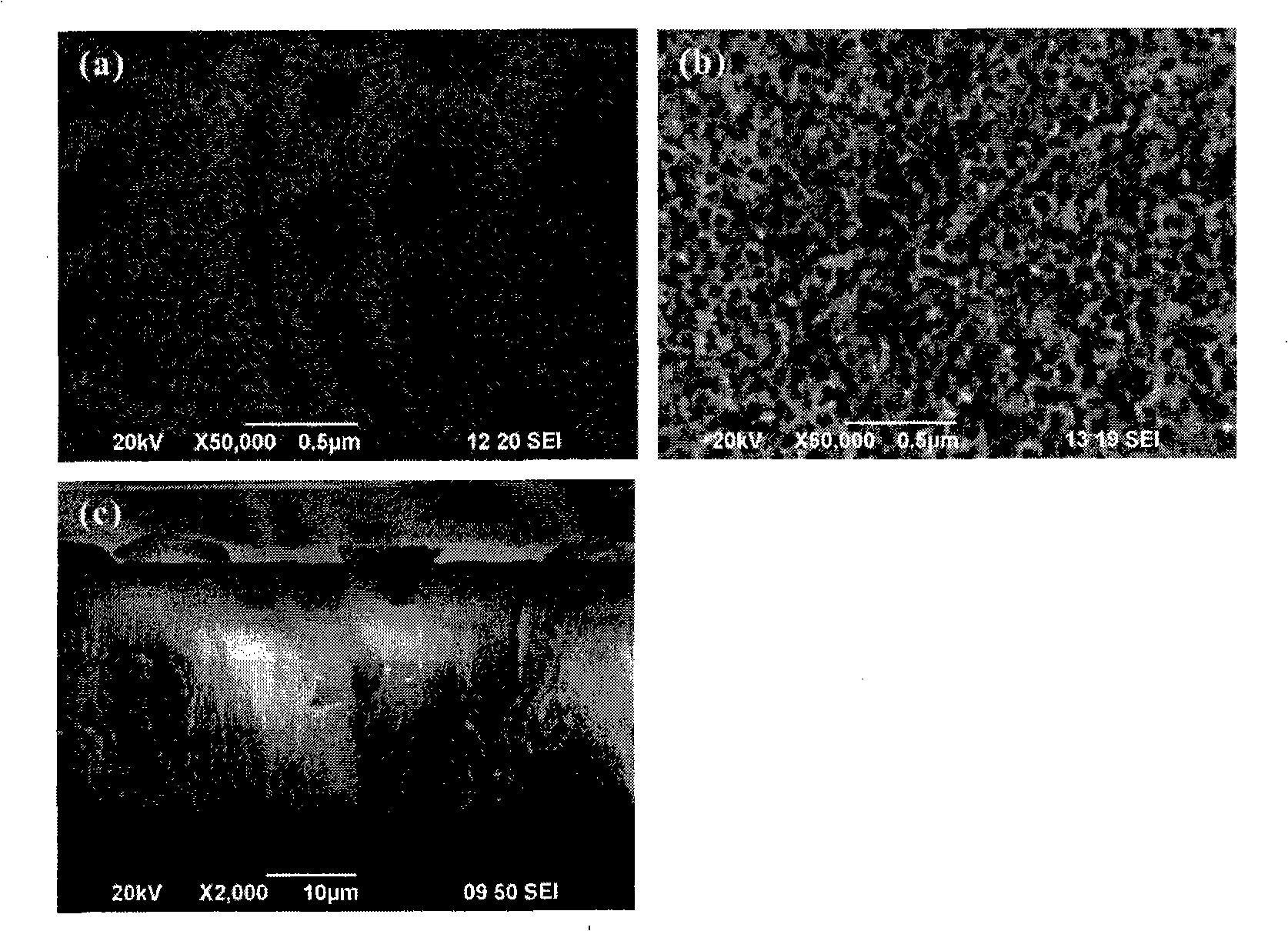

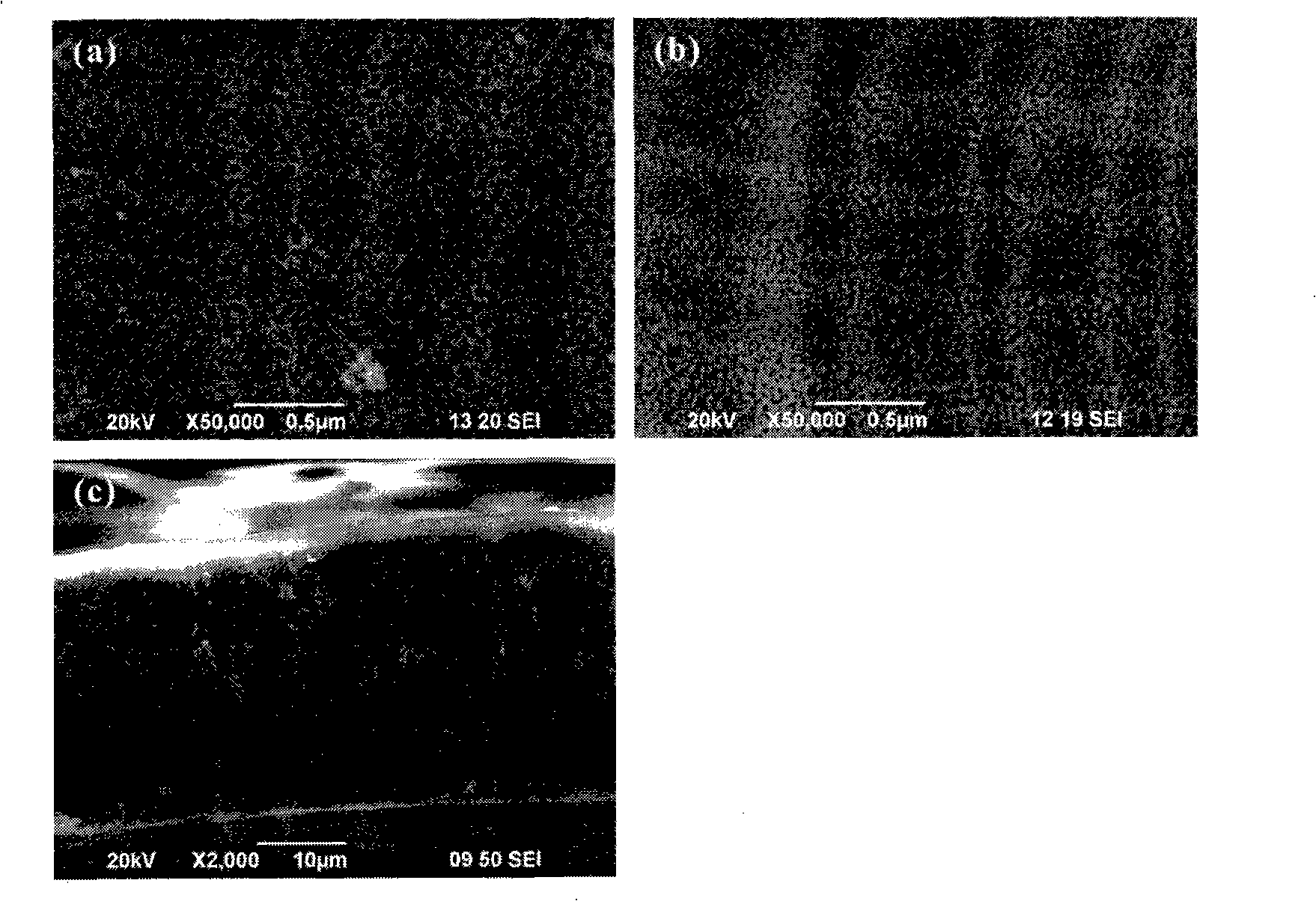

InactiveCN105239133ASimplify the anodizing processIncreased self-corrosion potentialSurface reaction electrolytic coatingElectrolysisTitanium

The invention discloses a titanium and titanium alloy surface anodic oxidation coloring method and belongs to the technical field of metal surface treatment. The method includes the following steps that a cleaned commercial pure titanium sample is put in a solution with a proportion of HF: HNO3: H2O for electrolytic polishing; the cleaned and dried sample is put in a mixed solution of concentrated sulfuric acid and methanesulfonic acid for anodic oxidation treatment; and the sample obtained after being subjected to the anodic oxidation treatment is rapidly cleaned through ethyl alcohol and deionized water and then dried under the vacuum condition so that the colored sample can be obtained. Anodic oxide films in different colors are obtained through control over anodic oxidation voltage and treatment time, and the anodic oxide films are bright and uniform in color and luster and good in corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

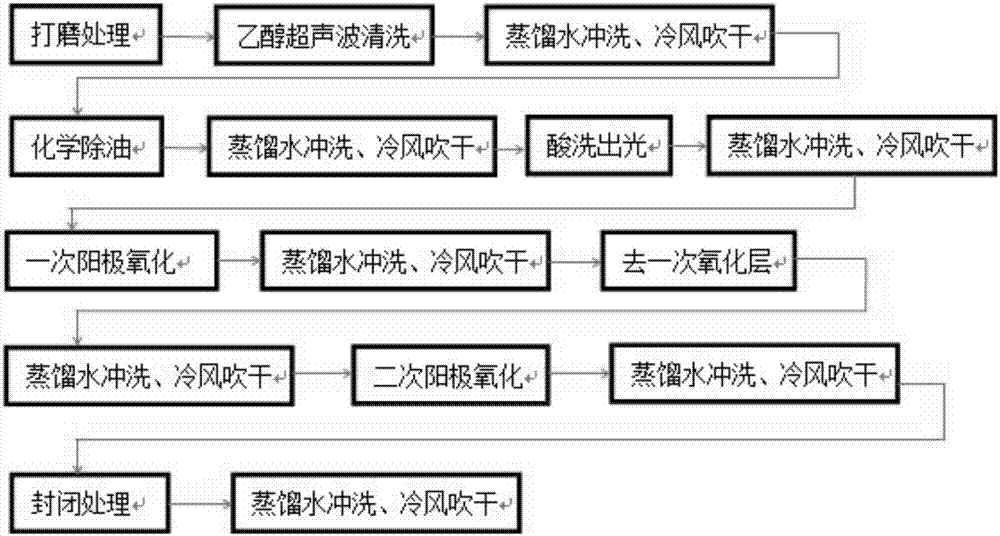

Aluminum alloy two-step anodizing process

InactiveCN107245748AEasy to operateReduce manufacturing costSurface reaction electrolytic coatingPhytic acidSodium salt

The invention discloses a secondary anodic oxidation process for aluminum alloys. Surface pretreatment is carried out first: the polished aluminum alloy samples are ultrasonically cleaned in an ethanol solution for 5-10 minutes; Sodium oxide 10-20g / L, coconut oil diethanolamine 2-8g / L, nonylphenol polyoxyethylene ether 0.5-5g / L in 2min for degreasing treatment; after rinsing and drying, put the sample into the solution: nitric acid 5-20g / L, sodium nitrate 5-10g / L, phytic acid sodium salt 0.1-3g / L for 1min for light treatment. Carry out the secondary anodizing process, the process parameters of the first anodizing are: the anodizing temperature is 10-25°C, the anodizing voltage is 30-60V, and the anodizing time is 60-150min; the process parameters of the second anodizing The process parameters are the same as the first anodizing. Finally, the sealing treatment is carried out. The composition of the sealing solution is: nickel acetate 0.5-1g / L and boric acid 0.5-1g / L, and the time is 20-40min to obtain a dense anodic oxide film. The invention has the advantages of environmental friendliness, simplicity, and high corrosion resistance of the formed oxide film.

Owner:NANJING UNIV OF POSTS & TELECOMM

Light metal surface micro plasma ceramic coating technology

The present invention provides a light metal surface microplasma ceramic coating process. It is characterized by that it utilizes electrolytic method to make oxidic film be grown on surface of base material. Its electrolytic solution is made up by using the following raw materials: (by wt%) 5-10% of alkaline salt solution, 4-6% of Na2O2, 0.5-1% of NaF, 2-3% of CH3COONa, 1-3% of Na3VO3 and 80-87% of H2O. Besides, said invention also provides the concrete steps of its electrolytic method.

Owner:上海施迈尔精密陶瓷有限公司

Titanium dioxide nanocomposite and one-step preparation method by utilizing anodic oxidation device

InactiveCN102534727AImprove photoelectric performanceSurface reaction electrolytic coatingElectrochemical responseNanowire

The invention discloses a titanium dioxide nanocomposite and a one-step preparation method by utilizing an anodic oxidation device; the preparation method comprises the steps of: polishing a pure titanium sheet to be smooth, cleaning ultrasonically and drying, fixing the pure titanium sheet to an anode by the anodic oxidation device, fixing a platinum gauze electrode to a cathode, and placing the pure titanium sheet and the platinum gauze electrode into electrolyte to perform an electrochemical reaction, wherein the electrolyte is an ethylene glycol / water mixing solution of ammonium fluoride, the concentration of NH4F in the solution is 0.1wt%-0.5wt%, the volume ratio of water is 1vol%-5vol%, the temperature of the solution is kept to be 20 DEG C-60 DEG C,the reaction time is 16 hours-48 hours, and the anodic oxidation voltage is 50V-70V. In the invention, the preparation process with low cost and simple preparation process is provided, a composite structure material of a nanotube and a nanowire in a microstructure can be provided, and good photoelectric efficiency is achieved.

Owner:TIANJIN UNIV

A preparation method of through-hole anodic aluminum oxide film with controllable pore size and thickness

The invention relates to a technique for preparing an anode alumina film, in particular to a method for preparing the anode alumina film which has small aperture, is ultra thin and is controllable in aperture and thickness. In the method, high-pure aluminum is used as an anode, a certain constant-voltage and direct-current power supply is applied onto a sulfuric acid electrolyte to perform anodicoxidation, proper voltages between the cathode and the anode, electrolyte concentration, electrolyte temperature and anode oxidization time are selected, and after the reaction, anode alumina with analuminum substrate is used as an anode and placed in mixed solution of perchloric acid and acetone, anode electrolysis treatment is performed under a voltage which is 5 to 15V higher than an anode oxidization voltage to make an alumina film separate from the aluminum substrate and to remove a baffle layer, and thus, the small-aperture through-hole anode alumina film with controllable aperture andthickness is obtained. When the method is used, the mass, simple, nondestructive, uniform and large-scale preparation of small-aperture and through-hole anode alumina film is realized, and the technical problem that the small-diameter and ultra-thin through hole anode alumina film is not available at present is solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

