A kind of all-solid aluminum electrolytic capacitor and its preparation method

An aluminum electrolytic capacitor, all-solid-state technology, applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., can solve the problems of not being able to provide anodic oxide film, etc., and achieve improved conductivity, strong pressure tolerance, and wide operating temperature range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

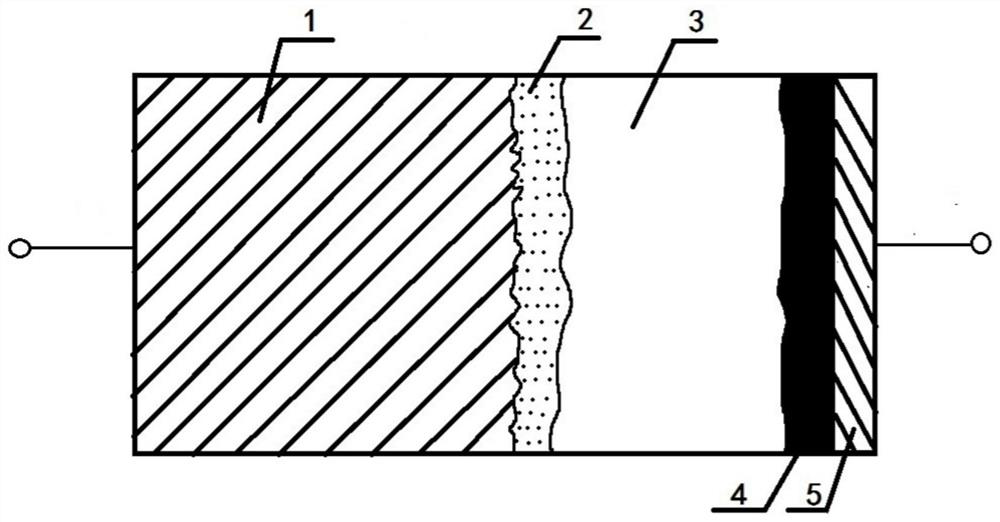

[0025] like figure 1 As shown, the nanocomposite material of polyaniline PANi and PbTe was prepared by in-situ polymerization, and the nanocomposite film was obtained after hot pressing; %, 10% ammonium hypophosphite electrolyte, the solid-state nanocomposite membrane 3 containing anode aluminum foil repairing ions was prepared; 2 SiO 3 Prepare a pH=8 active silicon solution with acetic acid HAc, immerse the anode aluminum foil 1 in a mixed solution of aminomethyltriethoxysilane APS and a pH=8 active silicon solution for surface modification, and finally form siloxane on the anode aluminum foil 1 base surface modification layer 2; the solid nanocomposite film 3 containing the repairing ions of the anode aluminum foil and the anode aluminum foil 1 forming the siloxy surface modification layer 2 are assembled, and one side of the solid nanocomposite film 3 containing the repairing ions of the anode aluminum foil is sequentially The graphite layer 4 and the conductive silver pa...

Embodiment 2

[0027] A nanocomposite material of polyacetylene PA and carbon nanotubes was prepared by in-situ polymerization, and a nanocomposite film was obtained after hot pressing; Solid-state nanocomposite membrane 3 containing anode aluminum foil repairing ions was prepared in the electrolyte of 7% ammonium phosphate; sodium silicate Na 2 SiO 3 Prepare a pH=6.9 active silicon solution with acetic acid HAc, immerse the anode aluminum foil 1 in a mixed solution of aminomethyltriethoxysilane APS and a pH=6.9 active silicon solution for surface modification, and finally form siloxane on the anode aluminum foil 1 base surface modification layer 2; the solid nanocomposite film 3 containing the repairing ions of the anode aluminum foil and the anode aluminum foil 1 forming the siloxy surface modification layer 2 are assembled, and one side of the solid nanocomposite film 3 containing the repairing ions of the anode aluminum foil is sequentially The graphite layer 4 and the conductive silver...

Embodiment 3

[0029] Preparation of poly-3,4-ethylenedioxythiophene PEDOT and Bi by in situ polymerization 2 Te 3 The nanocomposite material obtained is obtained by hot pressing to obtain a nanocomposite film; the obtained nanocomposite film is immersed in an electrolyte containing 20% of succinic acid, 75% of N,N-dimethylformamide, and 5% of ammonium hypophosphite by weight. Solid-state nanocomposite membrane 3 containing anode aluminum foil repairing ions was prepared in 3; sodium silicate Na 2 SiO 3 Prepare a pH=7.8 active silicon solution with acetic acid HAc, immerse the anode aluminum foil 1 in a mixed solution of aminomethyltriethoxysilane APS and a pH=7.8 active silicon solution for surface modification, and finally form siloxane on the anode aluminum foil 1 base surface modification layer 2; the solid nanocomposite film 3 containing the repairing ions of the anode aluminum foil and the anode aluminum foil 1 forming the siloxy surface modification layer 2 are assembled, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com