Method for preparing large-hole-interval porous anodic alumina membrane at high voltage

A technology of porous anode and aluminum oxide film, which is applied in the field of high-voltage preparation of porous anodic aluminum oxide film with large pore spacing, can solve the problems of complicated equipment and process, difficult to obtain raw materials, high cost, etc., and achieves fast film forming speed and convenient operation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a porous anodic aluminum oxide film with a large-pore spacing at high voltage, the large-pore spacing is generally considered to exceed 300nm, comprising the following steps:

[0027] (1) Cleaning high-purity aluminum sheets with a mass fraction ≥ 99.99% in absolute ethanol and deionized water in sequence to obtain clean aluminum sheets.

[0028] (2) With the clean aluminum sheet obtained in step (1) as the anode and the graphite as the cathode, perform electrochemical polishing at 20V in a mixed solution of perchloric acid and absolute ethanol with a volume ratio of 1:4 at 0°C to obtain Polished aluminum sheet.

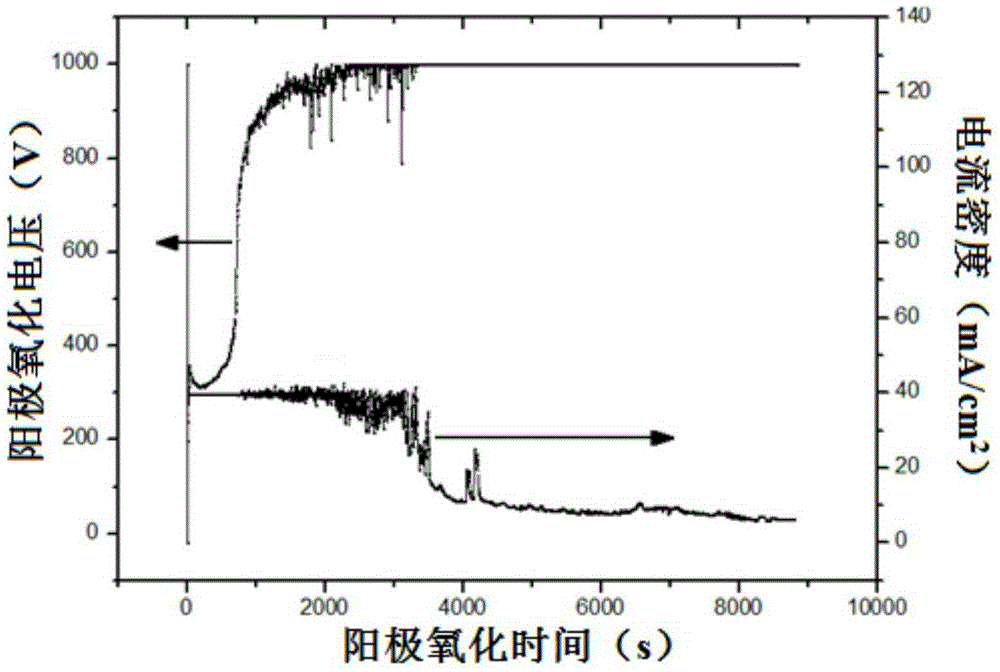

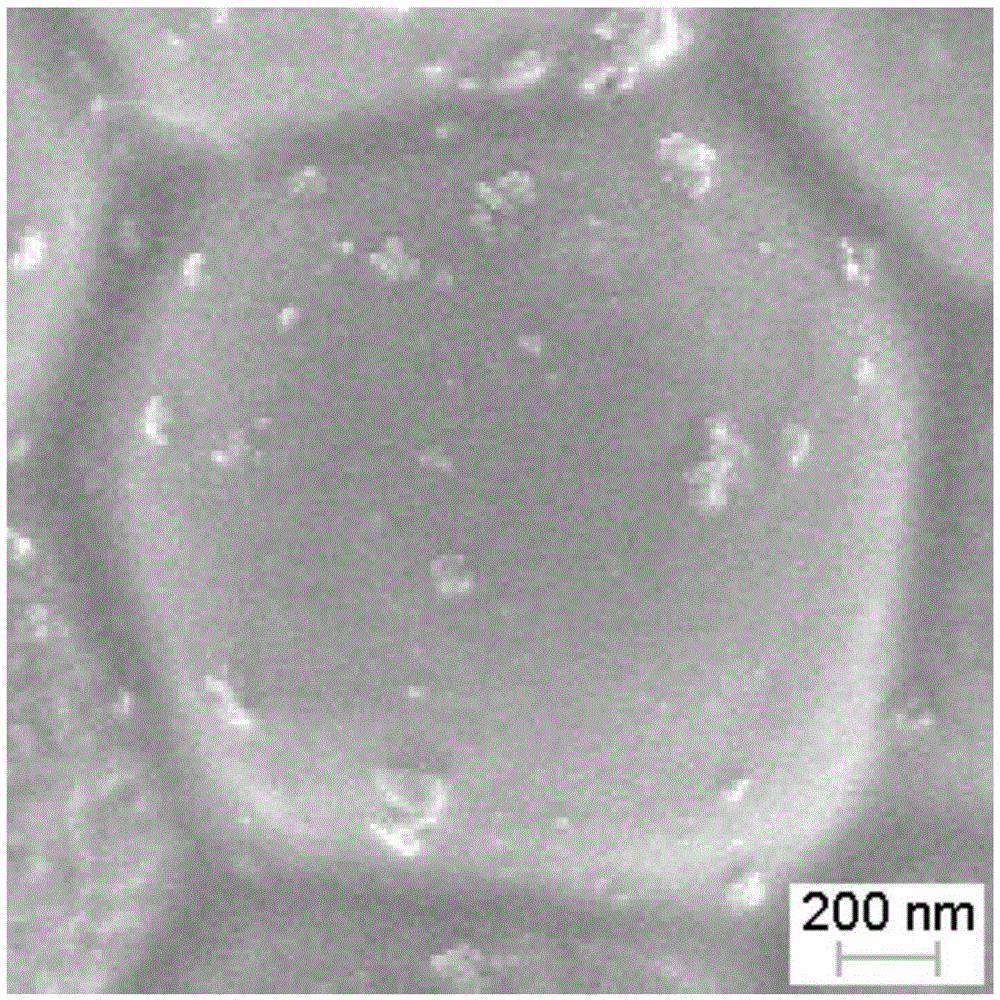

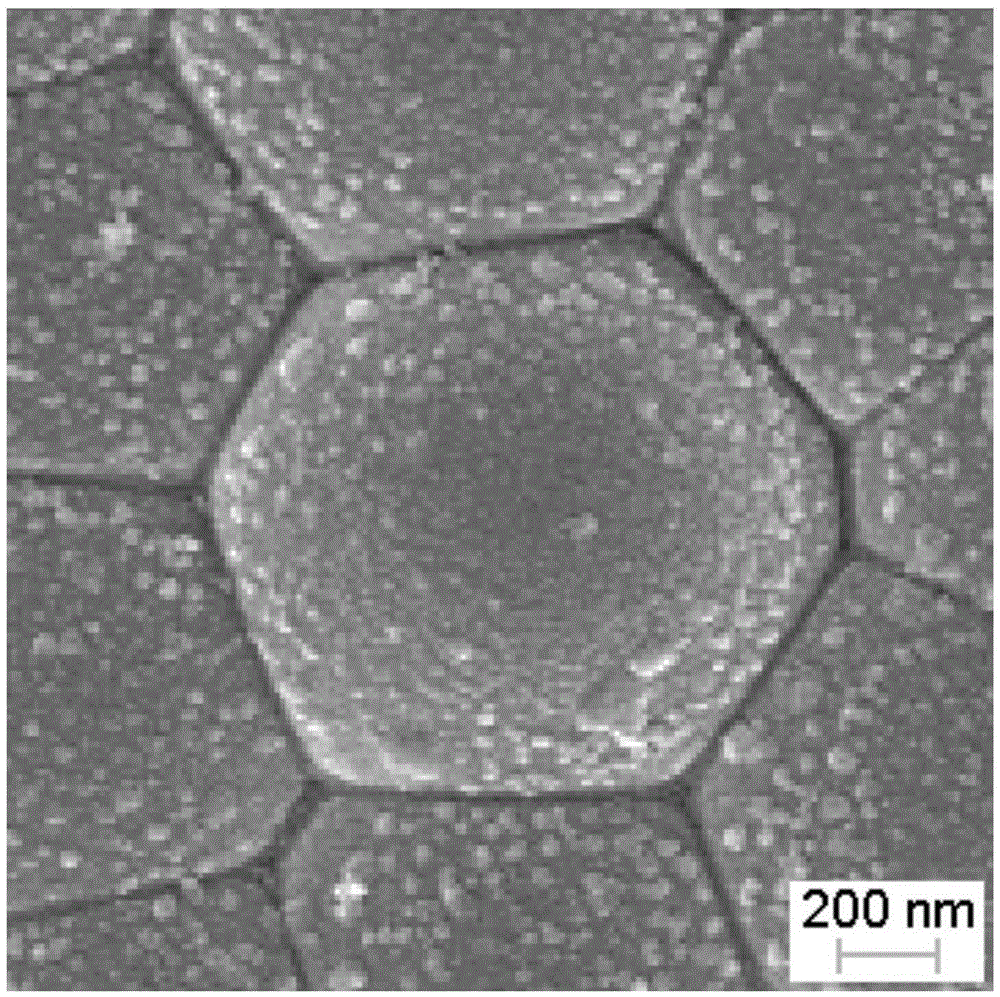