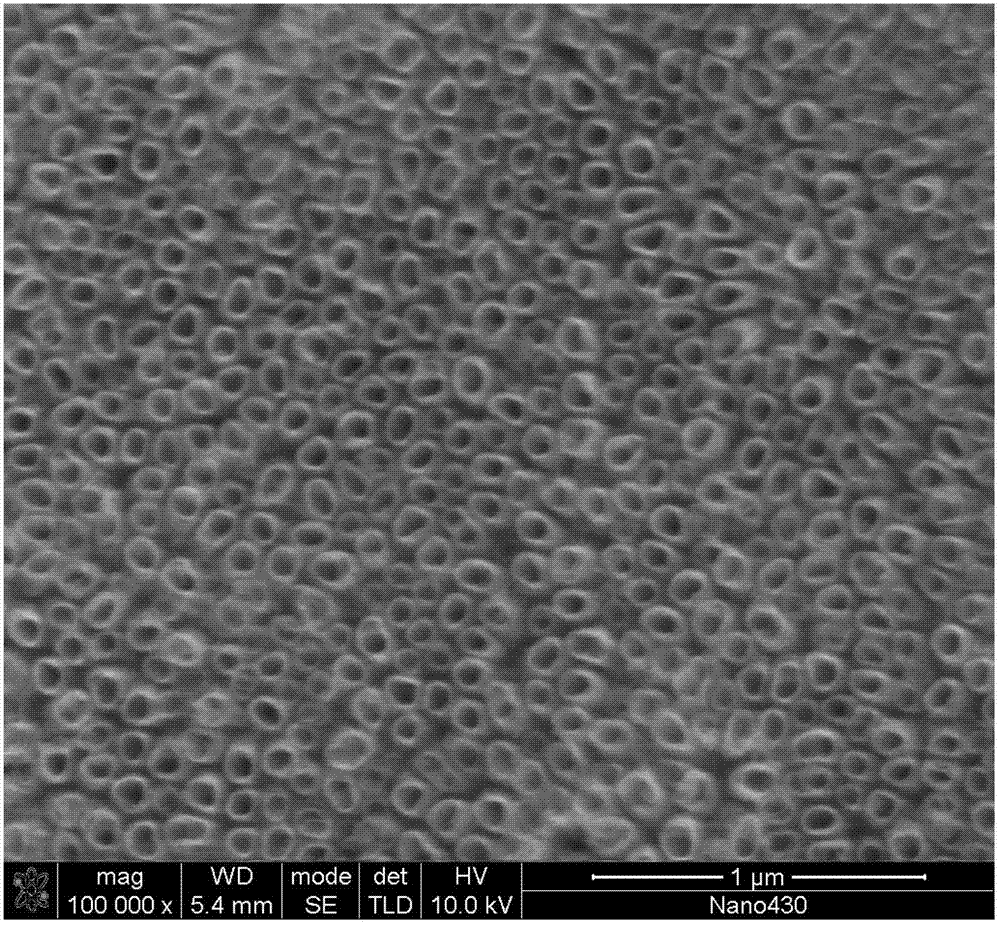

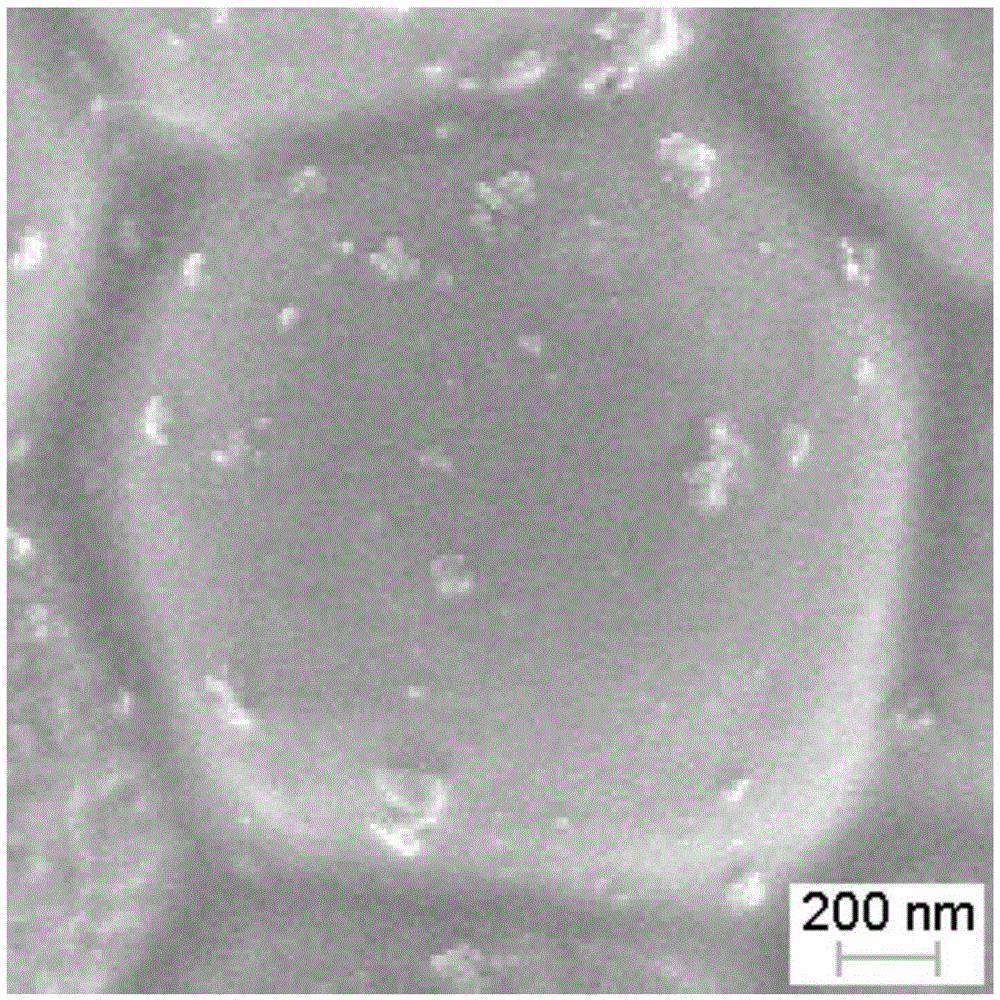

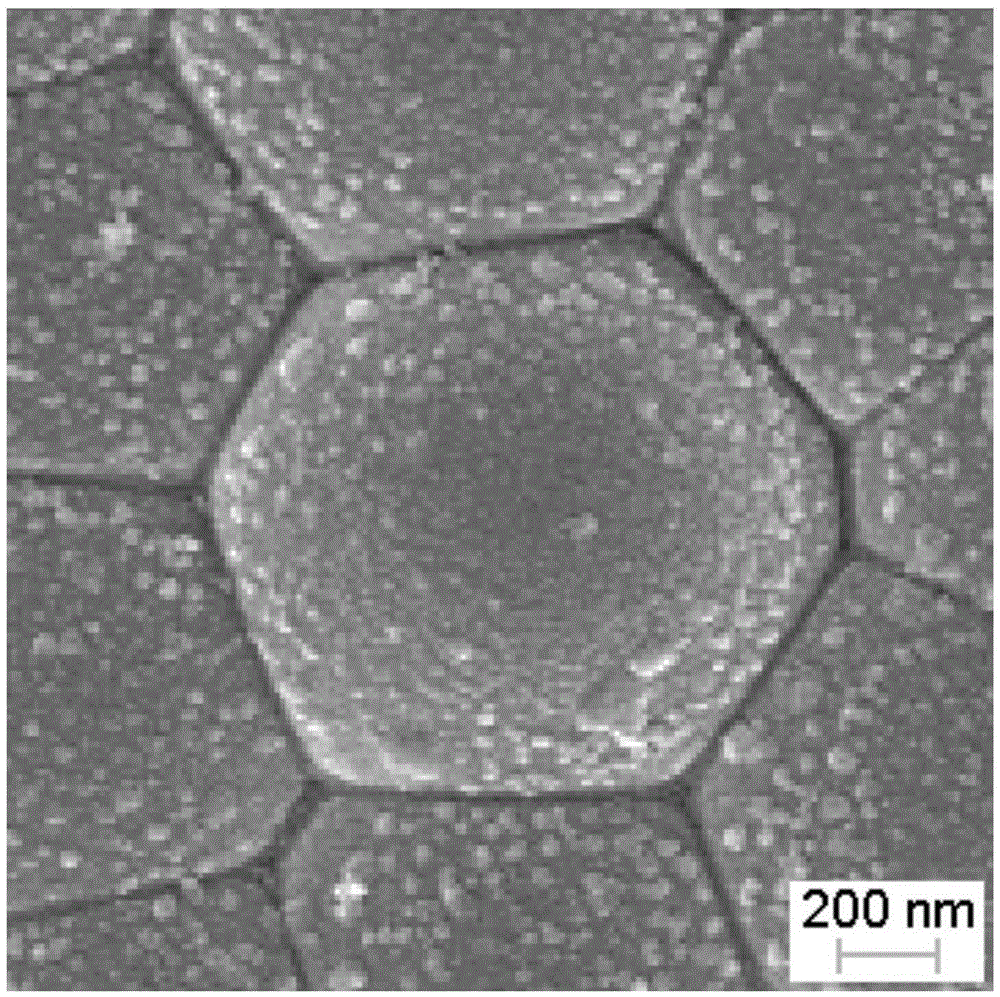

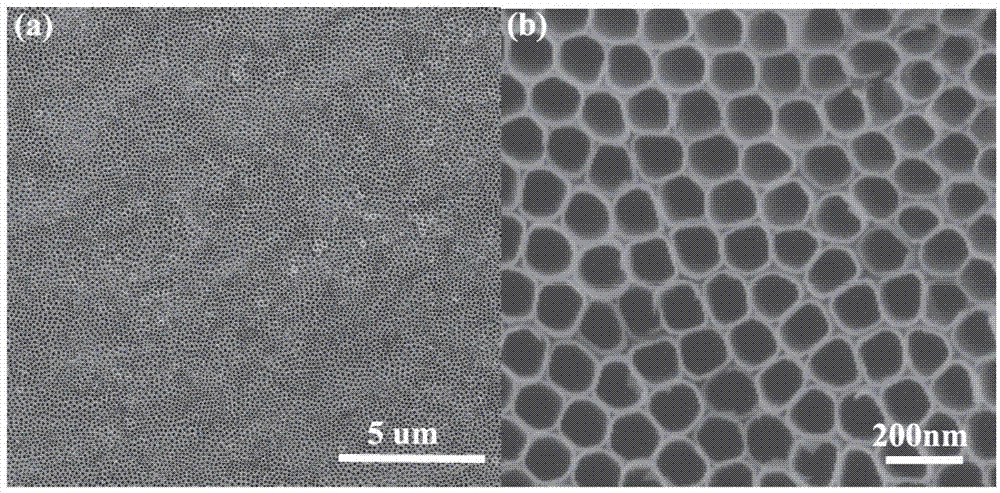

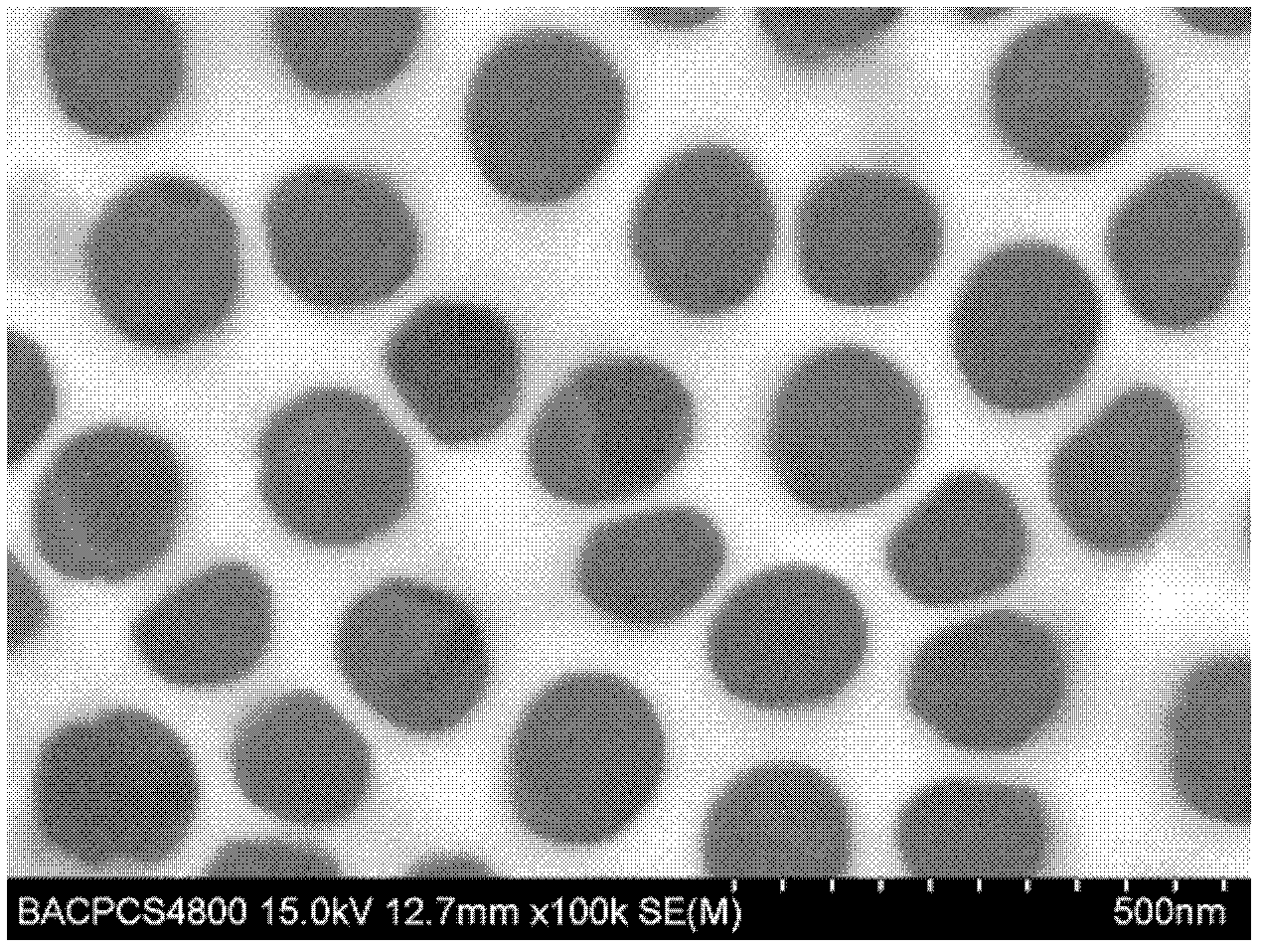

Thin-wall anodic aluminum oxide film with large aperture and preparation method thereof

The invention discloses a hexagonal thin-wall anodic aluminum oxide film with large aperture. The aperture of the anodic aluminum oxide is 200 to 300 nanometers, and the thickness of the hole wall is 5 to 20 nanometers. A method for preparing the film comprises the following steps: ultrasonically cleaning an aluminum sheet for 10 minutes by acetone, ethanol and high-purity water in turn, putting the cleaned aluminum sheet into mixed electrolyte in which the mass percentage of phosphoric acid to acetic acid is (10-1):(1-10) percent, and anodically oxidizing the aluminum sheet for 1 to 5 minutes under the voltage of 40 to 160 volts; then, cleaning the obtained anodic aluminum oxide film by the high-purity water, and soaking the cleaned anodic aluminum oxide film in mixed solution of 0.2 mol / L chromic acid and 0.4 mol / L phosphoric acid for 20 minutes at the temperature of 60 DEG C; anodically oxidizing the anodic aluminum oxide film for the second time for 5 minutes to 10 hours under the condition of the same mixed electrolyte and anodic oxidizing voltage as the first anodic oxidization; and soaking the obtained anodic aluminum oxide film into 10 percent phosphoric acid solution in percentage by mass for 20 minutes, finally cleaning the anodic aluminum oxide film by the high-purity water, and drying the anodic aluminum oxide film by nitrogen.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Self-supporting through-hole alumina film preparation method

InactiveCN101265602ANo pollution in the processSimple and fast operationAnodisationElectrolysisMetallic aluminum

The invention relates to a method for preparing a self-supporting through-hole alumina film by cathode electrolysis process in the neutral aqueous solution, which belongs to the physical material field. An electropolished metallic aluminum sheet is oxidated by an anodic oxidation method to form an alumina film on the surface thereof, a barrier layer separates the porous alumina film from a metallic aluminum substrate, the thickness thereof meets the linear relation of 1.4nm / V to the constant-pressure corrosion condition; the barrier layer is thinned by adopting a current reversion method, as the thickness of the barrier layer is proportional to the anode oxidation voltage, reducing the oxidation voltage gradually can effectively lower the thickness of the barrier layer, the alumina film can be peeled off by lower cathode electrolysis voltage; at last a cathode electrolysis method is adopted to electrolyze the peeled film and through holes in neutral potassium chloride aqueous solution, the self-supporting through-hole alumina film can be fully peeled off from the aluminum substrate to obtain a product. The method has the advantages of simple operation, low energy consumption, no environment pollution and so on. The product has broad prospects in the aspects of nanometer material synthesis and nanometer device application.

Owner:QINGDAO UNIV

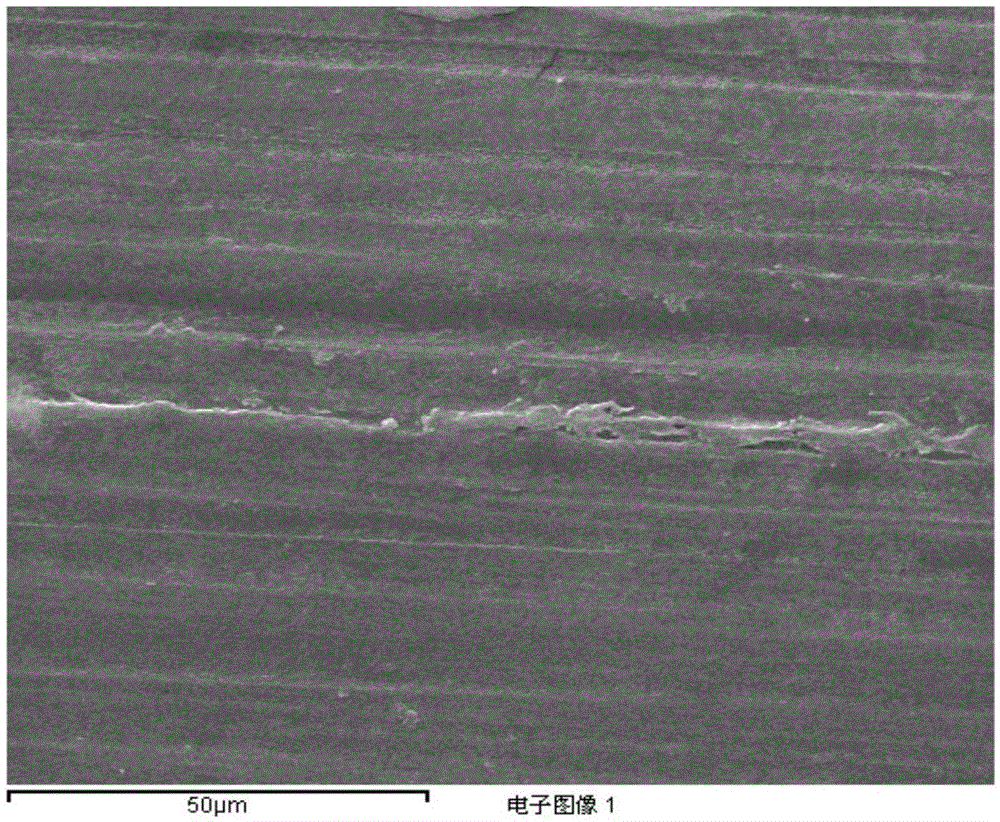

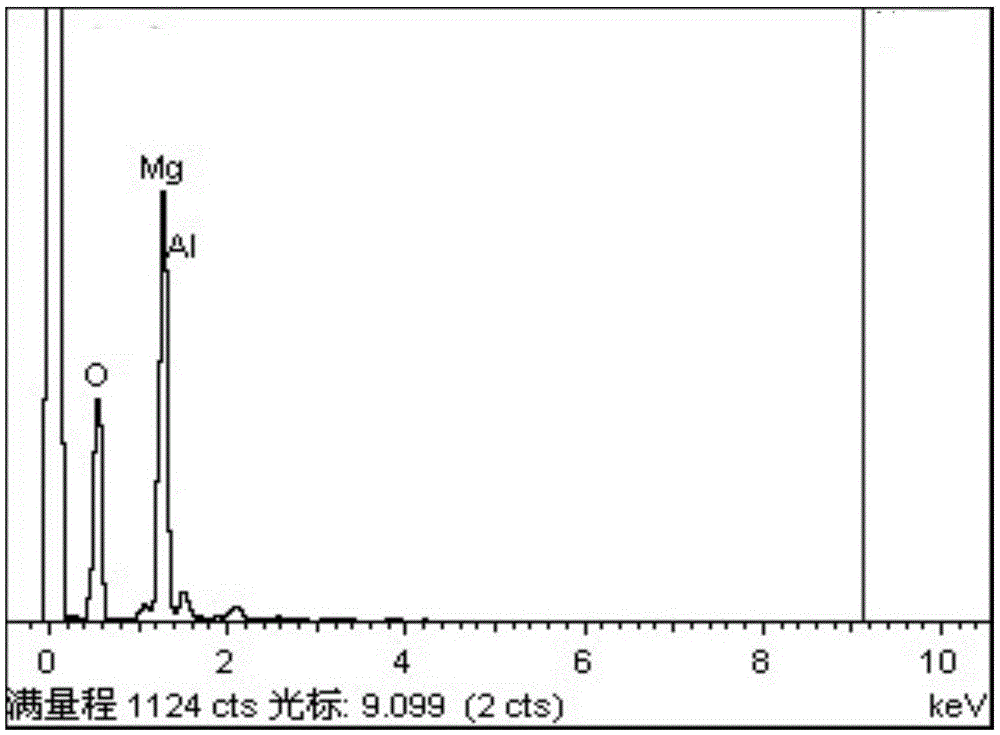

Magnesium alloy anodizing electrolyte and method for preparing anodic oxide film by electrolyte

The invention belongs to the technical field of magnesium alloy surface treatment, and discloses magnesium alloy anodizing electrolyte and a method for preparing an anodic oxide film by the electrolyte. The electrolyte consists of 10-50 g / L of sodium tetraborate, 10-30 g / L of boric acid, 5-30 g / L of sodium hydroxide, 4-15 g / L of film forming accelerant and 5-10 g / L of buffer agent; and the pH value of the electrolyte is adjusted within 8.5-9.5. The electrolyte is used for performing the anodic oxidation treatment to obtain the anodic oxide film. The prepared anodic oxide film is a black film layer excellent in corrosion resistance. The electrolyte is stable in system, environment-friendly, free of poison, low in cost and easy to realize the industrialization; the anodic oxidation process temperature is low, so that the energy saving is facilitated; and the anodic oxidization voltage is lower, no spark discharge phenomenon is generated, and large cooling equipment is not needed, so that the process is simple, and the energy consumption is lower.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing titanium dioxide nanotube membrane

InactiveCN101717984APromote exchangeImprove photocatalytic performanceNanostructure manufactureSurface reaction electrolytic coatingElectrolysisHigh voltage pulse

The invention discloses a method for preparing a titanium dioxide (TiO2) nanotube membrane with two permeable ends of a nanotube thereof. The method for preparing the titanium dioxide nanotube membrane comprises the following steps of: firstly, generating a titanium dioxide membrane with a required thickness on the surface of a titanium substrate material in a mode of electrolytic oxidation; secondly, thinning a barrier layer at the bottom of the titanium dioxide nanotube membrane by adopting gradual voltage-lowering oxidation; and finally, applying a high-voltage pulse higher than an anode oxidation voltage to continue oxidizing after finishing the last process until the titanium dioxide nanotube membrane with two permeable ends is shed from the substrate.

