Method for preparing neat porous anodic alumina film

A porous anode and aluminum oxide film technology, applied in the field of electrochemistry, can solve the problems of irregular surface pores, different pore sizes, and discontinuous spacing between aluminum oxide template pores, so as to improve the adjustment range, improve stability, and avoid shocks. effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

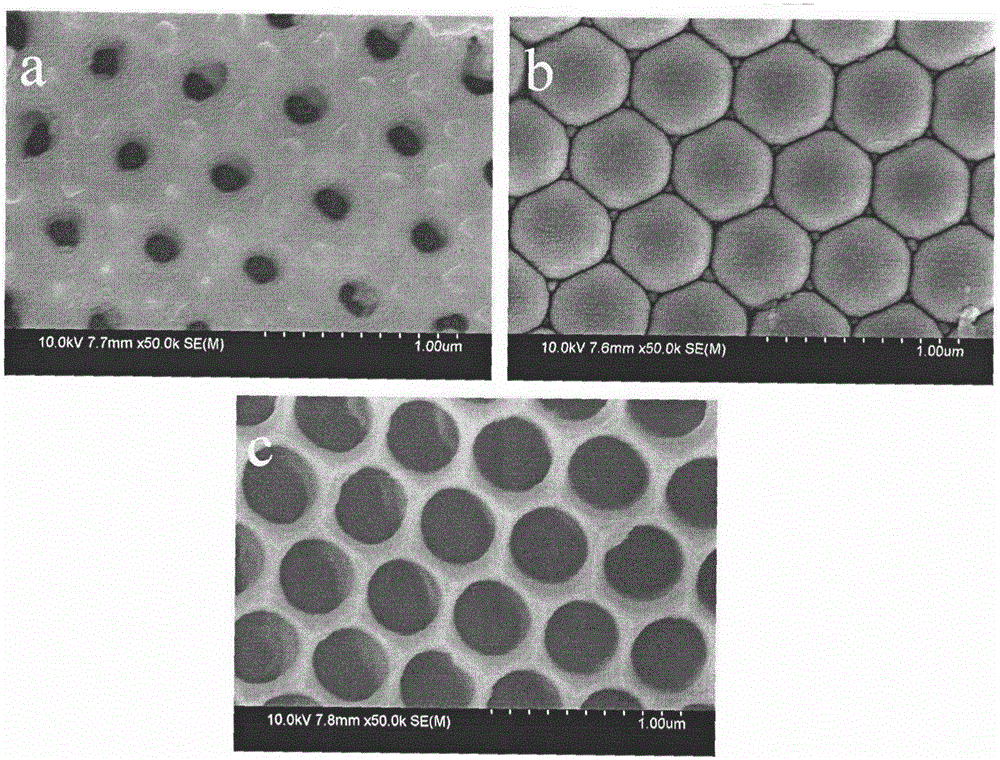

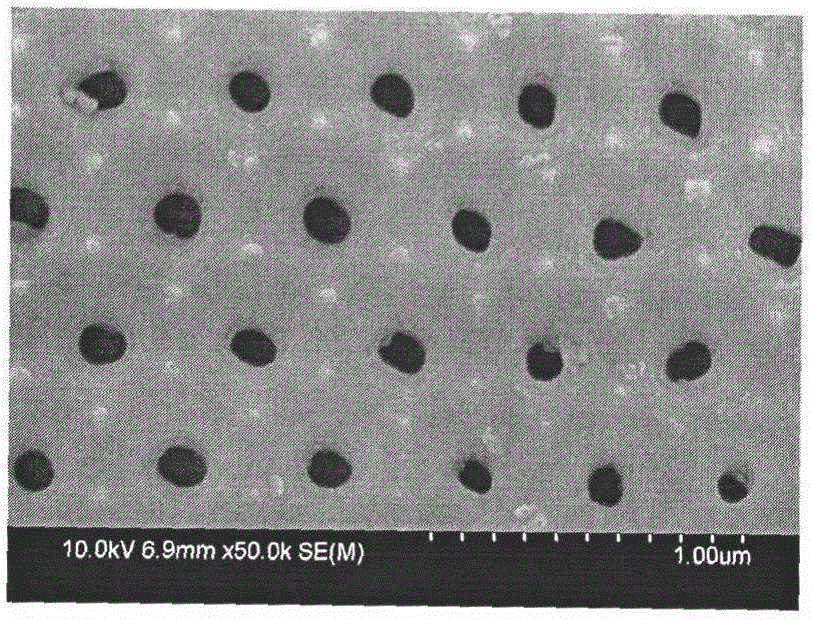

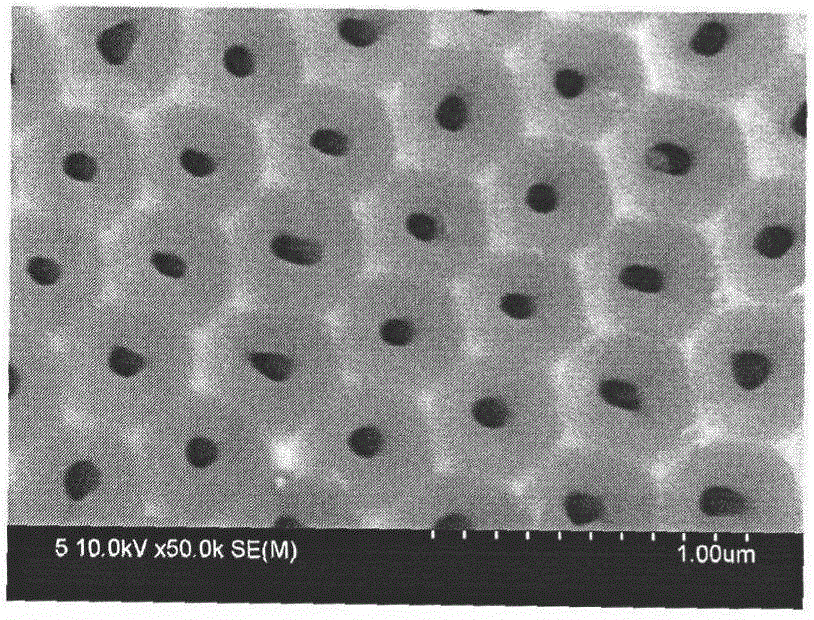

Embodiment 1

[0030] The high-purity aluminum sheet with a purity of 99.999% was ultrasonically cleaned in acetone for 5 minutes to remove the grease on the surface, then cleaned with deionized water, and then placed in a 1mol / L NaOH solution for 10 minutes to remove the natural oxide layer on the surface, and finally used Wash and dry with ionic water; take the pretreated aluminum sheet as the anode and the titanium plate as the cathode, in perchloric acid and absolute ethanol with a solution volume ratio of 1:4, at a voltage of 21V, at a temperature of 0-5°C, for 5min Electrochemical polishing to obtain an aluminum sheet with a smooth surface; the polished aluminum sheet is used as the anode, the titanium plate is used as the cathode, and a 1wt% phosphoric acid solution with 0.03M oxalic acid is used as the electrolyte for primary oxidation. The oxidation voltage is 200V and the temperature is 0 ~3°C, the oxidation time is 2h; the aluminum oxide film with aluminum substrate after primary o...

Embodiment 2

