Preparation method of titanium dioxide core/shell nanometer cable array

A technology of titanium dioxide and nano-cables, applied in chemical instruments and methods, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of difficult removal of titanium sheet substrates, easy cracking, and restricted use, and achieve product morphology. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) First, ultrasonically clean the metal sheet with a titanium content of 96% in a mixed solution of ethanol and acetone with a concentration ratio of 1:1 for 60 minutes to remove organic matter on the surface, then repeatedly clean it with deionized water, and dry it in the air ;

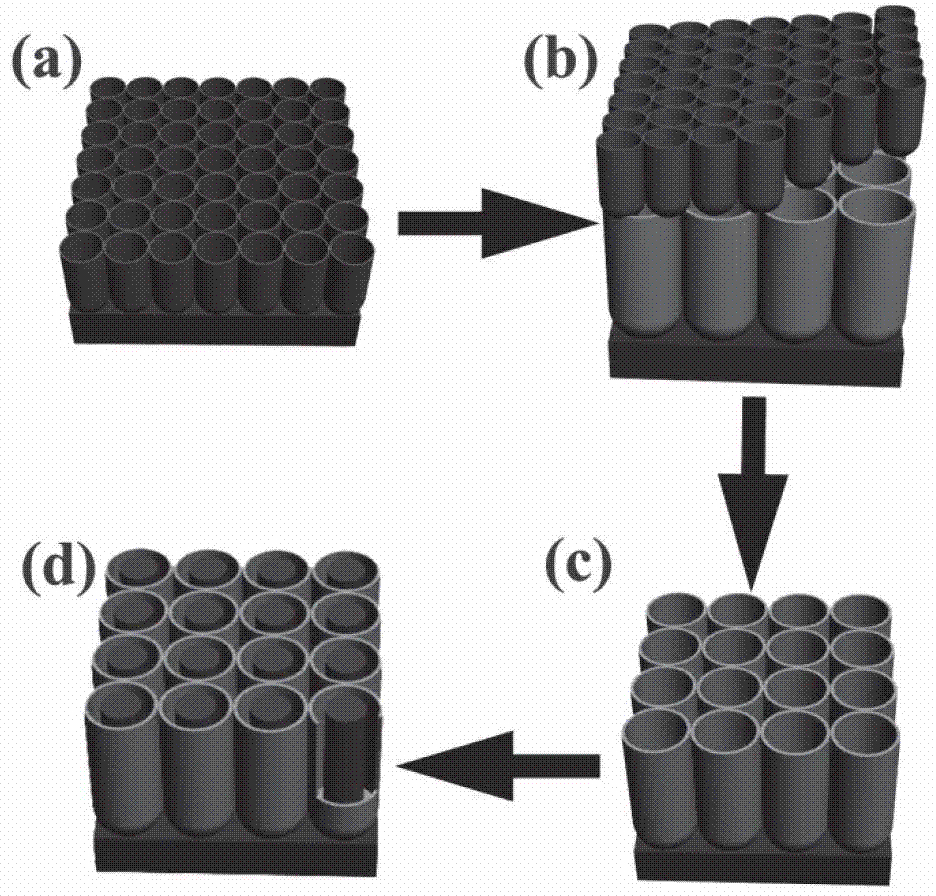

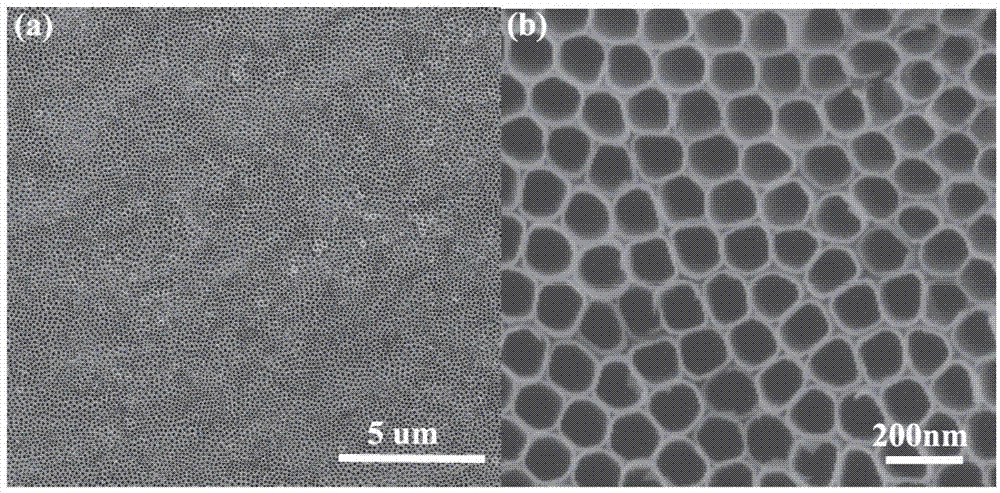

[0021] (2) Anodize the cleaned and dried metal sheet in an ethylene glycol solution containing 0.30mol / L hydrofluoric acid, where the oxidation voltage is 15v, and the oxidation time is 15min; then increase the anodic oxidation voltage to 50v, and oxidize 2h, forming the upper and lower layers of titanium dioxide nanotube arrays with different sizes and diameters;

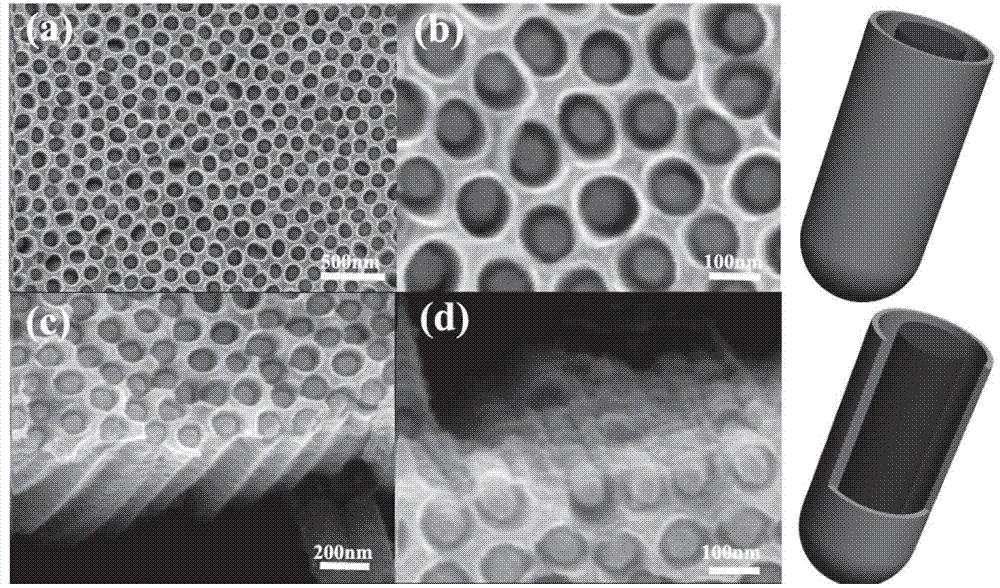