Owner:LANZHOU UNIVERSITY

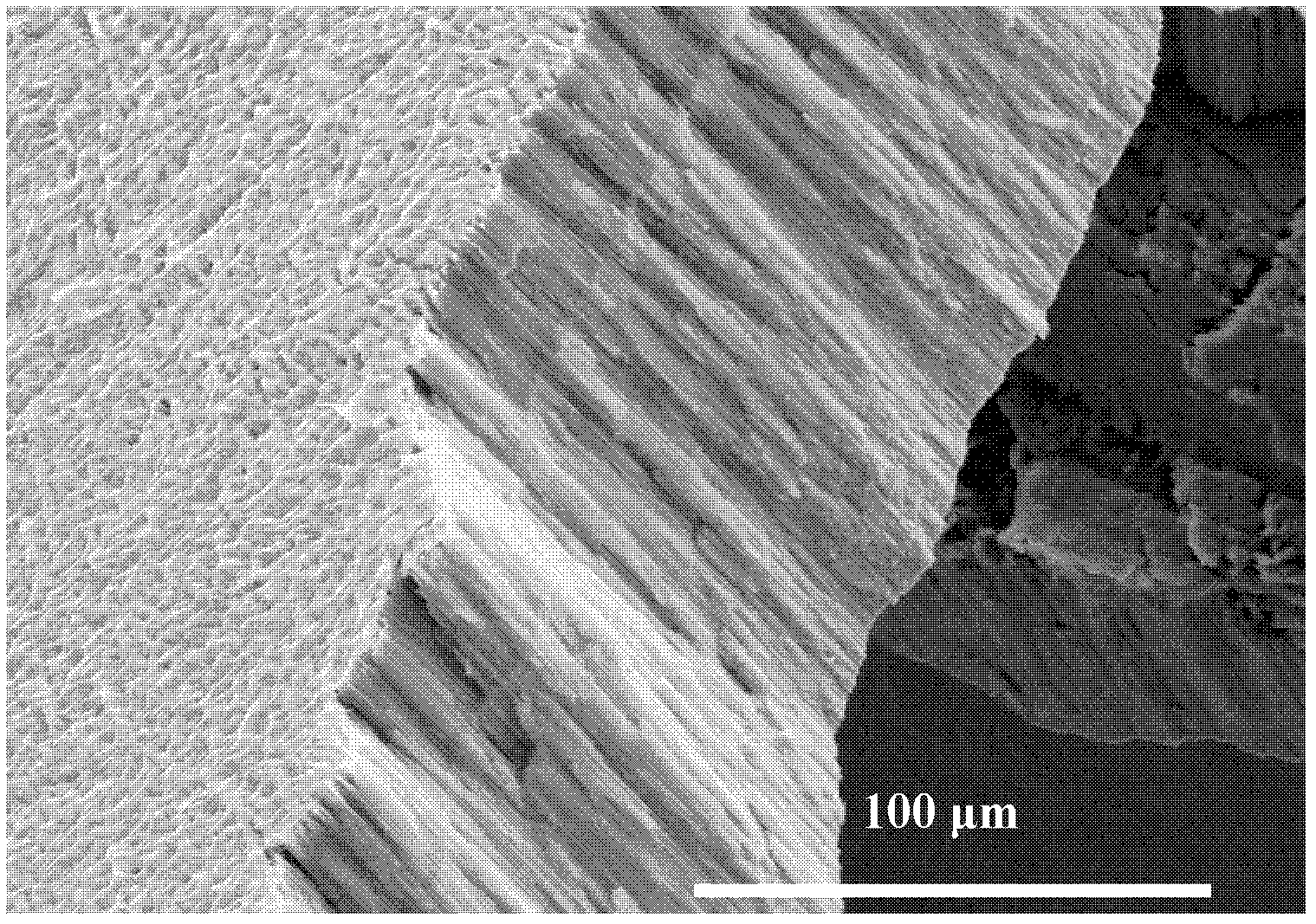

Fast stable growth process of alumina film with nanometer pore array in relatively great pore distance

The fast stable growth process of alumina film with nanometer pore array in relatively great pore distance includes the following steps: 1. compounding electrolyte solution with H3PO4, C2H5OH and water; 2. pre-treating aluminum sheet through soaking in acetone, wipping, rinsing with deionized water and electrochemical polishing with mixed solution of perchloric acid and ethanol; 3. the first etching of the aluminum sheet in the electrolyte solution at -5 to -10 deg.c under the action of anode oxidizing voltage of 195V and current density of 1500-4000A / sq m; 4. soaking the aluminum sheet in water solution of chromic acid at 60 deg.c to eliminate alumina generated in the first etching; and 5. the second etching of the aluminum sheet in the same condition as that in the step 3.

Owner:SHANGHAI JIAO TONG UNIV

Titanium alloy anodic oxidation coloring technique

InactiveCN108301029AVariety of colorsUniform coloring filmSurface reaction electrolytic coatingElectrochemistryTitanium alloy

The invention belongs to the technical field of material surface treatment and particularly relates to a titanium alloy anodic oxidation coloring technique. According to the following technical scheme, the titanium alloy anodic oxidation coloring technique adopts an electrochemical two-electrode system, in an inorganic acid electrolyte, a direct current voltage-stabilizing power source is used forregulating and controlling the anodic oxidation voltage, and a titanium alloy is subjected to anodic oxidation coloring treatment under the indoor temperature condition. According to the titanium alloy anodic oxidation coloring technique, the titanium alloy surface with the abundant color and with a uniform colored film can be obtained, and the titanium alloy anodic oxidation coloring technique can be used in industry on a large scale.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for improving high-temperature oxidation resistance of titanium-based alloy

InactiveCN108486631AGood high temperature oxidation resistanceSolve the technical problem of poor high temperature oxidation resistanceSurface reaction electrolytic coatingCeriumCe element

The invention discloses a method for improving high-temperature oxidation resistance of a titanium-based alloy. The method takes the titanium-based alloy as an anode, the high-temperature oxidation resistance of the titanium-based alloy is improved through an active element to modify an anode oxidation film, and the active element is cerium element. According to the method, the anodic oxidation film is modified by adding the active element, the high-temperature oxidation resistance effect can be achieved with lower anodic oxidation voltage and shorter anodic oxidation time compared to an electrolyte without the active element, the technical difficult problem that the titanium-based alloy is poor in high-temperature oxidation resistance is solved, the oxidation time is also shortened, and the oxidation voltage is reduced; due to the fact that the oxidation film is grown in situ, the binding force of the oxidation film is good with a substrate, the manufacturing process is simple, the cost is low, the operation is convenient, the efficiency is high, the implementation is easy to be realized, and the anti-oxidation property is good under the high-temperature oxidation of 1000 DEG C.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing overlarge crystal-cell porous pellumina

InactiveCN102127788AOvercome the shortcoming of requiring low temperature (-10~5℃)Increase the flash voltageSurface reaction electrolytic coatingPhosphoric acidElectrochemistry

The invention belongs to the technical field of nanometer physical material preparation, in particular to a method for preparing an overlarge crystal-cell porous pellumina. The method comprises the following steps of: firstly, preparing a mixed solution of citric acid, ethylene glycol and deionized water for an electrolyte, preparing citric acid and deionized water into 1-2% by weight of aqueous citric acid solution; then, compounding the aqueous solution and the ethylene glycol into the electrolyte; selecting an annealed and electrochemically polished aluminum flake as a raw material and controlling the temperature and the anodizing voltage of the electrolyte for primary anodizing to prepare a sample; soaking the sample in the mixed acid solution of chromic acid and phosphoric acid at a controlled temperature and removing alumina generated in the primary anodizing process; and then, carrying out secondary anodizing to make an alumina film with the crystal cell of 2.0 micros and the hole of 800 micros under the condition of primary anodizing parameters. The invention has simple preparation process, reliable principle, high flash voltage, large product crystal-cell size and loose oxidization condition.

