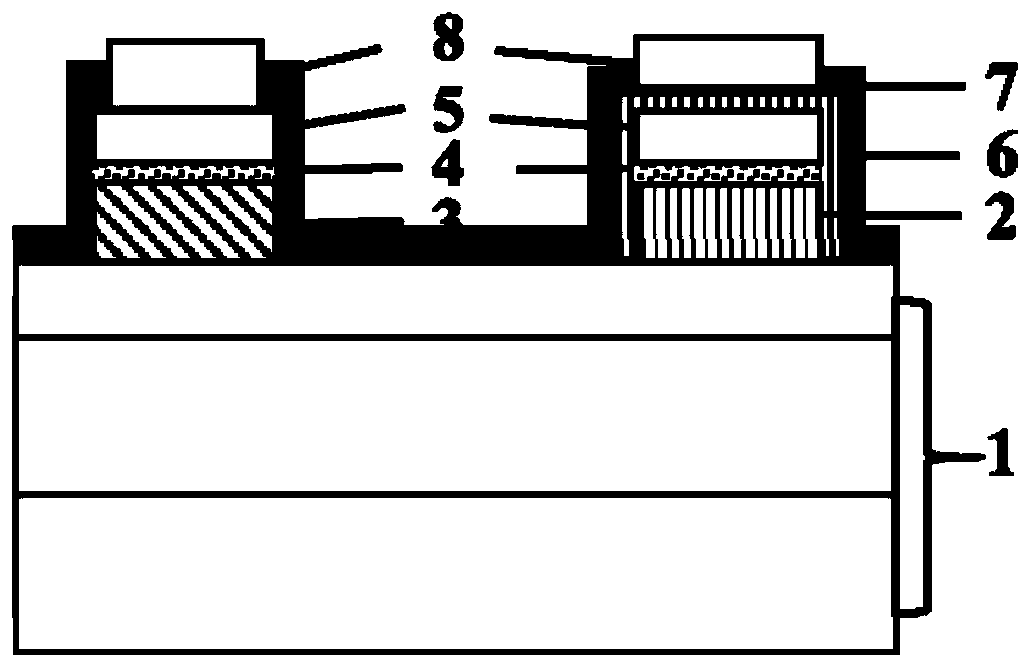

Graphene-assisted GaN rectifier and preparation method thereof

A technology of graphene and rectifiers, which is applied in the field of graphene-assisted GaN rectifiers and its preparation, can solve problems such as failure of high-frequency working devices, achieve the effects of solving desorption, suppressing device breakdown problems, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the graphene-assisted GaN rectifier of the present embodiment comprises the following steps:

[0039](1) Surface cleaning of the epitaxial wafer: place the AlGaN / GaN epitaxial wafer in acetone, isopropanol, absolute ethanol, and deionized water for 5 minutes, and then take it out and dry it with high-purity nitrogen;

[0040] (2) Alignment mark etching on the surface of the epitaxial wafer: Spin-coat a photoresist with a thickness of 2um on the surface of the epitaxial wafer, and then expose the alignment mark on the photolithographic mask on the epitaxial wafer by means of photolithography and development, Then put the photolithographically completed epitaxial wafer in the ICP equipment, etch for 45s, and re-etch the alignment mark on the epitaxial wafer by etching, and then put the epitaxial wafer in the degumming solution and ultrasonically clean it for 5 minutes to remove the excess surface of the epitaxial wafer. Photoresist.

[0041] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com