[0029] (3) the polished aluminum flake obtained in step (2) is an anode, and graphite is a cathode, and the voltage is 1000V, and the current density is set to 40mA / cm 2 , solution A (absolute ethanol) and solution B (0.25mol / L oxalic acid aqueous solution) volume ratio is A: B = 2 mixed solution to carry out anodic oxidation process, t...

Embodiment 2

[0032] A method for preparing a porous anodic aluminum oxide membrane with large pore spacing at high voltage, comprising the steps of:

[0033] (1) Cleaning high-purity aluminum sheets with a mass fraction ≥ 99.99% in absolute ethanol and deionized water in sequence to obtain clean aluminum sheets.

[0034] (2) With the clean aluminum sheet obtained in step (1) as the anode and the graphite as the cathode, perform electrochemical polishing at 25V in a mixed solution of perchloric acid and absolute ethanol with a volume ratio of 1:5 at 3°C to obtain Polished aluminum sheet.

[0035] (3) the polished aluminum flake obtained in step (2) is an anode, and graphite is a cathode, and at a voltage of 700V, the current density is set to 50mA / cm 2 , solution A (absolute ethanol) and solution C (0.3mol / L oxalic acid aqueous solution) volume ratio is A:C=1 mixed solution to carry out anodic oxidation process, the temperature is 4 ° C: first under constant flow conditions Adapt to the...

Embodiment 3

[0038]A method for preparing a porous anodic aluminum oxide membrane with large pore spacing at high voltage, comprising the steps of:

[0039] (1) Cleaning high-purity aluminum sheets with a mass fraction ≥ 99.99% in absolute ethanol and deionized water in sequence to obtain clean aluminum sheets.

[0040] (2) With the clean aluminum sheet obtained in step (1) as the anode and the graphite as the cathode, perform electrochemical polishing at 15V in a mixed solution of perchloric acid and absolute ethanol with a volume ratio of 1:4 at 5°C to obtain Polished aluminum sheet.

[0041] (3) the polished aluminum sheet obtained in step (2) is an anode, and graphite is a cathode, and at a voltage of 900V, the current density is set to 20mA / cm 2 , the volume ratio of solution A (absolute ethanol) and solution D (0.35mol / L oxalic acid aqueous solution) is A: D = 4 mixed solution conditions to carry out anodic oxidation process, the temperature is 2 ° C: first under constant flow condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com