Owner:QINGDAO UNIV

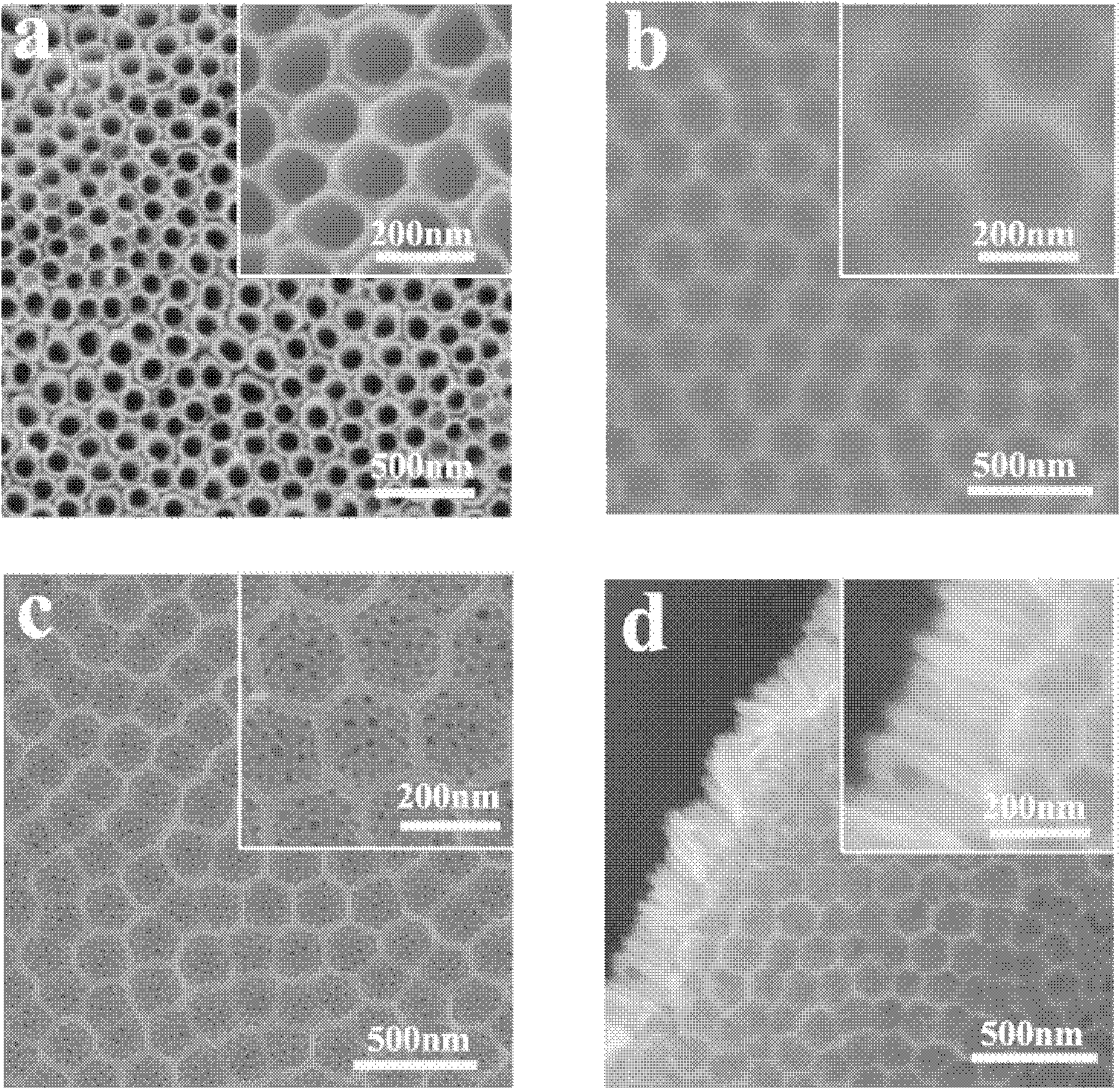

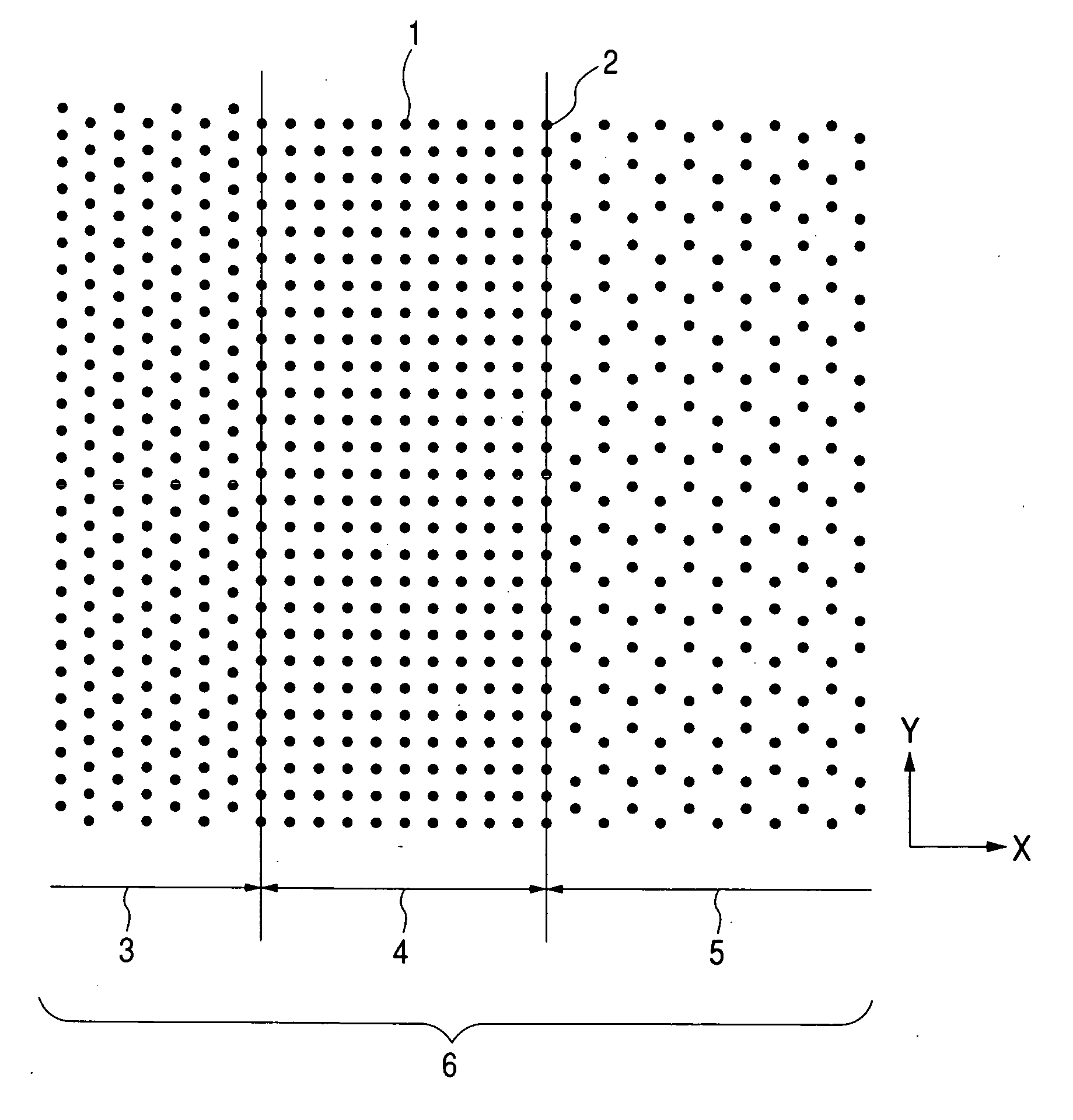

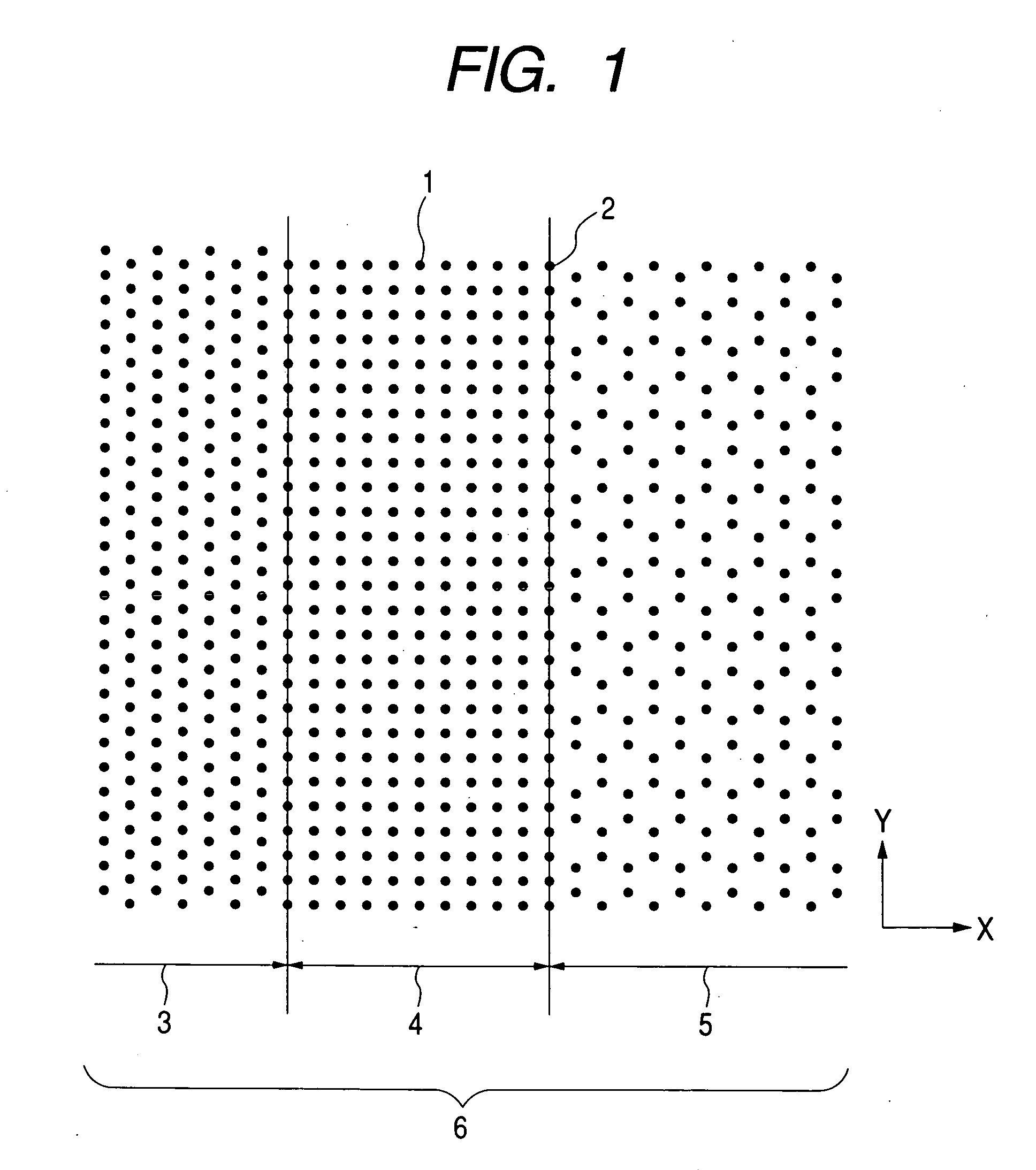

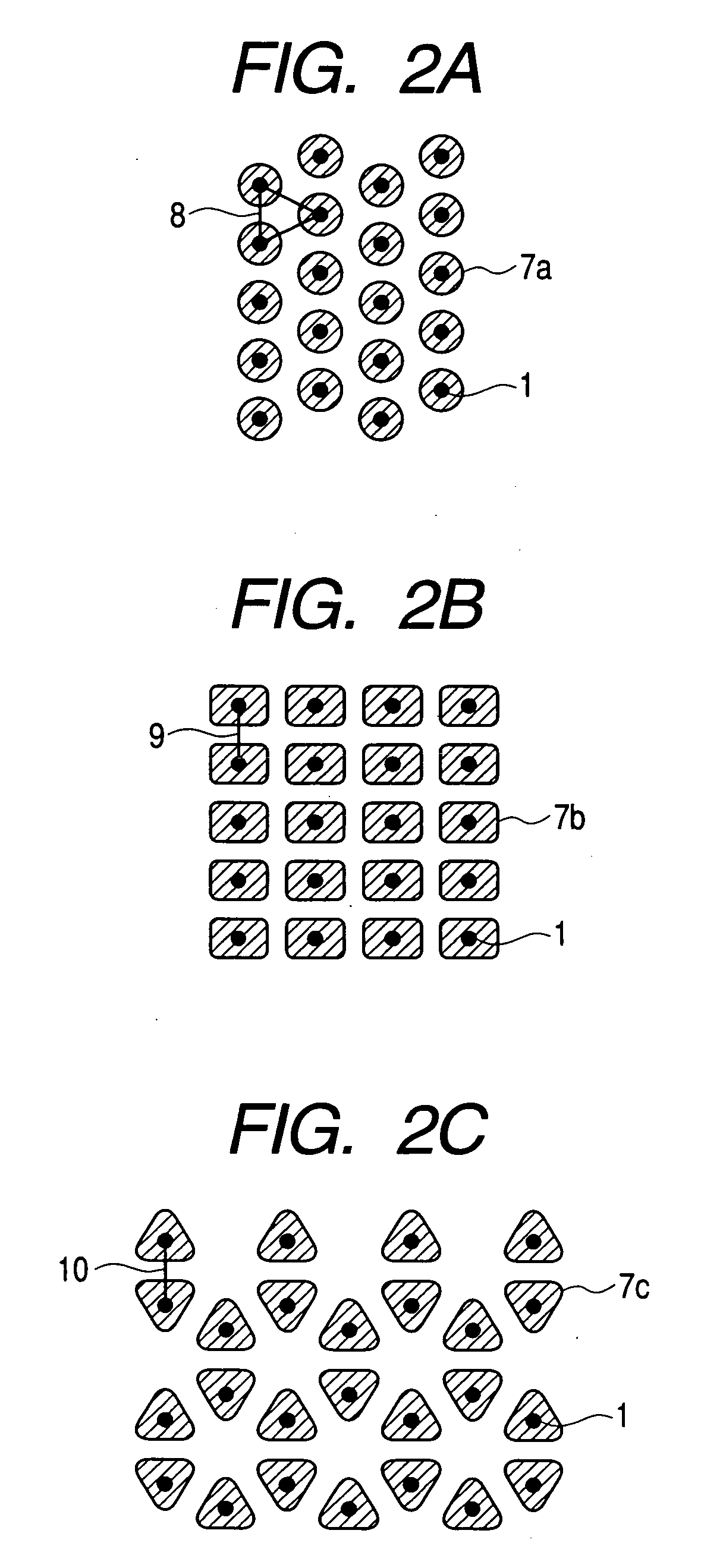

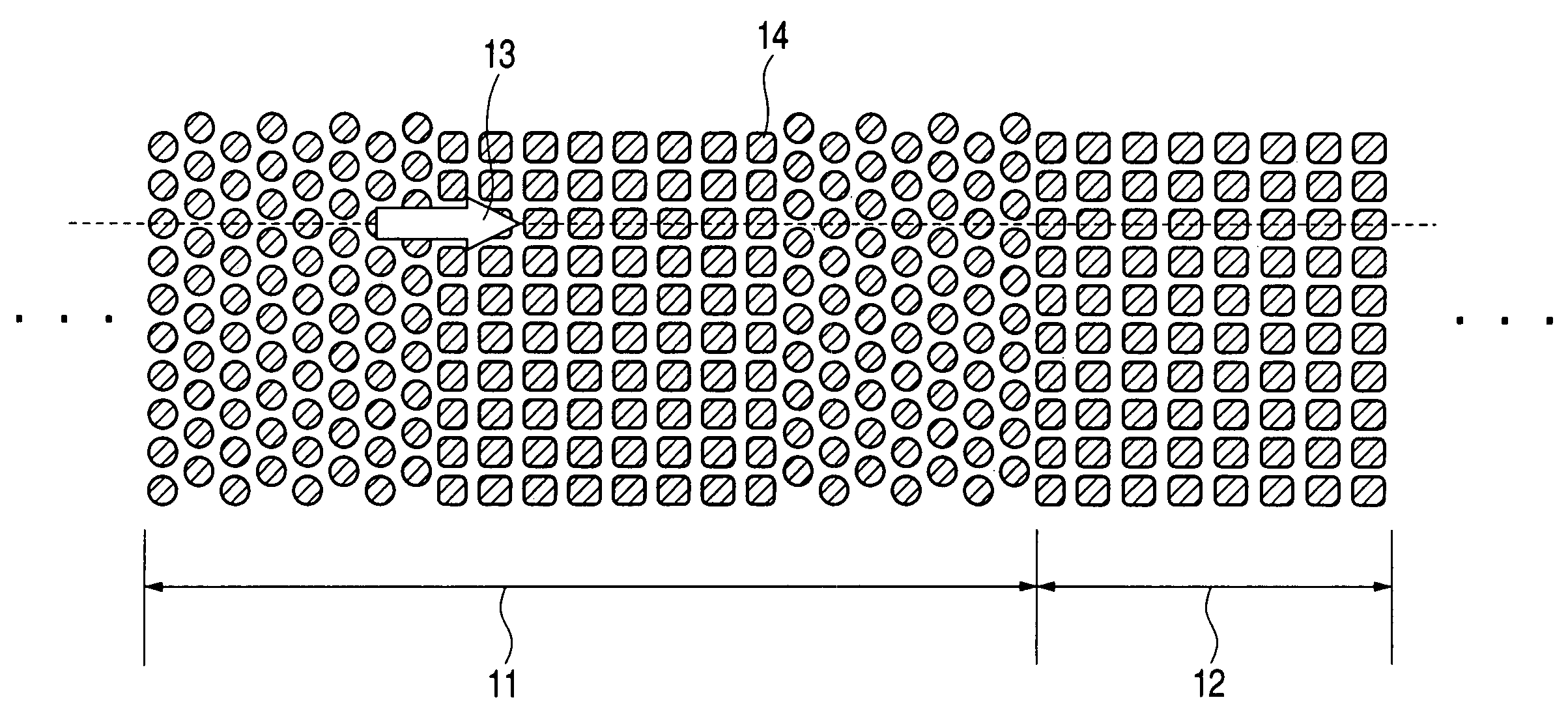

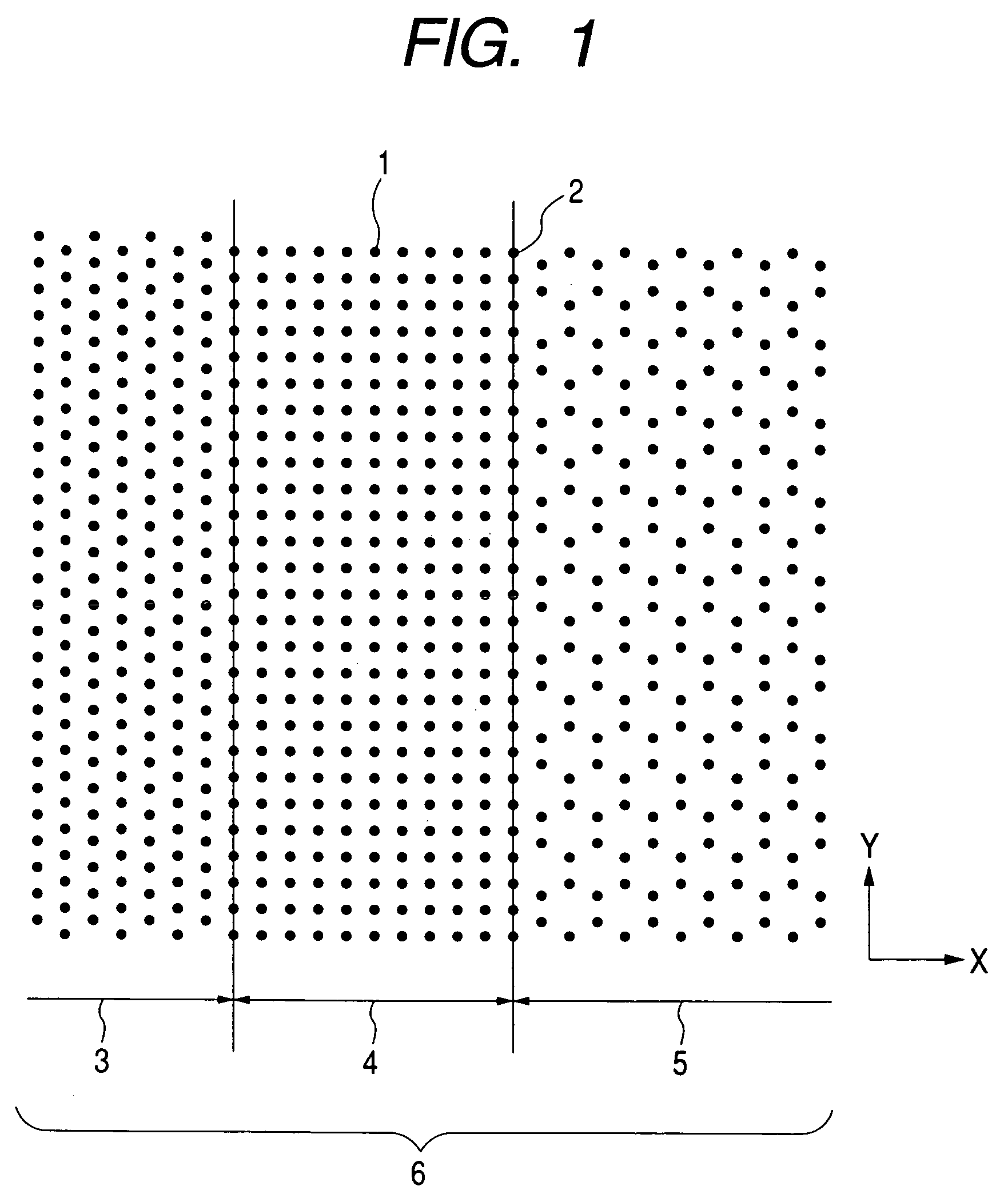

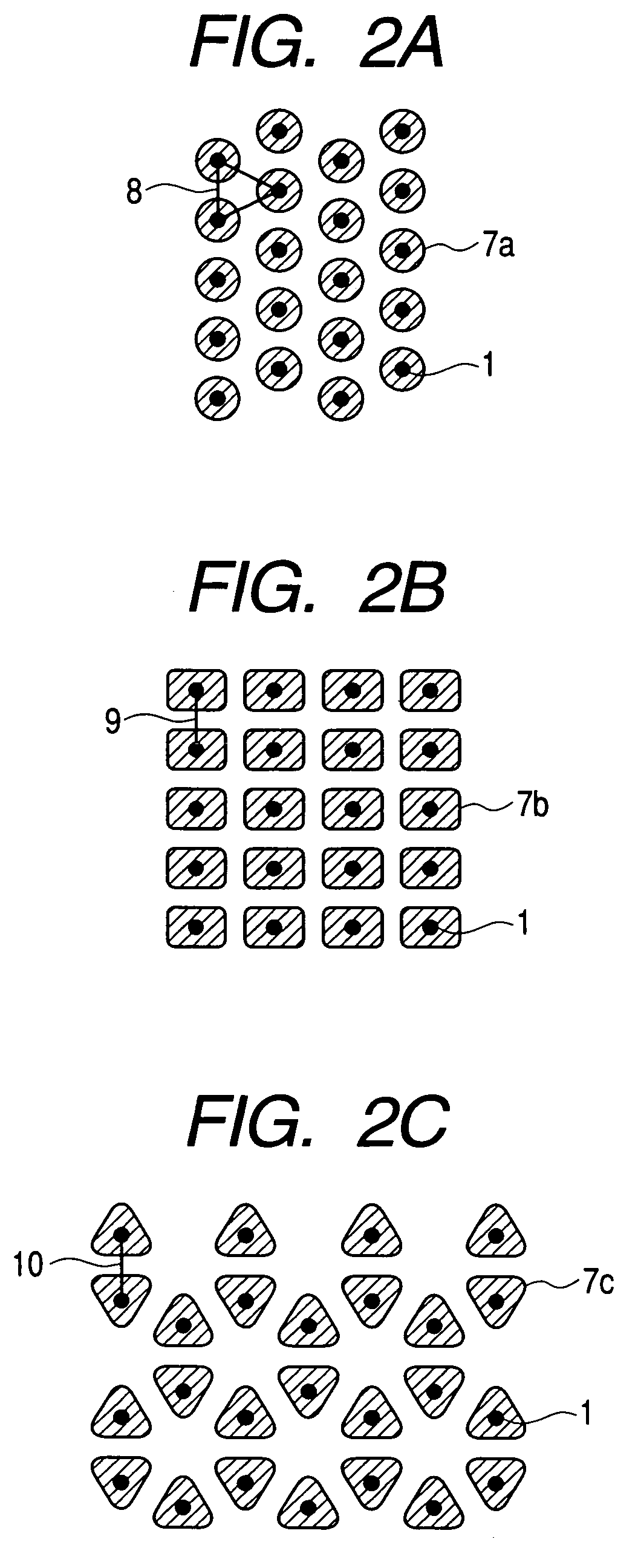

Structure, optical device, magnetic device, magnetic recording medium and manufacturing method thereof

A nano structure having pore array structures in which a plurality of periodic arrays are formed adjacent to one another and a method of manufacturing the nano structure are provided. A nano structure having periodic array structures of pores formed in an anodized oxide film with a plurality of types of the periodic array structures arranged adjacent to one another is provided. Furthermore, a method of manufacturing a nano structure in which a plurality of periodic array structures formed in an anodized oxide film having different periods are arranged adjacent to one another, including (1) a step of forming pore starting points made up of a plurality of types of periodic arrays on the surface of a substrate comprised of aluminum as a principal component and (2) a step of anodizing the substrate simultaneously at the same anodization voltage is provided.

Owner:CANON KK

Structure, optical device, magnetic device, magnetic recording medium and manufacturing method thereof

A nano structure having pore array structures in which a plurality of periodic arrays are formed adjacent to one another and a method of manufacturing the nano structure are provided. A nano structure having periodic array structures of pores formed in an anodized oxide film with a plurality of types of the periodic array structures arranged adjacent to one another is provided. Furthermore, a method of manufacturing a nano structure in which a plurality of periodic array structures formed in an anodized oxide film having different periods are arranged adjacent to one another, including (1) a step of forming pore starting points made up of a plurality of types of periodic arrays on the surface of a substrate comprised of aluminum as a principal component and (2) a step of anodizing the substrate simultaneously at the same anodization voltage is provided.