[0032] The high-purity aluminum sheet with a purity of 99.999% was ultrasonically cleaned in acetone for 5 minutes to remove the grease on the surface, then cleaned with deionized water, and then placed in a 1mol / L NaOH solution for 10 minutes to remove the natural oxide layer on the surface, and finally used Wash and dry with ionic water; take the pretreated aluminum sheet as the anode and the titanium plate as the cathode, in perchloric acid and absolute ethanol with a solution volume ratio of 1:4, at a voltage of 21V, at a temperature of 0-5°C, for 5min Electrochemical polishing to obtain an aluminum sheet with a smooth surface; the polished aluminum sheet is used as the anode, the titanium plate is used as the cathode, and a 1wt% phosphoric acid solution with 0.05M oxalic acid is used as the electrolyte for primary oxidation. The oxidation voltage is 190V and the temperature is 0 ~3°C, the oxidation time is 2h; the aluminum oxide film with aluminum substrate after primary o...

Embodiment 3

[0034] The high-purity aluminum sheet with a purity of 99.999% was ultrasonically cleaned in acetone for 5 minutes to remove the grease on the surface, then cleaned with deionized water, and then placed in a 1mol / L NaOH solution for 10 minutes to remove the natural oxide layer on the surface, and finally used Wash and dry with ionic water; take the pretreated aluminum sheet as the anode and the titanium plate as the cathode, in perchloric acid and absolute ethanol with a solution volume ratio of 1:4, at a voltage of 21V, at a temperature of 0-5°C, for 5min Electrochemical polishing to obtain an aluminum sheet with a smooth surface; the polished aluminum sheet is used as the anode, the titanium plate is used as the cathode, and a 1wt% phosphoric acid solution with 0.07M oxalic acid is used as the electrolyte for primary oxidation. The oxidation voltage is 180V and the temperature is 0 ~3°C, the oxidation time is 2h; the aluminum oxide film with aluminum substrate after primary o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com