[0022] (3) Take out the anodized metal sheet, and separate the small-diameter titanium dioxide nanotubes prepared by anodizing at a small voltage from the large-diameter titanium dioxide nanotube array by ultrasonic oscillation, leaving titanium dioxide nanotubes with a flat surface and no cracks. tube array film;

[0023] (4)...

Embodiment 2

[0026] (1) First, ultrasonically clean the metal sheet with a titanium content of 96% in a mixed solution of ethanol and acetone with a concentration ratio of 1:1 for 60 minutes to remove organic matter on the surface, then repeatedly clean it with deionized water, and dry it in the air ;

[0027] (2) Anodize the cleaned and dried metal sheet in an ethylene glycol solution containing 0.30mol / L hydrofluoric acid, where the oxidation voltage is 15v, and the oxidation time is 15min; then increase the anodic oxidation voltage to 50v, and oxidize 2h, forming the upper and lower layers of titanium dioxide nanotube arrays with different sizes and diameters;

[0028] (3) Take out the anodized metal sheet, and separate the small-diameter titanium dioxide nanotubes prepared by anodizing at a small voltage from the large-diameter titanium dioxide nanotube array by ultrasonic oscillation, leaving titanium dioxide nanotubes with a flat surface and no cracks. tube array film;

[0029] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com