Owner:CANON KK

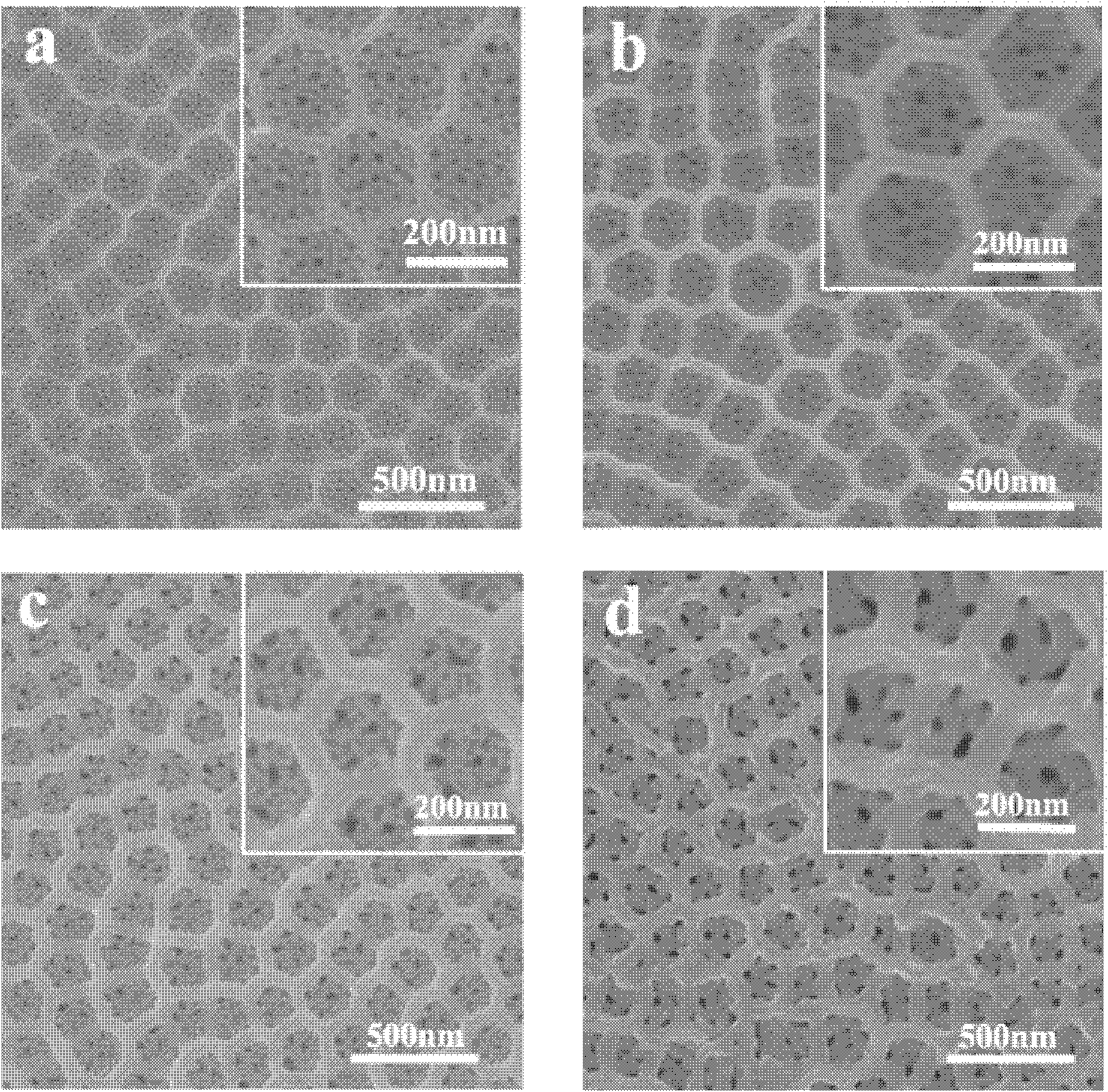

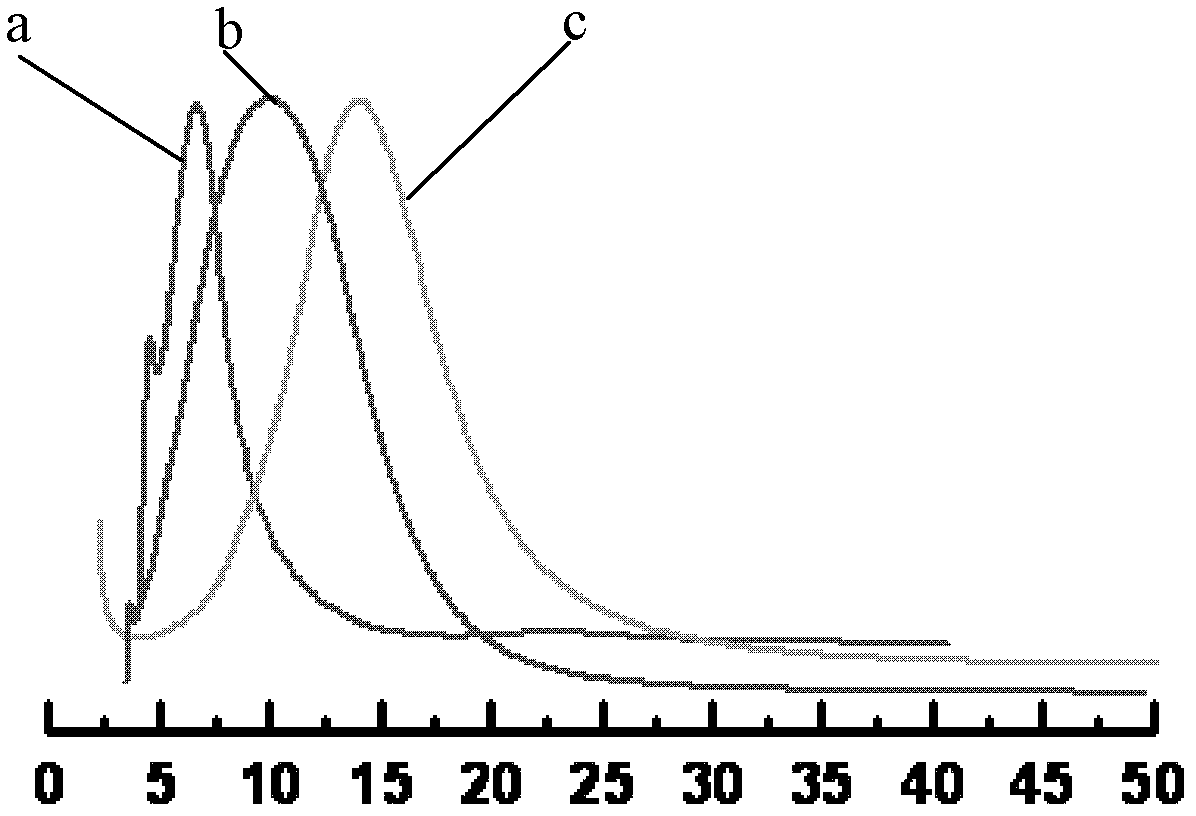

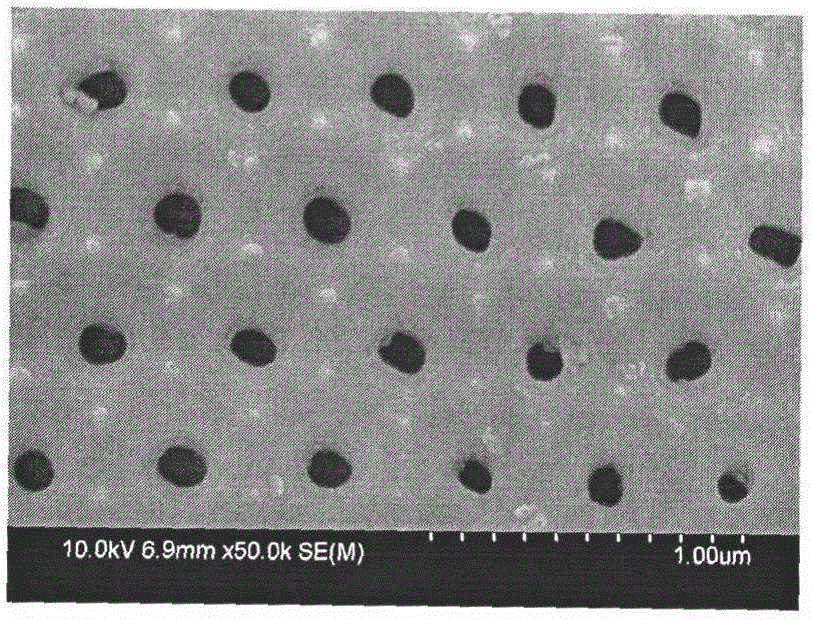

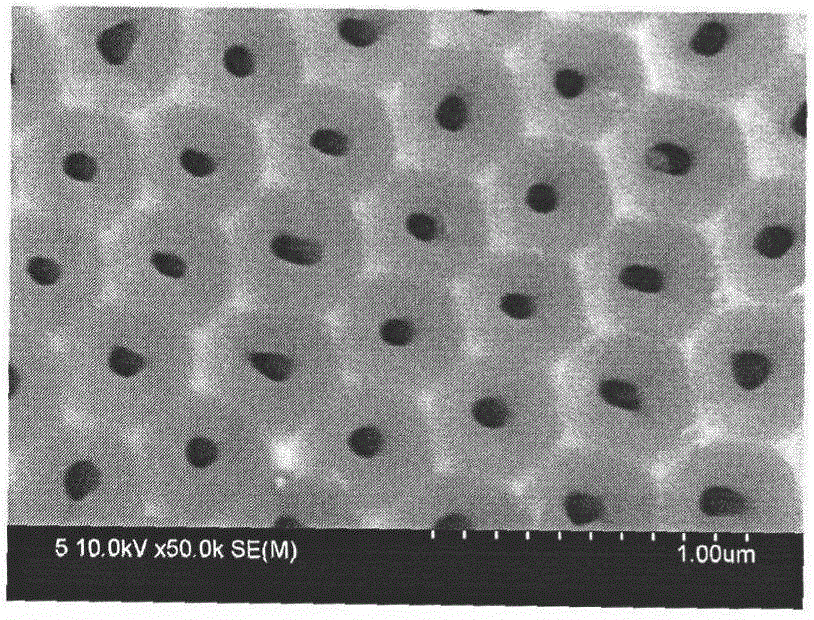

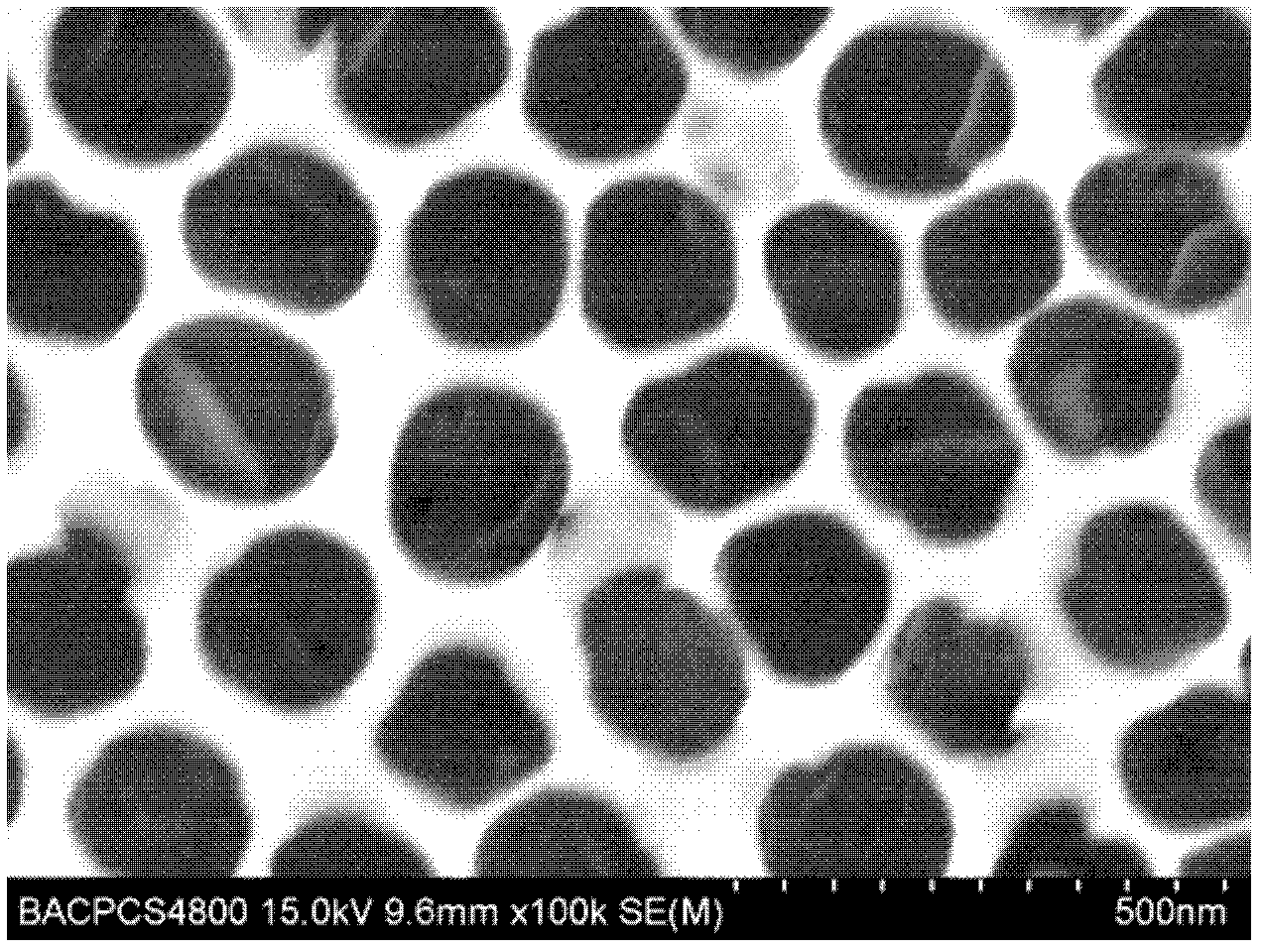

Method for preparing neat porous anodic alumina film

InactiveCN105040065AImprove stabilityExpand the adjustment rangeAnodisationMicro nanoPhosphoric acid

The invention discloses a method for preparing a neat porous anodic alumina film. The method comprises the steps that firstly, a pretreated aluminum piece is placed in a mixed solution of phosphoric acid and oxalic acid, then first-time anodic oxidation is carried out to obtain an alumina film, and the alumina film is removed; second-time oxidation completely identical to the first-time oxidation in condition is carried out; the obtained alumina film is placed into a phosphoric acid solution, and pore-enlarging at different times is carried out; and through adjustment of oxidation voltage and pore-enlarging time, the highly-neat porous anodic alumina film with the pore pitch ranging from 348 nm to 500 nm and the pore diameter ranging from 72 nm to 400 nm is prepared. The oxalic acid content in the dilute phosphoric acid solution is adjusted, so that the anodic oxidation voltage value is improved, the regularity of alumina film pores is improved, and the range of the pore pitch is widened. The application of the alumina film to the field of preparation of neat micro-nano materials can be greatly expanded.

Owner:TIANJIN POLYTECHNIC UNIV

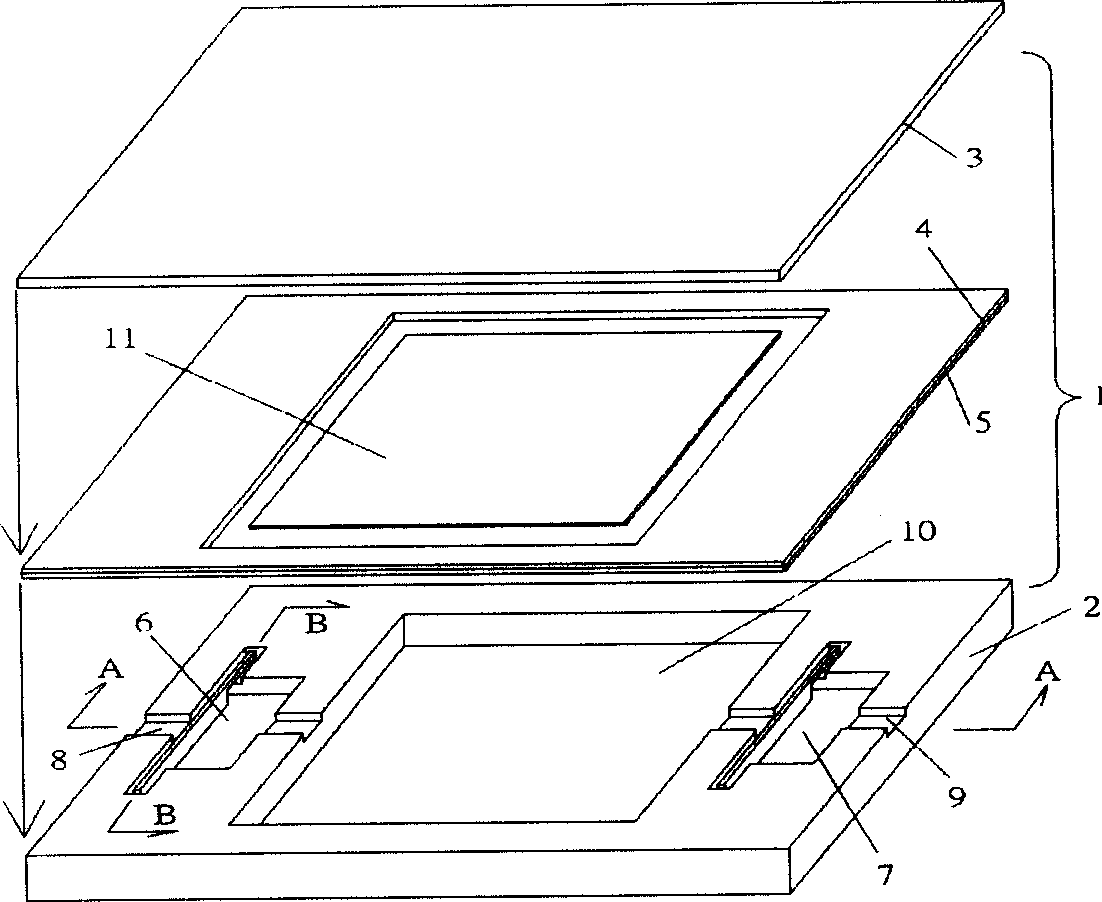

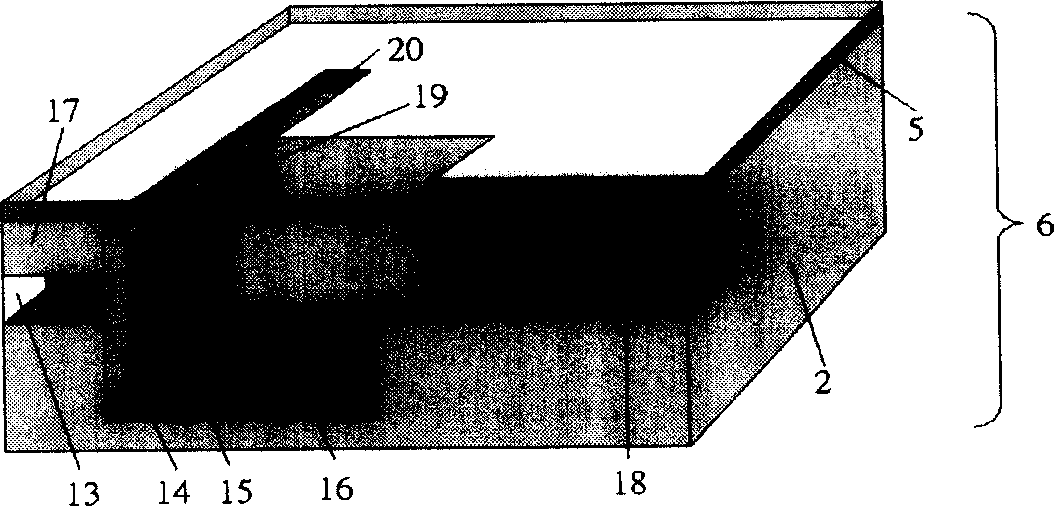

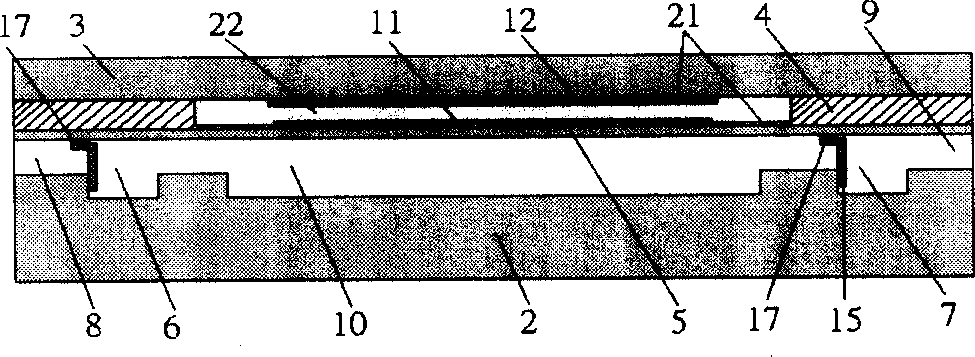

Monolithic unidirectional liquid micropump having suspension T shaped valve film micro valve

InactiveCN1534193ASolve the problem of adverse effects on efficiencyTurn on low energy consumptionFlexible member pumpsPositive-displacement liquid enginesManufacturing technologyEngineering

A single sheet type monodirectional liquid micropump with the microvalve having suspended T-shaped valve membrane is prepared on the basis of anodizing voltage switching technique and monosilicon film transfer technique. Its advantages are low energy consumption for opening it and high borne pressure when it is closed.

Owner:汤玉生

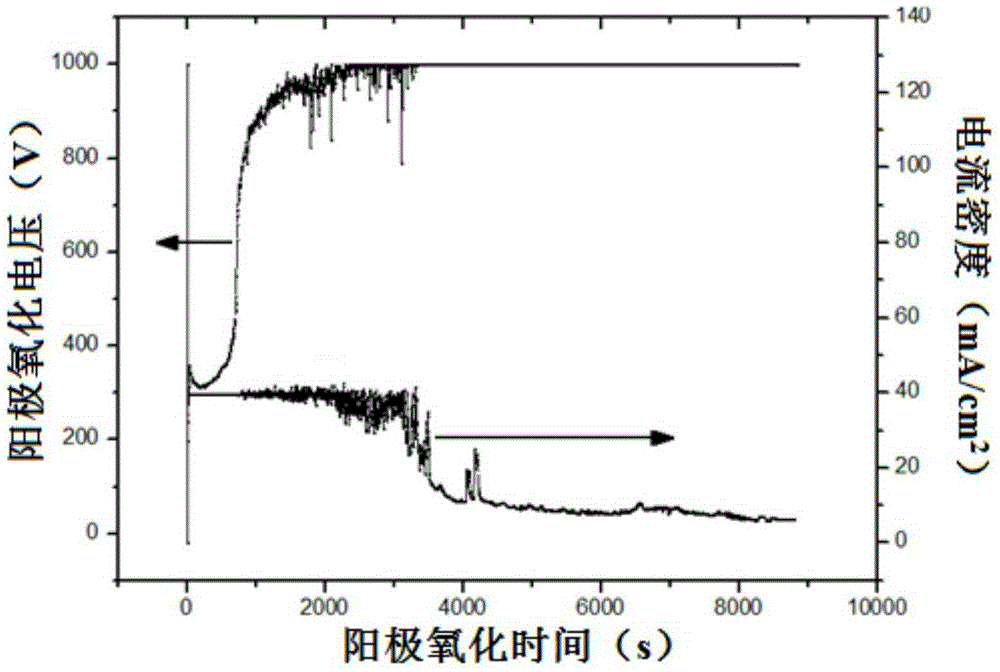

Method for preparing large-hole-interval porous anodic alumina membrane at high voltage

InactiveCN105297106ASuppress breakdownAchieving controllable equipmentSurface reaction electrolytic coatingConstant current densityHigh voltage

The invention discloses a method for preparing a large-hole-interval porous anodic alumina membrane at high voltage. The method includes the steps that a high pure aluminum sheet is subjected to electrochemical polishing after being washed; the polished aluminum sheet serves as an anode, graphite serves as a cathode, the anode oxidation process is performed while an oxalic acid-ethanol-water mixed solution serves as an electrolyte, and high anode oxidization voltage is obtained by performing self-adaption boosting under constant current density; a sample obtained through anode oxidization is soaked in a saturated copper chloride solution, then the large-hole-interval porous anodic alumina membrane is obtained, and the average hole interval of the prepared porous anodic alumina membrane is regulated and controlled by adjusting the ethanol adding proportion, the anode oxidization voltage and the current density. The large hole interval size of the prepared porous anodic alumina membrane is adjustable so that the porous anodic alumina membrane can serve as a template to synthesize various functional submicron and micron materials. Meanwhile, the large-hole-interval porous anodic alumina membrane has the advantages that raw materials are easy to obtain, operation is easy, cost is low, and repeatability is good, and feasibility is improved when the large-hole-interval porous anodic alumina membrane is applied to production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of titanium dioxide core/shell nanometer cable array

InactiveCN102953110AShape is easy to controlSimple methodPolycrystalline material growthSurface reaction electrolytic coatingHigh concentrationTio2 nanotube

The invention discloses a preparation method of a titanium dioxide core / shell nanometer cable array. The method comprises: firstly, preparing a layer of TiO2 nanotube array film with small tube diameter on a titanium chip under a low oxidation voltage; and then, increasing the anode oxidation voltage, and obtaining a titanium dioxide nanotube array with large tube diameter below the titanium dioxide nanotube array with small tube diameter; performing ultrasonic oscillating; soaking the titanium dioxide nanotube array with a titanium chip substrate in a high-concentration alkaline solution, and cleaning the titanium dioxide nanotube array through deionized water; and soaking the titanium dioxide array in an acid solution for a period, taking out the titanium dioxide array, cleaning the titanium dioxide array with deionized water, and drying the titanium dioxide array to obtain the titanium dioxide core / shell nanometer cable array. The method is simple, feasible, quick and effective, the shape and outline of the product are controllable, and the method has practical value.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

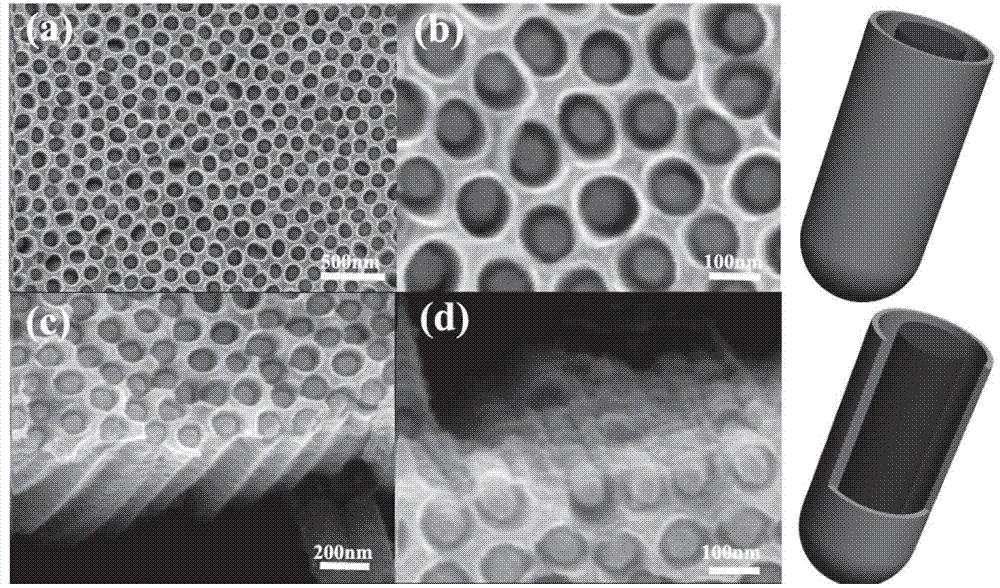

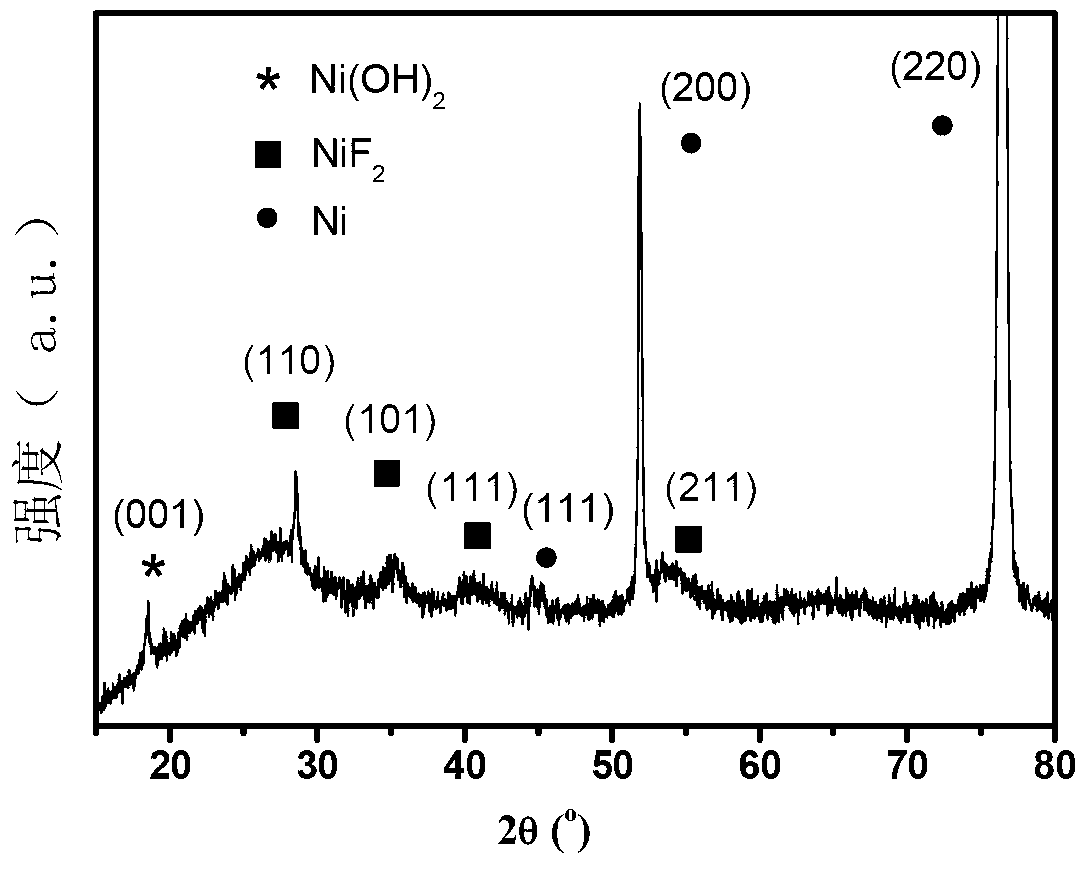

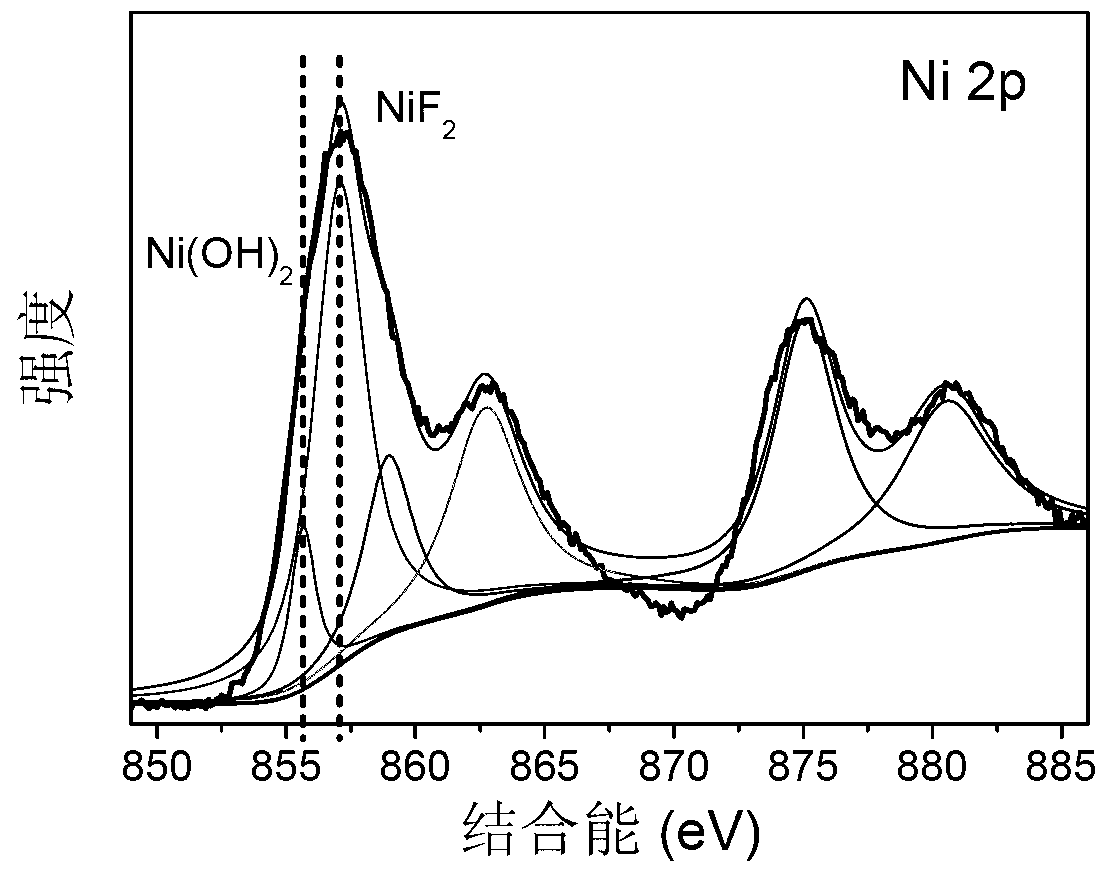

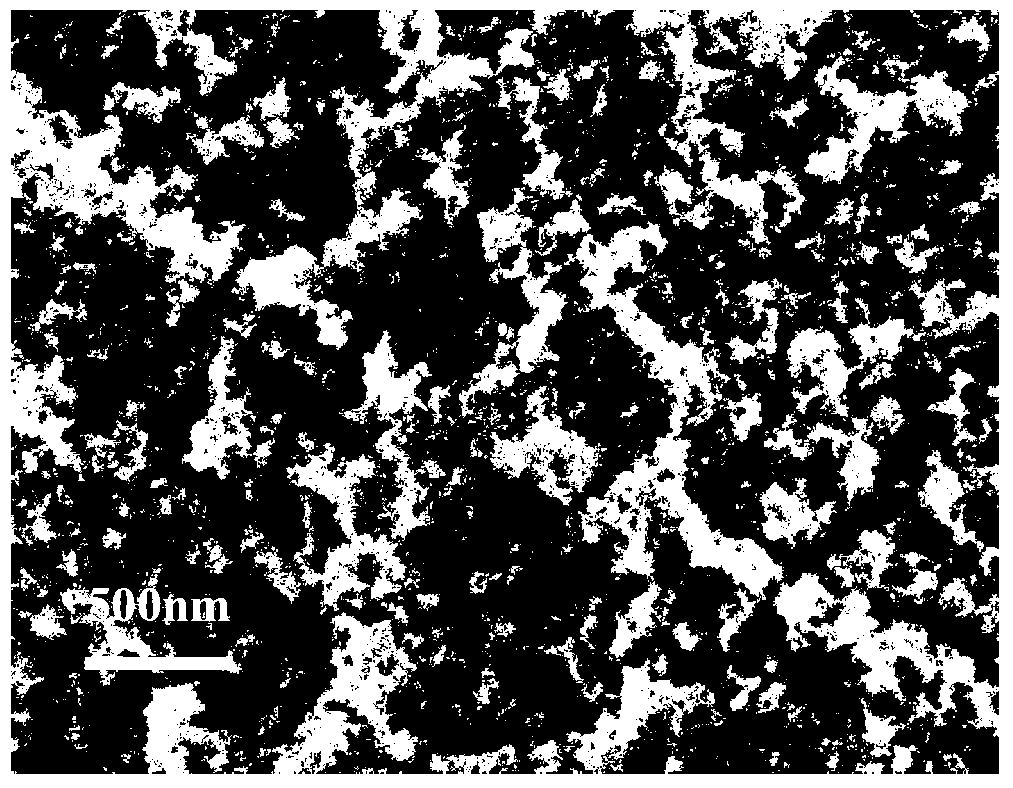

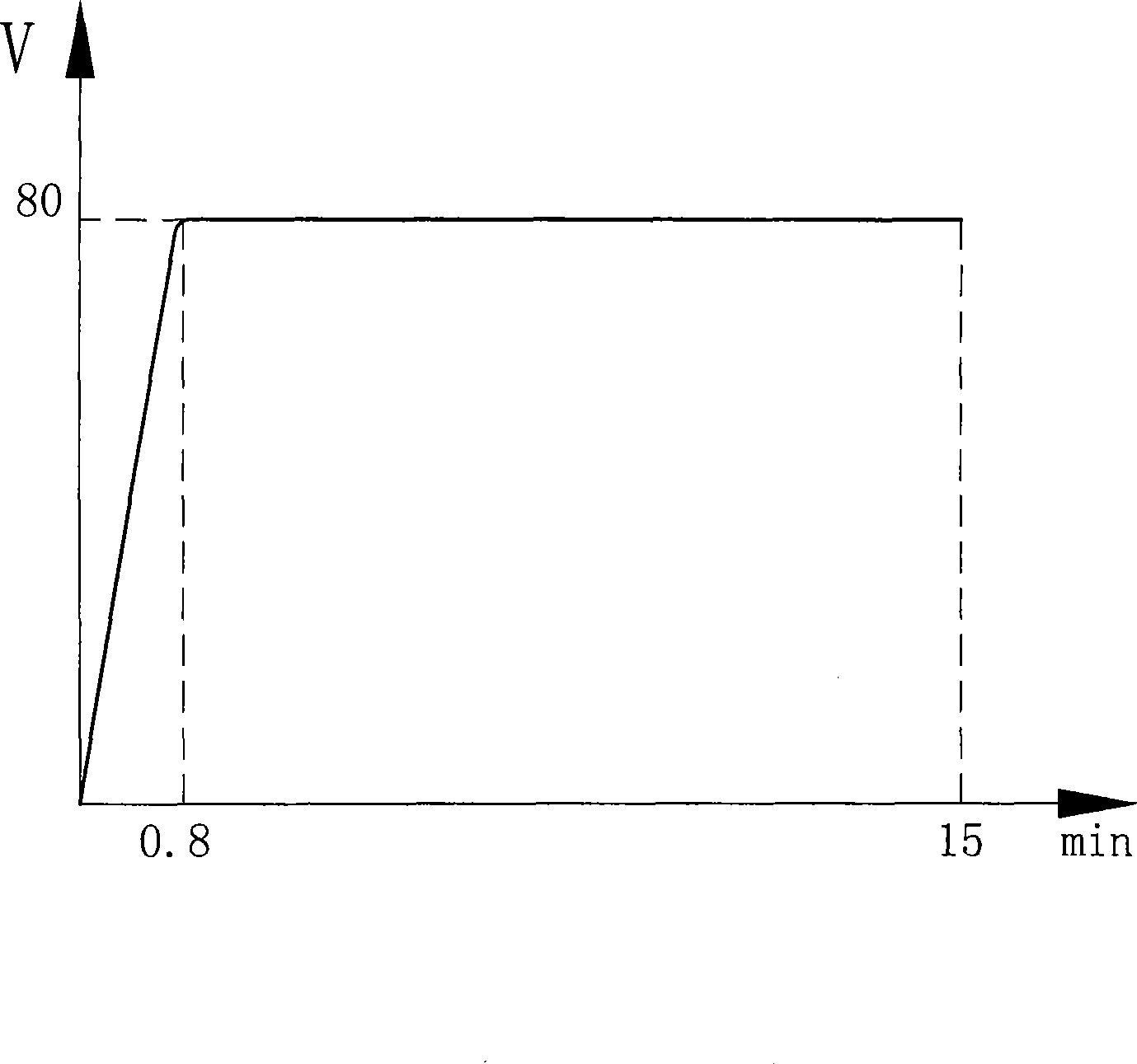

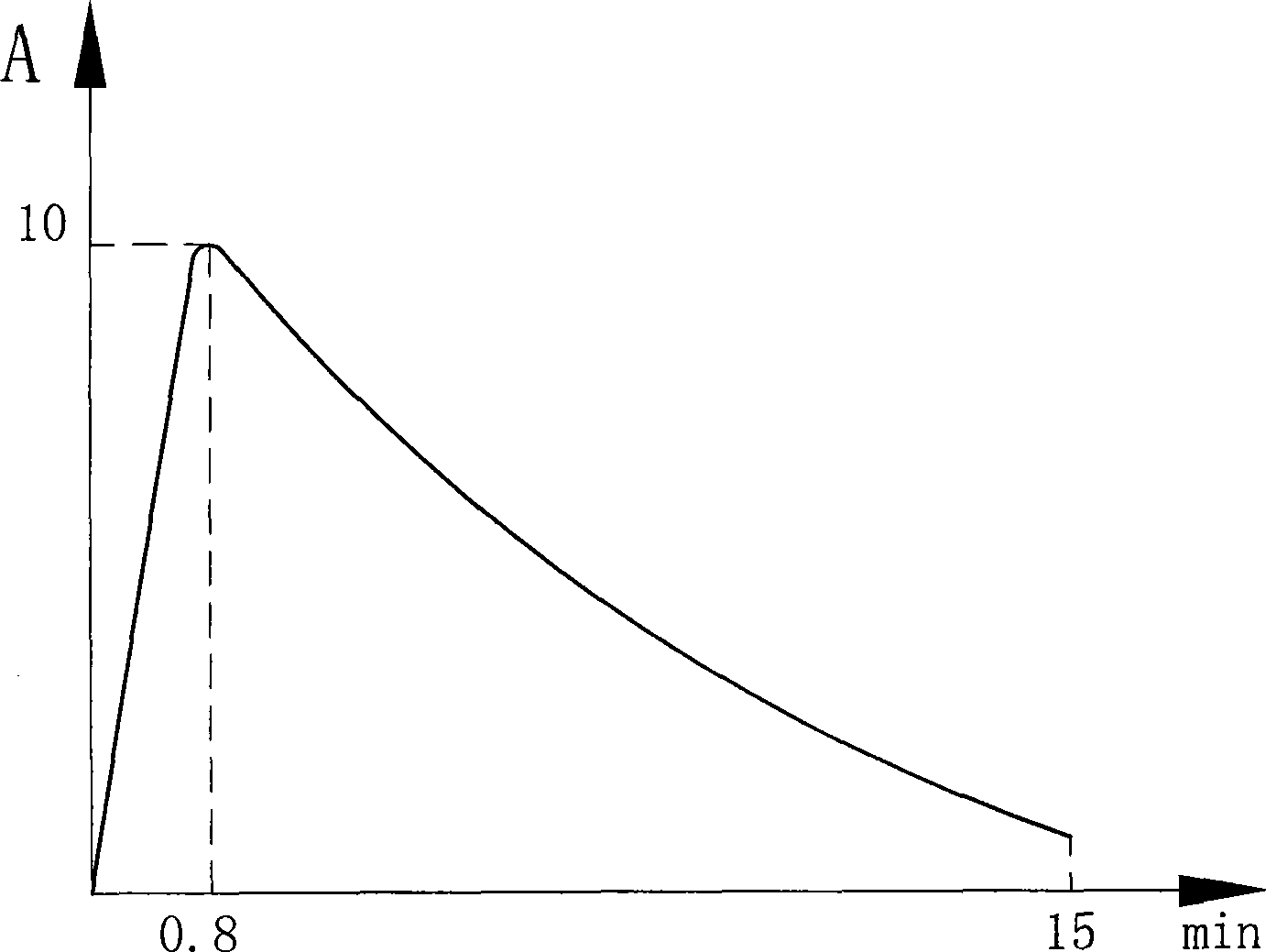

Nickel-based electrode material and preparation method thereof

InactiveCN103280340AImprove bindingImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePhosphoric acid

The invention belongs to the field of electrode materials of a supercapacitor, and discloses a nickel-based electrode material and a preparation method thereof. Fluorine-containing electrolyte is utilized for carrying out anodic oxidation on a nickel sheet; the anodic oxidation voltage is increased from 0V to 3-6.5V at a speed of 10mV / s to 500mV / s; then the voltage is maintained for 15-60 minutes; the nickel sheet is taken out for being cleaned and dried, so the nickel-based electrode material is obtained; and the electrolyte comprises fluoride of which the mass fraction is 0.5wt%-2wt%, phosphoric acid of which the mass fraction is 70wt%-85wt%, and the balance of water. The nickel-based electrode material and the preparation method thereof disclosed by the invention have the characteristics that 1) a nickel-based film which is generated by using the anodic oxidation method is combined with the nickel sheet firmly, and good electroconductibility is realized; 2) a conductive additive or a binder is not needed to be additionally added, the preparation process of the supercapacitor is simplified, and the preparation cost is lowered; and 3) the material still has very high specific capacitance under the condition of large charging and discharging current densities.

Owner:SOUTH CHINA UNIV OF TECH

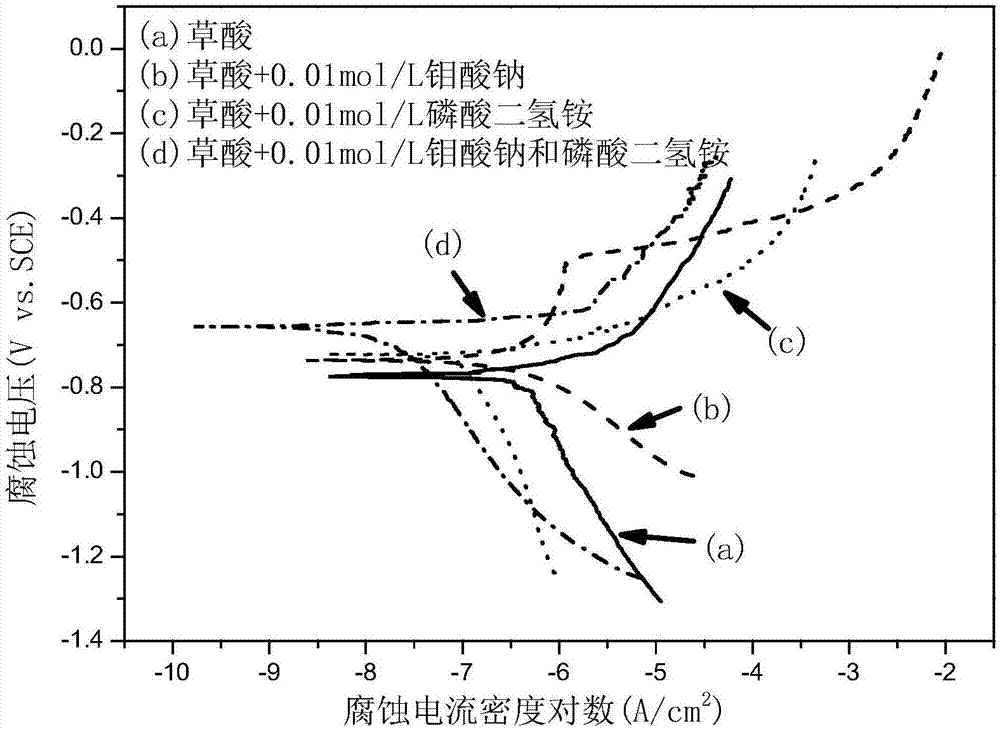

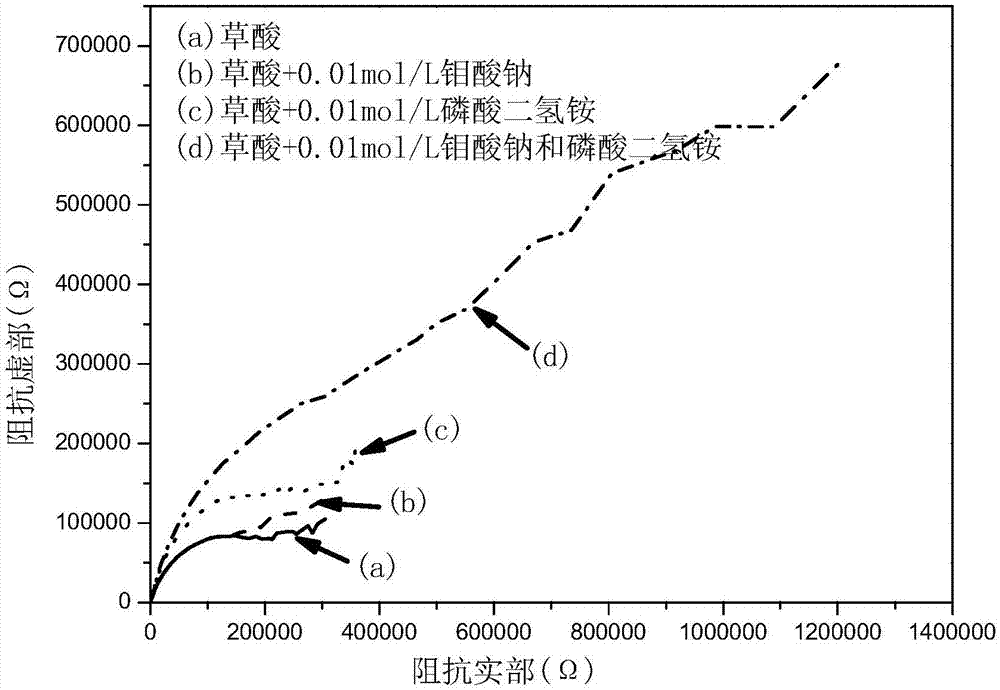

Aluminum alloy anodic oxidation electrolyte solution and technology based on corrosion inhibitors

InactiveCN107090590AImprove corrosion resistanceLow costSurface reaction electrolytic coatingSodium molybdateOxalate

The invention discloses an aluminum alloy anodic oxidation electrolyte and oxidation process based on a corrosion inhibitor. The concentration of oxalic acid in the anodic oxidation electrolyte is 40g / L, and a corrosion inhibitor is added to the oxalic acid. The corrosion inhibitor is sodium molybdate and ammonium dihydrogen phosphate, and the concentration range is 0.005-0.1mol / L. The steps of the oxidation process are: grinding, chemical degreasing, pickling, anodizing process, sealing treatment, and finally complete the entire anodizing process to grow an oxide film on the aluminum alloy substrate; the concentration of oxalic acid in the electrolyte during the anodizing process is 40g / L, then add a corrosion inhibitor to oxalic acid, the corrosion inhibitor is sodium molybdate and ammonium dihydrogen phosphate, the concentration range is 0.005 ~ 0.1mol / L; anodizing process conditions: anodizing temperature is 15 ~ 20 ℃ , the anodic oxidation voltage is 30-50V, and the reaction time is 60-150min. In the present invention, the two corrosion inhibitors are mixed and added into the anodic oxidation electrolyte in a small amount, and their synergistic effect can greatly improve the corrosion resistance of the aluminum alloy and significantly reduce the production cost.

Owner:NANJING UNIV OF POSTS & TELECOMM

Fibrous photo-active compound solar cell and preparation method thereof

InactiveCN105322093AHigh strengthImprove plasticityFinal product manufactureSolid-state devicesPorphyrinAnatase

The invention discloses a fibrous photo-active compound solar cell and a preparation method thereof. The method comprises the following specific steps: (1) selecting a fine copper wire as a conductive electrode; (2) preparing a working electrode through an electrochemical anodic oxidation method, wherein the step (2) comprises the processes as follows: with a titanium wire as an anode and a platinum wire as a cathode, an electrolyte is a glycol water solution containing ammonium fluoride with the mass fraction of 0.2%-0.4% and water with the volume fraction of 4%-6%; the anodic oxidation voltage is 40V to 60V; the anodic oxidation time is 10-30 minutes; and an oriented titania nanotube array which is 1-7 microns in height grows on the surface of the titanium wire; and (3) cleaning the titanium wire which is subjected to anodic oxidation with deionized water for a plurality of times, drying and heating the titanium wire to 450-550 DEG C, keeping the temperature at 450-550 DEG C for 1-3 hours, and naturally cooling the titanium wire, so as to obtain anatase crystal TiO2, immersing the anatase crystal TiO2 into an N,N-dimethyl formamide solution containing porphyrin for 2-4 hours, taking out and drying the anatase crystal TiO2, immersing the anatase crystal TiO2 into a PEDOT:PSS water solution containing thionyl chloride with the mass fraction of 5%-15% for 3-5 minutes, taking out and drying the anatase crystal TiO2, and convolving the anatase crystal TiO2 and a fine copper wire, so as to obtain the product.

Owner:ZHEJIANG SCI-TECH UNIV

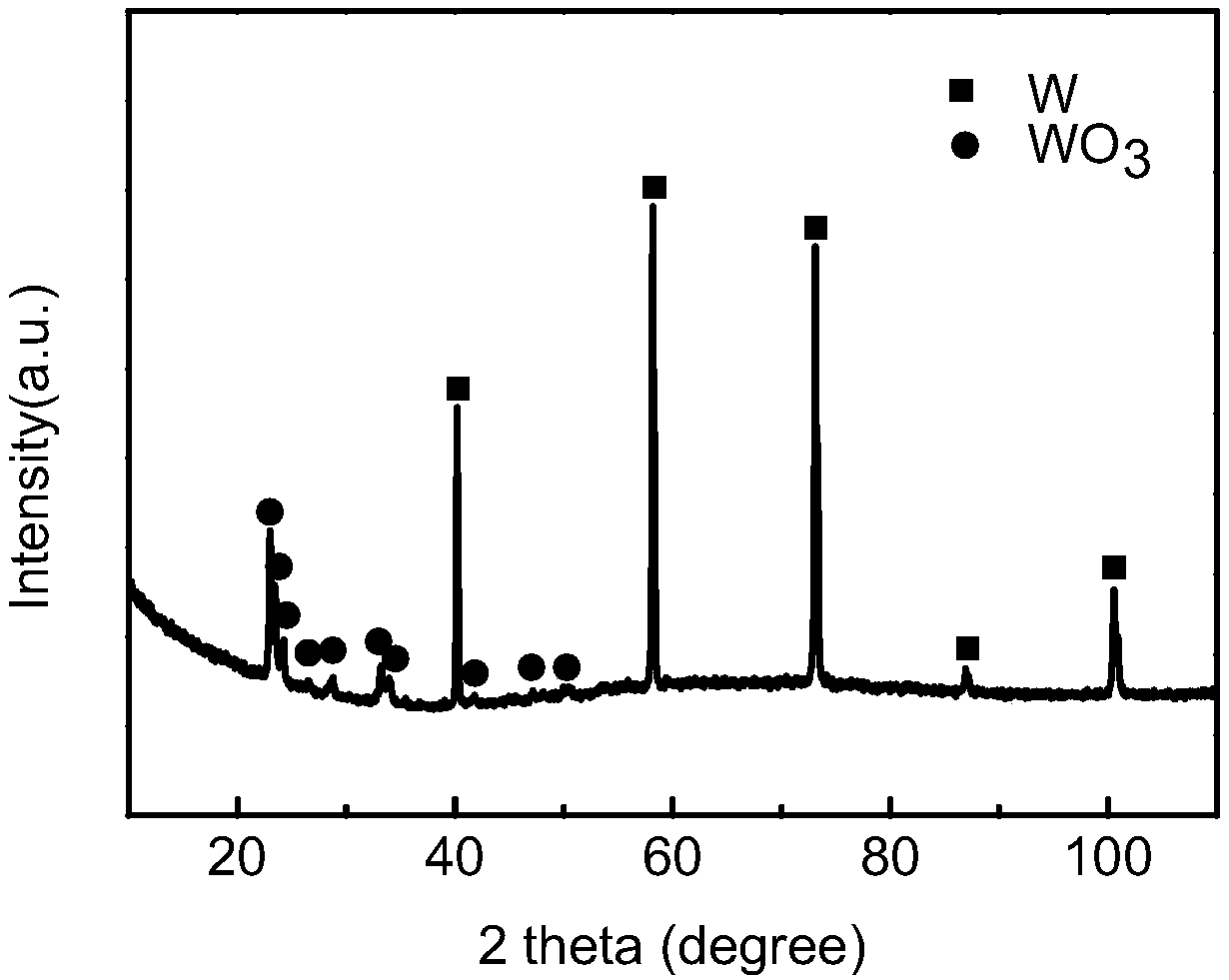

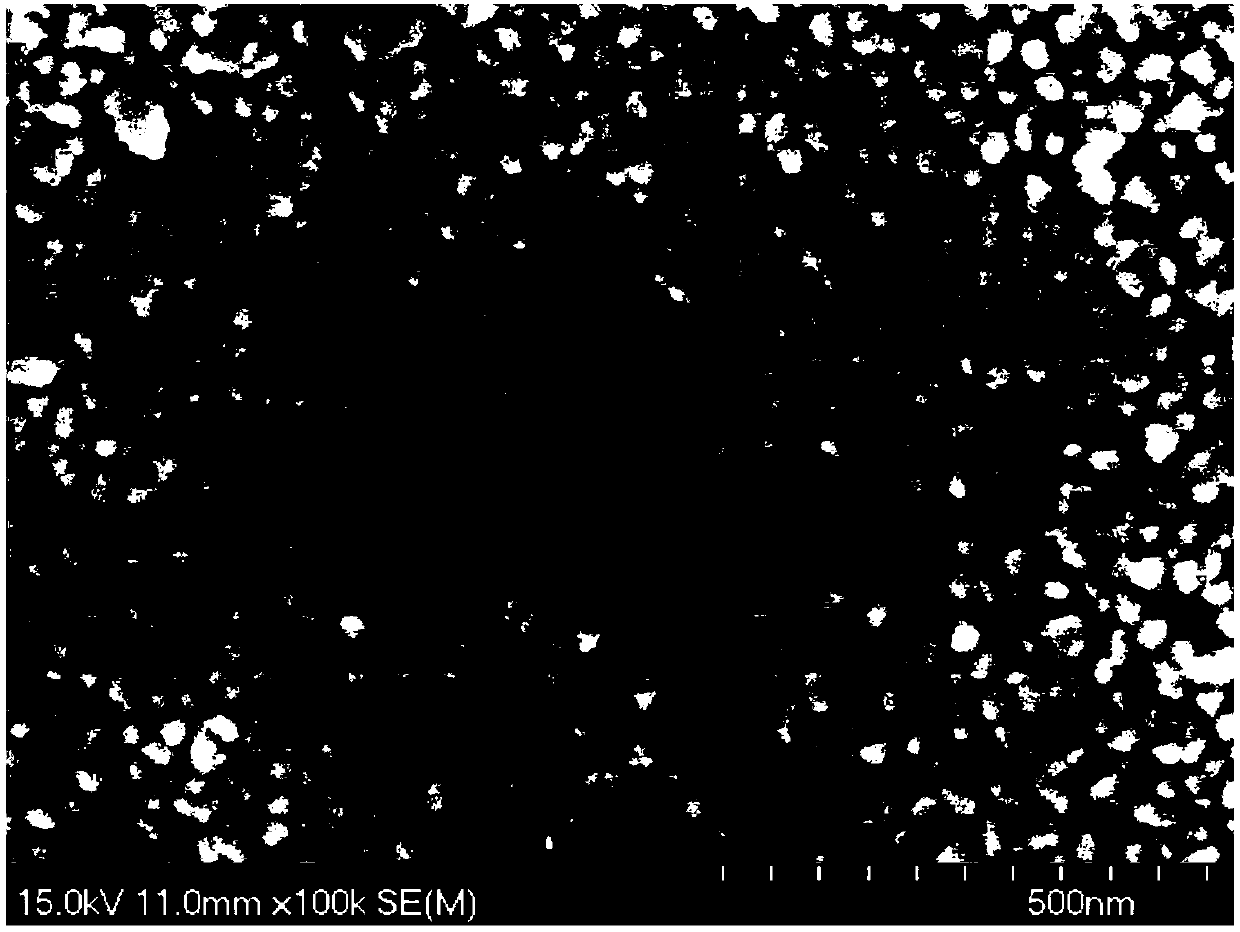

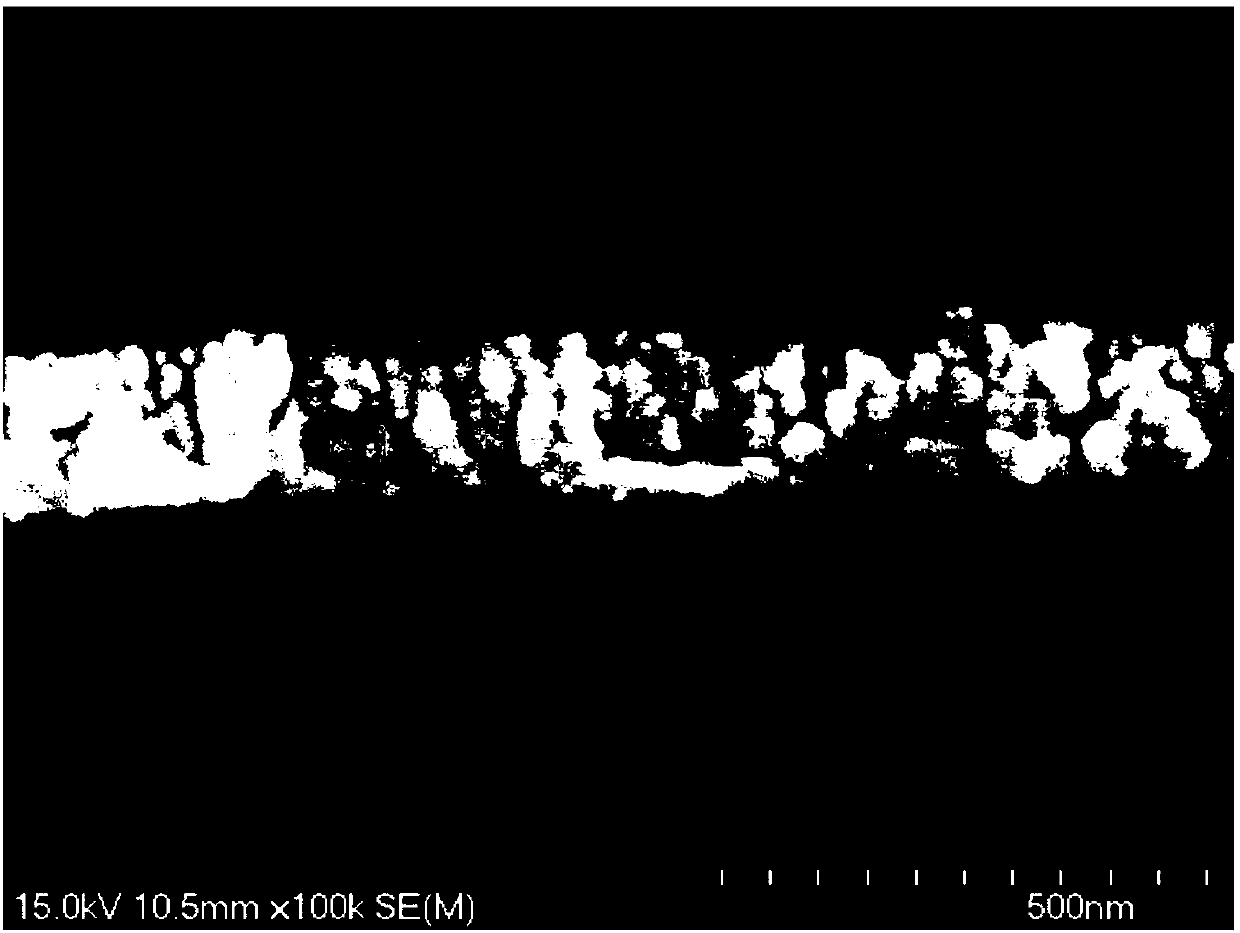

Electrochemical method for preparing mesoporous tungsten trioxide film

ActiveCN107858734AGood mesoporous structureLarge specific surface areaSurface reaction electrolytic coatingPlatinumPore diameter

The invention discloses an electrochemical method for preparing a mesoporous tungsten trioxide film. The method comprises the steps that metal tungsten subjected to pretreatment is taken as an anode,a titanium sheet or a platinum sheet serves as a cathode, in an electrolyte, constant-potential anodic oxidation is performed for 1-7 hours under the condition that the temperature ranges from 5 DEG Cto 40 DEG C and the voltage ranges from 3 V to 15 V, and then the metal tungsten is taken out to be cleaned and dried to obtain the mesoporous tungsten trioxide film on the surface of the metal tungsten. According to the electrochemical method, the tungsten trioxide films with different pore diameters can be obtained on the surface of the metal tungsten by controlling the electrolyte component, the anodic oxidation voltage and the oxidation time; the prepared tungsten trioxide film has a remarkable mesoporous structure, the specific surface area is large, and the prepared tungsten trioxide film is firmly combined with a metal tungsten substrate and is not prone to fall off; and the electrochemical method is simple in preparation process, low in cost, simple and convenient to operate, highin efficiency and wide in application prospect in the aspect of industrial application.

Owner:ZHEJIANG UNIV OF TECH

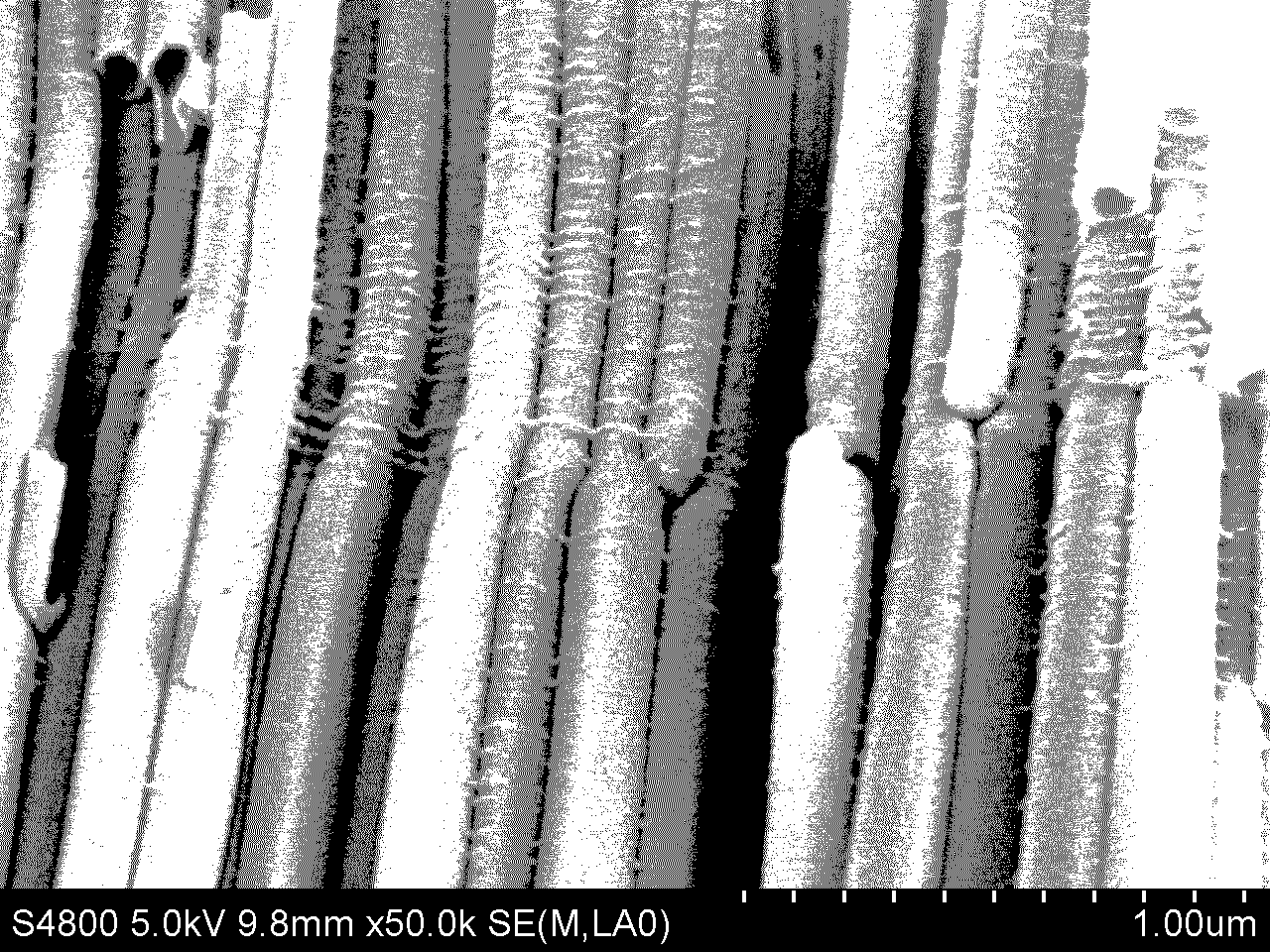

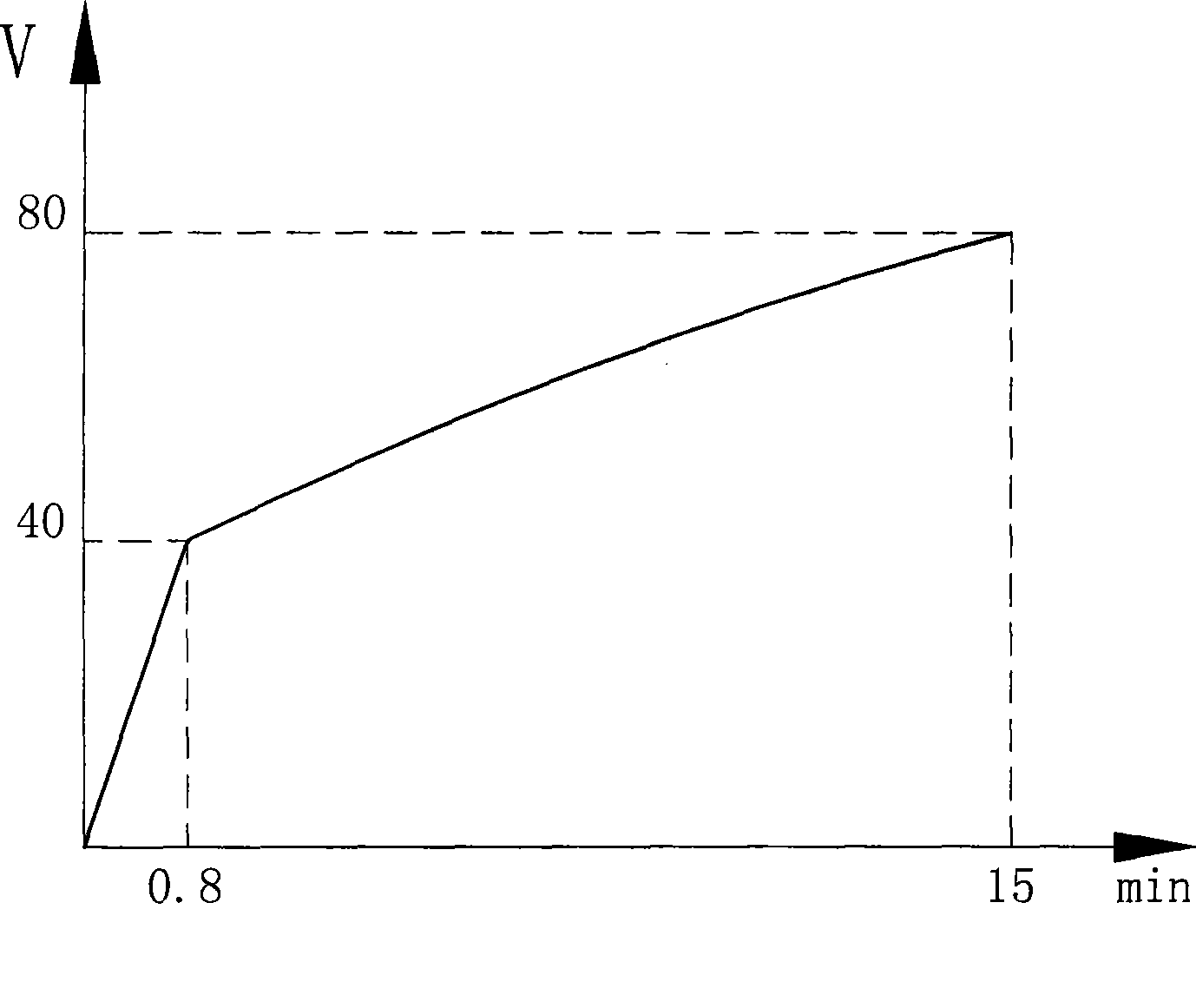

Preparation method of double-layer titanium dioxide nanotube thin film with pear-shaped structure

InactiveCN103436937ASimple and fast operationPrecise control of pipe diameterMaterial nanotechnologySurface reaction electrolytic coatingElectrolytic agentTio2 nanotube

The invention relates to a preparation method of a double-layer titanium dioxide nanotube thin film with a pear-shaped structure. The double-layer titanium dioxide nanotube thin film is prepared by immersing medical titanium in an ethanediol electrolyte solution containing 0.1 to 0.9wt% of NH4F and 0 to 10vol% of H2O for one-step in-situ boost anodic oxidation. The preparation method comprises following steps: firstly, an anodic oxidation voltage is raised from 0V to 20-40V, and is kept for 80min to 6h; then the anodic oxidation voltage is continuously raised to 50-90V, and is kept for 10min to 1h; and at last the double-layer titanium dioxide nanotube thin film with the pear-shaped structure is formed on the surface of the medical titanium. The preparation method is simple and quick, is convenient for operation, is possible to be used in the fields of surface modification of titanium-based implants used in orthopaedics, dentistry, plastic surgery departments, and is capable of reducing risks of failure after implanting and increasing osseointegration ability of the implants.

Owner:SICHUAN UNIV

Constant current anode oxidation treatment method for surfaces of aluminum and aluminum alloy materials

ActiveCN101445950ASuitable for large-scale industrial productionLess investmentAnodisationComposite electrolyteOxidative treatment

The invention discloses a constant current anode oxidation treatment method for surfaces of an aluminum and aluminum alloy material. The method comprises the following steps: the aluminum and the aluminum alloy material are taken as anodes and placed into a composite electrolyte; current density is controlled to rise from 0A / dm<3> to 1-5A / dm<3> that is the required current density within 20-120s and kept constant; anode oxidation voltage increases along with the increase of the current in 20-120s; the voltage slowly increases after reaching 20-60V, and reaches 70-120V in 600-1200s until a film is formed completely. The method is suitable for large-scale industrial production and has the advantages of low apparatus and equipment investment, low requirement, no need of special temperature control in the whole process flow, higher hardness of the produced anode oxide film, and better wear resistance, corrosion resistance, high temperature impact resistance and electrical insulation properties.

Owner:ZHEJIANG SUPOR CO LTD

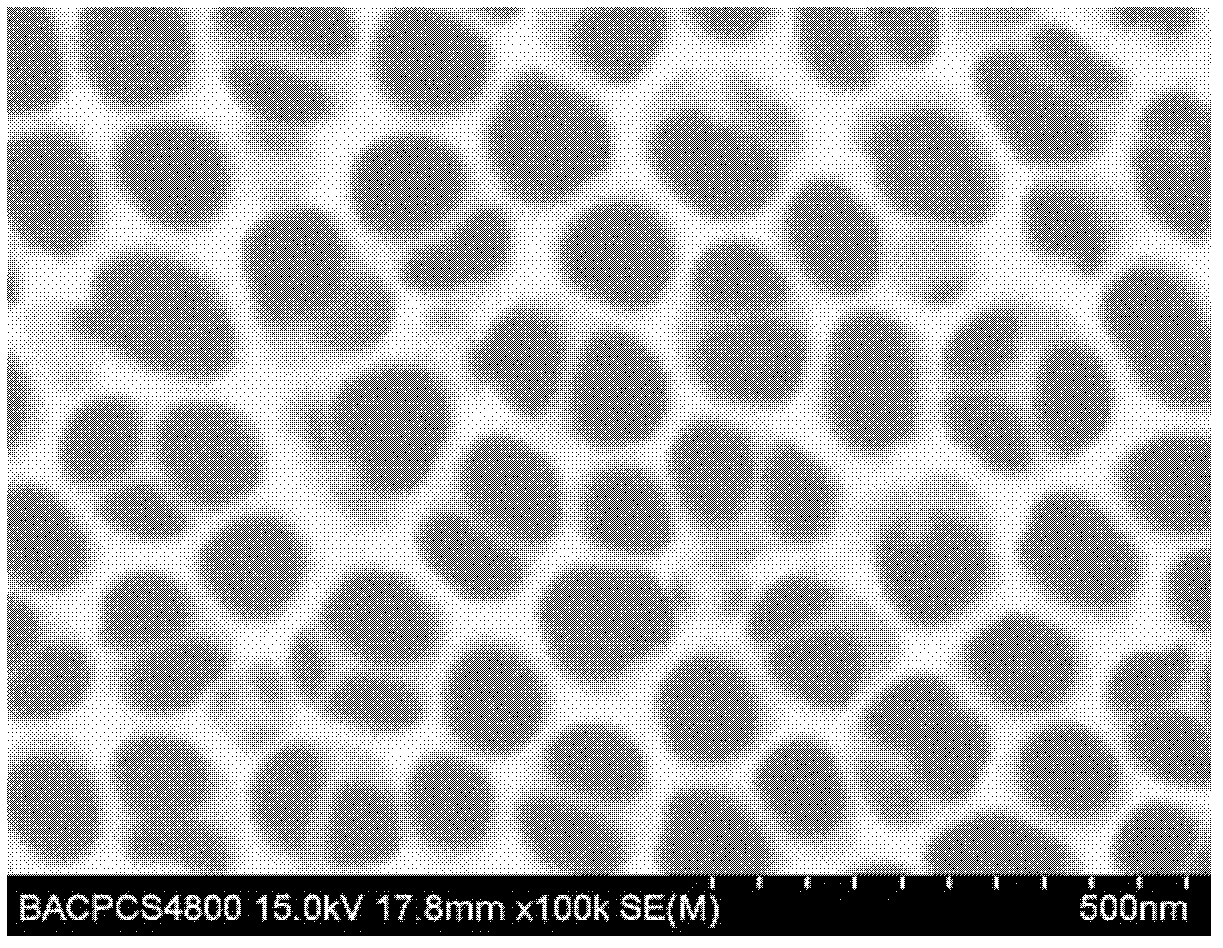

Method for preparing anodic aluminum oxide (AAO) template with large pore diameter and thin wall on silicon substrate

Disclosed is a method for preparing an AAO template with a large pore diameter and a thin wall on a silicon substrate. The steps include washing the silicon substrate; depositing an aluminum layer with the thickness of 500 to 1000 nanometers on the surface of the washed silicon substrate; anodizing the aluminum layer deposited on the silicon substrate, wherein an anodizing groove is arranged in ice and water mixtures, temperature during the anodizing process is controlled with stirring in a range of 0 DEG C to 5 DEG C, anodizing solutions are phosphoric acid ethylene glycol solutions, the phosphoric acid accounts for 18% to 24% of the ethylene glycol solutions, the anodizing voltage is 210 V to 250 V, and the anodizing time is 1 minute to 5 minutes; and cleaning the prepared AAO template with deionized water, placing the AAO template in 5 wt% phosphoric acid water solution at the room temperature to expand holes for 20 to 50 minutes, and removing oxide blocking layers at the bottom of the holes simultaneously. Accordingly, the AAO template with the large pore diameter and the thin wall is obtained on the silicon substrate, the pore diameter is larger than 100 nanometers, and the thickness of pore wall is smaller than the semi-diameter of the pore.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Micro-arc oxidation technology applied to vibrating membranes of metal trumpets

The invention discloses a micro-arc oxidation technology applied to vibrating membranes of metal trumpets. The micro-arc oxidation technology comprises the following technology steps: placing an aluminum workpiece and an anode material in a prepared electrolyte, enabling the voltage to rapidly raise to 300V, and keeping the voltage of 300V for 5-10 seconds; enabling the anodic oxidation voltage to raise to 450V, and performing electrolyzation for 5-10 minutes; placing the aluminum workpiece in a K2OnSiO2 water solution of which the concentration is 250 g / L, and oxidizing the aluminum workpiece with the anodic oxidation current being1A / dm2 for 5 minutes; then, placing the oxidized aluminum workpiece in a Na3P2O7 water solution of which the concentration is 70g / L, and oxidizing the aluminum workpiece with an anodic current being 1A / dm2 for 15 minutes. After the micro-arc oxidation technology disclosed by the invention is adopted to perform micro-arc oxidation on the vibrating membrane of a metal trumpet, a ceramic membrane of which the property is similar to that of sintered carbides can be formed on the surface of the vibrating membrane, so that the surface of the vibrating membrane has the properties of high hardness, high-temperature resistance, corrosion resistance, good insulation, wear resistance and the like; the micro-arc oxidation technology disclosed by the invention has the advantages of simple process, convenience in operation and control, low cost, and the like.

Owner:DONGGUAN PINPAI IND INVESTMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com